In this Paper, We study on establish for unit of measure. Quality control is means control for customer needs. We surveyed unit of measurement of quality feature of Juran and Taguchi teaching. We suggest new measure of quality feature. New quality measure which is combined with several quality control measures. Which measurement can be used management control of managerial level of company. We expect this new measurements can be applied and well used.

우리는 이 논문에서 측정 단위 설정에 대하여 연구하였다. 품질관리는 고객 요구를 관리하는 것이다. 쥬란과 다구찌가 연구한 품질 형태의 측정 단위를 조사하였다. 그리고 품질 형태의 새로운 측정을 제안하였다. 제안한 새로운 품질측정은 여러 품질 관리 측정을 조합한 것이다. 이러한 측정은 회사의 관리 수준에서 경영 관리에서 사용될 수 있을 것이다. 우리는 제안된 새로운 측정이 실제 사용되고 도움 되기를 기대한다.

In this Paper, we study on measure definition that measure quality characteristic. Quality characteristic measurement is one of problem of old quality. Engineering special quality can measure by numerical value exactly by developed sensor etc. Therefore, there is no problem on communication with customer about quality problem which are defined definitely. But, for nonobjective quality characteristic is not as like objective quality characteristic, we must make newly measuring methods. In this paper, we examine such general problem and suggest new quality measure method(Ree 2004).

Section 2, we survey Juran, Taguchi of measure methods. Section 3, we suggest measure idea. Section 4, we give conclusion of this theme.

Ⅱ. Survey on measure of Quality characteristic

2.1 Juran on investigation about quality characteristic measurement

2.1.1 Range of Measurement unit

Quality characteristic is utilized in wide extent that take advantage of quality with department of technology, administration Measurement unit is defined variously to display various quality characteristic.

Let's examine some kinds of measurement unit.

First kind is technological level. Some of these measurement unit are intimate to field people. By the example, if quality characteristic is distance measurement unit appears by km. Some technological measurement unit that is not familiar to field people. These are that it is known well to engineers. By the example, if quality characteristic is the calory, measurement unit uses Joul.

Second Kind of measurement unit is being involved in production efficiency. If service time measure time unit or hour unit.

Third measurement unit is involved in a mistake and miss. If quality characteristic is included within product are badness, measurement unit uses % or PPM.

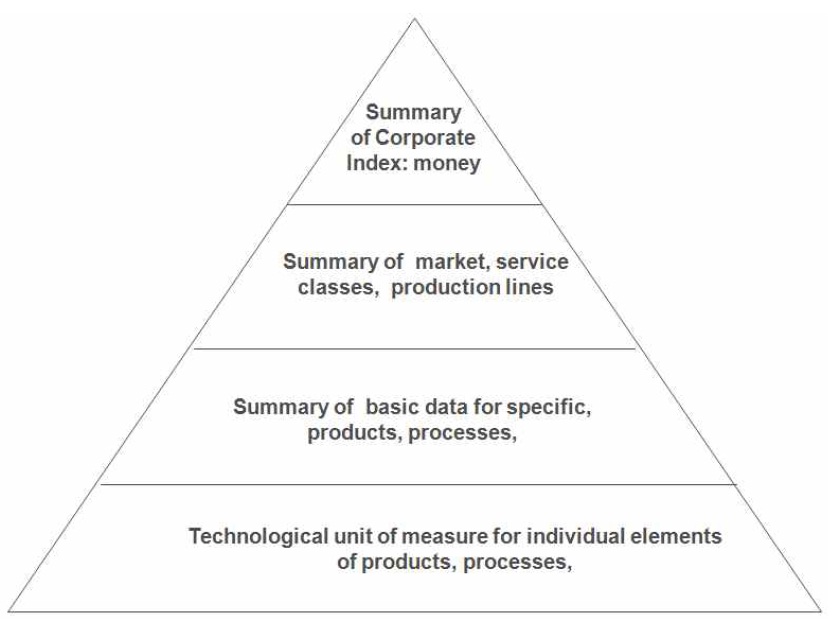

Fourth measurement unit includes performance of department of function measurement. If quality characteristic is production, measurement unit uses failure quality cost per dollar of production costs.

