Recently, sericin has attracted increasing attention in biomedical and cosmetic research because of its useful properties including acceleration of wound healing, improvement of cell attachment, and inhibition of ultraviolet-B induced apoptosis. However, sericin films have poor mechanical properties, which restricts the application to those fields. In this study, cellulose nanofibril (CNF)/sericin composite films were fabricated by solvent casting, and the effects of ultrasonication time and CNF content on the solution turbidity, molecular conformation, and film mechanical properties of sericin film were examined. As the ultrasonication time increased, the turbidity of the CNF/sericin suspension decreased. Conversely, as the CNF content increased, the turbidity increased. However, β-sheet crystallization and mechanical properties remained almost unchanged by varying the ultrasonication time and CNF content, indicating that CNF is not effective to improve the mechanical properties of sericin films.

Silk sericin was removed by a degumming process to improve the properties of silk textiles, including luster and touch. However, recent studies on sericin revealed that this material can be utilized in cosmetic and biomedical fields. Tsubouchi

To enable its application to biomedical and cosmetic fields, sericin needs adequate mechanical properties. However, the sericin film breaks during the formation because solid sericin is too brittle. Thus, even though the sericin film can be fabricated, its mechanical properties are limited; consequently, several studies focusing on the improvement of the mechanical resistance have been conducted. Yun

Cellulose nanofibrils (CNFs) have been produced from cellulose by various methods including chemical and physical treatments (Klemm

In the present study, the CNF/sericin composite film was prepared. The effect of homogenization time (i.e., ultrasonication time) and CNF content on the solution turbidity, molecular conformation, and mechanical properties of sericin were examined.

CNFs were isolated from cellulose pulp according to the modified TEMPO oxidation method (Saito and Isogai, 2004). In short, the kraft pulp sample (2 g of cellulose) was suspended in water (150 mL) containing TEMPO (0.025 g) and sodium bromide (0.25 g). The TEMPO-mediated oxidation of the cellulose slurry was initiated by adding 5 mM of 13% NaClO for every gram of cellulose and conducted at room temperature under gentle agitation. The pH was maintained at 10.5 by adding 0.5 mM NaOH. When a decrease in pH was no longer observed, the reaction was considered complete, and the pH was then adjusted to 7 by adding 0.5 M HCl. The TEMPO-oxidized product was filtered, thoroughly washed with water, and physically fibrillated by ultrasonication in a sonicator (Sonosmasher, Jeio Tech, Korea) for 20 min. The suspension was then centrifuged at 5,000 rpm two or three times for 30 min. The supernatant, which was in fact a suspension containing the CNFs, was decanted and collected. The yield of the CNFs was calculated as a percentage of the initial weight of the CNF suspension after drying in an oven at 105 °C. The final concentration of the CNFs was adjusted to 0.1% by weight/volume.

The preparation of silk sericin has been described in a previous study (Jo

>

Preparation of CNF/sericin composite film

The solid sericin was dissolved in 98% formic acid at 55°C to prepare a 2% (w/w) sericin formic acid solution. Approximately 5–15 wt% (against the dry mass of the sericin solid) of CNFs was dispersed in formic acid; the suspension was homogenized in an ultrasonicator (Sonosmasher, Ulsso Hi-tec, South Korea). The power and frequency of the ultrasonication were 560 W and 20 kHz, respectively. The CNF formic acid suspension was mixed with the 2% (w/w) sericin formic acid solution for 10 min using a magnetic stirrer; then, the CNF/sericin formic acid solution was poured into a petri dish. Finally, it was dried in a hood at room temperature to obtain the CNF/sericin composite film.

>

Measurement and characterization

To determine the solution state, the turbidity of the CNF/sericin solution was analyzed. The turbidity was calculated after measuring the transmittance of the solutions at 700 nm with an ultraviolet–visible (UV–VIS) spectrophotometer (Evolution 201, Thermo Fisher Scientific, USA). The following equation was used for the calculations: 𝜏 = −(lnT)/c, where 𝜏 is the turbidity, T is the transmittance at 700 nm, and c is the cell length.

Fourier transform infrared spectroscopy (FTIR, Nicolet 380, Thermo Fisher Scientific, USA) was performed using the attenuated total reflection method to examine the molecular conformation of the CNF/sericin films.

To evaluate the mechanical properties of the CNF/sericin composite film, breaking strength and breaking elongation were measured using a Universal Test Machine (OTT-03, Oriental TM, South Korea). The tensile tests were performed using a 3 kgf load cell at an extension rate of 10 mm/min for the composite film. The film sample was prepared with a length of 50 mm and a width of 5 mm. The gauge length was 30 mm. All samples were preconditioned at 20°C and 65% relative humidity, and five different CNF/sericin composite films for each sample were used for the measurement.

