Silk is an excellent textile material due to its high mechanical strength, excellent luster, and good touch feeling. Therefore, many researchers have tried to create silk-like fibers. Silk is composed of two proteins, fibroin and sericin; the removal of sericin, by degumming, improves the luster and handle of silk fabric. However, recently, raw silk without degumming has also attracted the attention of consumers and researchers. This is because raw silk containing sericin is cool and can be utilized as a good textile material for summer clothing.

Partially degummed silk has been investigated in order to produce a textile whose handle is intermediate between the soft silk fibroin (fully degummed silk) and the hard raw silk (non-degummed silk). Lee

This uneven degumming of silk is due to the fact that silk is a naturally produced material. Sericin is removed heterogeneously from raw silk during the degumming. Ko

Thus, the heterogeneous degumming of silk yarn is a main obstacle in the development of partially degummed silk products. It is therefore necessary to improve the homogeneity of degumming. To detect and measure the degumming of silk, a simple and effective evaluation method is needed.

Fourier transform infrared (FTIR) spectroscopy is a powerful tool to investigate the structure and conformation of silk polymers (Chen

Silk yarns were degummed with purified water at 100℃ for 10~60 min. After the degumming was completed, the degummed silk yarns were rinsed thoroughly in warm purified water to remove extra surface-associated sericin, and then dried. The purified water was obtained using a water purification system (RO50, Hana Science, South Korea) with a reverse osmosis membrane. To examine the effect of a surfactant, we used the non-ionic surfactant sorbitan monostearate (Span 60, Tokyo Chemical Industry Co., Ltd, Japan). The dry mass of the silk yarns was measured using a moisture analyzer (XM60, Precisa, Swiss).

The degumming ratio was calculated using the following equation:

Degumming ratio (%) = (1 ? (dry mass of degummed cocoons /dry mass of native cocoons)) × 100.

>

FTIR measurement and determination of crystallinity index

FTIR-ATR spectra were obtained on a FTIR spectrometer (Nicolet 380, Thermo Fisher Scientific, USA). The crystallinity index was calculated as the intensity ratio of the 1260 and 1235 cm-1 peaks in the FTIR spectrum, using the following equation (Bhat and Nadiger, 1980).

A1235 cm-1: Absorbance at 1235 cm-1

A1260 cm-1: Absorbance at 1260 cm-1

To determine the average and variation of the crystallinity index, FTIR measurement was performed at 30 different points along each silk yarn sample.

