Inverter surge resistant enameled wire was prepared with an organic/inorganic hybrid nanocomposite, and the effect of ambient temperature on the insulation lifetime of the enameled wire in the form of twisted pair was studied by a withstanding voltage tester. The organic polymer was Polyesterimide-polyamideimide (EI/AI) and the inorganic material was a Nano-sized silica (average particle size : 15 nm). The enamel thickness was 50 μm and the ambient temperature was 100, 150, 200, and 250, respectively. Transmission electron microscopy (TEM) observation showed that Nano-sized Silica were evenly dispersed in EI/AI. There were many air gaps in a twisted pair, therefore, when voltage was applied to the twisted pair, enamel erosion took place in the air gap area because of partial discharge accordi, ng to Paschen’s law. As ambient temperature increased, insulation lifetime decreased according to Arrhenius relationship, which was explained by the increasing mobility of polymer chains in EI or AI. And insulation breakdown voltage value at 10 kHz was 1,864.5 sec (31.1 min), which is 1.9 times higher than at 20 kHz, 981.6 sec (16.4 min).

As environmental issues have emerged as a global concern in recent years, energy efficiency issues in the industrial motor area have become more important such that many motors now have inverters or adjustable-speed drives to deliver high efficiency. And inverter power supplies with pulse modulated (PWM) technique, in which insulated gate bipolar transistors (IGBTs) are used as high speed switching device, can improve the controllability of the motor torque and reduce the switching loss [1-3]. Partial discharge (PD) is a key factor in the mechanism of the insulation breakdown due to the inverter surge [3-5]. PD can occur as internal discharge, surface discharge, end-winding discharge, slot discharge, discharge between bars of different phases, and/or copper conductor interfaces, and inter-turn discharge [4-6]. Generally, PD characteristics were studied in a twisted-pair with polymeric insulator enameled wire. When voltage was applied to a twisted pair, enamel film erosion takes place in an air gap area because of partial discharge according to Paschen’s law [7,8].

where V is the breakdown voltage in volts,

Polyesterimide-polyamideimide (EI/AI) has good thermal and electrical insulation properties. Polyamides are polymers having high insulation breakdown strength with good heat resistance, mechanical strength and chemical resistance. Therefore polyamide insulated wires are used in harsh environmental conditions [12-14]. Polyimides are used in inverter-fed motor windings and high pressure coil for electric translators. In recent years, elements allowing high-speed switching such as insulated-gate bipolar transistors (IGBTs) have been developed as inverter power devices. In order to enhance electrical insulation and heat resistance, Nano-sized silica has been incorporated into the EI/AI. In this study, insulation breakdown voltage and insulation lifetime were investigated in twisted pairs with EI/AI/Nano-sized silica hybrid enameled round wires (HW). The enamel thickness was 50 μm and the conducting copper diameter was 0.50 mm ~ 1.024 mm, respectively, and the effect of temperature on insulation lifetime was studied at 100℃ ~ 250℃.

EI/AI wires were prepared by coating a round copper wire with Polyesterimide-polyamideimide enamel (Sam Dong Co., Ltd., Korea). HW was synthesized by vigorous mixing EI/AI and 2.5 wt% of Nano-sized silica (average particle size: 15 nm) in toluene using an Ultrasonicator with an 500 W probe-type Ultrasonicator (VC 505, Sonics & Materials Inc.) at a frequency of 20 kHz for 60 min. The enamel thickness was 50 μm and the conducting copper diameter was 0.49, 0.74, and 1.014 mm, respectively. Therefore, the wire diameter increased to 0.50, 0.75 and 1.024 mm, respectively. All twisted pairs were prepared by twisting a couple of two straight lines of 125 mm length under constant 1.4 N·M torque using a twisting machine. The number of twisted turns for the wire diameter of 0.05, 0.75 and 1.024 mm was 22, 16, and 16 turns, respectively.

In order to study the insulation lifetime, a PD test was carried out in a temperature chamber (Model : OF-22, JEIO TECH Co.), as shown in Fig. 1(a). Five twisted pairs (Fig. 1(b)) for each kind of the wire diameter were simultaneously installed in a temperature chamber at 100, 150, 200, and 250℃, respectively. In order to apply high voltage, enamel insulation layer was removed from one side of the twisted pairs and then other side was left with the enamel insulation layer. And then, the five twisted pairs were installed in the chamber of the setting temperature and kept for 10 min, and PD measurements were performed by using the following system: A sinusoidal waveform voltage of 1.5 kV with 10 kHz or 20 kHz was applied to the twisted pairs by a withstanding voltage tester (Model : APCP-12kV-100, Sky Innotek Co., Ltd.) for frequency acceleration. The measurement was performed in atmospheric air. Insulation lifetime was performed at a speed of 40 V/s until 1.5 kV and was maintained at that voltage until electrical insulation breakdown took place.