Fifth measurement unit includes quality characteristic of high position management level. In this level, the latest phenomenon is interested relatively. If quality characteristic is competitive power in the market, measurement unit uses guidance rival company's production performance.

Sixth measurement unit is involved with administrator performance and development connected with quality. These of measurement unit unite with thing which is sometimes used in quality performance. That is, there is product ratio without poor quality, operation ratio cost and failure quality cost etc.

Sometimes, measure whether administrator's performance measure did special action. By the example, It is things such as training expense involved quality.

2.1.2 Juran’s Ideal Definition

The most of measure which we measure are variant. If word 'Error' is included for measurement unit, should define enough precisely as can agree how omit whether count word 'Error' how.

Propose 6 points as following to get into ideal justice.

(1) Should suggest basic data for decision-making.

(2) Should be comprehensible.

(3) Should be used widely.

(4) It must become translation(analysis) undoubtedly changelessly.

(5) Should be economical to apply.

(6) It must become existent sensor design and can be transposited..

If 6 points as above of singularity are equipped, which are called by ideal quality measurement unit.

2.2 Investigation about quality characteristic measurement of Taguchi

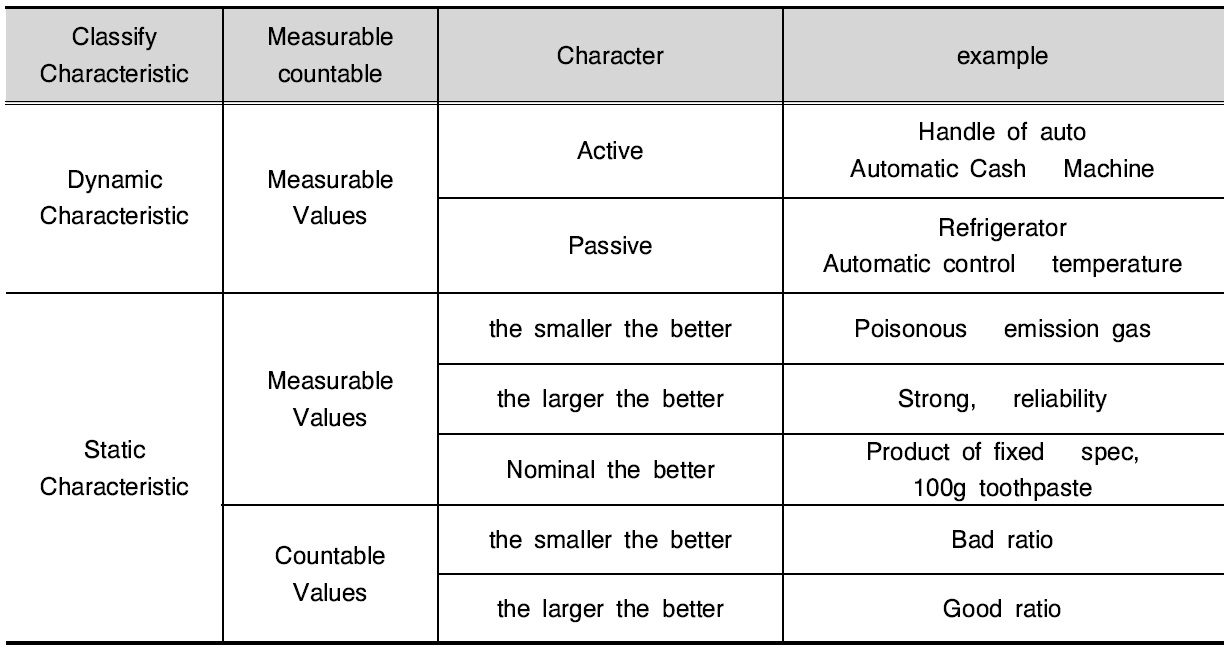

2.2.1 Taguchi’s quality characteristic

When Taguchi’s quality characteristic values are chosen, we proposed 3 points as following.

First, Quality characteristic values are measured possible up-stage which means design level. Characteristic value of design level step has dynamic characteristic value generally.

Second, Quality characteristic values are chosen, which can measure basic function exactly.

