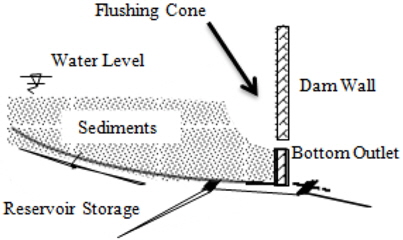

Many type of sediment-related problems can occur both upstream and downstream of dams, and sediment entrainment can also interfere with the beneficial use of diverted water. Sediment can enter and obstruct intakes and greatly accelerate abrasion of hydraulic machinery, thereby decreasing its efficiency and increasing maintenance costs. Turbid density currents can carry sediments tens of kilometers along the bottom of the impoundment, eventually entering deep intakes and accumulating in front of low level outlets. Localized sediment deposits in the delta region and streambed aggradations upstream of the reservoir can produce flooding, because soil water logging and salinization, impair navigation, alter ecological conditions, inundate powerhouses discharging into delta areas, and bury intakes (Fig. 1). In arid regions the growth of phreatophyte vegetation on delta deposits can significantly accelerate water loss. The combination of sediment trapping and flow regulation also has been used dramatic impacts on the ecology, water transparency, sediment balance, nutrient budgets, and river morphology downstream of the reservoir; dam construction is the largest single factor influencing sediment delivery to the downstream reach. Storage loss is but one of many sedimentation problems that can affect reservoirs. Operation of storage reservoirs is severely impacted by the time half the volume has been deposited, but severe sediment-related problems can appear when only a small percentage of the storage capacity has been lost. As reservoirs age and sediments continue to accumulate, sediment-related problems will increase in severity and more sites will be affected. At any dam or reservoir where sustainable long-term use is to be achieved, it will be necessary to manage sediments as well as water. This is not a trivial challenge.

Based on the inventory published by the International Commission on Large Dams (ICOLD, 1988) and the current rate of dam construction, as of 1996 there were about 42,000 large (over 15 m tall) dams worldwide. Pressurized flushing has been studied extensively in the literature (White and Bettess, 1984; Shen et. al., 1993; Shen and Lai, 1996; Scheuerlein et. al., 2004; Emamgholizadeh et. al., 2006) and Meshkati Shahmirzadi(2010). In spite of advances in the investigation of pressure flushing technique at reservoir storage, studies about the effect of bottom outlet diameter on flushing cone development are limited and more information about this phenomenon is needed. One of the most effective techniques is flushing through which the deposited sediment is hydraulically removed by the flow. The oldest known method of flushing, practiced in Spain in the 16th century, was referred to by D’Rohan (Brown, 1943). Traditional approaches to sediment management have not considered the need for sustained use. Large initial storage volumes and erosion control have traditionally been recommended to reduce sediment inflow and delay the eventual “death” of reservoirs, but erosion control alone cannot achieve the sediment balance required to stabilize reservoir storage capacity and achieve sustainable use. Furthermore, many erosion control programs are poorly conceived and implemented, and fail to achieve the desired reductions in sediment yield. As a result, reservoirs worldwide are losing storage capacity rapidly, possibly as fast as 1 percent per year (Mahmood, 1987).

Extensive treatments of these topics are already available by others (Yang, 1996; Simons and Senturk, 1992; Julien, 1995; Chang, 1988; Vanoni, 1975; Graf, 1971). Rather, Sedimentation problems and management techniques vary widely from one site to another, and by studying specific sites one can appreciate the complexity of sediment problems and the manner in which they can be addressed.