The solution properties of silk polymers have been extensively studied because they affect the structure and properties of the resultant silk solid, including fiber and film (Cho

The presence of a homogeneous dispersion of reinforcing material in a matrix polymer solution is a critical issue, as it determines the improvement of the mechanical properties of the matrix polymer by the reinforcing material (Jonoobi

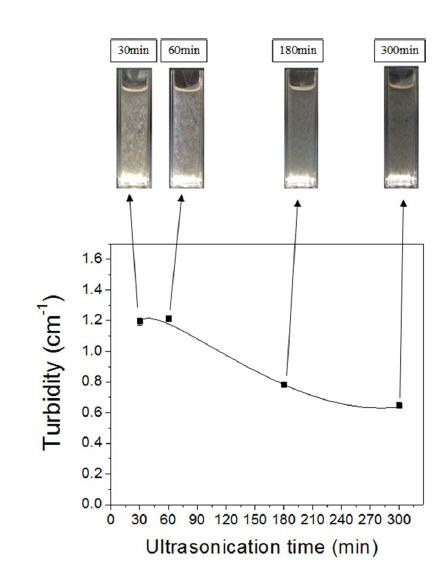

Fig. 1 shows the turbidity and pictures of CNF/sericin formic acid solutions with different ultrasonication times. As the ultrasonication time increased, the turbidity of the solution decreased, indicating a more homogeneous dispersion of CNFs in the sericin formic acid solution with the increase of the ultrasonication time. The homogeneity of CNFs in the sericin formic acid solution could be confirmed by the picture of CNF/sericin formic acid solutions in UV cells. This result indicates that the homogeneity of the CNF dispersion in formic acid can be improved by ultrasonication.

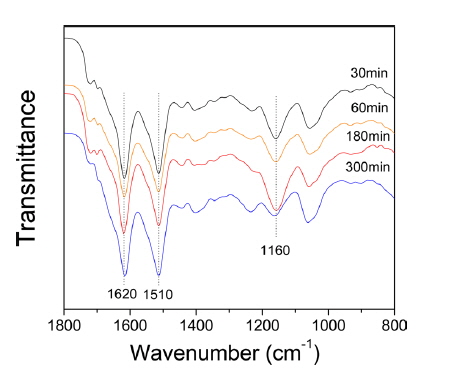

The molecular conformation of sericin has been widely examined because it affects the mechanical properties of sericin (Jo and Um, 2015). To examine the effect of the ultrasonication time on the molecular conformation of the CNF/sericin composite film, FTIR measurements were performed on the CNF/sericin films produced with different ultrasonication times; the results are shown in Fig. 2.

Regardless of the ultrasonication time, all CNF/sericin films showed strong IR absorption peaks at 1620 cm-1 and 1510 cm-1 for amide I and II bands, respectively. These peaks are attributed to the β-sheet conformation (Jo and Um, 2015; Jo

The β-sheet conformation of sericin in CNF/sericin composite films is consistent with the results of previous reports, and is due to the intense β-sheet crystallization occurring during the formic acid casting (Jo and Um, 2015). The absence of significant changes in the IR spectra when varying the ultrasonication time indicates that the ultrasonication does not affect the β-sheet crystallization of sericin during the formic acid casting. In this study, the ultrasonication was conducted on CNFs in formic acid prior to mixing with the sericin formic acid solution; thus, the ultrasonication was not directly performed on the sericin formic acid solution. However, the ultrasonication time influenced the homogeneity of the CNF dispersion in sericin formic acid solution, as shown in Fig. 1. Despite the different dispersion of CNFs in sericin solution, the unchanged IR spectra indicate that the homogeneity of the CNF dispersion in formic acid does not affect the crystallization of sericin during the formic acid casting.