Third, Countable values are not chosen by possible characteristic value. Characteristic value of lower step has countable values generally. Can’t improve by countable values at lower class step.

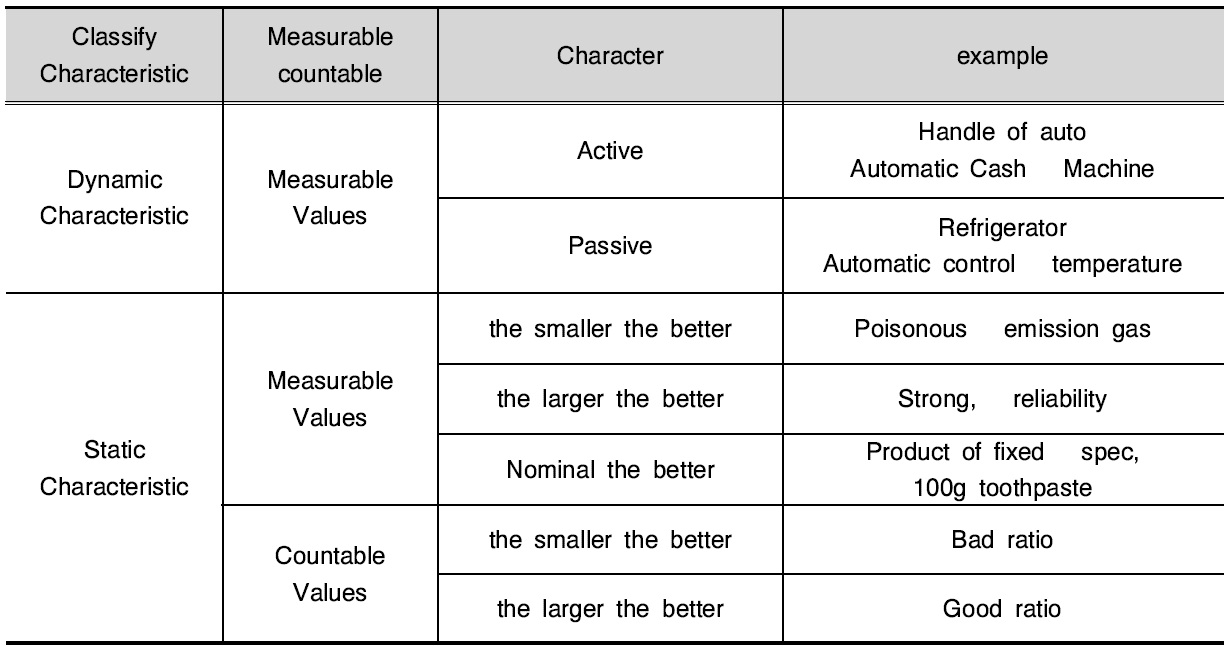

Quality characteristics can be divided into dynamic characteristic values and static characteristic values greatly. Dynamic characteristics can be divided into again active dynamic and passive dynamic characteristic values. Active dynamic characteristic values can generate power by changing signal factor. By example, Steering wheel is changed by driver from time to time, Car direction is changed according to handle. Passive dynamic characteristic values does not change signal factor random, it is. Automatic freezing device of refrigerator is operated automatically when temperature of refrigerator inside more than fixed numerical value.

Static characteristics values have 4 kinds as like the lager the better, the smaller the better, nominal the better and countable values. The smaller the better characteristic values are not negative number and is good special quality as is small. As like automotive exhaust gas, which is better as is smaller.

The larger the better characteristic values are not negative number and are good special quality as are large. As like automotive soundness, chemical substance is same situation.

Nominal the better characteristic values have limited desired values which are good when characteristic values are exactly same desired values.

As like 100g toothpaste, which is important that fill 100g exactly.

Countable values are represented by percentage. Countable values have characteristic of the smaller the better, the lager the better. Which are expressed by value from 0% to 100%.

For quality improvement, measurable values are better than countable values. If characteristic values are countable values, then give information of results, don’t inform about productive capacity of process. But measurable values can give statistics information as like average and variance and give quality information that can improve quality.