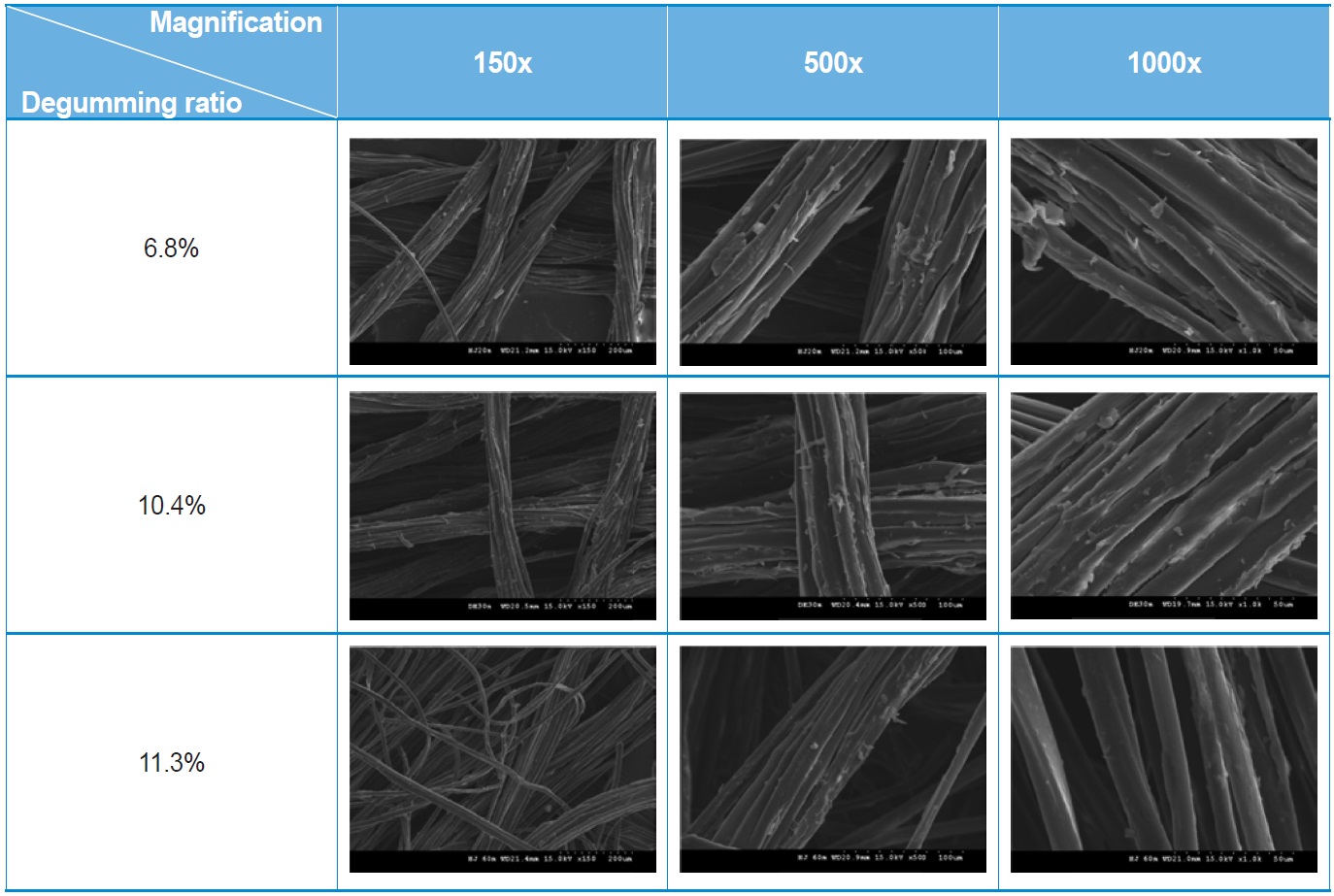

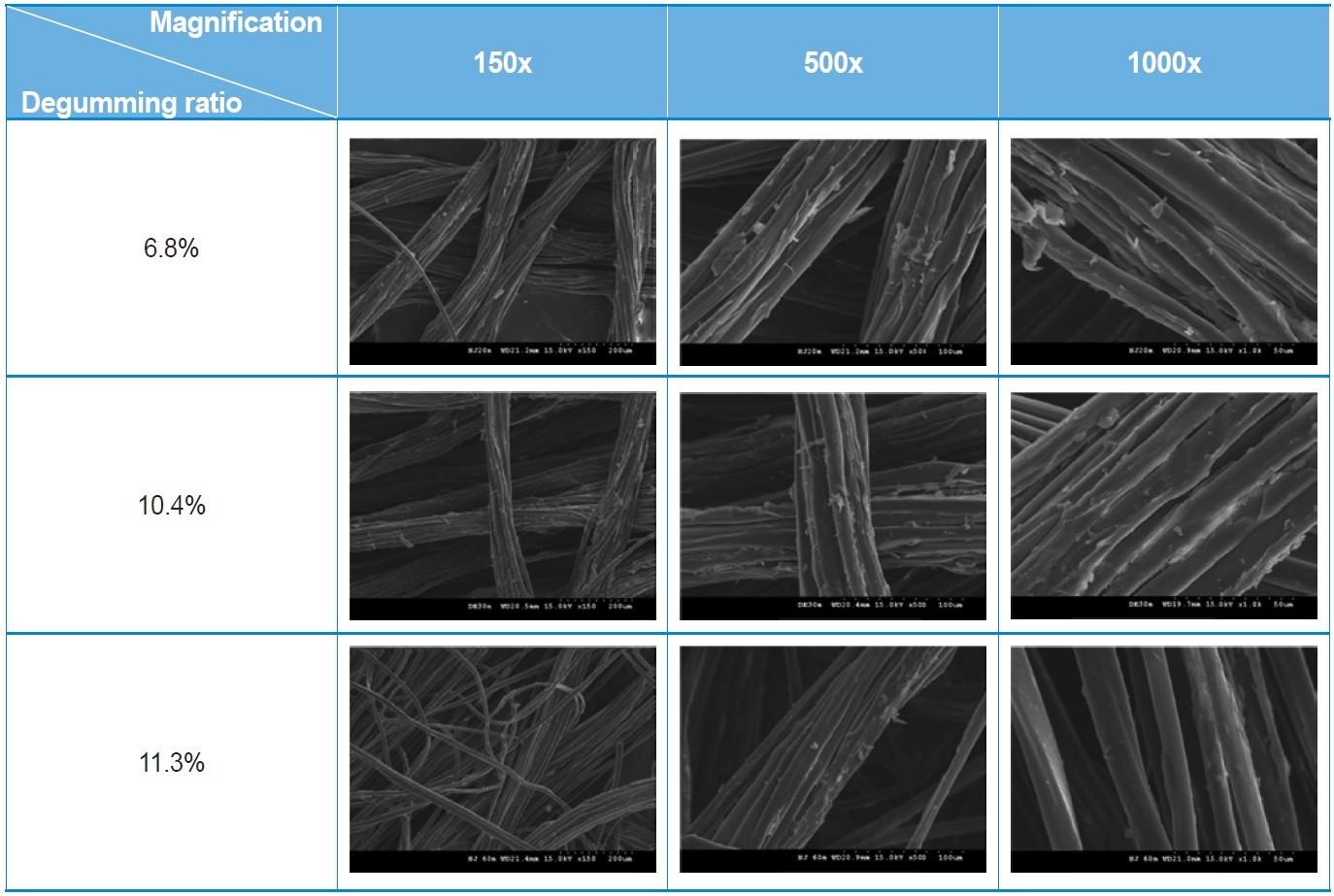

[Table 1.] SEM images of degummed silk yarns with different degumming ratios and magnifications.

SEM images of degummed silk yarns with different degumming ratios and magnifications.

The morphology of the degummed silk yarns was observed by field emission SEM (FE-SEM, S-4300, Hitachi, Japan) after silver coating.

>

FTIR for determination of degumming homogeneity

Table 1 shows SEM images of degummed silk yarns with different degumming ratios, at different magnification. Although sericin removal from silk yarns can be confirmed by SEM observation, using this method it is almost impossible to evaluate the homogeneity of degumming, owing to the short dimension range that can be observed by SEM. Although the images in Table 1 are taken over a wide range of magnifications, from 150× to 1000×, it is difficult to observe a sufficiently large area of the sample to evaluate homogeneity, under magnification that is high enough to detect sericin removal. That is, in the case of high magnification (1000×), sericin removal is clearly evident but the field of view is too small to evaluate the sample’s homogeneity. For low magnification (150×), the field of view is still not large enough to evaluate homogeneity, and the sericin removal cannot be determined exactly. Thus, we conclude that SEM cannot be used to determine the homogeneity of degumming.

