Recently, with continuous developments in the field of materials science, graphene oxide (GO) has emerged as a promising material with excellent electrical, thermal, mechanical, and optical properties, which play important roles in most fields. Researchers have achieved considerable progress with graphene. Chitosan (CS) is a natural polymer that has been studied intensively owing to its specific formation, high chemical resistance, and excellent physical properties. These outstanding properties have led to its universal use in applications such as textile fabrics, tissue engineering, medicine and health, coatings, and paints. By combining the advantages of GO and CS, different types of promising materials can be obtained. This review discusses the preparation of GO-CS fibers, hydrogel and aerogel, and the applications of GO-CS nanocomposites. In addition, directions for future research on graphene material composites are discussed.

Graphene oxide (GO) has many extraordinary properties and has great potential among nanomaterials. Since its discovery, it has been studied by many researchers for a variety of novel applications owing to its excellent chemical and physical properties, including low density, exceptional mechanical properties, large surface area, inherent impermeability, mechanical strength, and excellent electrical conductivity [1-5]. In other words, graphene is promising and gaining increasing attention for different applications [6-7]. The carbon atoms in GO within a single layer are combined via sp2-hybridization with other graphene layers [8-9]. Each carbon atom has an electron that is not involved in bonding, and these electrons form a large delocalized bond in the vertical direction. Thus, the intermolecular van der Waals interactions are strong, and the bond accumulation effect between each layer easily leads to irreversible graphene aggregation [10-17].

Chitosan (CS) is the product of chitin deacetylation and contains a large quantity of hydrophilic groups (e.g., amino and carboxyl groups). Thus, CS molecules are easily protonated. It has been widely used in medicine and has many excellent biological properties, such as biocompatibility, biodegradability, and coagulation activity [15-17]. Spinning CS into fibers for medical uses, such as for absorbable sutures, wound dressings, and artificial skin, is a particularly important goal for scientists. CS and its derivatives have been applied as clothing, food additives, cosmetics, and antibacterial agents, and have been used in medical treatment and medicinal development [18,19]. It is obvious that CS will bring about considerable economic and social benefits [20].

Not only does GO contain carboxyl and epoxy groups, it is also possible to insert small molecules or polymers between its layers [21-25]. The surface anionic groups of GO are able to interact with the CS matrix via hydrogen bonding and electrostatic interactions, to achieve good dispersion [15-17]. The composites prepared by combining the advantages of each material are expected to lead to new nanomaterials. In this paper, we present an overview of GO-CS composites and discuss recent theoretical advances in fibers, hydrogels, aerogels, nanocomposites, and their applications (Fig. 1).

2. Preparation of Graphene Chitosan Fiber

There are free amino groups in CS molecules; the greater the number of amino groups are, the more clearly the amino features manifest. CS can be dissolved in dilute acid solutions, where it acquires cationic properties. Because its chemical structure is similar to that of cellulose, researchers have considered using it in the synthesis of fibers [25], and this has attracted considerable interest [26]. Graphene CS fibers have a unique combination of properties that will lead to applications in many fields [27].

One of the most widespread spinning methods used to synthesize chemical fibers is wet spinning. This technique has the advantages of being applicable to multiple materials and being able to prepare bulky concentrates. The procedure is as follows: first, the required spinning solution is prepared. Then, the spinning solution is extruded to form a trickle through a spinneret orifice. Next, the trickle solidifies in a coagulation bath to generate nascent fibers. Finally, the fibers are subjected to stretching, water scrubbing, drying, and other procedures, or reprocessed directly [28]. Wastewater from the textile, dye, paint, papermaking, and plastic industries has severely threatened environmental security, yet wastewater is still handled inefficiently. Du et al. [29] prepared graphene CS silica fibers by wet spinning, and they showed very high adsorption and efficiency for the removal of dye in wastewater. Silica nanoparticles were etched from the graphene CS silica fiber by diluted HF solution to produce GO/CS fibers (GO/CS/ETCH). Tests demonstrated that GO/CS/ETCH could remove Congo red from an aqueous solution, which was used as an environmental protection material for removing Congo red from wastewater. Li et al. [30] prepared GO/CS composites by wet spinning to treat fuchsin acid dye in wastewater, which is harmful to the environment. The addition of GO enhanced the stretched length of CS fibers, and the experiment indicated that the initial PH was one of the most important factors that affected the adsorption capacity of GO/CS fiber for fuchsin acid dye. However due to its complicated preorder procedure, technological process, high cost, and low spinning speed, it is generally not used in industry.