[Table 1] classify of characteristic values

classify of characteristic values

2.2.2 Taguchi's SN ratio

The success of Taguchi’s Method is caused by signal-to-noise ratio which is measures according to purpose of Taguchi’s method. Purpose of Taguchi’s Method is to do robust design about noise.

Production fields have many various factors as like carelessness of worker, incontrollable condition such as external environment that can’t control of material.

Taguchi’s Method is robust about effect of noise factors than purpose to take away or reduces error about noise factors. That is, we find control factors which can reduce influence of noise factors. Which method is called Taguchi Robust design method. Products which are designed by robust design are quality cost decreased, because which products are decreased failure and repair. For Robust design, it need signal-to-noise ratio.

Signal-to-noise ratio means signal against noise in Telecommunication. Unit of signal-to-noise ratio uses decibel unit(db) that use in Telecommunication. Signal-to-noise ratio is fine as is high.

According to special quality characteristic of product, definition about signal-to-noise ratio is different.

As smaller of variance, signal-to-noise ratio is high.

We can divide signal factor, noise factors and control factors to find signal-to-noise ratio. We can arrange as like (Ree, 2001, 2003, 2008; Jang, 2004)

Ⅲ. Propose new quality measure index

Quality control is management about process and result. Management about process is consisted of mainly dynamic characteristic value and result is consisted of static characteristic value. Dynamic characteristic value by Taguchi’s Method means that characteristic values change according to signal factor.

This time, characteristic values are changed according to input values. Taguchi take advantage of this concept in product design that is strong at noise factors at product design. Management index use by making new index by searching between various index.

3.1 technical quality measure index

Technical quality measure index are technological measurement unit by 1 kind according to division Juran and itself can be managed to automatic control system. y is result value and can be used input value of next step. x is present value in process.

Present value y which is reflected by x is not reflected justly and is measured though some time passes. We can present as like