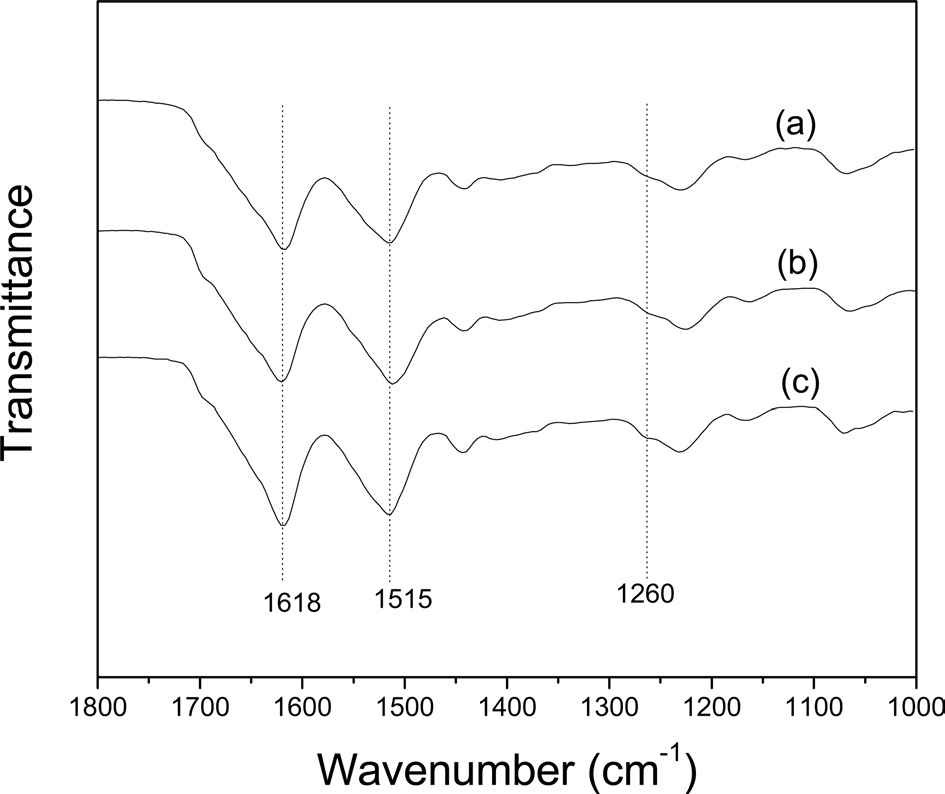

Fig. 1 shows FTIR spectra of degummed silk yarns with different degumming ratios and degumming time. All samples showed strong absorption peaks at 1618 cm-1 and 1515 cm-1 in the amide I and II bands,

respectively. Also, a shoulder at 1260 cm-1 appeared in the amide III band. These peaks and shoulder correspond to β-sheet crystallites of silk (Um

