Well-crystallized BaSi2O5:Eu2+ phosphor films were synthesized by heat treatment of spin-coated BaO:Eu on SiO2 glass. We investigated luminescence-structure properties of these phosphor films as a function of heat-treatment temperature. From x-ray diffraction patterns, our BaSi2O5:Eu2+ phosphor films revealed that (111)- and (204)-crystal planes of BaSi2O5 crystal were dominantly increased with an increase of heat-treatment temperature. Photoluminescence intensities of BaSi2O5:Eu2+ phosphor films were increased with amount of these crystal planes. It can be explained that Eu2+ ions were stably occupied at specific crystal orientation of BaSi2O5 crystal, enhancing the luminescent intensities of BaSi2O5:Eu2+ phosphor films. In addition, our BaSi2O5:Eu2+ phosphor films had transmittance of 70% at 510 nm,.due to the dense morphology and specific crystallinity of BaSi2O5:Eu2+ phosphor films.

silicate system is useful luminescent host, the luminescence process of Eu2+ ions activated in the silicate system is generated by the 4f65d-4f7 transition of Eu2+ ions acting as a color center. Blasse et al. have systemically reported the luminescent properties of Eu2+ ions activated in binary and ternary silicates [1]. Tanabe et al. reported the preparation of Eu-doped BaSi2O5 glass ceramic phosphors and investigated the luminescent properties with various heat-treatment temperatures [2]. However, the optical and luminescent properties related to crystal properties of Eu-doped silicate phosphors have not been reported in film-type phosphors.

Film-type phosphors offer noteworthy advantages over conventional powder-type phosphors for LED [3] and display applications, such as dense uniformity, long-term stability, thermal and chemical stability, and superior adhesion to the substrate [4]. Film-type phosphors can be fabricated using various techniques, including sputtering deposition [5, 6], pulsed laser deposition [7], atomic layer deposition [8] and chemical vapor deposition [9]. However, these methods are expensive and require complicated equipment for high vacuum techniques and other rigorous conditions. One of the methods for synthesizing film-type phosphors is the solution based spin-coating technique. This method is simple, inexpensive and does not need vacuum techniques as compared to other methods for synthesizing film-type phosphors. In addition, this method has the possibility of large-area coatings with high uniformity on various substrates including glass [10, 11]. The properties of the film-type phosphors are generally influenced by crystallinity and morphology of film dependent on growth condition and post-heat treatment [5, 12]. Especially, pores and grain boundaries for a polycrystalline film have a decisive effect on optical properties of the films [13].

In our experiment, we used a simple method for filmtype phosphors. We exploited the reaction at the interface between substrate material and spin-coated film material on the substrate for making film-type phosphors. In previous research, we had obtained phosphor film with high luminescence and dense morphology through this method [14, 15]. In this paper, we report luminescence-structure properties of BaSi2O5:Eu2+ phosphor films formed on SiO2 glass through heat treatment of spin-coated BaO:Eu film on SiO2 glass.

Sol solution of BaO:Eu was prepared for spin coating using the following procedure. Barium acetate [Ba(CH3 COO)2] was dissolved in 2-methoxyethanol and acetic acid solution at 60℃. The solution was stirred at 60℃ to obtain a clear and homogeneous mixture. Subsequently, europium acetate hydrate [Eu(CH3COO)H2O] was added to the solution and stirred at 60℃ for 2 hrs. Eu concentration was fixed to 11 mol% with respect to Ba. The BaO:Eu films were deposited by spin coating on 2 glass substrates (3000 rpm for 20 sec.). The films were dried at 300℃ for 10 min in air ambient to eliminate the solvent and organic residue. The same spin coating procedures were repeated 10 times. Finally, the films were heat treated at 1000, 1050, 1100, 1150℃ for 5 hrs in reduction atmosphere [H2(5%)/N2(95%)]. The obtained films were identified by X-ray diffraction (XRD) analysis using a Rigaku D/MAX 2500 with Cu Kα radiation. The cross-section images were obtained by conventional scanning electron microscopy (FESEM, JSM-6700F). The photoluminescence (PL) and photoluminescence excitation (PLE) spectra were obtained using PR-650 and Hitachi F4500 fluorescence spectrometer. Optical transmittance was measured using a UV-visible spectrometer (Hitachi U3000). The vacuum ultraviolet (VUV) photoluminescence spectrum obtained under vacuum ultraviolet (146 nm) by deuterium lamp.