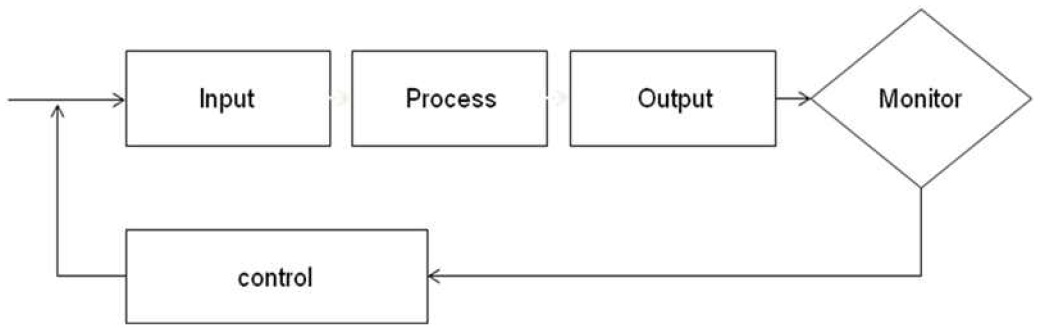

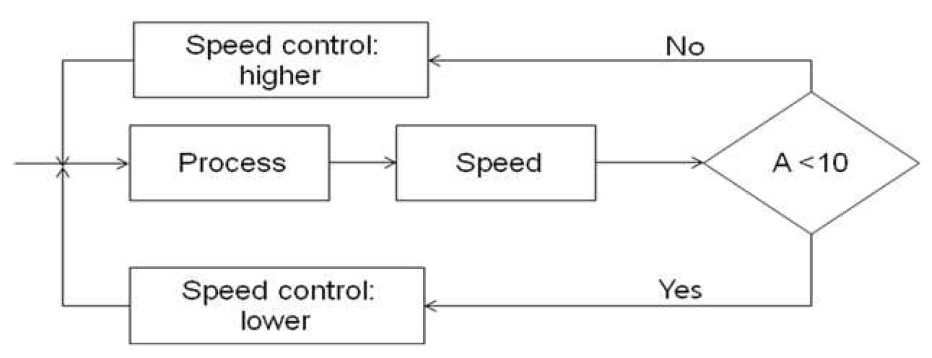

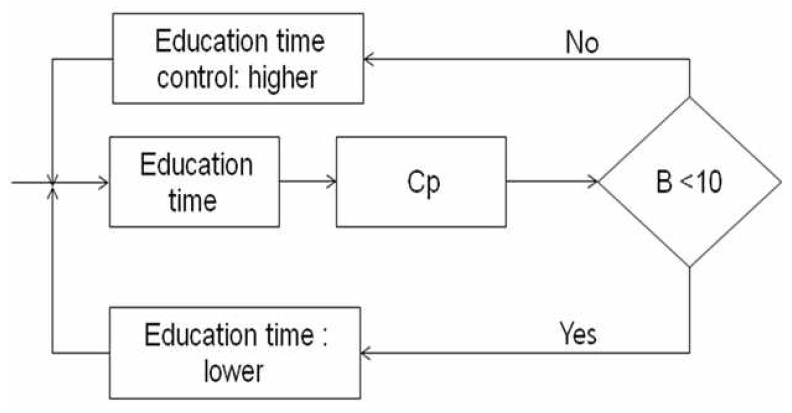

This formula don’t exist inverse formula, because time t can’t be turn back. This system is automatic control system as like < Figure 2>.

According to division Juran, Taguchi dynamic characteristic value can be used at technology step which is 1 step. Taguchi dynamic characteristic value concept can be applied more than 2 step in Juran. More than 2 step is that manage process of production. At 2 step management step, control slowness and fastness of production activity by each production line. Also, control to set quality level of produced product. These quality index do not exist specially until present.

Automatic control system keeps present state changelessly. Production line is not always fixed on several conditions. Change constantly. Automatic control system principle is system that control condition of cause input influencing in result when result changes. Purpose of control chart use is same with automatic control system.

3.2 Managerial quality measure index

Managerial quality measure index is seeming signal-to-noise ratio of Taguchi’s Method. Signal-to-noise ratio makes by 2 statistical quality measurements. That is, make combination of mean and variance. Thus Managerial quality measure index is consisted of collating of technological quality measurement index. Such a case are process capability index, 6 sigma level etc.