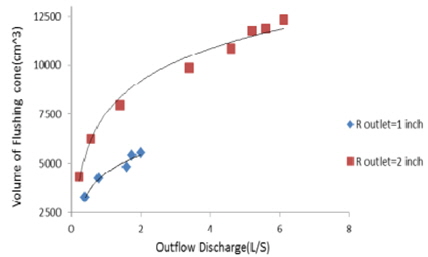

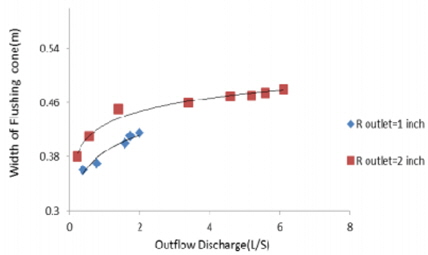

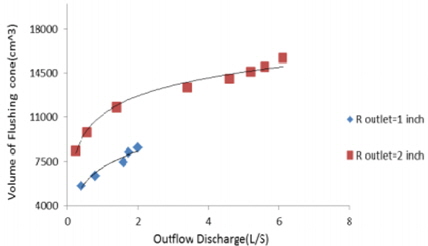

In streams where most or all sediments are sands, the sediment can be settling in an Imhoff cone, and the sediment content expressed as milliliters per liter. This method is useful in monitoring sediment release events because results can be obtained after short settling time, on the order of 1 min. Moreover, dimensions of flushing cone are also effective on rescue of power plant intakes. This paper deals experimentally with pressure flushing phenomena and investigation about the effect of bottom outlet cross section on volume and dimensions of flushing cone. The results are tabulated in terms of statistical measures and also illustrated in the scatter plots. However, this method requires that a calibration curve be constructed for each site where this method is used, to develop a relationship between settled sediment volume and sediment mass. During every event when this method is used, several samples should be collected and analyzed in a laboratory to confirm the original calibration. Because the grain size distribution can change significantly over the course of an event, it is also important that samples be taken at different periods as the calibration curve may shift during an event. In addition to speed, this method has the advantage of simplicity in equipment and procedure.

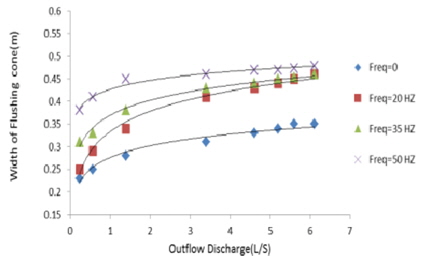

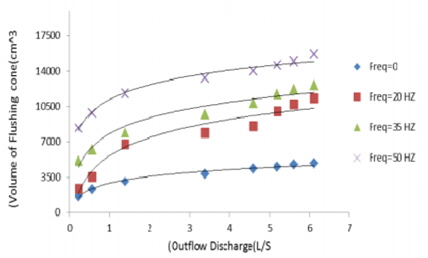

Estimation of sediment volume removed or volume of flushing cone in this technique with vibrations on a vibrator machine in layers of sediment is important for designing bottom outlet gates, in which the optimum and the best frequencies can be designed with respect to the cross section. Researches for understanding the geometric variations of scouring cone with the cross section change of the bottom outlet are necessary in order to make a rational design for the bottom outlet. Designing the bottom outlets must be through an optimization between some important rules (stipulations) such as: gate cost versus economic value of the increased reservoir volume after flushing. Dimensions of flushing cone are also effective on rescue of power plant intakes. Moreover, in the planning of dam operation, it can be vital to assess how much of the sediment can be removed, and how much flushing water is required. This paper deals experimentally with pressure flushing phenomena with vibrations on a vibrator machine in the layers of sediment in different frequencies and investigation about the effect of bottom outlet cross section on volume and dimensions of flushing cone.

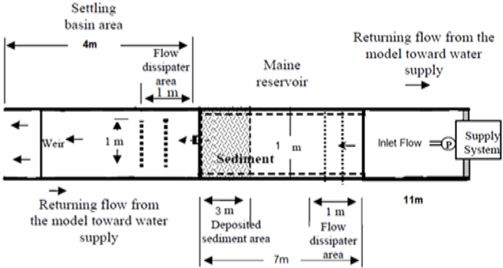

The experiments were conducted at hydraulic laboratory of Shiraz University. Experiments tests carried out on hexahedral shallow basin whose overall dimensions consist of 7 meter length, 1 meter wide and 1 meter height. Using two reticulate sheets at the reservoir’s entrance, a smooth flow is created. The front wall of model will be easy to change to modify different cross sections of reservoir bottom outlets. The outlets of main reservoir include two different gate valves with diameter of 2.54 and 5.08 cm. The sediment deposits at the main reservoir was consists of silica particles with uniform size distribution, with a median diameter of

