This study examined the dye-properties of natural fabrics dyed with Coptis chinensis and Curcuma longa root fermented with fungi. The optimum culture conditions for the fermentation of microorganisms, the relationship between natural dye color and fermentation conditions were investigated. Two different medical herbs (ground to 80-100 mesh in size) were used as a natural dyeing source. Phellinus linteus (P. linteus), which can grow in different media, such as Agarmedium (only agar containing medium), maltose extract agar (MA) and potato dextrose extract agar (PDA) culture media, were isolated from the medium. P. linteus was confirmed to be the optimum microorganism for the fermentation of Coptis chinensis and Curcuma longa, and the MA medium was confirmed to be the best for culturing. When using the microorganism as the fermenting agent, 32℃ was found to be the optimum fermenting temperature for both natural colorants. Regarding the dyeing property of the fermented natural dye, silk was dyed quite darkly in an appearance by naked eye estimation and the K/S value in the color strength of silk reached a high level of 16 after the fermenting process. The washing fastness of dyed silk after treatment washing was reduced from 4 to under4 and indicates that dyed silk with fermented plant was not unsubstantial. The light fastness was 1 to 2, showing intended to maintain due to the fermentation process.

Recently, consumers have shown growing interest in pursuing the LOHAS trend for natural color and environmental reasons. On the other hand, almost plant dyes used for natural dyeing have a lower affinity to fibers and less durable after dyeing due to denature that occurs during the dyeing process. Natural dyeing enthusiasts often perform dyeing room temperature and ferment it naturally to prevent the metamorphosis of plant dyes by the surrounding conditions. Nevertheless, there has been rarely study on fermented dyes according to the fungi and culture, while in my previous paper, the dyeing properties of fabrics was examined on the coloration with fermented several plants when the formation of plant not fungi but malt (Park, 2012a). Fermentation is a process where microorganisms create alcohols, organic acids and carbon dioxide as the residual products using carbohydrate as the energy source. Reaction of microorganisms to produce a certain substrate can be considered fermentation (Yu & Beun, 2008). In the case of a product fermented from plant extracts using microorganism fermentation, a distinctive element is produced during the enzyme secretion process or an element in the raw material transforms to a new element and the hypotonicity is improved (Yu et al., 1999). Therefore, it is important to examine the fermentation characteristics of plant dyes by micro organisms and the potential use of fermented plants as dyeing materials through the color changes.

