A direct-lit color-matching liquid crystal display using a lenticular lens array with grouped lens elements that image linear RGB light sources on the RGB subpixels of a color filter to enhance transmittance is designed, simulated, and fabricated. The RGB LED linear light sources were fabricated using small RGB LEDs in a linear array arrangement, and the lenticular lens array consisted of eight units of the same structure with a gap of 2.19 mm. The optical transmittance of the liquid crystal panel was improved by as much as 240% due to the color matching.

The major issues of future liquid crystal displays (LCDs) will be energy efficiency and image resolution, as LCDs become larger and consume more energy in proportion to size. The resolution issue has been already addressed very well by employing the ultra-high definition (UHD) format that has twice the pixel density of the current full high definition (FHD) format, and it seems that there remain no serious technical problems [1]. However, concerning energy efficiency there is no clear solution so far, although there have been many efforts to increase efficiency. The typical light transmittance of the LCD panel remains as low as about 5%, mainly due to absorption in the polarizer and color filter (CF) of the LCD panel. The effort to improve energy efficiency includes three approaches. The first is developing a polarized backlight that illuminates the liquid crystal panel (LCP) with polarized light, to avoid absorption by the bottom polarizer [2-4]. The second is using field sequential color (FSC), a time-domain multiplexing technology to enhance the transmittance of the LCP by removing the color filter [5]. This technology is especially attractive because it can enhance the light energy efficiency as well as the removal of subpixels of the LCP and color filter. Despite many efforts, however, it turned out that the color breakup problem is very hard to overcome, and most technologies to reduce the color breakup in FSC images have not been successful [6]. The third approach to enhance energy efficiency is using a color-matching technique that utilizes a three-color backlight to match the RGB subpixels of the color filter [7, 8]. Yamada et. al proposed a color-filterless LCD employing an edge-lit backlight that belongs to the spatial-domain multiplexing technology [9]. They utilized a blazed grating and lenticular lens array (LLA) to separate the red, green, and blue (RGB) colors from the white backlight and then focus the RGB light onto the corresponding RGB subpixels of an LCD panel from which the CF had been removed. Although they demonstrated a prototype LCD without a color filter, an increase of transmittance or light energy efficiency was not reported. It seems that the complicated optical structure comprised of the blazed grating and the lenticular lens array induces additional loss of light such as zeroth-order diffracted light, besides the complexity of the backlight system.

II. OPTICAL DESIGN, SIMULATION, AND FABRICATION

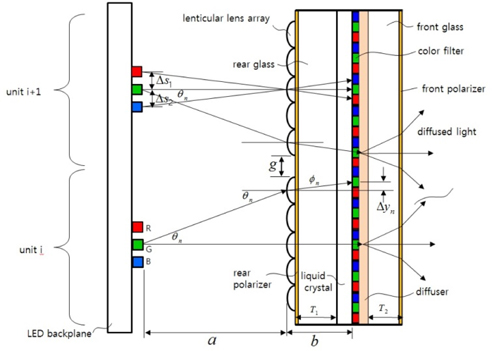

We propose a new direct-lit color-matching LCD scheme to enhance the light energy efficiency by employing a specially designed lenticular lens array and RGB linear light sources, as shown in Fig. 1. Although many current LCDs larger than 40 inches employ the edge-lit backlight system, the trend is changing back to the direct-lit backlight system because of its higher image quality and lower cost. The light sources are placed as linear arrays of RGB light-emitting diodes (LEDs) at a distance

where

The offset distance Δ

where

where Δ

We performed a Monte Carlo optical simulation to check the performance of the direct-lit color-matching LCD system. The panel size was 120×100 mm2 and the parameters were

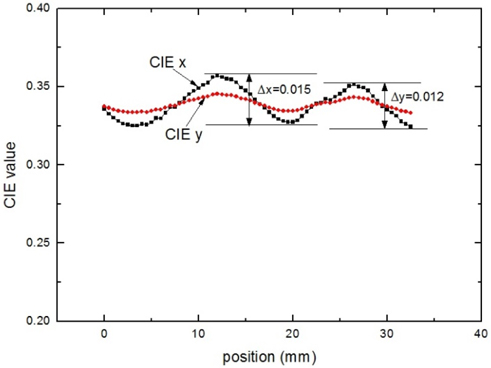

The simulated results for the enhancement factors for luminance and illuminance were 195% and 146%, respectively. The view angles were 103.5 and 76.5 degrees along the horizontal and vertical directions respectively. The color nonuniformity was CIE Δ