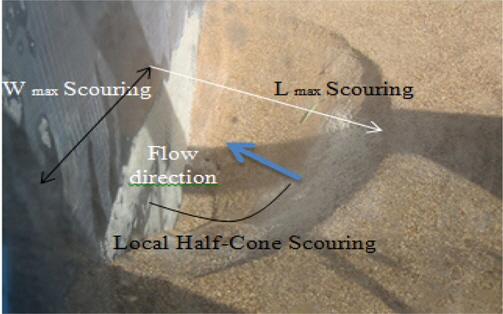

For the downstream section it was use another stilling basin which the mixing flow of water and sediment was collect in it and through a plastic pipe in a closed circuit with the under ground tank. The settling basin was a rectangular flume of 4 meter long, 1 meter wide, and 1 meter height. At the end of settling reservoir there was a V-notch weir (with angle of 90°) to measure of outflow discharge. In Fig. 3 a schematic plan view of the experimental setup and the hydraulic circuits is given. The notation of flushing half- cone under a discharge of 2 l/s, water depth of 80 cm and 5.08 cm diameter of the outlet are illustrated in Fig. 4.

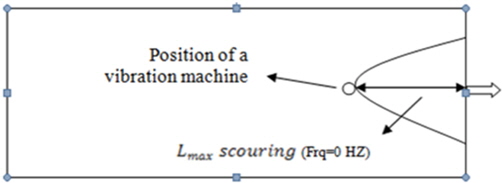

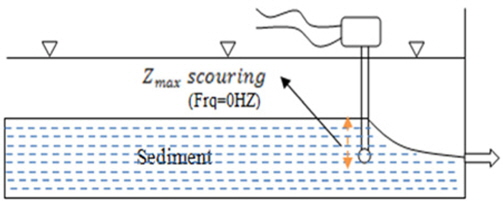

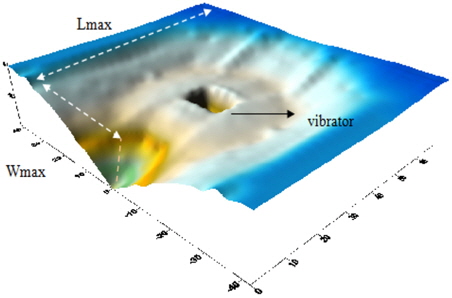

Position of a vibration machine a plan longitudinal profile are illustrated (

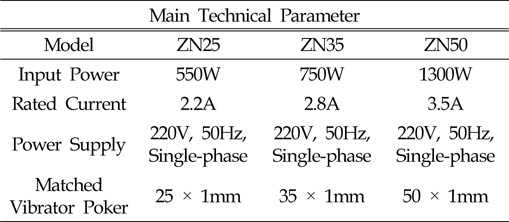

The vibrator is provided with a built-in converter in the switch box that converts the frequency 10 Hz to 50 Hz, and 1-phase 220 V to 3-phase 210 V which runs the 3-phase motor in the poker. As the poker vibrator is connected to a 1-phase wall socket-outlet it can be used everywhere. The comfortable start/stop knobs on the front side of the switch box are easily reached. The converter in the switch box has built-in functions that protect the equipment and the user against operational hazards. The strong and user-friendly switch box of impact resistant aluminum is designed to withstand the tough construction environment.