Electrospinning is a relatively unique method for fabricating fibers, where polymer solutions or melts are subjected to jet spinning by an applied electric field force. In the electric field, spherical drops within a needle become cones, and then fiber filaments extend from the cone tip. Electrospinning is a simple, effective, and widely available new processing technology for synthesizing nanofibers, in which a polymer fluid atomized by static electricity is moved a long distance, and finally stretched into fiber [31-35].

Liu et al. [33] successfully prepared polyvinyl alcohol (PVA)/CS/graphene biological composite nanofibers using aqueous electrospinning, and was the first to synthesize CS nanofibers with nontoxic, solution-based GO. The addition of GO improved the mechanical properties, hydrophilicity, and antibacterial activity of PVA/CS fibers to some extent. These fibers are promising for drug delivery systems, tissue engineering, and wound healing. Ardeshirzadeh et al. [34] prepared a polyoxyethylene/CS/graphene nanofiber scaffold able to control the release of adriamycin. The nanofibers, obtained by electrospinning, had good stability and demonstrated drug transportation, and they also eliminated previous shortcomings, such as low solubility, stability, and poor mechanical properties, of electrospun CS. In addition, adriamycin could be combined closely with π-π* bonds, and π-π* stacking was beneficial in controlling the release of drugs. Because they lack toxic effects on healthy cells and tissues, polyethylene oxide/CS/GO is ideal materials as delivering vehicles for anti-cancer drugs. The World Health Organization has stated that there are billions of people who do not have access to safe drinking water every year. However, water purification systems require high pressure and membranes to eliminate parvovirus and heavy metal ions. Bai et al. [35] discovered that a composite fiber of CS and GO formed by electrospinning could adsorb membraneless viruses and remove viruses and bacteria from water. Thus, this discovery is significant for areas that are short of fresh water and where filtration membranes cannot be used.

3. Preparation Chitosan Graphene Hydrogel

Hydrogel is a soft, cross-linked polymer that uses water as the dispersion medium. It can maintain a definite shape and absorb a large amount of water without being dissolved. Hydrogel is biocompatible and can be used in areas such as drug delivery systems, biomimetic materials, and chemo-mechanical systems [36].

To cope with the common problem of water pollution, Chen et al. [37] prepared a GO/CS hydrogel as a new type of adsorbent for water supply treatment that is environment friendly. The GO/CS hydrogel could adsorb organic dyestuff and heavy metal ions in wastewater. Absorbent GO-CS offers lower cost and better biocompatibility, which is important in water treatment. Han and Yan [38] conducted special research on CS chains with GO nano sheets, in which GO was used as a two-dimensional cross-linking agent. They fabricated GO-CS super-molecule hydrogel by controlling the GO concentration, rate of CS-GO, and temperature. This type of hydrogel is self-healing and reversible, and can be applied in biomaterials, sewage disposal, and smart materials.

Aerogels are widely applicable owing to their vast specific surface area, low density, and light weight. Although it is seems fragile, it is in fact very solid and durable and can withstand pressures equivalent to thousands of times its own weight. It can withstand a temperature of up to 1200℃, after which it melts. Its insulating ability is 39 times better than that of the best glass fibers. Aerogels are generally prepared by (1) preparation of solgel and (2) supercritical drying [39-40].

