Ferroelectric materials and their composite thin films have attracted enormous interest due to their vital roles in the electronics industry, supporting a wide variety of applications such as ferroelectric memory devices for very low voltage operations [1,2]. Some smart materials from different ferroelectric families have been studied and are being used in a variety of ways [3]. These ferroelectric materials have been used in single crystal form, pallet form and thin film form. Usually, some ferroelectric materials have very high coercive fields (in the order of kV/cm), and they need to be fabricated in the thin films form to switch the domains from one orientation to another at a low operating voltage [4-6]. Recently, thin films of many ferroelectric materials have been fabricated by various methods such as r.f. magnetron sputtering, pulse laser deposition (PLD), pulse laser ablation (PLA), metal organic chemical vapor deposition (MOCVD), chemical solution deposition (CSD) and sol-gel [7,8].

1.1 Materials and its properties

Potassium nitrate (KNO3) is a well known ferroelectric material which was discovered in 1958 by Sawada et. al. [9].Since then, its ferroelectric [10], dielectric [11] and structural [12] properties have been investigated. In a recent theoretical study, KNO3 has been found to exist in a variety of phases [13-15]. Upon heating, its crystal structure changes from orthorhombic (phase II) to rhombohedral (phase I) and upon cooling, its phase I changes first to phase III at about 124℃ and then to phase II at about 110℃ [1]. Phase III always reverted back to phase II, but the rate at which this process occurred was strongly affected by the temperature of the specimen [16-18]. Phase III structure, which is ferroelectric, can be applied ferroelectric memory devices [19-22]. Ferroelectric phase III of KNO3 arises from a small shift of 0.55 Å of the nitrate groups along the c-axis from the centre of the unit cell, which creates a dipole moment.

Potassium nitrate has great fundamental value because it is a ferroelectric material which can be easily fabricated into thin film form for low voltage operations.

The scientific interest in potassium nitrate as a ferroelectric material is due to the attractive large signals that indicate the switching properties of its thin films form [19-22]. The square hysteresis loop, low switching potential (≤5 V), and fast switching times (≥20 ns) of KNO3 thin films make them promising as a permanent storage medium in large scale integrated ferroelectric random access memories (Fe-RAMs)[6].

Polyvinylidene fluoride (PVDF) is prominent semi crystalline ferroelectric polymer having an amorphous phase that occupies about 50% of the polymer volume. The amorphous part itself does not contribute to the residual polarization; nevertheless, it plays an important role in the ferroelectric polarization buildup in the ferroelectric crystallites [2]. Poly(vinylidene fluoride) (PVDF) has been extensively investigated because of its interesting ferroelectric properties and technological applications. PVDF can exist in several crystalline phases. There are two main phases namely; α- and β. The α- phase, which is the more common and stable one, arises usually from the melt when PVDF crystallizes under quiescent conditions. The β-phase offers the offers the highest values of piezo-pyro and ferroelectric properties

Recently the crystallization of PVDF at different cooling rates has been investigated [23,24].

Polyvinyl fluoride (PVF) polymer crystallizes much like polyethylene because the fluorine similar in size to hydrogen, not interfering with regular packing. PVF has head-head and tail-tail defects, where the successive repeat units are backwards. These defects comprise 5% of the volume of PVDF and 25-32% of the volume of PVF. The dipole moment of PVF can be large in the transplanar conformation if all the fluorines were on the same side on the carbon-carbon (C-C) plane (isotactic) [2,25,26].

1.2 Composite materials and its applications

Advanced work on ferroelectric composite materials has been carried out [26-35]. A ferroelectric composite is usually comprised of a ferroelectric material embedded in a polymer matrix [30-34]. These materials exhibit and retain ferroelectric, pyroelectric and piezoelectric properties. Ferroelectric composites of ceramic and polymers have received considerable attention due to their superior piezoelectric properties for transducer applications. These composites thus constitute a new structure, which combines the high ferroelectric activity of ceramics with the high mechanical strength of polymers. Therefore, composites with optimum properties become difficult to develop because their electro-active properties depend not only on not only the materials and their compositions but also on their interaction of dipoles [28-36]. Composites made of electroactive ceramics and ferroelectric polymer are attractive for the latest applications because they can be easily prepared in a variety of shapes, they exhibit piezoelectric and piezoelectric response as well as ferroelectric properties, and their properties can be tailored to various requirements [36-41]. Polymer-ceramic composites can combine the advantageous properties of both the polymer (such as flexibility, easy processing) and the ceramic (high dielectric permittivity, high piezo and pyroelectric activity). They are under extensive study as a technologically promising, integrated ferroelectric capacitor.

