Carbon micro particles with dimple patterns were produced by electro-spraying a solution of pitch in tetrahydrofuran. Particle formation depended on separation in an electrical field and volatilization of the solvent. More than 80% of the obtained carbon exhibited an average particle size of less than 50 μm. X-ray diffraction analysis suggests that the carbon with dimple patterns has increased crystallinity after heat treatment.

The application of electrospinning for the formation of various polymeric shapes has been widely reported in recent years [1-3]. Electrospraying is a useful process for production of droplets that are highly charged to prevent aggregation [4,5]. This process can be used with a diverse selection of polymers, and droplets can be controlled according to flow rate, tip-tocollector distance (TCD), and concentration of the polymer solution [6]. Electrospraying has been actively researched in many industries because of its potential applications for microencapsulation [7], electroemulsification [8], and fine powder production [9] from a polymer solution. Recently, microscale and nanoscale particles obtained using the electrospraying technique have been used in biochips, biosensors, and drug delivery systems due to their high specific surface area [10]. The materials for biosensors need to have good electrical conductivity because they react to electrical signals. Pitch, which is obtained from a heat-treatment process for coal and petroleum, is a mixture of aromatic compounds of various molecular weights. Pitch is applied to different applications depending on the composition of the aromatic compounds and its softening point. In this study, the electrospray technique was used to produce a pitch powder with a unique shape that differs from other polymers described in the literature.

Pitch (HPCP-60, SP 296℃, Hanwha Chemical, Korea) was purified with dimethylformamide (DMF, 99.8%, mp 152℃, Aldrich) to obtain a high molecular weight pitch precursor that was favorable for orientation during heat-treatment. The purified pitch was dissolved in tetrahydrofuran (THF, mp 66℃, J.T. Baker), and the solution was vigorously stirred at 55℃. After being poured into a 30 mL syringe, the prepared pitch solution was electrically sprayed using electrospraying equipment.

The experiment was conducted by changing the weight percent of the pitch solution, the applied voltage, and the flow rate. In the first experiment, the weight percent of the pitch solution was 5, 10, 15, 20, or 25 wt%. However, 25 wt% was not electro-sprayed. These solutions were experimentally sprayed at a fixed voltage of 22 kV, a flow rate of 2.0 mL/h, a TCD of 10 cm, a rotational velocity of 800-850 rpm, and through an 18 gauge (18G) needle. In the second experiment, the applied voltage was 17, 20, 22, or 25 kV. The solution concentration was fixed at15 wt%; the other conditions were similar to those in the first experiment. In the third experiment, the flow rate was 0.5, 0.7, 1.0, 1.3, 1.5, or 2.0 mL/h. The solution concentration was fixed at 15 wt%, and the other conditions were similar to those in the first experiment.

The pitch powder prepared from 15 wt% pitch solution was heated for stabilization and carbonization at 300℃ at a rate of 1℃/min under air atmosphere in a convection oven, and then at 1050℃ at a rate of 5℃/min under a 100 cc/min flow of nitrogen gas, respectively. In both cases, the sample was maintained at the set-point temperature for 1 h.

Field-emission scanning electron microscopy (FESEM, Hitachi, S-4700, the Korea Basic Science Institute [KBSI], Jeonju Center) was used to investigate the shape of the electro-sprayed pitch powder and that of the pitch powder after heat-treatment. The size of the electro-sprayed pitch powder was examined using a particle size analyzer (HEROS, Sympatec GmbH, Germany). The crystal structure of the heat-treated pitch was also analyzed by X-ray diffraction diffractometer (XRD, D8 DISCOVER, Bruker AXS, Germany). The X-ray source was Cu Kα radiation generated by a 3-kW X-ray tube with Cu target. The diffractometer was used over the 2

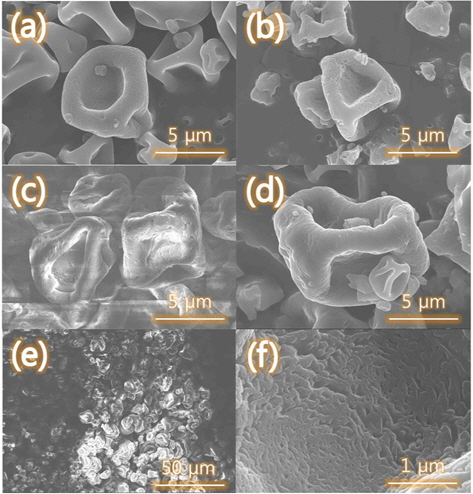

Changes in particle shape were observed in association with changes in the solution conditions. Fig. 1 shows changes in particle size depending on the concentration of the pitch solution. As the concentration of the pitch solution increased, the particles of electro-sprayed pitch powder became larger. The 25 wt% pitch solution could not be electro-sprayed because of its high density. This resulted from its low solubility in THF at this concentration. This result is believed to be because the increased concentration of the pitch solution requires a stronger electrical field to separate the solution into droplets at the tip, at a constant voltage [11]. Therefore, the solution could not be divided into distinct particles.

Fig. 1e shows the pitch powder on the substrate. The shape of the pitch powder obtained was similar to that of popcorn. This phenomenon was caused by the increase in concentration of the pitch near the electro-sprayed powder, which likely increased the Peclet number (Pe) [12,13]. The Pe is a measure of the relative importance of advection to diffusion. The more important advection is, the higher the value of Pe will become, indicating increased particle displacement. As the concentration of the pitch powder surface increased, a thin crust was formed on the surface of the pitch powder. As more solvent vaporized, the crust thickness increased to form hollow particles, and then collapsed to form popcorn particles [14,15].