3.2.1 Case of technical quality index

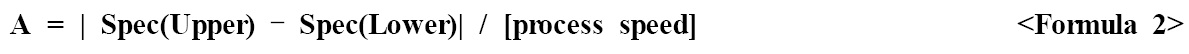

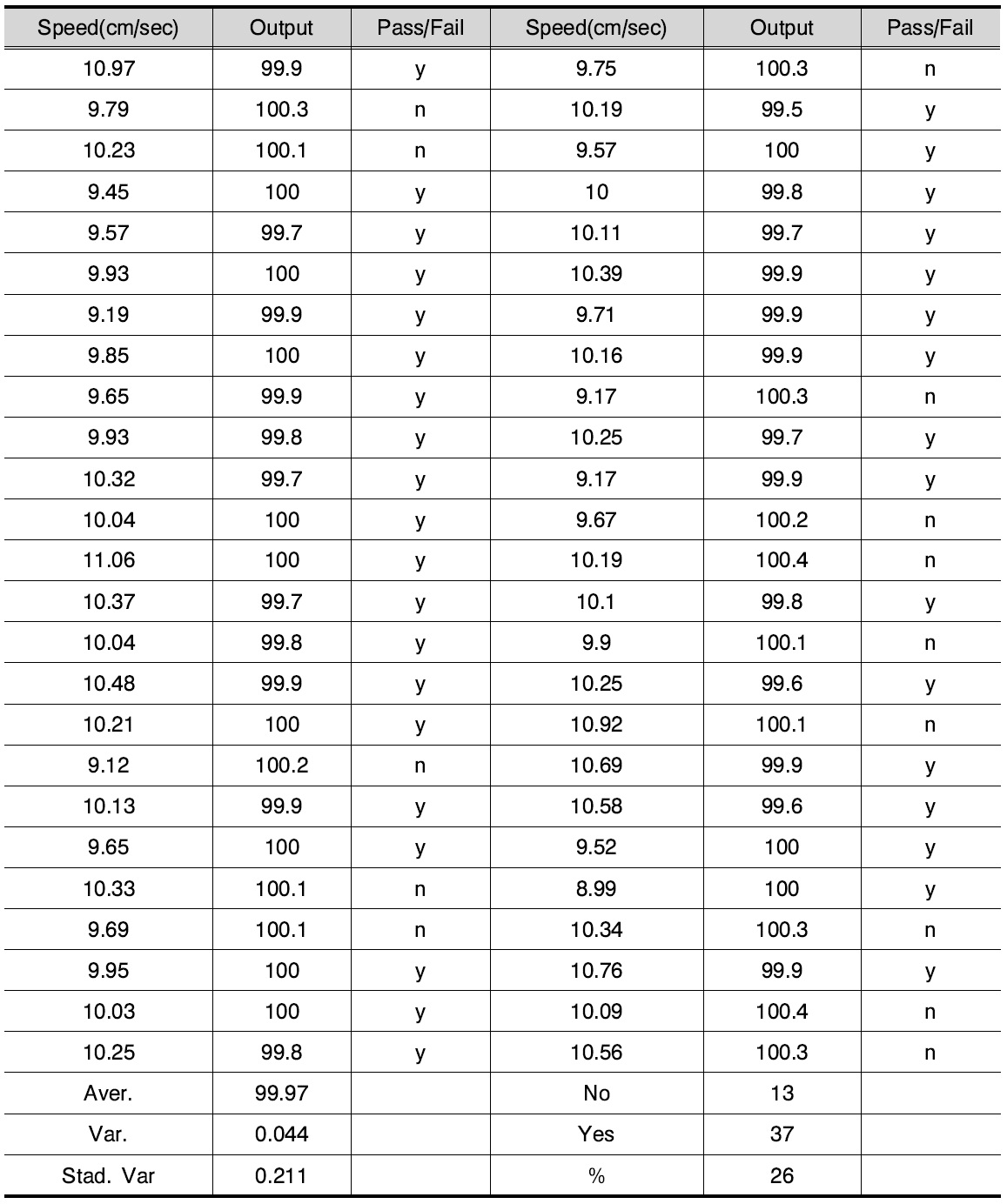

Give example as following in case include technology quality index. If we set defective managerial index is A. Index A is defined as following Formula 2 as relation of production speed (assumption which production is measured by m as like a pipe length) and specification of products.