The plants used for the fermented dyeing materials in this study were

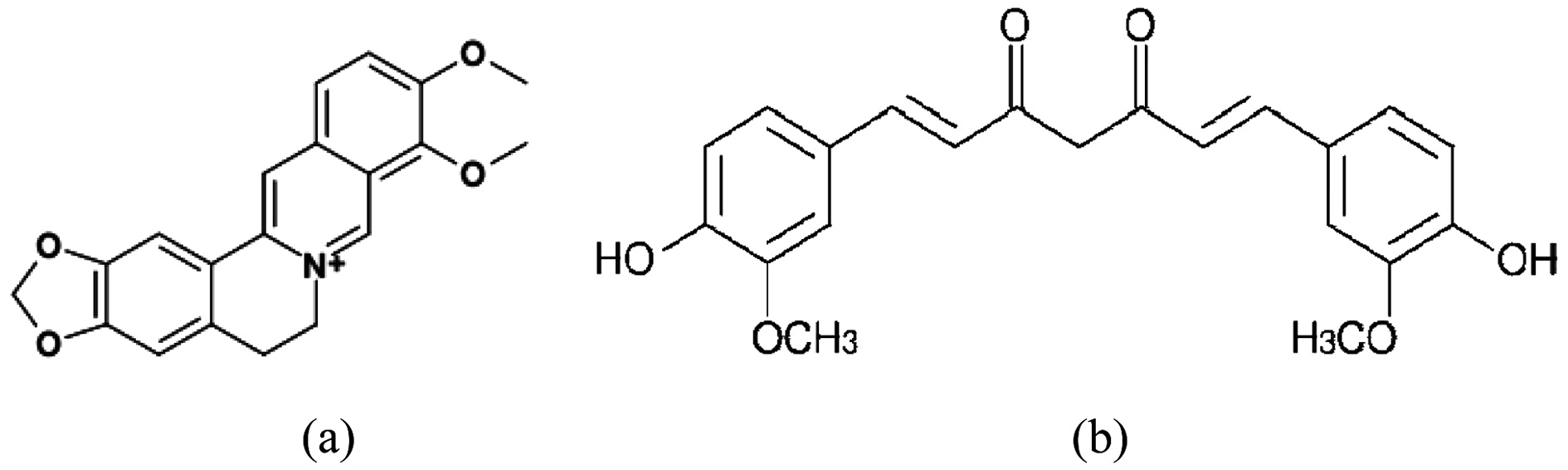

Fig. 1(a) shows the chemical structure of berberine, which is the main element in

dyeing properties and anti-microbial functions (Cho, 2009; Eum, 2012).

The main ingredients of

The roots of both

This study examined the culture conditions using the plant root and

Scoured silk (satin weave; weight 42 g·m2; density 160×98 inch2; Thickness 0.11 mm) was obtained commercially from local market in Daegu (Korea). The roots used for dyeing source were obtained from

2.2. Preparation of natural dye and nitrogen source

After sterilizing the prepared natural dye and endophytic fungi which exist in the rice bran (Hanshin Medical Co. Ltd, Gravity Type, Korea), 2 g of the natural dye and rice bran sterilized at 121℃ for 15 min and unsterilized natural dye and rice bran with distilled water, were diluted by 50%. The supernatant was obtained using a centrifuge. 5 μl of the supernatant was injected into the MA and PDA medium, cultured in an incubator at 29℃ and the clear zone (mm) was measured every 7 days to check the fungi condition of the schale.

2.3. Preparation of growth medium and selection of the culture medium by fungi culture

Solid MA and PDA medium were used as growth media. The solid medium was added to agar 1.5%, sterilized at 121℃ for 15 min, cooled it to 65℃ in a clean bench, placed in the refrigerator at 4℃ and the fungus was injected where necessary.

2.4. Optimal fermentation temperature and the content of rice bran

To determine the effect of

2.5 Fermentation and extraction of dye

The quick sterilized plant dye was cultured in a culture bath with

2.6. Dyeingwith and without the mordant

Dyeing was performed using an IR dyeing machine (KSL-24 PERFECT, Korea Science Co., Korea). Silk was dyed at a liquor ratio of 60:1 (g/ml), keeping the pH at medium state. The fabric was immersed when the temperature reached 30℃. The temperature was then increased to 60℃ and dyeing was performed at that temperature for 30 min. The dyed fabrics were then rinsed with tap water, followed by soaping with 2 g L1 of a nonionic surfactant for household use (safe, LG Ltd., Korea) at room temperature. Finally the fabrics were washed thoroughly with water and dried over a 24 hrs. The methods of dyeing with the mordant were the same as that of the pre-mordant treatment. Two different mordants, aluminum acetate and sulfate, were used at a concentration of 3% (w/w), which is equal to 0.75 g L1. In the pre-mordant treatment, the fabrics were first immersed in an aqueous solution of the mordant for 30 min at 60℃. All the mordant treated fabrics were then dyed using the above method. The fabrics were then rinsed, soaped with detergent, washed with distilled water and dried at room temperature.

2.7 Color values of the dyed fabrics

The X-Rite8200 color measurement system (X-Rite Co., USA) was used to measure the K/S, L (lightness), a (redness), b (yellowness), h (hue), and C (chroma) values of the fabrics with illuminant D65 and a visual angle 10° standard observer system at 400-800 nm. The system measured the difference in surface reflectance and calculated the relative color strength (K/S value) using the Kubelka-Munk equation as following; K/S = (1-R)2/2R, where K and S refers absorption and scattering coefficient and R is the reflectance of the dyed material at the maximum absorption wavelength, respectively.

