Multilayered silicates have been used as nano-sized fillers in polymer nanocomposites, and the most well known are montmorillonite, saponite, hectorite, talc, and mica [1-3]. Generally, they are naturally synthesized in bulk shape, and are pulverized into fine particles of μm size. Therefore, to synthesize polymer nanocomposites, the multilayered μm particle should be separated into sheet-like monolayers in the polymer matrix, whose dimension are (20~1,000)×(20~1,000)×1 nm3. The driving force to separate them from each other is provided by polymer penetration through the interlayers of the silicate monolayers. The polymer chains are in the form of coil-like conformation in the interlayers, and this result leads to the intercalated or exfoliated nonocomposites [1,2]. However, it is very difficult for the polymer chains to penetrate into the hydrophilic interlayers. Therefore, it should render the interlayers organophilic, by means of cation exchange with alkyl ammonium ions [2-5].

Epoxy resins are well-known materials in the field of insulative systems for heavy electric equipment, because they have good mechanical and thermal properties, as well as excellent electrical properties [6-8]. When a multilayered silicate particle was mixed with an epoxy resin, the epoxy resins and curing agents penetrated into the interlayers of the multilayered silicate, and separated the sheet-like monolayers from each other in the epoxy matrix, forming an intercalated or exfoliated state.

To study the insulative performance of the epoxy/layered silicate nanocomposites, many works have been done by studying the electrical treeing phenomena, in order to estimate the insulative characteristics of neat epoxies or their nanocomposites, because the treeing phenomena has often been referred to as the most important mechanism for the deterioration of polymeric insulators (e.g. high voltage polymeric cables) [9-12]. The treeing growth mechanism was divided into three processes: (1) incubation process, (2) initiation process, and (3) propagation process. If an electrical treeing was initiated, it would propagate rapidly and the breakdown would finally occur. Hence, the initiation time should be delayed, and the propagation rate be retarded, in order to get excellent insulative polymeric materials.

In this study, an epoxy/layered silicate nanocomposite with two reactive diluents for the insulation of heavy electric equipment was prepared by our electric field method, and the effects of electric field frequency on the electrical treeing phenomena were studied, in needle-plate electrodes.

A commercial DGEBA (diglycidyl ether of bisphenol A) type epoxy resin, YD 128 (Kukdo Chem. Co.) was used. The equivalent weight was 184~190, and the viscosity was 11,500~13,500 cps at 25℃. The curing agent was Me-THPA (3- or 4-methyl- 1,2,3,6-tetrahydrophthalic anhydride), whose grade name was HN-2200 (Hitachi Chem. Co.). It is widely used in the field of electric insulation. An accelerator was BDMA (benzyl-dimethyl amine, Kukdo Chem. Co.). A reactive diluent employed as a flexibilizer was a polyglycol (PG), under the trade name of DY-040 (Ciba-Geigy Co.). Its molecular weight was about 7,000~10,000, and its viscosity was 60~90 cps at 25℃. Another reactive diluent as an aliphatic epoxy resin was purchased from Kukdo Chem. Co., under the trade name of BDGE. Its equivalent weight was 120~140, and its viscosity was 15~30 cps at 25℃. Its chlorine content was 25,000 ppm (max). Cloisite® 10A (Southern Clay Products, Inc., USA) was used as a multilayered silicate, which was a natural montmorillonite, organically modified with 2MBHT (dimethyl-benzyl-hydrogenated tallow quaternary ammonium), as a sort of quaternary ammonium salt. It was also dried at 110℃ for 24 h in vacuum oven, and stored in desiccator, before use. A needle-type steel electrode was purchased from Ogura Jewelry Co., Japan. Its diameter and length were 1 mm and 60 mm, respectively, with a tip angle of 30°, and a curvature radius of 5 μm.

2.2 Specimen preparation for AC treeing test

To prepare epoxy/reactive diluent/layered silicate nanocomposite, DGEBA (100 g), reactive diluent (10 g) and Cloisite 10 A (2.74 g) were mixed with ultrasonic homogenizer (20 kHz) for 30 min, and then put into an AC electric field apparatus developed by us [13]. The AC electric field was generated by a high voltage (HV) generator, in the following conditions: (1) inter-electrode distance: 50 mm, (2) application voltage: 11 kV, (3) frequency: 1 kHz, and (4) application time: 60 min. During the AC application time, epoxy resin penetrated into the interlayer, making the layered silicate swoll. Then, the mixture was mixed with THPA (80 g) and BDMA (0.9 g). The weight percent of nano-silicate in the epoxy nanocomposite was 1.5 wt%. The mixture was poured into a mould, having a cavity of 15×15 mm2 with 30 mm height, in which a needle electrode was arranged beforehand, to make the distance of needle-plate electrodes be 4.2 mm. Then, it was cured at 120℃ for 2 hr, and post-cured at 150℃ for 2 hr, and it was then cooled slowly, at a rate of -0.5℃/min until room temperature, to avoid internal stress. Finally, the opposite side of the needle electrode in the epoxy specimen was coated with the conductive silver paste.