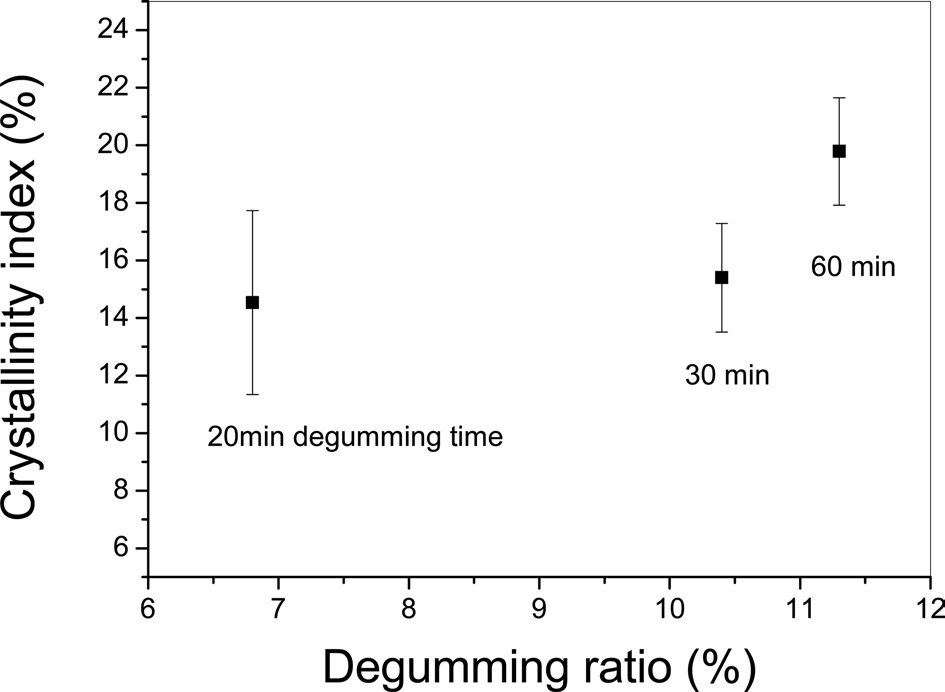

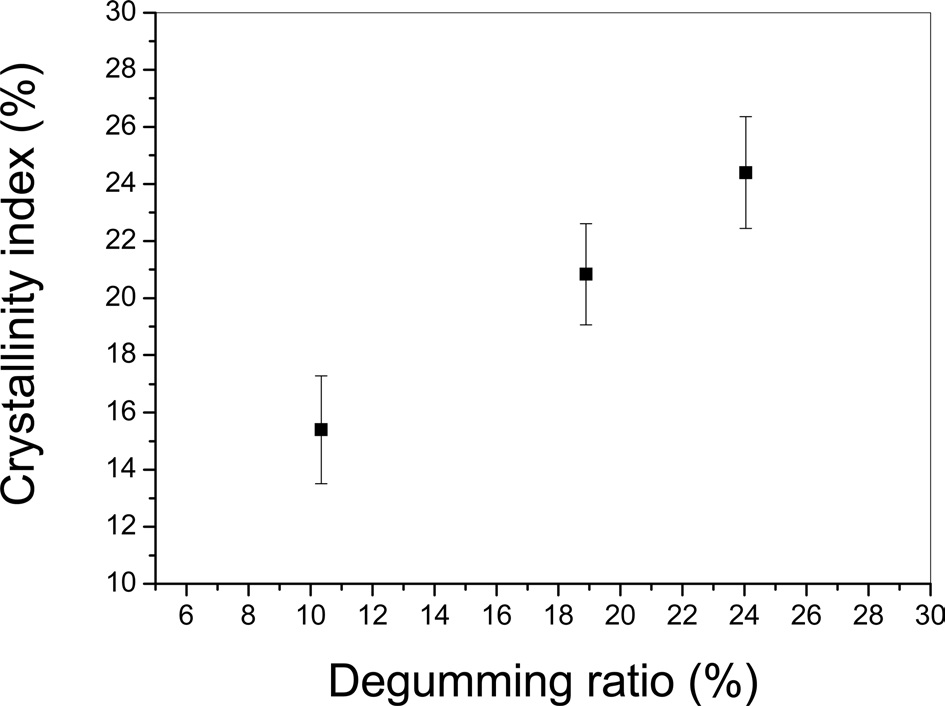

To examine the crystallinity of degummed silk with different degumming ratios, the crystallinity index was calculated from the FTIR spectra. The results are shown in Fig. 2. As the degumming ratio was increased, the crystallinity index also increased. Fig. 3 indicates similar trend among yarns processed at different degumming ratios and degumming conditions. The increased crystallinity index of degummed silk yarns may be related to the removal of sericin. In raw silk, sericin is amorphous, whereas silk fibroin is a highly crystalline material. Therefore, removal of the amorphous sericin increases the total crystallinity index of the silk (fibroin + sericin).

More importantly, Fig. 2 and Fig. 3 show that the crystallinity index of degummed silk yarn varies depending on the degumming conditions. In the

present study, FTIR spectra of silk yarns were obtained using ATR geometry. Because a very small area of the silk sample is probed during each FTIR-ATR measurement, many different sites on the same silk yarn sample can be studied. FTIR spectra taken at different points along the degummed silk yarns can report upon the homogeneity of the degumming. In our study, 30 different points along degummed silk yarns were measured with FTIR-ATR and the corresponding crystallinity index was calculated from the FTIR spectrum of each point. Because the crystallinity index is positively related to the degumming ratio, the variation among the 30 values of crystallinity index indicates the variation in degumming ratio along the silk yarn sample. A higher variation in the crystallinity index means that the degree of sericin removal (or degumming ratio) is more heterogeneous. The variation in the crystallinity index of degummed silk yarns was thus utilized to evaluate the homogeneity of degumming.

>

Effect of degumming conditions on the homogeneity of degumming of silk

Fig. 2 also shows the effect of degumming time on the crystallinity index of silk yarns degummed with boiling purified water without any degumming agent. The variation of crystallinity index (i.e., height of the error bars) is the highest at a degumming time of 20 min, and was reduced with increasing degumming time. This result implies that the homogeneity of degumming is improved with increasing degumming time. For the degumming of silk, the silk yarn is first wetted, and the penetration of water into the silk yarns then dissolves the sericin. Evidently, 20 min is not sufficient for homogenous degumming of silk, considering (1) that degumming times of 30 min and 60 min resulted in a lower variation in crystallinity index than was observed after 20 min of degumming and (2) that the variation in crystallinity index remained nearly constant between degumming times of 30 and 60 min. This means that at least 30 min of degumming with hot purified water is necessary for homogeneous degumming of silk yarns.