Figure 1(a) shows the formation procedure of BaSi2O5:Eu2+ phosphor film and Fig. 1(b), (c) shows cross-section SEM images of spin-coated BaO:Eu film and formed BaSi2O5:Eu2+ phosphor film on SiO2 glass after heat treatment at 1100℃ for 5hrs in reduction atmosphere (5% H2 / 95% N2). Figure 1(b) reveals that spin-coated BaO:Eu film is stacked up to 300 nm with small grains from SiO2 glass. And the grains are agglomerated because of the dry process for elimination of residual organic material during the spin-coating process. After heat treatment, BaSi2O5:Eu2+ phosphor film formed on SiO2 glass with thickness is about 800 nm as seen in Fig. 1(c). It can be explain that thermal diffusion and reaction is generated at the interface of BaO:Eu film and SiO2 glass during heat treatment. Consequently dense BaSi2O5:Eu2+ phosphor film is formed on SiO2 glass. Figure 1(c) shows that the interface of formed BaSi2O5:Eu2+ phosphor film and SiO2 glass is not clear and it shows a corrugated shape. This means that the diffusion rate is not uniform at all points of the interface, therefore, it naturally induces a corrugated interface.

Figure 2 shows XRD patterns of BaSi2O5:Eu2+ phosphor films with increasing heat-treatment temperature. Broad signals appear at around 2θ = 21° in all samples, indicating amorphous SiO2 glass. Spin-coated BaO:Eu film shows sharp signal peaking at 2θ = 40° , this signal is monoclinic Eu2O3 phase (JCPDS file 71-0589). Usually monoclinic Eu2O3 crystal is stable at high temperatures and pressure [16]. Chen et. al reported on appearance of pure monoclinic Eu2O3 formed at low temperatures and pressure in air [17]. BaO phases are not found in spin-coated BaO:Eu film. In this stage, Eu ions are not completely occupied at Ba sites and monoclinic Eu2O3 phase and amorphous BaO coexist in the form of a cluster. After heat treatment, Eu2O3 and BaO crystals are not detected in all heat treated samples as seen in Fig. 2. Heat treated samples are well matched with BaSi2O5 crystal (JCPDS file 71-1441), which means that spin-coated BaO:Eu film and SiO2 glass are completely reacted at the interface during heat treatment and Eu ions completely occupied in Ba sites due to the high temperature soaking. During the heat treatment, monoclinic Eu2O3 crystal is broken down due to the high temperature soaking, and Eu ions are migrated into Ba sites concurrent with synthesizing BaSi2O5 crystal at the interface. Consequently dense BaSi2O5:Eu2+ phosphor film formed on SiO2 glass as seen in SEM images of Fig. 1(c). And they have some preferred crystalline which is revealed (110)-, (111)-, (204)-crystal planes as seen in XRD patterns of Fig. 2. Increasing the heat-treatment temperature peak intensity of (111)-, (204)-crystal planes is drastically increased. In addition a cristobalite phase appears having (101)-crystal plane at 1150℃ heat treated sample. It is due to the transition from amorphous SiO2 glass to crystallized SiO2 with increasing heat-treatment temperature.