To measure the treeing initiation and propagation rate, constant alternating current (AC) of 10 kV with three different electric field frequencies (60, 500 and 1,000 Hz) was applied to the specimen, in needle-plate electrode arrangement, in insulating oil bath of 30℃. Then, the specimen was inserted into the insulating oil, and maintained sufficiently for 2 hr, until the temperature of the needle tip area reached the testing temperature. Then, high voltage (HV) was applied by AC Endurance Voltage Tester (Haefely, Germany), at a rising speed of 1 kV/s until 10 kV, and the test voltage was kept, until electrical breakdown took place. The treeing morphology was monitored by a video microscope system (ICS-305B, SOMETECH Inc.), with the treeing images being collected every 1 min.

It was well known that the epoxy/reactive diluent/layered silicate was in the exfoliated state, which was confirmed and observed by using WAXD (wide-angle X-ray diffraction) analysis and TEM (transmission electron microscopy), as was explained in our previous work [13]. The exfoliated monolayers were sheetlike dimensions of (20~1,000)×(20~1,000)×1 nm3. If a monolayer was located perpendicularly to the treeing growth direction, electrical treeing was blocked, so that the treeing should develop a new root, through the interface between the epoxy matrix and the monolayer. It was a time-consuming process. Therefore, the well-dispersed monolayers would act as barriers to treeing propagation. This meant that the peeled monolayers were well dispersed in the epoxy matrix, and would act as barriers to treeing propagation.

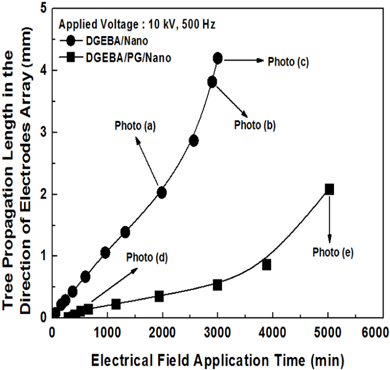

In order to confirm the barrier effect of the monolayers on the treeing phenomena, treeing growth rate curves for the epoxy/ PG system and epoxy/PG/nanosilicate (1.5 wt%) system were obtained from the AC treeing test at 10 kV, with electric field frequency of 500 Hz, and they are displayed in Fig. 1. Electrical treeing of the epoxy/PG system was propagated at the speed of 1.40×10-3 mm/min, and that of the epoxy/PG/nanosilicate system was 0.41×10-3 mm/min, which was 3.4 times slower. The propagation speed until 3,000 min was 0.19×10-3 mm/min. It was rapidly increased after 4,000 min at the speed of 1.12×10-3 mm/min, which was 5.9 times faster than that in the initial state. This was because as the treeing length increased with increasing time, the distance between needle-plate electrodes decreased. If the distance between needle-plate electrodes became shorter, the electrical field value at a newly generated carbonized conductive tree tip increased. This was explained by Masons formula [14], Etip = 2V/(r·ln(1+4x/r)), where Etip was the applied electrical field at the needle tip, V was the applied voltage, r was the needle tip radius, and x was the distance between the needle-plate electrodes. When high voltage was applied to a needle tip, the electrical field value at the needle tip was far higher than the applied voltage. In this study, the values r=5 μm, V=10 kV and x=4,200 μm were introduced into Masons formula, the electrical field value at the needle tip, Etip was to be 492.6 kV/mm, and the electrical field value at a newly generated carbonized conductive tree tip was much higher. Therefore, the tree length grew rapidly, as the distance between the conductive treeing tip and plate electrode.