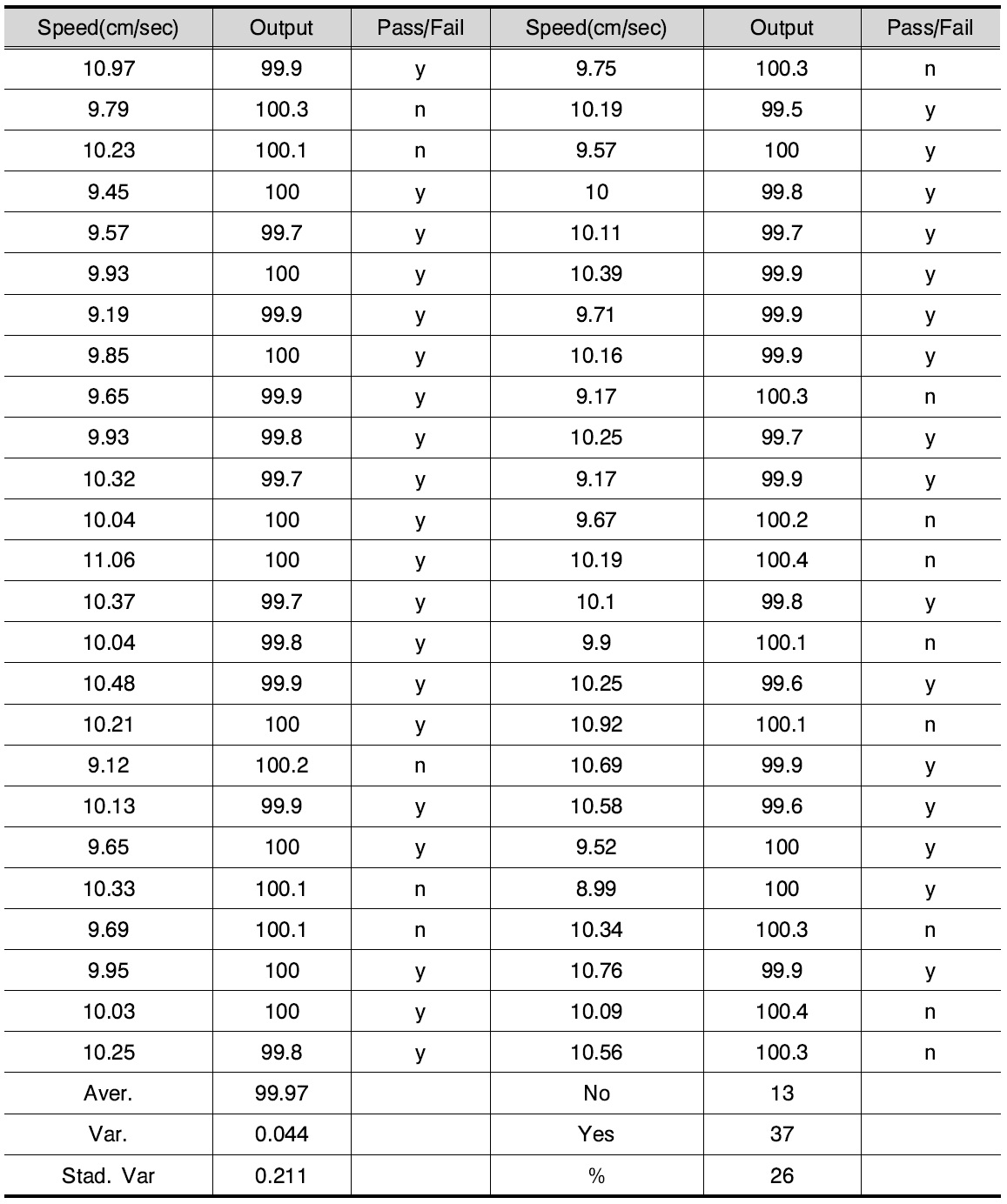

Meaning of this formula is that defective ratio is high if A becomes low because the production speed rises. If this formula is useful meaning, which can be used standard index. By various value of A. if we can find relation defective ratio and produce speed, which is very good managerial index. By example, let specification of pipe diameter is 100φ±0.5 and the average production speed is 0.1m/sec, then become A = (100.5 - 99.5)/0.1 = 10. If A is below 10, then the production speed higher than regular speed, then can be rise fraction defective ratio, then we can control produce speed lower. In this occasion, Automatic control system can be shown as like <Figure 3>.

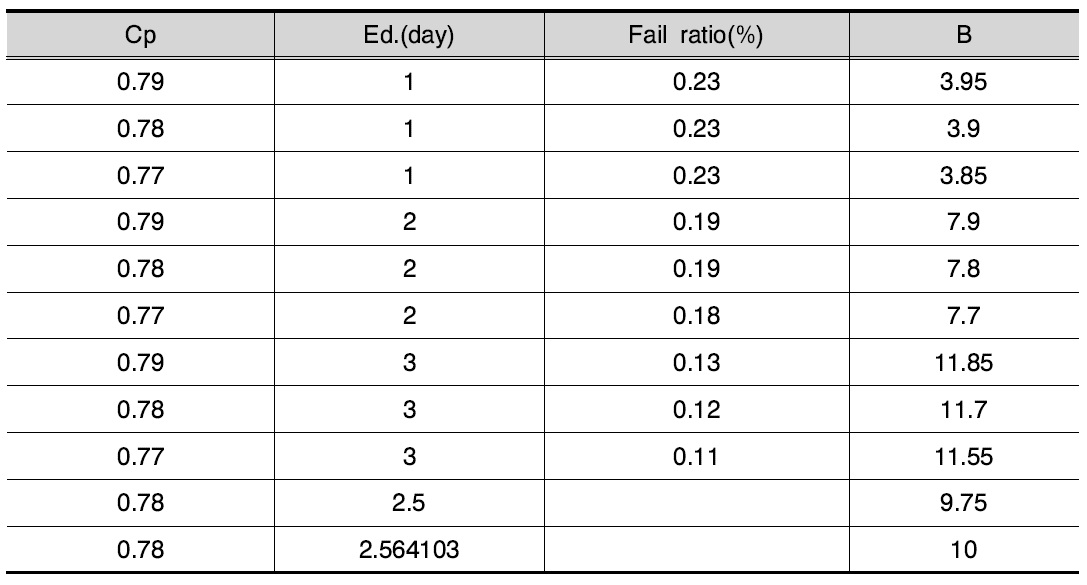

3.2.2 Case of Education time index

The case of including only quality index are many as like change index(=sample standard deviation/sample mean) which use statistical value and Taguchi’s SN ratio, Process Capability index etc.

