Recent tremendous development of LED (light emitting diode) technologies and the world-wide industrial boom has enabled the era of solid state lighting to come into our lives. One of the mainstream of LED applications is, without a doubt, solid state lighting for home, electronic goods, street lighting lamps, industry, etc. There has been very much effort for lighting applications utilizing LEDs to replace incandescent light bulbs and downlights. Although the planartype LED lighting possesses high luminance efficacy of up to ~180 lm/W (at package level cool white 4,750~7,040 K), color index, and long lifetime, there are still strict restrictions that should meet the customers’s needs, such as the avoidance of shiny glare of LED point sources and achievement of high brightness toward the viewing angle. Usually, for the application of LED lighting to the downlights and planar type lamps, uniform illuminance is critical. Therefore optical films are generally employed when LED lighting devices are assembled and packaged. Their role is to redistribute the light rays coming out from the point LED sources and uniformly radiate onto the forward direction without sacrificing illuminance [1-4].

There have been great efforts to form upright pyramid geometry, especially in Si solar cell technologies [5-8]. Texturization of a (100) oriented mono-crystalline silicon substrate with a subsequent deposition of an anti-reflection coating has become a well-established method for the minimization of reflection losses. Anisotropic etching, such as sodium or potassium hydroxide solutions, is used to form pyramidal structures on the mono-crystalline silicon solar cell surfaces [9-11]. Elimination of light trapping by upright pyramid geometry can be attributed to the increase of the escape cone for light extraction caused by the alteration of propagation direction of light rays at the pyramid surfaces [12].

Here, we report a quite simple and efficient way of fabricating uniform high light-extraction optical films for LED lighting by utilizing micro/nano-patterned silicon wafer masters.

In this section, we briefly describe the fabrication method. The method for surface texturization utilizing an anisotropic etching process is well established [13, 14], but we moved a step ahead to achieve efficient and cheap ways of fabricating improved light-extracting films.

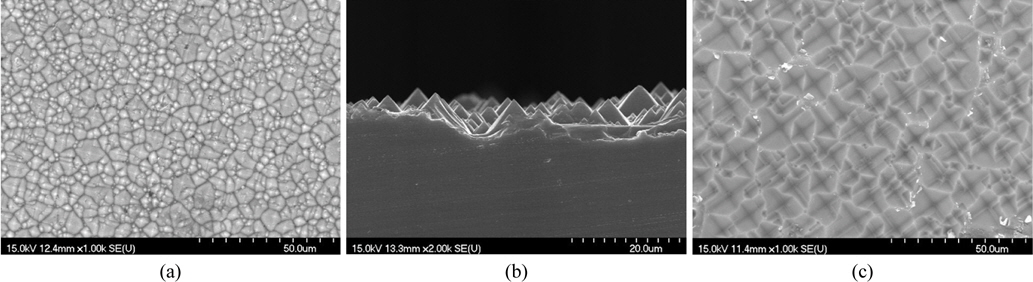

First, master patterns were simply and efficiently fabricated by KOH additives under the proper wet etching conditions. 4” (100)-orientation silicon wafers were etched by formulated solutions (DI water : IPA : KOH = 50:47:3 wt%) along with ultrasonic vibration of 40 kHz for 50~70 minutes. Etched textures were slightly different depending on the detailed etching conditions. The surface texturing of etched wafer surfaces was shown in Fig. 1(a). Quite well shaped nano-, and micro-sized pyramid patterns were formed on the entire 4”-wafer surfaces. Orientational positions and size distributions of individual patterns were observed to be random (within a range from 100 nm to 5 μm) under the SEM observations. The apex angle of the pyramids is estimated to be 70.5°, which is fixed due to the intrinsic crystalline nature of (100)-oriented silicon wafers. We could successfully wet-etch the wafers up to 8” so far, therefore larger wafer etching can also be done.

Secondly, a replica process of patterns onto the film was carried out by coating molding fluids (film thickness ~ 10 μm) on top of Si-wafer and pressing base plates (transparent PC (polycarbonate), PMMA (poly methyl methacrylate) from

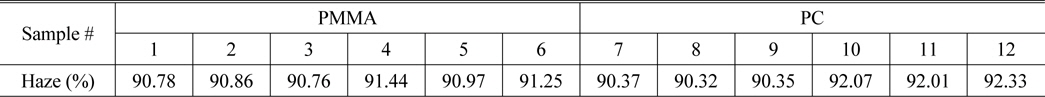

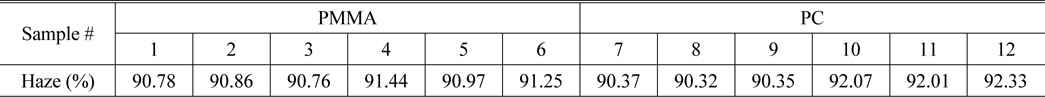

When we put the 4” fabricated optical films on the LED lighting, we observed the transmitted light was quite uniform and hazy by naked eye so that no pointy shape of LEDs was detectable (Fig. 2). Haze was measured by using a hazemeter (NDH-5000, NIPPON DENSHOKU) for several samples made of PMMA and PC. The results were listed in Table 1. One can find that haze ratio values (= Diffuse transmittance/Total transmittance) are over 90%, which is a quite unique characteristic since high transmittance of clear PMMA or PC sheets usually results in low haze ratio.