The sol-gel phase is a wet gel. In this phase, the precursor is dissolved in solvents to obtain a solution with homogeneous dispersion. Hydrolysis or alcoholysis is used to form the sol. Then, the gel is produced by evaporation or drying. The wet gel contains rudimentary solvents and water; therefore, the wet gel volume contracts significantly in the drying process. Holes can collapse due to surface tension in typical drying and this leads to low pore volume and surface area. In order to avoid this effect, supercritical drying is used to turn the liquid into a supercritical fluid by putting it into a pressure vessel under high pressure and temperature. In the critical state where gas and liquid phases coexist, the density of the liquid is identical to its saturated vapor pressure, the interface between the gas phase and liquid phase disappears, the capillary force in the wet gel also disappears, holes cannot collapse, and relatively higher pore volume and surface area are achieved [39,41].

4.1 Preparation of graphene chitosan aerogel

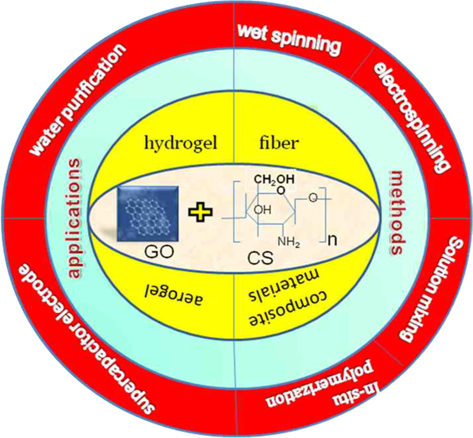

Yu et al. [42] prepared graphene CS aerogel because the excessive superposition of GO sheets in GO adsorbent influences its adsorption capacity for pollutants. An aerogel, however, can easily be separated from the system after adsorption. The aerogel had good adsorption for cupric ions, especially with higher pH, lower ionic strength, and higher temperature. They also made a comparison of the

Supercapacitors possess many extraordinary properties, such as high power density, long lifetime, and safety and have been applied in various fields. At present, high energy-storage capability is usually achieved with activated carbon. However, its high cost and low energy density limit its broad application. GO is superior because of its excellent electrical, thermal, mechanical, and optical properties. Hao et al. [44] produced ‘graphene-based-nitrogen self-doped hierarchical porous carbon’ with outstanding performance by the carbonization of CS aerogel and activation with KOH. The obtained aerogel had macropores, mesopores, and micropores, as well as a high specific surface area. Until now, there has been little research on the fabrication of aerogels for use in supercapacitors; hence, it was a great breakthrough in the field of energy storage.

5. Preparation of Graphene Chitosan Composite

The preparation of GO-CS usually involves the GO reduction method. Graphite is a basic element that has good dispersibility and stability after surface modification. It is mixed with a second component to form a composite. According to different combinations of graphene and the second component, there are several categories: (1) graphene is regarded as a continuous phase for the second material, and the second component covers graphene during the formation of nanoparticles; (2) both graphene and the second component are continuous phases; and (3) the second component is a continuous phase, and graphene is a filling phase as the second component (Table 1) [13,14].

