We propose a simple model to elucidate the dispersion behavior of spiraling modes on silver nanowire by finding correspondence parameters and building a simple equivalent relationship with the planar insulator-metal-insulator geometry. The characteristics approximated for the proposed structure are compared with the results from an exact solution obtained by solving Maxwell’s equation in cylindrical coordinates. The effective refractive index for our proposed equivalent model is in good agreement with that for the exact solution in the 400-2000 nm wavelength range. In particular, when the radius of the silver nanowire is 100 nm, the calculated index shows typical improvements; the average percentage error for the real part of the effective refractive index is reduced to only 5% for the 0th order mode (11.9% in previous results) and 1.5% for the 1st order mode (24.8% in previous results) in the 400-800 nm wavelength range. This equivalent model approach is expected to provide further insight into understanding the important behavior of nanowire waveguides.

In realizing integrated nanophotonic circuits, a promising key is the use of surface plasmons, collective electron oscillations that allow the localization, confinement, and transmission of electromagnetic energy [1, 4]. Various geometries for plasmonic waveguides and integrated components have been suggested; these include grooves and slots in metal films [2-5], metal strips [6-8], dielectric strips deposited on a metal film [9], metal caps on a silicon-on-insulator rib waveguide [10-12], and others [13-15].

An alternative approach to achieve integrated nanophotonic circuits involves utilizing the nanowire (NW)-based plasmonic waveguides, which are typical one-dimensional waveguide structures with relatively low losses in visible and near-infrared spectral ranges [16-20]. To understand the properties of NW-based waveguides, it is essential to investigate their modal dispersion behavior. Schmidt and Russell established a connection between the dispersion of propagating modes on NW geometry and the dispersion of those on planar metal-insulator geometry with a single interface [17]. For an NW radius less than 100 nm, however, there is wide discrepancy owing to interaction with the electromagnetic field.

In this study, we propose a simple model to elucidate the dispersion behavior of spiraling modes on silver nanowire by building a relationship with the planar insulator-metal- insulator geometry. This approximated analysis is compared with a more exact solution obtained by solving Maxwell’s equation in cylindrical coordinates. Schmidt and Russel previously established a connection between the dispersion of propagating modes on an NW geometry and those on a planar metal-insulator geometry when the radius of the NW is much larger than the skin depth [17]. For a Ag NW with a radius of 100 nm, the average percentage error for the fundamental mode of the real component of the effective refractive index was reduced from 11.9% (previous result [17]) to 5% in the 400-800 nm wavelength range. The average percentage error for the 1st order mode was reduced from 24.8% (previous result [17]) to 1.5% in the 400-800 nm wavelength range. This approach provides important insights into the behavior of NW waveguides. Further, it has much broader applicability than previous methods and it can be extended to provide insights into more complicated NW-based waveguides.

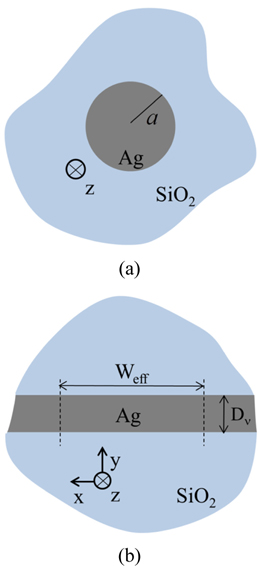

An infinitely long and straight Ag NW (with radius

where ,

where

for the fundamental mode. Here,

where

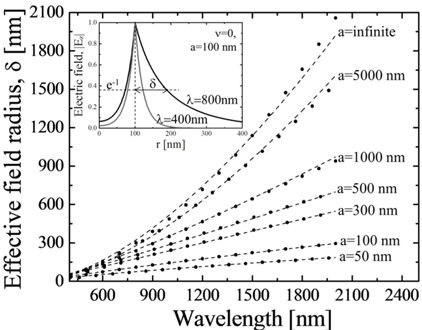

To obtain the effective field radius δ , we used a direct a direct solution of the dispersion relation of the Ag NW obtained by solving Maxwell’s equation in cylindrical coordinates, as follows [23]:

where

The propagation constant

where

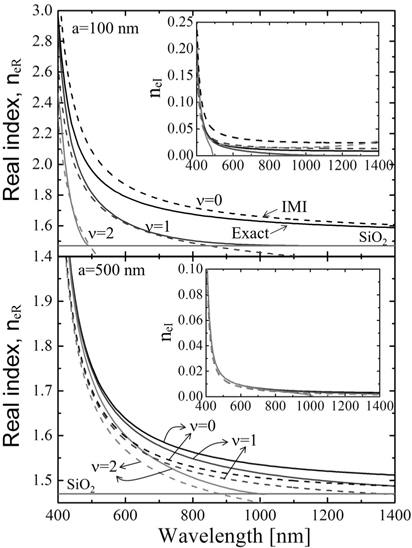

The complex values of the effective refractive index

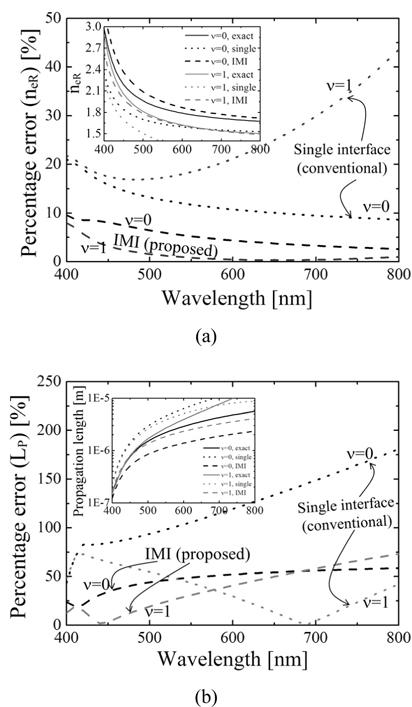

We now examine in detail the percentage error of the real part of the effective refractive index and the propagation length in the 400-800 nm wavelength range as shown in Fig. 4. For the real part of the effective refractive index, the percentage error (

Figure 4(b) shows the percentage error (LP) of the propagation length. The propagation length is given by

In summary, we proposed a simple model to elucidate the dispersion behavior of spiraling modes on Ag NW by building a relationship with the planar IMI geometry. The previous model with planar metal-insulator geometry has large discrepancies compared with the exact solution when the radius of NW is compatible with the skin depth, due to interactions with the electric field around the NW. Our equivalent model solved this problem by introducing plasmon modes that exist on thin metal films sandwiched between two regions of identical dielectrics, and the percentage error was remarkably reduced. This approach provides important insights into the behavior of NW wave-guides. In addition, it has much broader applicability than the previous model and it can be extended to provide insights into more complicated NW-based waveguides.