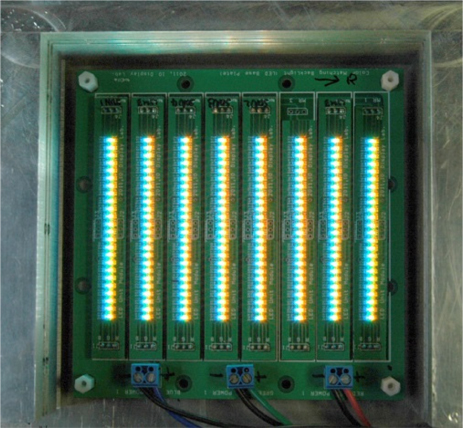

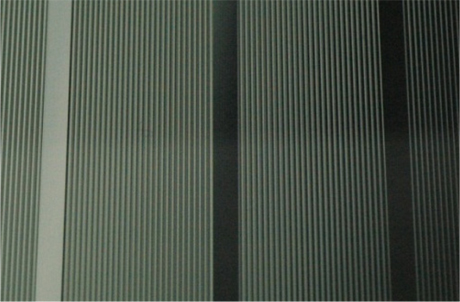

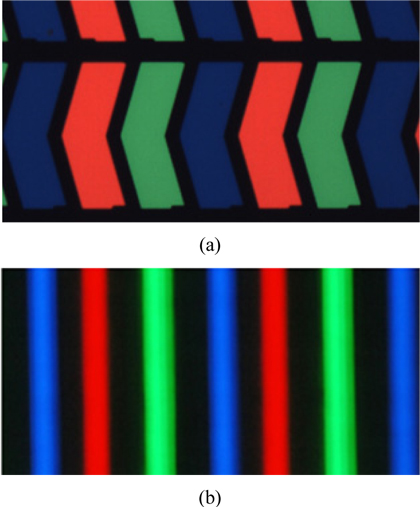

A prototype direct-lit color-matching LCD system was constructed by fabricating and assembling the RGB LED linear arrays, the LLA sheet with 8 units, and the CF according to the simulation model. Figure 2 shows the RGB LED array module with RGB light beams emitted by the RGB LEDs. The peak wavelength and power for each of the RGB LEDs were 650 nm, 520 nm, and 470 nm and 3.6 lm, 9 lm, and 1.8 lm respectively. The separations between the adjacent red, green and blue LEDs were chosen to be 1.03 mm because the width of the CF subpixels was sufficient, compared to the width of the RGB color lines formed on the CF subpixels. Figure 3 shows a magnified portion of the fabricated LLA sheet. The height, radius and width of each lenticular lens were 15.7

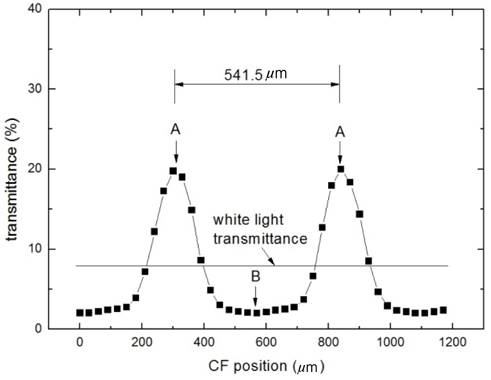

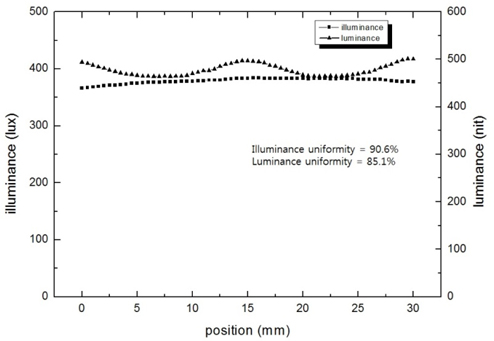

The illuminance and luminance of the assembled prototype color-matching LCD were measured using the T-1 Luxmeter and the CA-210 colorimeter (Konica Minolta). Figure 5 shows the effect of transmittance change due to the CF position shift. The highest transmittance, designated as A in Fig. 5, is obtained when the color-matching condition is satisfied, and the transmittance becomes very low when the color-matching condition is not satisfied, designated as B in Fig. 5. The difference between the highest and lowest transmittance values is about a factor of 10, and the highest transmittance is about 2.4 times the average transmittance that is similar to that of a conventional LCD with uniform white-light backlighting. The slight mismatch between the color filter and the RGB lines is due to the unequal spacings between the RGB color lines that is introduced by the dispersion of the red, green, and blue wavelengths by the lenticular lens array. This effect is described by Eq. (5). However, since the mismatch is not serious, it is not corrected in our prototype experiment.

The enhancements of luminance and illuminance were 192.5% and 139.1% compared to the non-color-matched LCD. These values are very close to the simulation results of 195% and 146% for luminance and illuminance respectively. The relatively low increase of the illuminance is due to the limited acceptance angle 2

In the prototype the RGB color sources were constructed from linear arrays of small RGB LEDs. However, a better design for the RGB color sources would be RGB linear lightguides with RGB LEDs located at their ends. Because the human eye is more like a luminance sensor, uniformity in luminance is more important than in illuminance uniformity, and so it is necessary to improve the luminance uniformity in future research. The development of light sources consisting of RGB lightguides instead of LEDs will enable much better uniformity of the luminance and color uniformity with fewer blue LEDs.

The color-matching LCD requires alignment of the RGB LED array, the LLA, and the color filter. The alignment of the RGB LED array with the LLA is less critical because any misalignment of the RGB LED array is reduced due to the demagnification effect of the LLA. However, the alignment of the LLA with the CF is important because otherwise Moire fringes and nonuniformity may occur. The alignment tolerance was not studied in this research because we focused on the feasibility of the color-matching LCD by fabricating a 4-inch sample. Alignment will become critical when the color-matching LCD is larger. A rough estimate of the alignment tolerance would be about 10

We demonstrated a prototype color-matching LCD comprised of a RGB LED array, an LLA with 8 units, and a color filter. Simulation and experimental results show that this color-matching LCD is a good candidate for an energy-saving LCD. The luminance and illuminance of the color filter were increased as much as 192.5% and 139.1% respectively compared to a non-color-matched LCD, due to the color-matching effect. The color-matching technique demonstrated in this prototype LCD will allow us to develop eco-friendly energy-saving displays in the near future.