Optical performance of replicated film, i.e., haze ratio (= Diffuse transmittance/Total transmittance) shows very large values over 90%

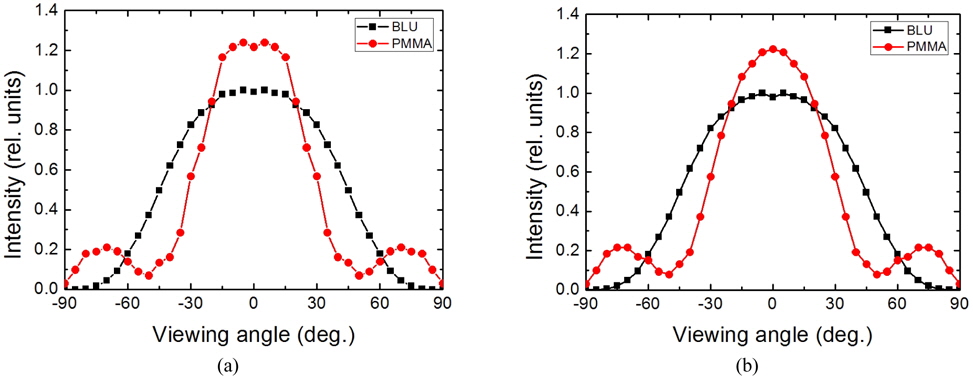

Next, we checked the brightness enhancement effect of putting films on top of a BLU (backlight unit, white light source), from which the diffuser film was removed, by comparing it with & without (w/o) optical films. We used index-matching oil between the BLU and the optical film for the maximum brightness. Intensity profiles were measured by Goniophotometer (C-type, Pimacs). Fabricated films were attached in front of the BLU source and placed at the center of the Goniophotometer. The detector was 12 meters away from it, and intensity distributions were measured from -90 to 90 degrees at the interval of 5 degrees. The intensity of BLU w/o film shows broad illumination across the visible wavelength region. However, when optical films were employed, the maximum intensity was measured to be 13~14% at the center. Intensity profile was also dominated ~±20° along the viewing angle direction (Fig. 3), but intensity outside the viewing angle decreased as the result of light redistribution, i.e. photonic energy redistribution from the tails to the center (viewing angle) occurred as shown in Figs. 3 and 5. Compared with the previous work [1], brightness enhancement (15~20%) is lower, maybe due to dirt or imperfect index matching between film and BLU.

We claim that the proposed fabrication process is quite unique, simple and most of all, cost-saving. There are many methods that employ conventional photo-lithography and semi-conductor fabrication processes. These techniques require high cost and many more process steps including two step-etch masking and dry etching and replications [1]. In contrast, our proposed method uses only simple wet etching along with sonication, moreover master patterns can be fabricated as large as the available silicon wafer (up to 8” in this work).

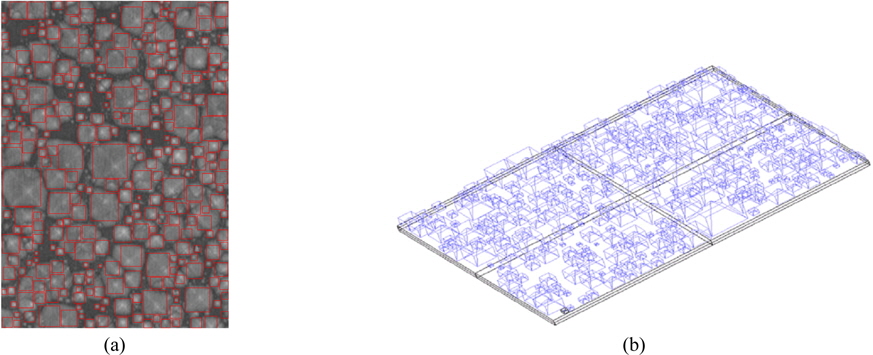

Next, computer simulation with

We have already checked alternative fabrication methods for pattern master using photo-lithography and dielectric etch mask (SiO2, SiNx) to form highly ordered lattice-like patterns with uniform size [1, 2, 15]. When we compare the uniformity and brightness of films between randomlypositioned and periodic-positioned patterns, data showed no considerable differences in brightness enhancement.

In summary, we introduced the simple fabrication method to form random-positioned and random-sized pyramid patterns on the (100) silicon wafer surface. A simple way of replication was also introduced and optical performances were measured. We could check the feasibility for LED/OLED lighting applications by simply laminating on top of LED lamps and testing uniformity and brightness and shiny glare. Fabricated optical films in this work turned out to be quite suitable for targeted LED lamps. Simulational results also turned out to be in good agreement with experimental data. Furthermore, the proposed method is quite simple, efficient and most of all cost-saving that a large area pattern master will meet the requirement of cheap mass-production.