Vertically aligned carbon nanotubes (VACNTs), also known as a carbon nanotube (CNT) forest, are a porous material that is well known for its exceptional optical absorbance property. The reflectance from a VACNT forest has been reported to be as low as 0.045% [1,2]. It is known as the darkest material on Earth. Because of its remarkable material properties, it has various other applications as gas sensors [3], pressure sensors [4], temperature sensors [5], and strain sensors [6]. Recently, various efforts have been made to mechanically manipulate the vertical structure of the nanotubes in the CNT forest and to conduct their optical characterization [7,8]. Optical reflection from bare VACNTs has also been investigated at different wavelengths by Wąsik et al. [9]. Controlled densification by wetting of the CNT forest is another post processing technique that has been reported by other researchers [10]. A densification process is necessary to make the CNT forest useful as a future electronics interconnect [10]. However, no study has been done so far on the optical behavior of CNT forests densified by a wetting process. In this letter, for the first time, we investigate and explain the nature of the optical reflectance of densified VACNTs.

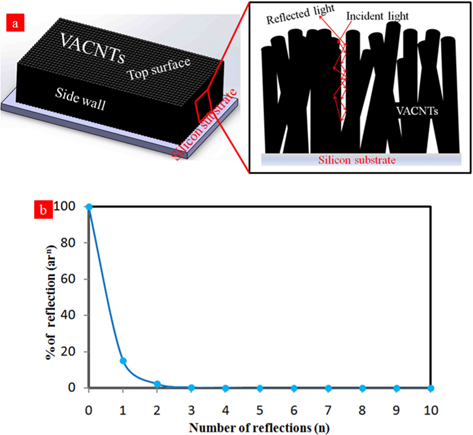

Fig. 1 illustrates how the CNT forest is able to absorb most incident light. It was reported elsewhere that VACNT arrays are highly porous [11]. As a result, when incident light enters the bare CNT forest, it goes through several internal reflection-absorption cycles

Mathematically, a simple model can be developed to estimate the final amount of light coming out of a CNT forest after several internal reflections; this process is explained by eq (1):

where

In line with the above hypothesis, reflection from VACNTs is expected to be enhanced if the nanotubes of the CNT forest can be squeezed and densified so that incident light beams cannot penetrate into the forest due to the reduced porosity. To verify this, we carried out simple water assisted densification of VACNTs to reduce the porosity. Subsequently, the optical reflectance was investigated.

The vertically aligned CNT samples were synthesized using a typical chemical vapor deposition method on a highly doped silicon substrate (<100> n-type, resistivity 0.008–0.015 Ωcm). Then, as a catalyst, Al and Fe in thin layers of 10 and 2 nm, respectively, were deposited on the silicon substrate using an e-beam evaporator. After that, the production of VACNTs was carried out by balancing the flow of different gases such as ethylene (C2H4), hydrogen (H2) and argon (Ar) with different ratios at various temperatures. Through this process, the vertically aligned CNTs grew to several 100s of µm in length, with diameters in a range of 10 to 50 nm. The detailed process of VACNT sample preparation has been demonstrated by Khalid et al. [13].

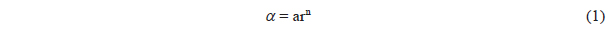

Vertically aligned CNTs are known as the darkest materials on earth due to their significant absorption of incident light, which results from their intrinsic porosity [11]. To minimize this porosity among adjacent VACNTs, we have attempted a simple method known as water assisted densification of VACNTs. To this effect, a bare VACNT forest (as grown and attached to the Si substrate) was sunk in water for 12 h. After that, it was dried at ambient temperature for 6 h. Wetting followed by evaporation is a proven technique for densifying a CNT forest [10]. Moreover, the field emission scanning electron microscope image (Fig. 2) shows the topography of the original CNT forest and the densified CNT forest. As water evaporates, the individual CNTs become closer due to capillary action [10], as can be seen in Fig. 2b.