Fig. 1f is an enlarged image of the wall surface of the pitch powder. The surface wall displayed a dimple pattern like that of a golf ball because of evaporation of the solvent (i.e., THF) during the electro-spraying process. THF, which is a highly volatile solvent at room temperature, removed a small amount of pitch while volatilizing. The SEM images show that all particles were separated from each other, which indicate a low surface tension force in THF acting on the pitch particles during drying [16,17].

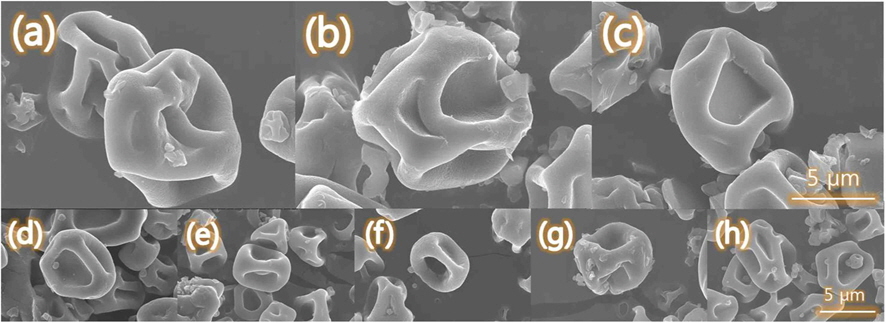

Shape changes due to changes in the applied voltage and flow rate were also observed. The obtained pitch powder was insignificantly changed by varying the applied voltage and flow rate during the electro-spraying process as shown Fig. 2. However, the particle morphologies were shown to vary with increasing applied voltage and decreasing flow rate, both of which resulted in reduced particle size. However, the size of the pitch obtained was similar on the whole. The pitch solution apparently experienced stable fluctuations between dripping and jet modes, which differs markedly from the behavior exhibited by other polymeric solutions [13,18].

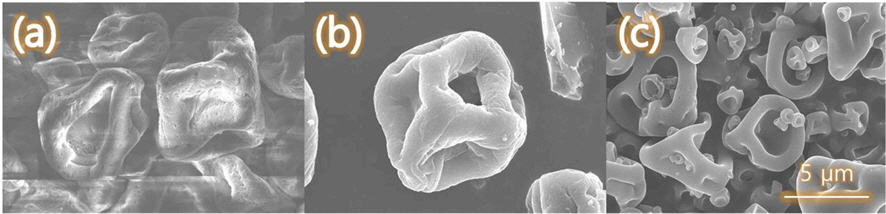

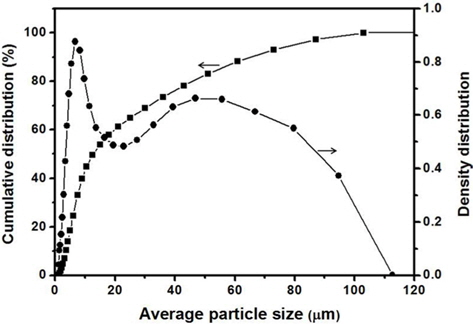

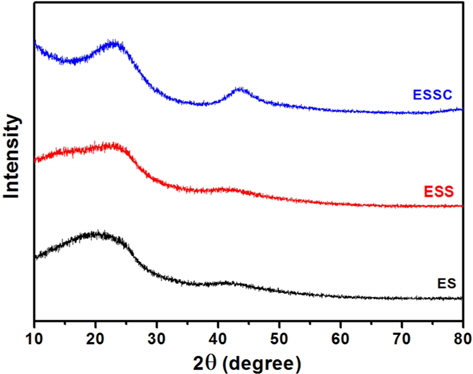

The size and structural properties of the resulting carbon were also investigated. Fig. 3 shows the shape of the pitch particles after electro-spraying (ES), stabilization (ESS), and carbonization (ESSC) processes. The electro-sprayed pitch powder exhibited a dimple pattern on its surface; however, this pattern disappeared after heat-treatments. This is likely because the carbon hexagonal plane was rearranged by the heat-treatment. The stabilized pitch powder exhibited a cage structure, whereas the carbonized pitch powder exhibited a smooth surface. Fig. 4 shows the size of the pitch particles obtained using the spraying conditions of 15 wt%, voltage 22 kV, flow rate 2.0 mL/h, TCD of 10 cm, rotational velocity of 800-850 rev/min, and needle size of 18G. In Fig. 4, the cumulative distribution demonstrates that more than 80% of the electro-sprayed pitch particles exhibited a size smaller than 50 μm. This result indicates that ES does not produce pitch particles of uniform size. The particle size obtained after ES depends on the pitch molecular weight dissolved in the solvent, here THF, under constant applied voltage. Fig. 5 shows the crystallinity of the pitch powder after ES, ESS, and ESSC, respectively. ESSC showed amorphous peaks at approximately 23° and 43°, compared to the patterns of ES and ESS. Originally, broad XRD peaks for amorphous carbon materials typically appear around ~26° and ~43°, which contributed to reflection from the (0 0 2) and (1 0 1) crystal planes, respectively [19]. The appearance of amorphous peaks indicated that crystallites for a specific crystal plane were arranged during the heat-treatment.

Pitch powder with a dimple pattern was obtained via an ES process under various solution concentrations, applied voltages, and flow rates. The resulting pitch powder was not affected by these variables because the pitch solution was more stable than other polymer solutions.The particle sizes of the obtained powder were primarily smaller than 50 μm in diameter. After stabilization, a cage structure appeared in the middle of the pitch powder, and after carbonization, amorphous peaks of the pitch powder increased slightly, without a significant change of form. These findings demonstrate that ES pitch powder solution created a new form of carbon micro particles.