The present study investigates the polarization switching properties of potassium nitrate with PVDF and PVF in the form of composite films, which retain the ferroelectric phase III of potassium nitrate at room temperature at low voltage operation. To reduce the brittleness of and remove the excessive moisture in KNO3, this material is fabricated as a composite film under suitable experimental conditions.

2.1 Ferroelectric composite films by using melt press machine

In this study, we prepared the ferroelectric composite films of 50wt.% KNO3 in PVDF with the melt press (hot-press) machine as follows. Purified and vacuum dried potassium nitrate crystalline powder filtered through standard brass sieves, mesh no. 240 (particle size ~ 60 μm), was added to 50 wt.% of PVF2 powder (supplied by Aldrich USA) and thoroughly mixed. The mixture of both materials was spread on a thin aluminum foil and then kept in a fine stainless-steel die in the melt press machine. The mixture was heated up to a temperature of 218℃ ±2℃ and then applied with a stress of 250 Kg/cm2. After the procedure, the temperature of stainless steel die was brought down to room temperature slowly at 30℃/hr and then the pressure was released. Composite films of 30-40 μm thickness were obtained. Circular indium electrodes [22,42,43] having areas of 0.785×10-2 cm2 were vacuum deposited on both surfaces of the sample. The same method was employed to fabricate composite films of 50wt.% KNO3 in PVF.

Polarization switching, or the polarization -reversal effect, is the change in the direction of spontaneous polarization by an applied electric field, which is the most important property of a ferroelectric material. This switching effect in ferroelectric materials have been studied extensively. Switching time ts, is defined as the time from the onset of the pulse to the point of 90% decrease from the maximum value of the polarized switching pulse curve. In fact, switching in ferroelectric materials or in ferroelectric composite thin films is difficult because the coercive field Ec is not constant during the switching process but varies with the material or film thickness.

It is important to study polarization switching in a ferroelectric material from an application and academic point of view. Switching can be exploited in the fabrication of memory cells and / or memory devices. Potassium nitrate has been known to be a fast switching ferroelectric [5,6,19-21,41-46]. The study of switching transients in the composite ferroelectric films can be helpful in understanding the underlying mechanism of switching as well as in finding their potential use in memory devices. In view of this, the present study is devoted to the studies on the switching current transient characteristics in composite films. The switching current response after the application of the square wave signal has been analyzed using the Ishibashi and Takagi theory [47]. The effect of applied voltage on KNO3 for switching transients characteristics have also been investigated [41-46]. A switching current peak can also ferroelectric polarization, which would imply the existence of phase-III in a composite film.

>

Ferroelectric switching transient measurements

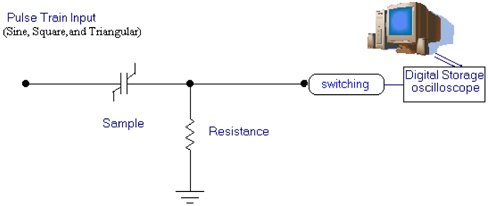

The polarization switching characteristics obtained from the sinusoidal, triangular and square wave signals and the output current was observed across a resistance in series with the sample through the storage oscilloscope in the X-t mode. The storage oscilloscope was also connected to the computer with standard software (SP107e Germany). The schematic circuit diagram and set up for measuring the switching characteristics are shown in Fig. 1. The typical output of switching current pulses was obtained from a composite film after the application of a bipolar square wave signal.

The time dependence of the ratio Vs(t) of the switched volume to the total volume is given by the Ishibashi and Takagi theory based on the Avrami model [47],

where t is the time, t0 is the characteristic time and n is the effective dimensionality of the domain growth. If P is the polarization associated with Vs, then the expression for the displacement current density can be written as [47],

Combining equations 1 and 2 , we obtain,

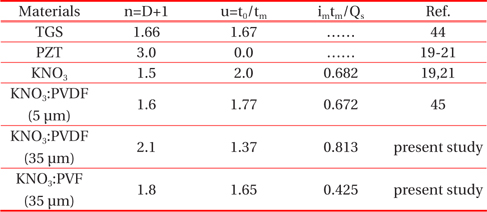

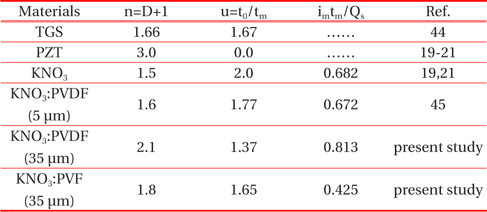

With the value of the reduced characteristic time u=t0/tmax [tmax is the time at which the current density j(t) is maximum] and the effective dimensionality n, we can examine Ishibashi's prediction and ascertain information about the switching mechanism. This model has been successfully applied to various ferroelectric thin films such as TGS [44], PZT [19-21], and KNO3 films[19-21]. This model has been applied to analyze the switching transients in composite films.