Quality statistics that argue good or defective goods can make by statistical average and standard deviation because suppose normal distribution. It should be defined by different method if is not normal distribution.

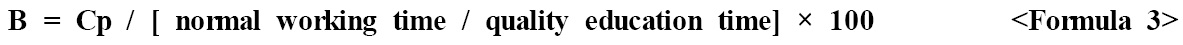

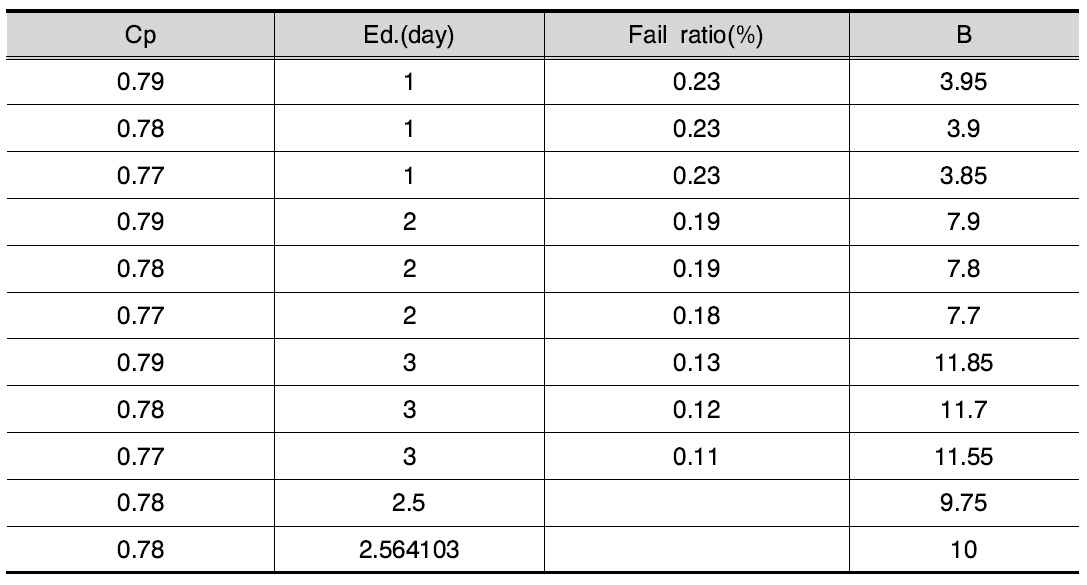

Let's new managerial index B defined like

[Table 2] data of Speed and Output

data of Speed and Output

Meaning of B is mean that invest education when Cp is bad more. If Cp is lower or quality connection education investment time is low, then B index become lower, which is not desirable direction. By the example, any field production department middle manager works average 20 day a month, and 2 day(2×8 time) is educated. We can calculate as like B = 1/ [ 20×8 / 2×8]×100 = 10. If we have standard indicate relation Cp and Education time. Then we can advise need education time or not. This case, we can control by Automatic Control System as following <Figure 4>.

[Table 3] data of Speed and Output

data of Speed and Output

As like above example, Each enterprise makes own managerial index and can use.

In this Paper, we investigate about measurement of quality characteristic. First, examined research on quality characteristic of existing investigators. Juran and Taguchi’s works are survey. And we propose new quality characteristic value.

Referring that give example in section 3, each enterprise can use defining own quality index to manage and makes. Which effect is expected in enterprise that these proposals do quality control.

There is meaning in direction that mean of quality characteristic that propose in this paper understands actuality to be deeply and reconcile exact point of theory.

But, subject remains to be shown realistic a lot of examples and theoretical accuracies to do objective authentication for proposed index.