The dispersion of Nano-sized silica particles EI/AI was observed by a high-resolution transmission electron microscope (TEM, Hitachi S-4100). The nanocomposite film was cut into ultrathin sections of about 70~90 nm by a Power TOME X microtome equipped with a diamond knife and the ultrathin sections were placed on a 200 mesh copper grid. The observation was performed using an accelerating voltage of 200 kV.

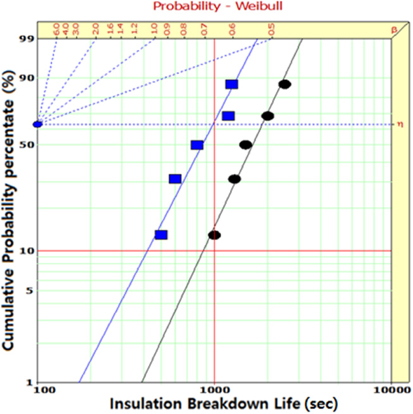

Figure 2 shows Weibull statistical analysis (Weibull++ 7.0) for the insulation lifetime of EI/AIW () and HW () twisted pairs whose wire diameter was 0.75 mm. Applied voltage was 1.5 kV at 20 kHz and ambient temperature was 100℃. Insulation lifetime was performed at a speed of 40 V/s until 1.5 kV and was maintained at that voltage until electrical insulation breakdown took place. The scale and shape parameters and B10 value were obtained from the Weibull plots and listed in Table 1, i.e. the scale parameter represented the AC electrical breakdown strength by which 63.2% of the cumulative probability was expected to fail and the shape parameter could be obtained from the slope meaning the data distribution. And The B10 value referred to the electrical lifetime at which 10% would fail (90% would survive) under a given test condition.[15]. The scale parameter of HW was 981.6 sec (16.4 min), which is 19.4 times higher value than EI/AIW at, 81 sec (0.8 min). B10 value of HW was 402.5 sec, which is 11.4 times higher than EI/AIW at, 35.3 sec, where B10 value meant the safety factor of an insulation material. These results meant nano-sized silica improved excellent AC insulation lifetime characteristics of EI/AIW. However the shape parameter of HW was 0.4 times lower value than EI/AIW and meaning the homogeneity decreased in the HW system comparing to EI/AIW system.

Weibull parameters for insulation lifetime of EI/AIW and HW twisted pairs obtained from Fig. 2.

In order to study the uniform dispersion of nano-sized silica (2.5 wt%) in the hybrid system, TEM observation was performed and TEM images were shown in Fig. 3. The low magnification image shows the even dispersion of nanoparticles and the low magnification image shows that most of the 15 nm particles were dispersed without aggregation. These particles contributed to the high level of partial discharge resistance in the HW system so that electrical insulation lifetime of HW system was remarkably modified by the incorporation nano-sized silica. The mobility of polymer chains in EI or AI was interrupted by nano-sized silicas due to the hydrogen bonding between hydroxyl groups on the surface of nano-sized silica and ester, amide or imide group in the polymers. The strong interface characteristics prevented the electrons from easily passing the interface between silica and EI/AI.