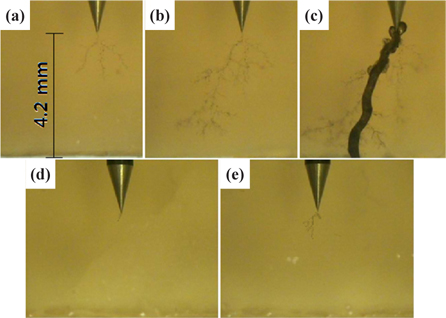

In order to confirm the barrier effect of the silicate monomers, the treeing morphology for the epoxy/PG system and the epoxy/PG/nanosilicate (1.5 wt%) system was observed, and the electrical treeing morphologies corresponding to photos (a)~(e) from Figure 1 were collected, after 10 kV (500 Hz) was applied for (a) 1,982 min, (b) 2,899 min, and (c) 2,998 min in the epoxy/ PG system, and (d) 652 min, and (e) 5,030 min in the epoxy/PG/ nanosilicate (1.5 wt%) system. The treeing morphology photos are displayed in Fig. 2. In the DGEBA/PG system, typical branch type electrical treeing was obtained from the morphology observation. That is to say, electrons that were injected and extracted at the needle tip initiated electrical treeing from the needle tip, as shown in Fig. 2(a); and then electrons were injected and extracted at the newly generated conductive treeing tip, which had been carbonized, so that several branches were newly appeared (Fig. 2(b)). Then, final breakdown occurred. However, in the DGEBA/PG/nanosilicate system, very small treeing was initiated at 652 min (Fig. 2(d)) and it grew very slowly, with few branches (Fig. 2(e)). These results meant that treeing growth was disturbed by the dispersed silicate monolayers.

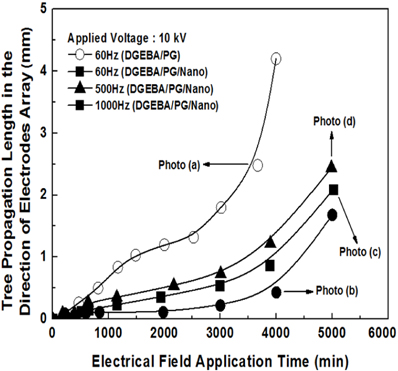

In order to study the effect of electric field frequency on the AC treeing growth in the epoxy/PG/nanosilicate (1.5 wt%) system, treeing growth curves at three different electric field frequencies were shown in Figure 3. The treeing growth curve for the DGEA/ PG system without nanosilicate is also displayed as a reference in Fig. 3. As the electric field frequency increased, the treeing propagation rate increased. At 60 Hz, the treeing propagation rate of DGEBA/PG/nanosilicate system was 0.33×10-3 mm/min, which was 3.2 times slower than that of the DGEBA/PG system. This was also because of the barrier effect of the nanosilicate layers. At 1,000 Hz, the value of the DGEBA/PG/nanosilicate system was 0.49×10-3 mm/min, which was 1.5 times faster than that at 60 Hz. This was due to the collision frequency of electrons at the needle tip, or the newly generated treeing tip.

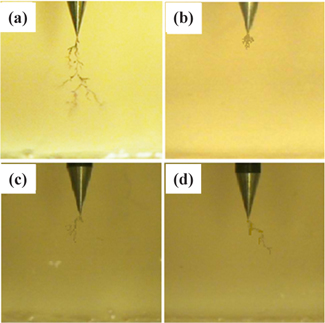

As was expected, the barrier effect of the silicate monolayers was also confirmed by observation of the treeing morphology, as shown in Fig. 4. At 60 Hz in the DGEBA/PG/nanosilicate system, bush type treeing was generated in the initial state, and the treeing density became dense, and their thickness became fat and dark (Fig. 4(b)). It was very different from the branch type treeing in the DGEBA/PG system without nanosilicate (Fig. 4(a)). The bush type tree might be because the momentum power of the injected electrons couldn’t pass through the silicate monolayers, so they should develop a new root, to avoid the silicate monolayers. It was a time-consuming process. Therefore, it was found that well-dispersed silicate monolayers acted as good barriers to the treeing propagation. However, as the frequency increased, the bush type was changed to the branch type, having few branches, with very slow propagation rate.

The effects of electric field frequency on the AC electrical treeing phenomena in an epoxy/PG/nanosilicate (1.5 wt%) system were carried out, in needle-plate electrode geometry. At 500 Hz, the treeing propagation rate of the epoxy/PG/nanosilicate system was 0.41×10-3 mm/min, while that of the epoxy/PG system was 1.40×10-3 mm/min, which was 3.4 times faster than that of the system with nanosilicate. As the electric field frequency increased, the treeing propagation rate increased. At 1,000 Hz, the value of the DGEBA/PG/nanosilicate system was 0.49×10-3 mm/ min, which was 1.5 times faster than that at 60 Hz. The electrical treeing morphology was dense bush type at 60 Hz; however, as the frequency increased, the bush type was changed to the branch type, having few branches, with very slow propagation rate. These results were due to the collision frequency of electrons at the needle tip, or the newly generated treeing tip. It was also found that well-dispersed silicate monolayers acted as good barriers to the treeing propagation.