>

Switching in KNO3 :PVF composite films

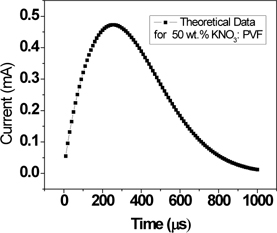

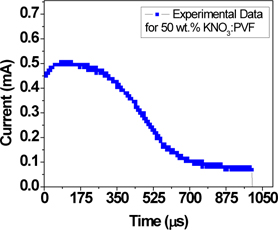

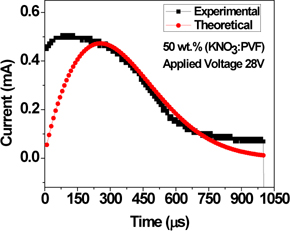

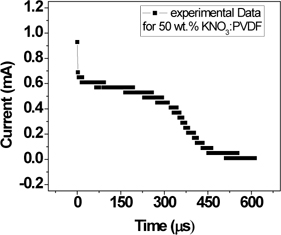

The polarization switching in a 35- μm thick 50 wt.% KNO3 : PVF composite film was studied using a square wave bipolar signal, as shown in Figs. 2,3 and 4. The output current was observed across a 0.1kΩ resistance in series with the sample. Switching current transients have been analyzed in a single crystal [44] and in composite films [19-21,44,45] based on the Avrami model [47]. The following equation for switching current transient gives the current variation with time as

where Ps is the spontaneous polarization, n is the dimensionality of the domain growth. A is the area of the sample electrodes and t0 is the characteristic switching time.

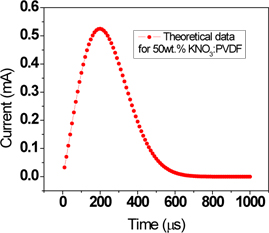

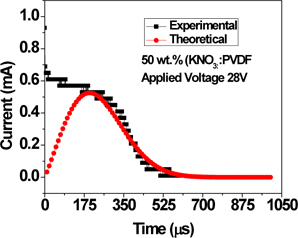

The theoretical data generated by equation 4 for the calculation of various parameters and compared to the experimental results observed for the 28 V output switching transient pulse are shown in Fig. 2. The fitting parameters are n=1.8 and t0=400 μs. The effective dimensionality of domain growth n= 1.8 and the ratio u=t0/tm=1.65 are obtained for the 35 μm (50% PVF: KNO3) composite films at room temperature.

>

Switching response in KNO3 :PVDF composite films

The polarization switching in a 35- μm thick 50 wt.% KNO3 : PVDF composite film was studied using a square wave bipolar signal, as shown in Figs. 5,6 and 7. The theoretical fit to the 28 V output switching transient pulse is shown in Fig. 7. The fitting parameters are n=2.1, and t0=270 μs.

The high value of 'n' indicates nonhomogeneous nucleation in these films, so category II may be operative with no new nucleation [47]. The effective dimensionality n= 2.1 and the ratio u=t0/tm=1.37 are obtained here. We find imtm/Qs=0.813, which is in reasonable agreement with that of the continuous nucleation model [47]. Based on this model, D=n-1, which gives D=1.1, for the PVDF: KNO3 composite films.

Both composite films show some asymmetry due to the space - charge accumulation at the electrode / ferroelectric interface. In the Ishibashi and Takagi [47] model, an infinite crystal was considered, in which ferroelectric switching occurs by motion of the domain walls after nucleation. Here, the two-dimensional case may be depicted, because the dimensionality of domain growth D is > 1, where the boundary moves two dimensionally after the formation of cylindrical nuclei. Hence, the dimensionality of domain growth implies an indication towards pancake -like domains [19-21,44,45,47].

In PZT, the dimensionality of domain growth, n, is found to be 3.0. This result is compatible with continuous nucleation at a constant rate with true dimension D=n-1=2.0 (two-dimensional domain growth perpendicular to the applied field [47]. We can use the values of the effective dimensionality n, reduced characteristic time u=t0/tmax as well the dimensionless ratio imax/tmax/ P to examine Ishibashi's prediction for the constant nucleation rate and one step nucleation rate. The values of n and u have been found to be 1.66 and 1.67 for the TGS crystals for a spatial uniform distribution of domain nuclei and to be 1.79 and 1.31 for a nonuniform distribution of domain nuclei, respectively. The agreement implies d=n-1≈1 and hence, one - dimensional growth of the domains. One-dimensional growth of the domains (needle -like shape) is likely [44].