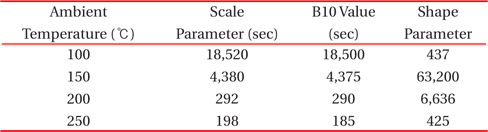

Figure 4 shows the effect of ambient temperature on the insulation lifetime of HW twisted pairs whose wire diameter was 1.024 mm and applied voltage was 1.5 kV at 20 kHz. Ambient temperature was 100℃ (), 150℃(), 200℃() and 250℃() with, Weibull parameters listed in Table 2. As was expected, when ambient temperature increased, insulation lifetime decreased logarithmically. Insulation lifetime at 100℃ was 18,520 sec (308.6 min), which was 93.5 times higher value than that at 250℃ and 198 sec (3.3 min). In order to estimate the effect of ambient temperature on insulation lifetime, an Arrhenius plot was shown in Figure 5 and is expressed as follows: , where t is insulation lifetime and T is ambient temperature. The decrement of insulation lifetime due to increasing temperature is explained by the increasing mobility of polymer chains in EI or AI, i.e. as ambient temperature increase, hydrogen bonding between hydroxyl groups on the surface of nano-sized silica and ester, amide, or imide groups in the polymers become weak and the interfacial characteristics became poor. Therefore, electrons can relatively easy to pass through the interface between silica and EI/AI with electrical breakdown occurring easily at high temperatures. The B10 value at 100℃ was 18,500 sec (308.3 min), which is 100 times higher value than at 250℃, 185 sec (3.1 min).

Weibull parameters for insulation lifetime of HW twisted pairs at various ambient temperatures obtained from Fig. 4.

Figure 6 shows the effect of wire diameter on Weibull statistical analysis for insulation lifetime of HW twisted pairs with different wire diameter: () was 0.75 mm and () was 1.024 mm. Applied voltage was 1.5 kV at 20 kHz and ambient temperature was 100℃. The Weibull parameters are listed in Table 3. The scale parameter for 1.024 mm was 18,520 sec (308.7 min), which is 18.9 times higher than at 0.75 mm and 981.6 sec (16.4 min). In general, it is well known that air gap distance and temperature affected on the enamel erosion. As the diameter of enameled copper wire increased, air gap distance increased. Therefore, according to Paschen’s law [7,8] electrical breakdown voltage steeply decreased until a low air gap distance and increased gradually after the air gap distance. And as the diameter of enameled copper wire increased, temperature between the wires decreased. Therefore enamel erosion rate was low in the larger diameter conditions. The shape parameter of 1.024 mm was 437, which was 168.1 times higher than in 0.75 mm and 2.6.

Weibull parameters for insulation lifetime of HW twisted pairs with different wire diameter at 100℃ obtained from Fig. 6.

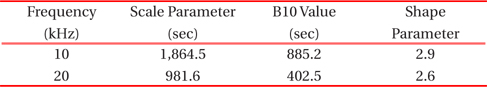

Figure 7 shows the Weibull statistical analysis of insulation breakdown voltage for HW twisted pairs with diameter at 0.75 mm. Applied voltage was 1.5 kV at () 10 kHz and () 20 kHz, and ambient temperature was 100℃. The shape and scale parameters were obtained from the Weibull plots and listed in Table 4. Insulation breakdown voltage value at 10 kHz was 1,864.5 sec (31.1 min), which is 1.9 times higher than at 20 kHz and 981.6 sec (16.4 min). The B10 value at 10 kHz was 885.2 sec (14.7 min), which is 2.2 times higher than at 20 kHz and 402.5 sec (6.7 min). The breakdown mechanism has been explained on the basis of collision and ionization. [16] When a low-frequency voltage was applied across the air gap, the positive ions are trapped in the gap, increasing the field considerably, casuing the breakdown occur earlier, i.e. the breakdown voltage is lowered. As the frequency increases two decades or more, the electrons become trapped in the gap and an enormous number of electrons and positive ions are present in the gap, further decreasing the breakdown voltage.

Weibull parameters for insulation lifetime of HW twisted pairs at different ac frequency at 100℃ obtained from Figure 7.

Insulation breakdown characteristics of an inverter surge resistant enameled wire were investigated in a twisted pair wire prepared with organic/inorganic hybrid nanocomposite. T The effect of ambient temperature on the insulation lifetime was studied using a withstanding voltage tester. The organic polymer was polyesterimide-polyamideimide (EI/AI) and the inorganic material was a nano-sized silica (average particle size: 15 nm). Insulation lifetime of HW and EI/AIW twisted pairs with 0.75 mm diameter was 981.6 sec (16.4 min) and 81 sec (0.8 min), respectively, where applied voltage was 1.5 kV at 20 kHz and ambient temperature was at 100℃. The former was 19.4 times higher value than the latter. As ambient temperature increased, insulation lifetime decreased according to the Arrhenius relationship, which was explained by the increasing mobility of polymer chains in EI or AI. Insulation lifetime for 1.024 mm of wire diameter was 18.9 times higher than 0.75 mm wire diameter, and insulation breakdown voltage value at 10 kHz was 1,864.5 sec (31.1 min), which was 1.9 times higher than at 20 kHz, 981.6 sec (16.4 min).