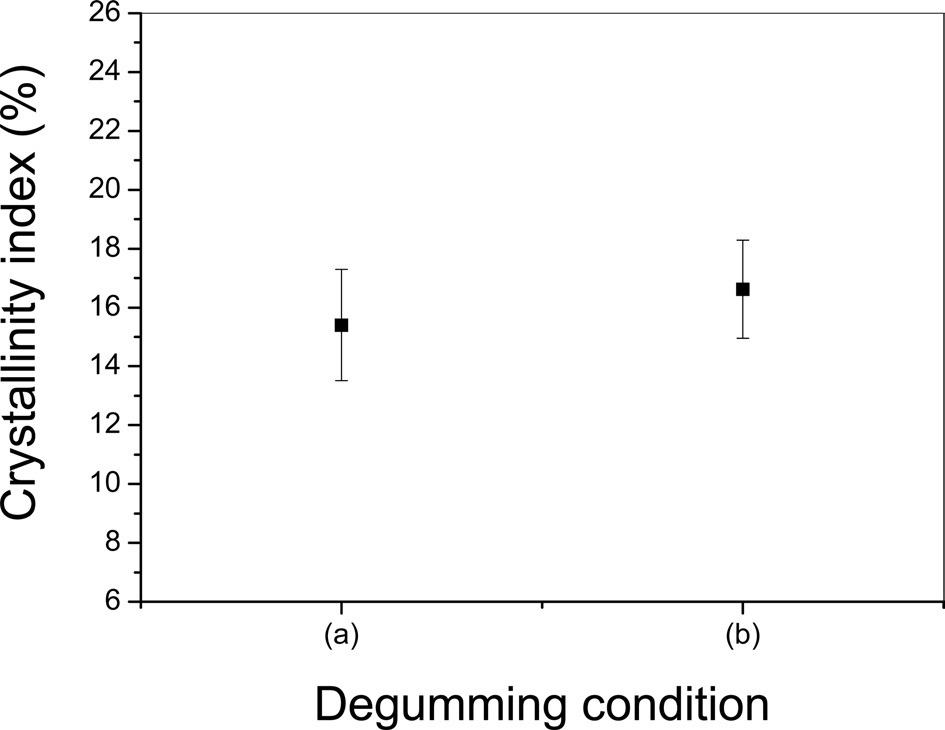

For the same total period of degumming (30 min), a different number of degumming cycles can also be performed. That is, the silk yarns can be degummed for 30 min at once, or subjected to three 10-min cycles of degumming. Fig. 4 shows the effect of the number of degumming cycles on the homogeneity of degumming, for the same total degumming time (30 min). The crystallinity index of the two samples was quite similar, and the variation of crystallinity index remained almost constant with the number of

degumming cycles, indicating no significant effect on the degumming ratio and the homogeneity of degumming.