The color difference (Δ

2.8. Fastness to washing and light test

The light fastness of the dyed fabrics with and without fermentation

and mordant were evaluated using a Carbon-Arc Fade-Ometer (Atlas Device Electronic Co., USA) according to the KS K ISO 105 B-02: 2010 methods. To measure the K/S value, the specific tests for color characteristics before and after washing were tested using a Launder-O-meter (Atlas LP-2, USA) and the fastness to washing was investigated in compliance with KS K ISO 105- C06: 2007.

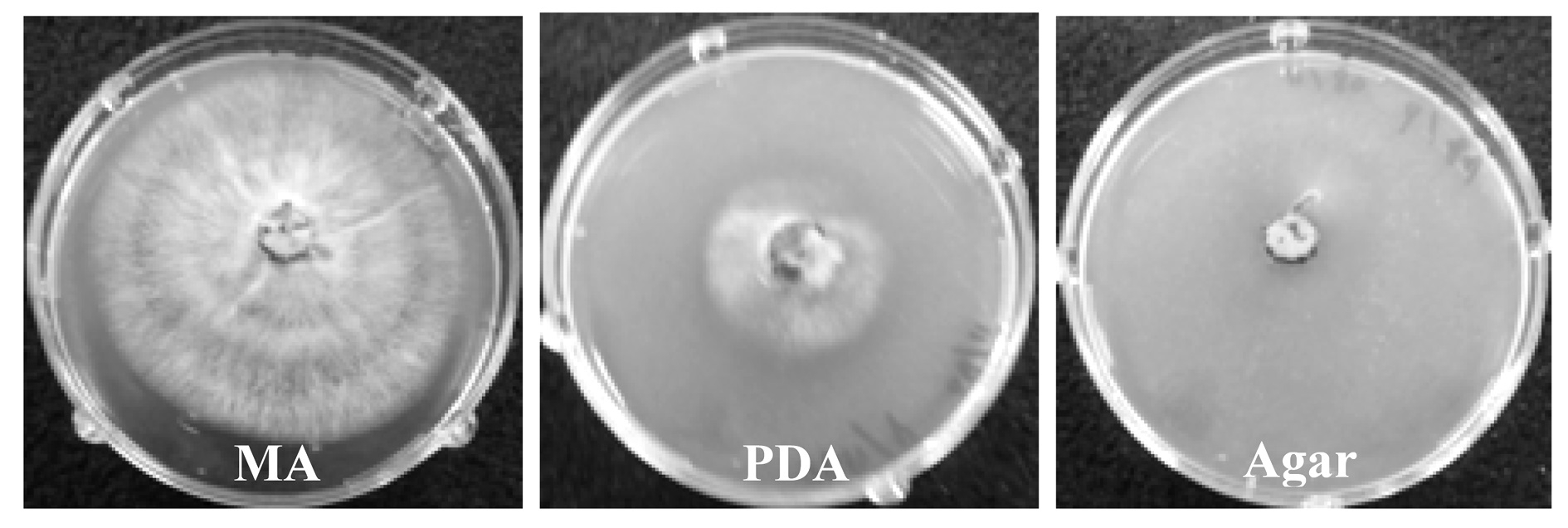

3.1. Selection of the growth medium and culture medium of P. linteus by fungi culture

As a result of testing the fungus subcultured in the MA and PDA medium,

3.2. Comparison of the growth of fungus according to the natural dye powder content

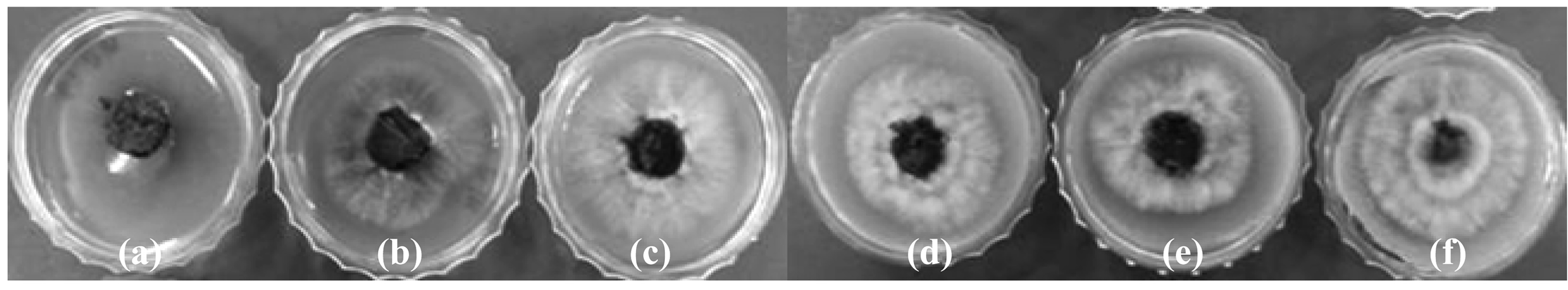

The growth of

3.3. Comparison of fermentation according to the rice bran content

To determine the optimal rice bran content for the optimum fermentation conditions,