Figure 3(a) shows PL spectra of BaSi2O5:Eu2+ phosphor films excited by 365 nm UV-lamp as a function of heattreatment temperature. All samples show broad-green emission peaking at 510 nm which originates from the 5d-4f transition of Eu2+ ions due to the strong coupling of 5d electrons with the host lattice [1]. With increasing heat-treatment temperature, PL intensity is significantly increased and then maximized at 1100℃. From XRD patterns from Fig. 2(b), peak intensity of (111)-, (204)-crystal planes of BaSi2O5:Eu2+ phosphor films is significantly increased with increasing heat-treatment temperature. This means that PL properties of BaSi2O5:Eu2+ phosphor films are deeply related to these crystal planes. Up to 1050℃, crystallization of (111)-, (204)-crystal planes is poor and begin to drastically appear these crystal planes at 1100 and 1150℃ heat treated samples as seen in XRD patterns of Fig. 2(b). PL intensity of BaSi2O5:Eu2+ phosphor films increases with increasing the signal of these crystal planes as seen in Fig. 3(b). It can be explained that Eu2+ ions are selectively migrated into specific crystal planes and (111)-, (204)-crystal plans of BaSi2O5 crystal offer stable site for activation of Eu2+ ions. PL intensity of the sample treated at 1150℃ slightly decreased. It is due to the phase impurity (cristobalite) acting as luminescence killer. PL-excitation spectrum monitored at 510 nm of BaSi2O5:Eu2+ phosphor films shows reasonable excitation in near the UV region as seen in the inset of Fig. 3(a). Thus our phosphor films can be applied as a green phosphor of a green LED or a white LED excited by a UV chip.

Figure 4 shows vacuum ultraviolet (VUV)- PL and PLexcitation spectra of BaSi2O5:Eu2+ phosphor film heat treated at 1100℃. BaSi2O5:Eu2+ phosphor film has high excitation at 167 nm wavelength as seen in VUV-PLE of Fig. 4. Our phosphor films also can be used in the green component of plasma display panels (PDP).

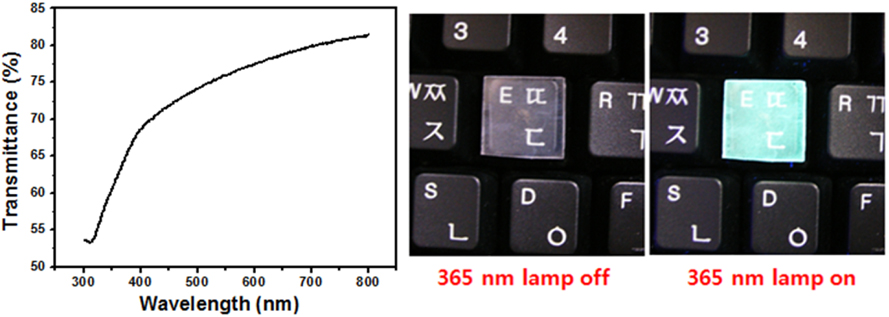

Figure 5 shows transmittance spectrum and photograph of BaSi2O5:Eu2+ phosphor films on SiO2 glass excited by 365 nm UV lamp under daylight lamp. Transmittances of our sample revealed about 70% at 510 nm wavelength range. It is due to reduction of scattering by reducing grain boundaries and pores. Generally, the transparency of a ceramic is limited by light scattering from grain boundaries or pores [13]. Our BaSi2O5:Eu2+ phosphor film shows dense morphology as seen in SEM images of Fig. 1. In addition, the phosphor film has some preferred crystal planes as seen in XRD patterns of Fig. 2, which is different from general poly-crystalline ceramic powder. These factors affect optical properties of our film. It can reduce pores and grain boundaries.

Green-emission BaSi2O5:Eu2+ phosphor films were successfully formed on SiO2 glass using a simple method through thermal-diffusion reaction at the interface between spin-coated BaO:Eu film and SiO2 glass. We investigated luminescence-structure properties of these phosphor films with increasing the heat-treatment temperatures. The BaSi2O5: Eu2+ phosphor films revealed specific crystal structure and this crystal property was profoundly linked to the luminescent property of BaSi2O5:Eu2+ phosphor films. In addition, our BaSi2O5:Eu2+ phosphor films had excellent optical transmittance; it is due to the crystallinity and dense morphology of the BaSi2O5:Eu2+ phosphor films. Our phosphors films formed through a simple synthesis method can be applied in lighting and display devices such as W-LED and PDP.