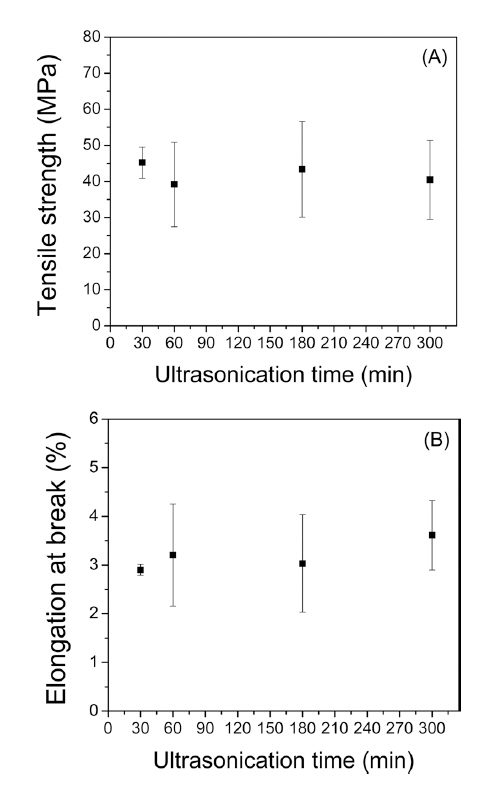

Fig. 3 shows the effect of ultrasonication time (i.e., homogeneity of the CNF dispersion) on the mechanical properties of the CNF/sericin composite films. Regardless of the ultrasonication time, all CNF/sericin composite films showed a tensile strength of ~40–50 MPa and an elongation of ~2.5–4 %. Considering the error ranges of tensile strength and elongation, it appears that the ultrasonication time has almost no influence on the mechanical properties of the CNF/sericin composite film.

Fig. 4 shows the turbidity of the CNF/sericin solutions with different CNF contents. As the CNF content increased, the solution became more turbid. This result can be easily rationalized considering that the turbidity increased by increasing the particle concentration. When the CNF content increased to 10%, the solution became remarkably turbid, even though the CNFs were homogenized in formic acid for over 5 h.

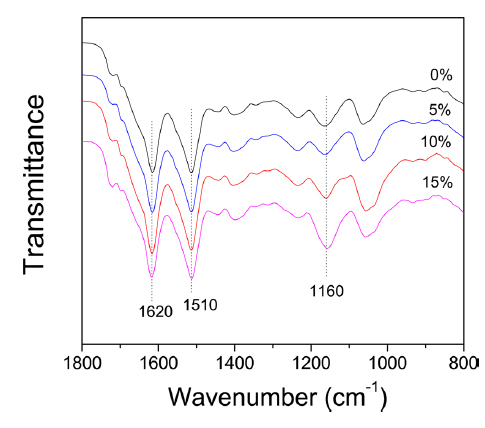

To examine the effect of the CNF content on the molecular conformation of sericin in the CNF/sericin composite film, FTIR measurements were performed, and the results are shown in Fig. 5. The IR absorption peaks at 1620 cm-1 and 1510 cm-1 remained almost unchanged with the CNF content, implying that the β-sheet crystallization of sericin with formic acid casting was not influenced by the amount of CNF content. Conversely, the IR peak at 1160 cm-1 increased by increasing the CNF content, as this peak originated from cellulose, as mentioned in the previous section.

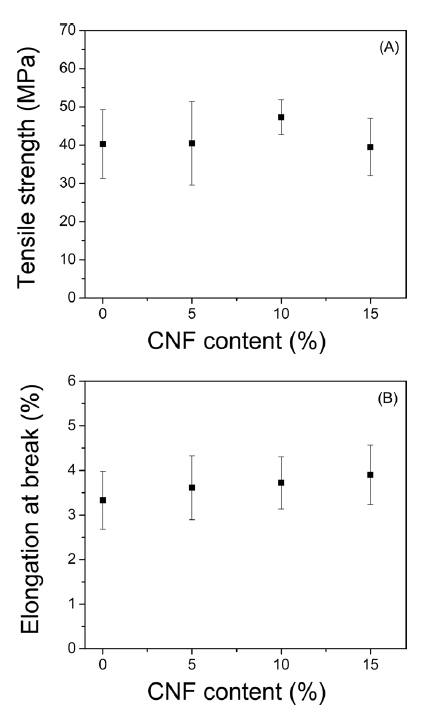

Fig. 6 shows the mechanical properties of the CNF/sericin composite film. Although the 10% CNF content sample showed a slight increase of the tensile strength, a clear improvement in the breaking strength of sericin by addition of CNF cannot be definitely claimed, considering the error range of measurement. As the CNF content increased, the elongation at break increased very slightly. Therefore, the addition of CNF up to a content of 15% did not improve the mechanical properties of the sericin film.

In this study, CNF/sericin composite films were prepared. Solution turbidity, molecular conformation, and mechanical properties of CNF/sericin were examined. The molecular conformation of sericin was not affected by the presence of CNF. The mechanical properties of the sericin film could not be enhanced by the use of CNF as a reinforcing material. Therefore, more reinforcing materials should be tested to improve the mechanical properties of the sericin film and additional studies will be conducted in the future.