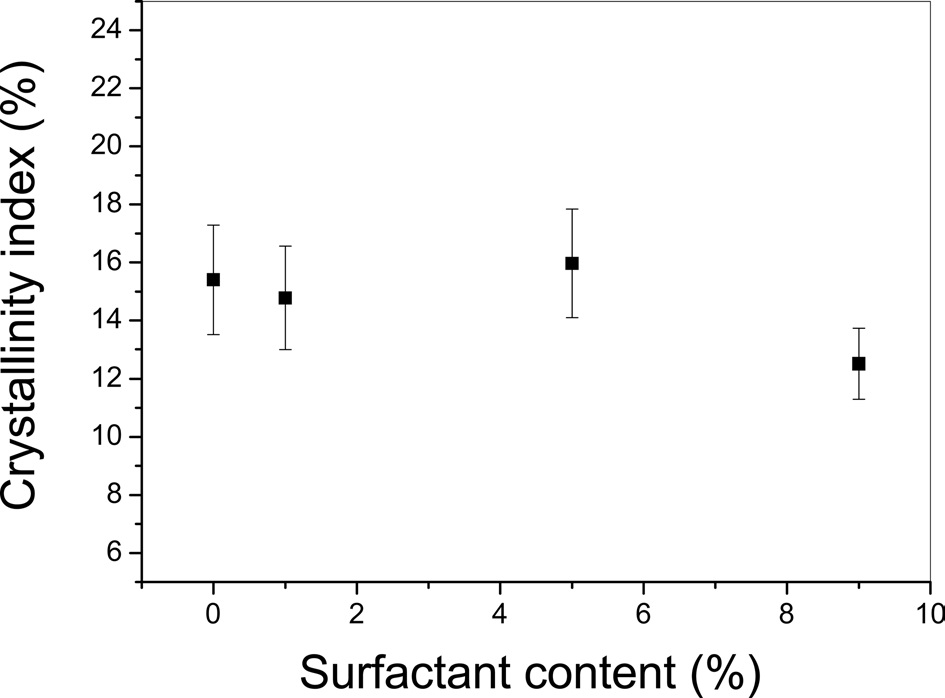

Controlling the penetration of water and degumming agents into silk yarn is also important for homogeneous degumming of silk. Surfactants have been used as wetting agents because of their ability to reduce the surface tension of a solid sample in the liquid medium. Therefore, it is expected that surfactant might improve the wetting of silk yarn during degumming, and thus, improve the homogeneity of degumming. Silk yarns were degummed in boiling purified water with different amounts of nonionic surfactant (sorbitan monostearate); the variation in their crystallinity index is shown in Fig. 5. Up to 5% surfactant, the crystallinity index variation showed nearly no change. However, when the content of surfactant was increased up to 9%, the crystallinity index showed less variation, implying that the homogeneity of degumming was improved. This result indicates that specific amounts of surfactant can help improve the homogeneity of silk degumming. Because the surfactant acts as a wetting agent for silk yarns, the hot water can penetrate the silk yarns evenly and remove the sericin

in a homogeneous manner.

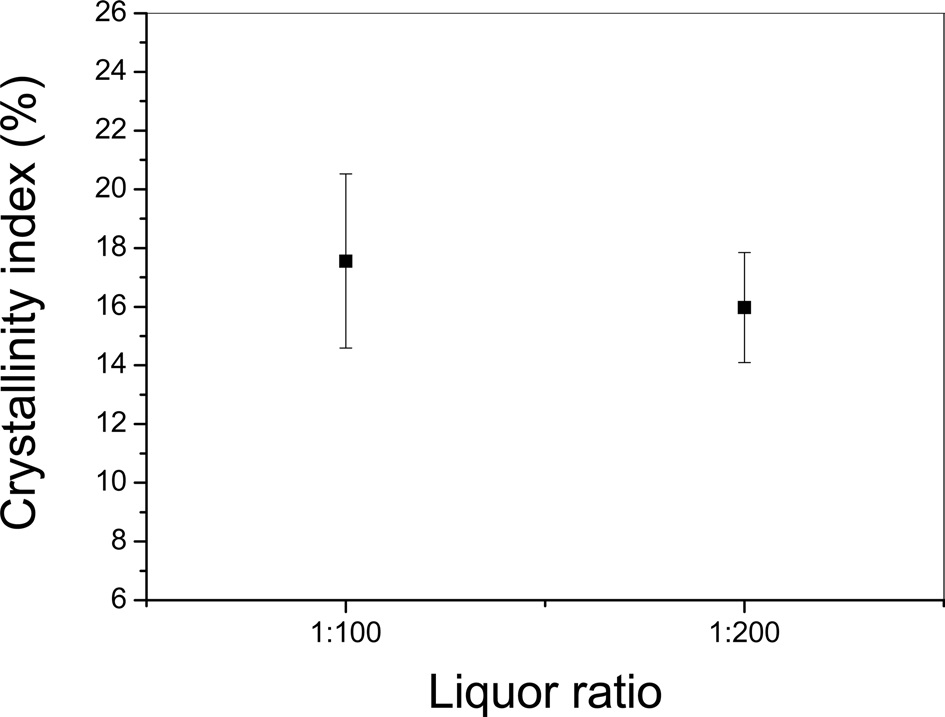

The degumming of silk yarns can also be affected by the liquor ratio, which indicates the ratio of silk yarn to degumming solution. Fig. 6 shows the effect of liquor ratio on the crystallinity index variation of degummed silk yarns. As the liquor ratio was changed from 1:100 to 1:200, the crystallinity index varied to a lesser extent, indicating an improvement in degumming homogeneity. Increasing the relative amount of hot water, which acts as a solvent for sericin, improves the accessibility of hot water into the silk yarn. In contrast, as less water (or degumming bath) is used in degumming, silk yarns become more closely assembled and the hot water becomes less accessible to the silk yarns. Thus, a lower liquor ratio (a larger volume of water) can be helpful to promote homogeneous degumming of silk yarns.

This study demonstrates that the crystallinity index calculated from FTIR-ATR spectra of silk yarns is positively related to their degumming ratio, and it can be is a powerful and convenient method for evaluating the homogeneity of silk degumming. The silk yarns were degummed under various conditions, including degumming time, number of cycles, amount of surfactant, and liquor ratio. The homogeneity of the silk yarn was improved by increasing the total degumming time, the content of surfactant, and the liquor ratio, whereas the homogeneity did not change upon increasing the number of cycles at the same total degumming time.