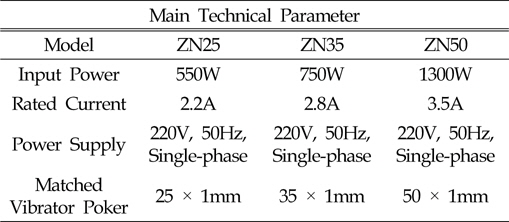

[Table 1.] Product description of electronic vibrator

Product description of electronic vibrator

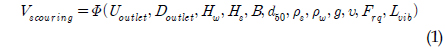

The volume of the flushing cone (

where,

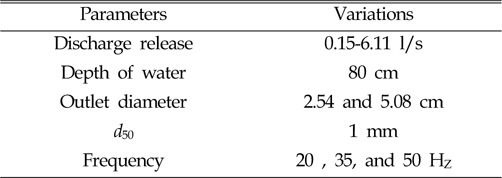

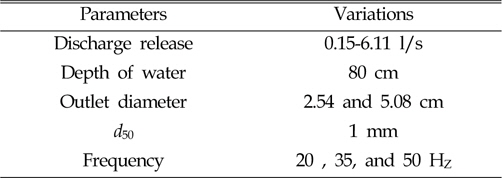

[Table 2.] Range of variables in this research and parameter variations

Range of variables in this research and parameter variations

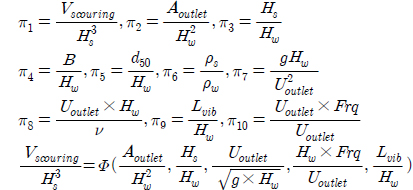

Where

For running the experiments, the deposited sediment were flattened and leveled firstly to a specific level above the center of bottom outlet (15 cm), and the model was slowly filled with water until the water surface elevation reached to a desired level. Then, the bottom outlet was manually opened until the outflow discharge, become equal to the inflow discharge. Consequently, the sediment was released from main reservoir. At the beginning of the experiment when the downstream outlet opened, sediment was discharged with high concentration, but the concentration of sediment flushing decrease with time.

Experiments were continued until the flushing cone reached to an equilibrium (no further particle motion will be observe) condition in which the sediment concentration was negligible at the end of the experiment. The time required for the formation of the flushing cone depends on hydraulic conditions. The development of flushing cone was very fast, and the process finished in less than one minute to ten minutes in the experimental model. In this study, the time for running the experiment was set to 45 minute. At the end of each experiment, the flushing outlet was closed in which the incoming discharge was set to zero then water was carefully and slowly drained from the main reservoir. After the run of each experiment, the bed level of scouring was measured using digital point gauges, and the volume of flushing cone was calculated by Surfer 8.0 software.

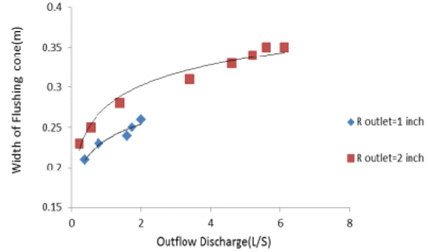

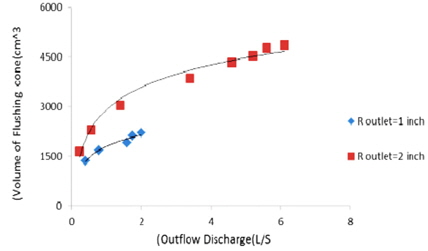

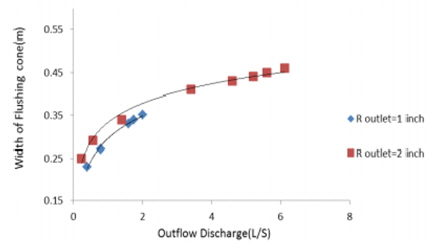

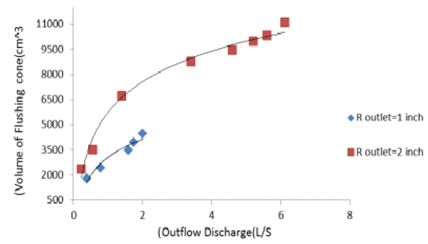

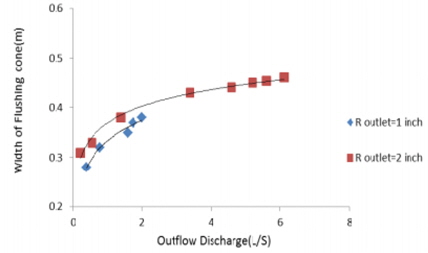

As previously mentioned, a half-funnel scouring shape was created at the vicinity of the outlet gates in the pressure flushing operation. The maximum scour depth of this cone was found to be very close to the dam wall. The surface development of the scouring cone was the same in both the width and length, but the plan shape of the flushing cone over the deposited sediment was close to half the circumference. The longitudinal and side cone slopes were approximately equal, and were similar to the angle of sediment submerged repose. The results show that the position of the vibrator with respect to the dam axis and the vibration frequency were the main parameters affecting the flushing cone dimensions. In addition, with an increase in the vibration frequency, the dimensions of the flushing cone (volume, length, and width) increased.

This study showed that