The fit for the 28 V transient in Fig. 7 was obtained with fitted parameters at n=2.1, and t0=270 μs. The effective dimensionality n=2.1 and the ratio u=t0/tm=1.37 were obtained for the 35 μm (50% PVDF: KNO3) composite films at room temperature. However, for the 50% PVF: KNO3 composite films, the effective dimensionality n=1.8 and the ratio u=t0/tm=1.65 were obtained as shown in Fig. 4. The Ishibashi and Takagi [47] theory for continuous nucleation predicted that for u=2 and n=1.5, the value of imtm/Qs should be 0.682. From Table 1, we find imtm/Qs=0.672±0.13, which is in reasonable agreement with that of the continuous nucleation model [47]. On the basis of this model, D=n-1, which gives D=1.1, for PVDF: KNO3 composite films and D=0.8 for PVF: KNO3 composite films implies needle - like domain growth in the composite films. In potassium nitrate, the shape of displacement current transients depends strongly on the film thickness. We assume that this arises from the different contributions of surface and bulk nucleation mechanisms in films of different thicknesses [19-21]

We find imtm/Qs=0.425 for KNO3 : PVF films, which is a small value that may be due to the difficulty arising out of polarization reversals. This order of value has been obtained in NaNO2 by other investigators [47].

In Table 1, various switching parameters obtained from the present study and from the literature are summarized [47].

Various switching parameters obtained from the present study and from the literature are summarized

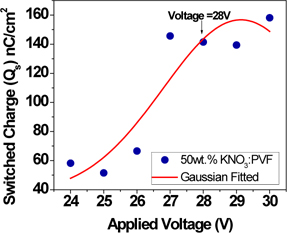

Figure 8 shows the variation of the switched charge with applied voltage. The switched charge is saturated at the applied voltage of almost 28 V. This saturation behavior has been reported for many ferroelectric materials [19-21,44,45,47].

In potassium nitrate, the shape of the displacement current transients depends strongly on the film thickness. This may be due to the different contributions of the surface and the bulk nucleation mechanisms in films of different thicknesses [11]. In our earlier investigations [34,35] on KNO3.The 50 wt.% KNO3 composite films showed the largest value of remnant polarization (Pr), but > 50 wt.% KNO3 the remnant polarization (Pr) showed a decreasing trend. The composite films with more than 50 wt.% KNO3 doping were found to be more fragile. Therefore, 50 wt.% KNO3 composite films showed better ferroelectric properties [35]. The dimensionality of domain growth n seems to be decrease with increasing percentage of KNO3. This may be due to the even distribution of the ferroelectric particles of KNO3 with enhanced doping [34]. An analysis from recent research on KNO3 composites indicates a need for further studies to fabricate composite films from these materials by various techniques for nano scale characterization of memory / storage devices, especially 120 nm FRAMs and even thinner DRAMs.

The total charge (Q) switched during reversal of polarization was obtained from the areas under the switching current curves as Q=2PsA, where A is the electrode area.

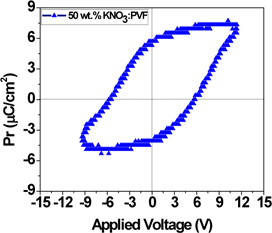

From the P-E characteristics, the values of Ps for the 50 wt.% KNO3 composite films (as shown in Fig. 9) are slightly higher for the switched charge, which may due to the contribution of the space charge.The conduction effects are comparable with the switched charge measurements for the composite films.

Ferroelectric polarization switching characteristics were observed in composite films. The theoretical fit to the switching transient pulse was measured in 35-μm 50 wt.% KNO3 :PVF and 50 wt.% KNO3 :PVDF thick composite films. The values of imtm/Qs are comparable with the values of pure NaNO2 [47]. Therefore, in the KNO3: PVF composite films, most probably continuous nucleation may be applied. The experimental switching responses of potassium nitrate based composite films were characterized, and they fitted well to results of the Ishibashi and Takagi theoretical model based on the Avrami model. The resultant fitting parameters suggested one dimensional growth and implied needle-like domains with walls in one direction perpendicular to the ferroelectric axis. The fitting parameters were also compared with those of other materials. Ferroelectric polarization hysteresis (P-E) characteristics supported the prominent features of ferroelectric polarization switching in the composite films at room temperature.