3.4. Color characteristics of Coptis and Curcuma dyed silk fabrics

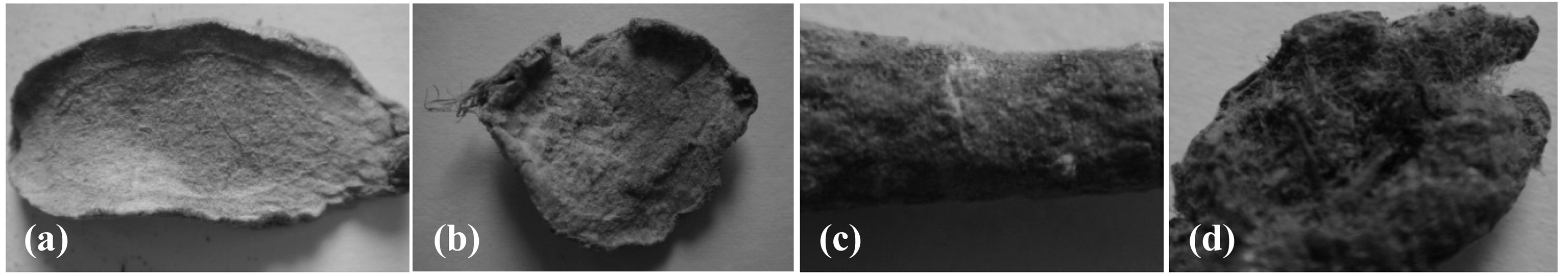

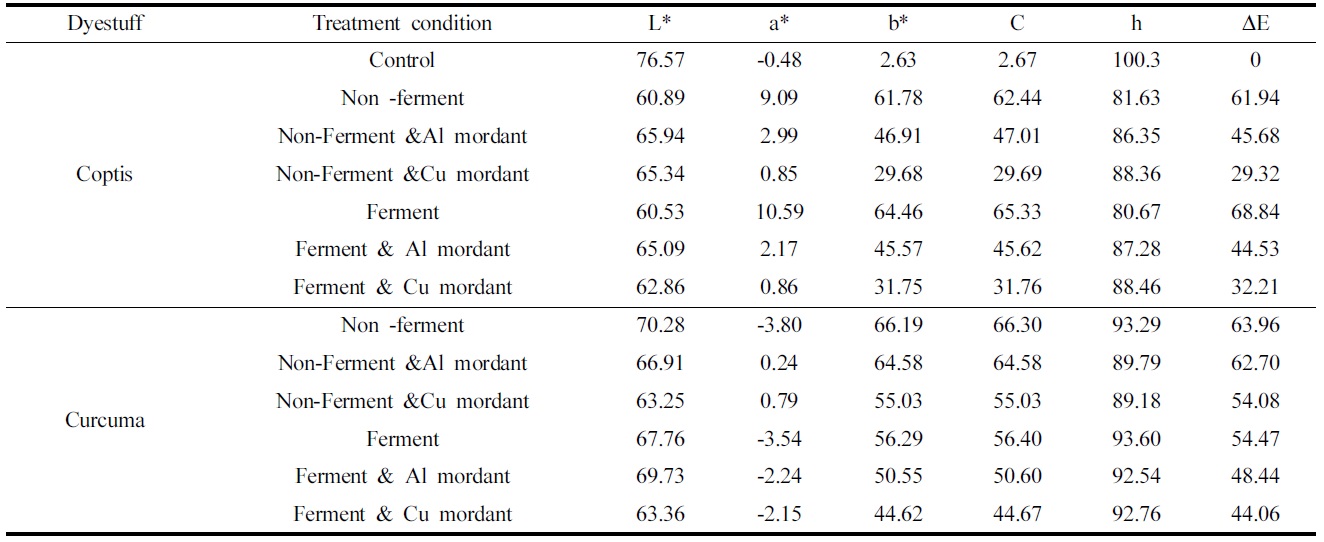

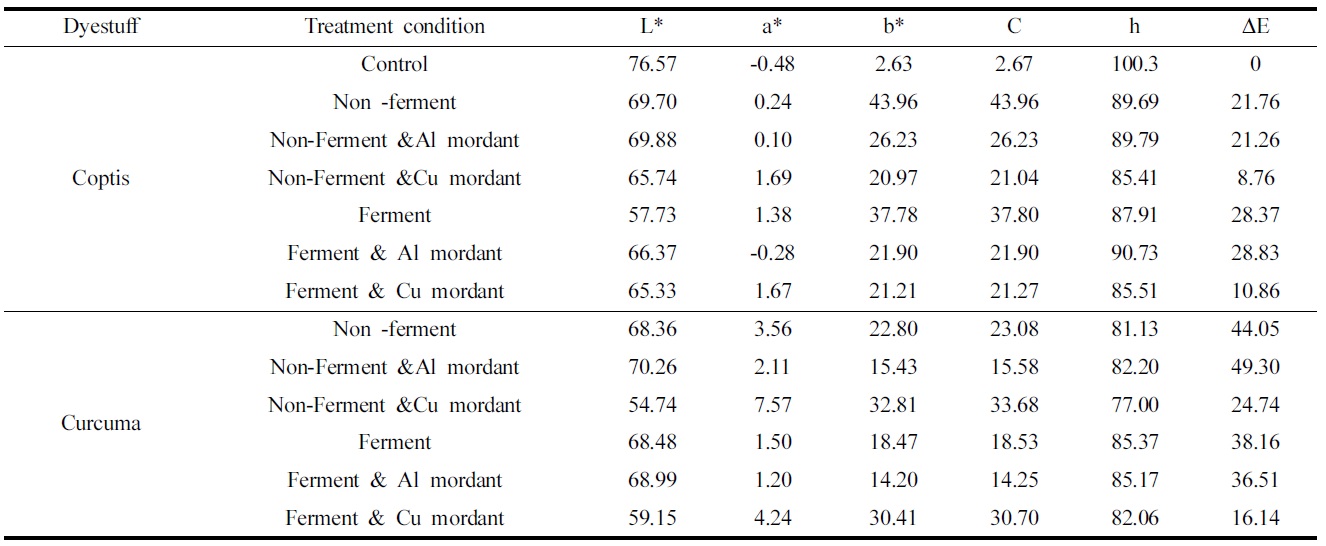

After dyeing the fabrics with the dyeing materials extracted from fermented