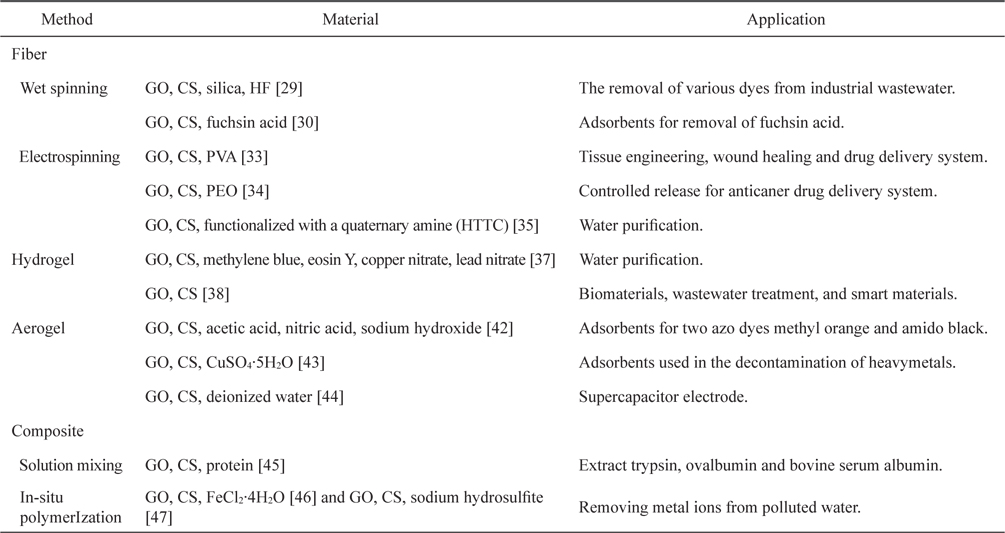

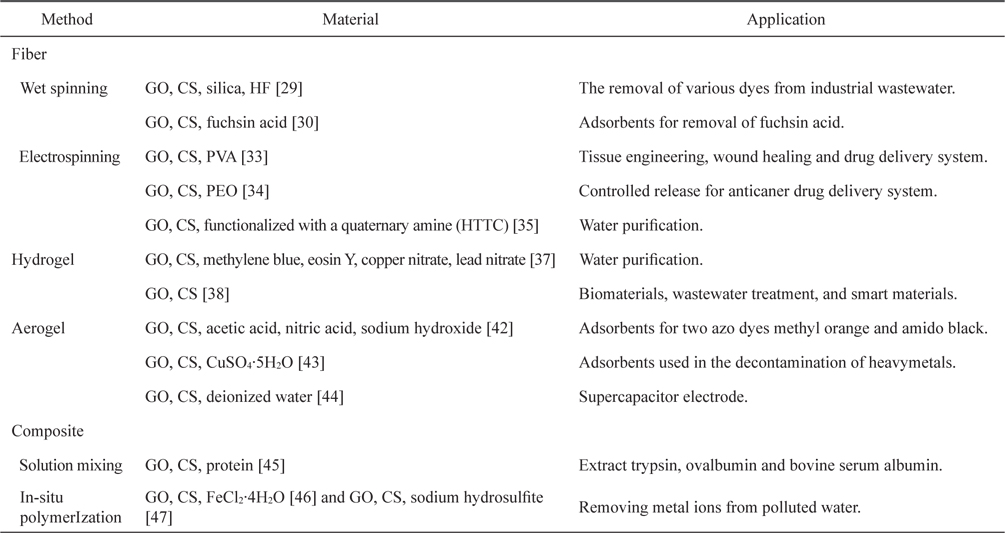

[Table 1.] List of GO-CS composites made by different processes

List of GO-CS composites made by different processes

Solution mixing is a process in which graphene and a second component are mixed such that the second component is inserted into the graphene via a solvent. Then, the composite is formed with a reducing agent. Ding et al. [45] fabricated cationic functional hexa-alkylguanidinium ionic liquids and anionic functional tetra-alkylguanidinium ionic liquids; then prepared a magnetic chitosan graphene oxide (MCGO) composite with unique properties. Trypsin, lysozyme, ovalbumin, and bovine serum albumin could be extracted well. MCGO-functional guanidinium ionic liquid can easily be recycled and will find applications for handling other biomolecules. Li et al. [46] prepared an MCGO ionic liquid composite and discovered that it could remove Cr3+ quickly and efficiently. In addition, it has the advantages of economy and environmental friendliness.

In in-situ polymerization, graphene and monomers are mixed, and monomers aggregate between the layers of graphene via an initiator. The discovery of and research on new materials must finally apply theory to practice. Zhou et al. [47] abandoned former means of reducing graphene and created a process for the vat dye industry where GO was reduced using sodium dithionite, and by which graphene CS composites were produced by insitu polymerization. The study indicated that sodium dithionite could reduce GO to graphite efficiently and that the addition of graphene could greatly improve the mechanical and electrical properties when graphene was dispersed uniformly within the polymer matrix.