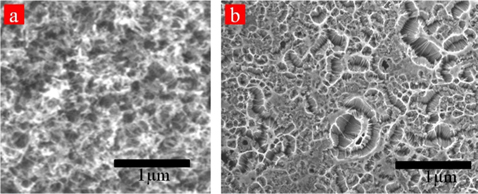

To investigate the polarized reflectance from densified VACNTs, we used the experimental arrangement shown in Fig. 3. In this case, we used a partially polarized laser source (having a visible wavelength of 532 nm) and a polarizer to change the state of polarization of the incident light by rotating directly from P (θi = 0°) to S (θi = 90°). The incident light was directed towards the sample (VACNTs) at the angle θ, which can be varied by rotating the sample (VACNTs), which is attached to a rotary stage. The reflection from the VACNTs was captured by a photo-detector at 10° intervals until θ = 80°. In this study, the incident optical power (Pi) was measured behind the polarizer and the power reflected (Pr) from the CNT forest was also measured. Then, reflectance was calculated using the ratio of Pr/Pi. Using a green laser light (λ = 532 nm), we studied the reflectance from both the bare CNT forest and the densified CNT forest for comparison.

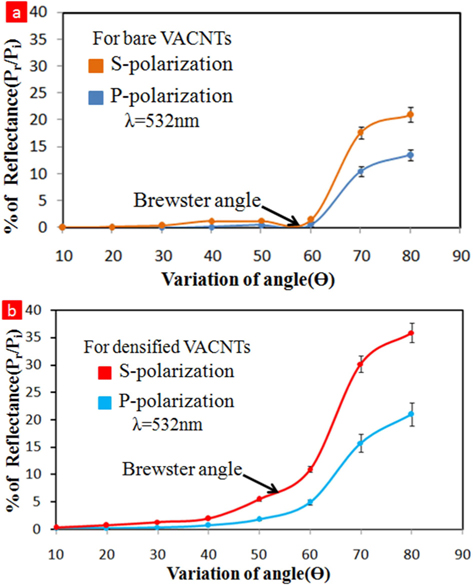

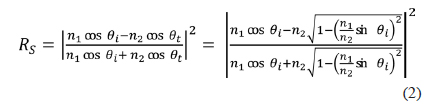

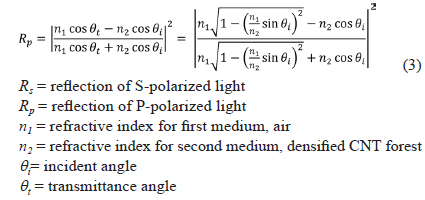

Fig. 4 reveals the reflectance characteristics for both the densified (Fig. 4a) and bare VACNTs (Fig. 4b) only at the P- and S-polarization states for different angles of incidence. It can be seen that there is an increasing trend over the entire incident angle, although the S-polarized reflectance is always significantly higher than the P-polarized reflectance, which is consistent with the reflection characteristics (i.e., Fresnel reflection) for a smooth interface [14]. According to Fresnel’s theory, the reflectance values of S- and P-polarized light will follow the relationship explained in eqs (2) and (3). The P-polarized light will reach a minimum value at a particular angle of incidence, which is known as the Brewster angle, due to the full transmittance of light through the sample. The Brewster angle is more prominent in the bare CNT forest than it is in the densified CNT forest, in which the Brewster angle is in the range of 58°.

The reflectance of P-polarized light for bare VACNTs varied from 0.03% to 13.53%; for S-polarized light, the variation was from 0.05% to 21% (as shown in Fig. 4a). These values of obtained reflectance are in a range similar to that found in a previous study [9] that investigated the specular reflectance of a bare CNT forest with a 514 nm laser source. Interestingly, when we used the densified CNT forest, the maximum reflectance increased to ~7.5% for P-polarized light and to ~14.5% for S-polarized light at an incident angle of 80°. Because the CNT forest is densified, individual nanotubes come closer and seal the opening of the top surface of the original VACNT, which retards the penetration ability of the incident laser beam into the CNT forest. Hence, the optical reflectance from the densified CNT forest is higher than that from the bare VACNTs.

In this letter, we have explained the underlying reason for the exceptional optical absorption characteristics of the CNT forest and also showed for the first time the optical characterization of densified VACNTs. It was observed that the densification process reduces the porosity of the bare CNT forest. Therefore, incident light was unable to penetrate into the forest and bounced back from the top surface. This eventually increases the reflectance of the densified VACNTs compared to that of the bare CNT forest by ~14.5% for S-polarized light and ~7.5% for P-polarized light. These findings could be useful in exploring the use of a densified CNT forest as an angle sensor because of the change of reflectance (for both S- and P-polarized light) with the rotational angle; this angle changes more for the densified CNT forest than it does for the bare CNT forest. Moreover, with the obtained understanding of the optical behavior of the densified CNT forest, we can now use this device as an on/off sensor to detect water vapor.