6. Applications of Graphene-Chitosan Composites

Most current research on carbon nanomaterials, including carbon nanotubes, graphite, and GO, has been focused on their unique physical and chemical properties [48]. As soon as their basic properties have been fully described, the next level of research should be focused on their potential and practical applications [49]. They will be promising candidates for applications in diverse fields.

6.1 Applications in biomedicine

The structure of GO-CS composites produced with chemical synthesis using thin pieces or layers of graphite is symmetrical, which means that GO-CS composites can be applied as antibacterial agents in stem cell proliferation and nanostructural templates. Mazaheri et al. [50] discovered that the strength and elastic modulus of the layers increased by improving the concentration of GO in CS. In addition, the GO-CS composite showed a significant resistance to

6.2 Applications in sewage treatment

Fouling of reverse osmosis membranes remains a challenging and restrictive aspect of membrane filtration performance, so it is necessary to find new methods to enhance membrane antifouling properties. Hegab et al. [52] used GO functionalized CS (GO/f-CS) in a commercial brackish water thin-film composite using a novel surface modification. The GO/f-CS/polyamide (PA) composite membranes showed superior performance compared to the unmodified PA membrane in terms of hydrophilicity, surface smoothness, water flux, and antifouling. Travlou et al. [53] researched magnetic GO-CS, and thermomechanical analysis suggested that this material has a high adsorption capacity for sewage.

6.3 Applications in batteries and electrochemistry

Nowadays, lithium-ion batteries (LIBs) are essential energy storage systems in portable electronic devices, owing to their high energy density, high working voltage and low self-discharge rate [54-55]. Therefore, new electrode materials with good compatibility with LIBs electrolyte are obviously significant. Ma et al. [56] prepared ultrathin MoS2/graphene hetero structures that had excellent electrochemical properties and large specific surface areas. They achieved this using a facile CS-assisted hydrothermal and subsequent calcination approach. It is believed that this simple and efficient strategy will be a milestone for large-scale production of various hetero structures with many potential applications in fuel cells, supercapacitors, and lithium ion batteries.

It is difficult to detect dimethyl disulfide (DMDS); especially volatile sulfur compounds (VSCs). Today, the most popular method for the quantitative analysis of sulfur compounds in environmental samples relies on gas chromatography (GC) [57-59]. However, GC analysis of VSCs requires efficient sample pretreatment and enrichment methods, and such procedures are complicated, time consuming, and tedious [60-61]. In contrast, electrochemistry has much higher sensitivity, much lower detection limits, and lower cost. Rajabzadeh et al. [62] first published on graphene-CS sensing of DMDS in liquid samples, which is simple, fast and environmentally friendly.

GO-CS is a new type of nanomaterial that combines carbon and the natural polymer. Then new material possesses not only large specific surface area and good electrical properties, but also specific functional groups with properties different from those of iron-carbon. Therefore, by creating a composite material, the advantages of both materials can be combined, and is expected to be applied extensively. However, research on it is not sufficient and must be improved. Modification and research in the future can be considered from the following points of view: (1) we can discover more suitable polymers to combine with GO and obtain a more valuable nanomaterial. (2) Polyvinylpyrrolidone (PVP) is also a linear polymer, which has a high solubility in water and good biocompatibility. We can consider combining PVP, CS, and GO to prepare composites [15,17]. (3) The surface of GO still has many defects; thus we need to find other materials to modify it in order to utilize its properties better.

![Maximum adsorption capacity (qm) of various adsorbents for Cu2+ [42]. CNT, carbon nanotubes; GO, graphene oxide; CS, chitosan.](http://oak.go.kr/repository/journal/20853/HGTSB6_2016_v17n1_11_f002.jpg)