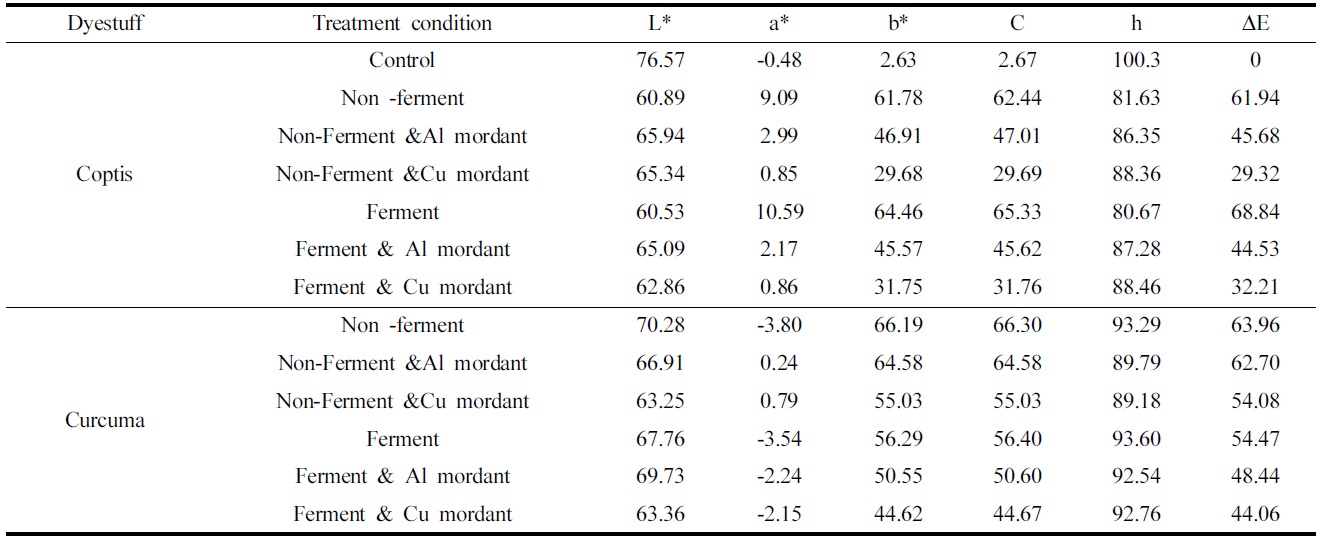

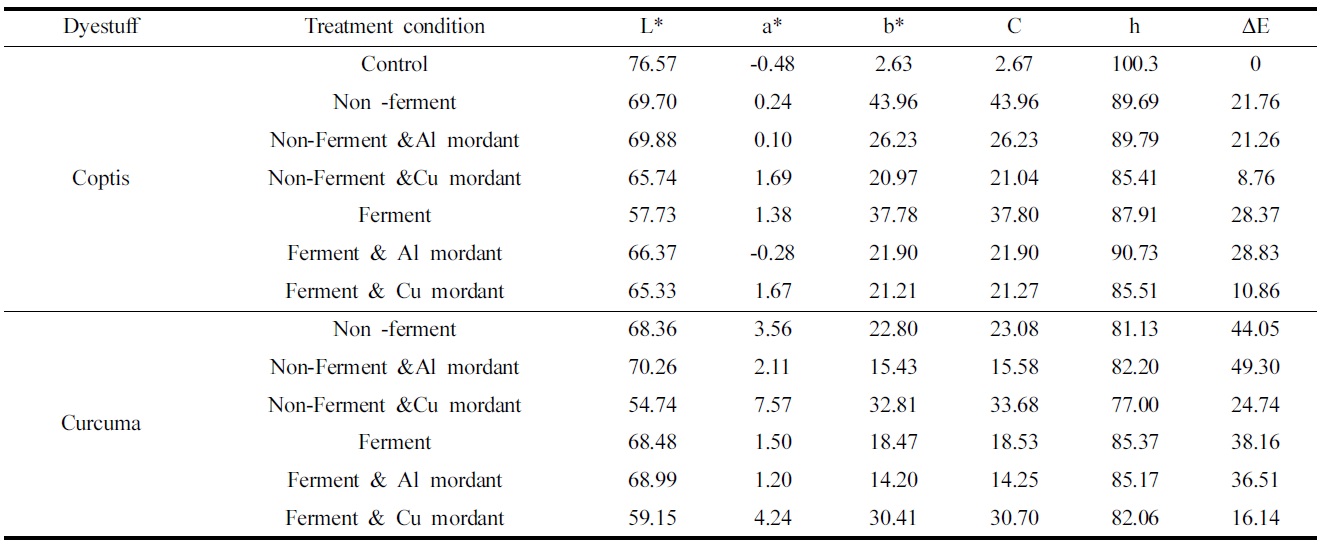

Table 1 show that the color characteristics of the fermented and unfermented dye were significantly different. Initially, the b* value increased significantly compared to the only control specimen without dyeing. In particular,

[Table 1.] Color characteristics of Coptis and Curcuma dyed silk fabrics under various conditions

Color characteristics of Coptis and Curcuma dyed silk fabrics under various conditions

Color characteristics of Coptis and Curcuma dyed silk fabrics under various conditions after washing

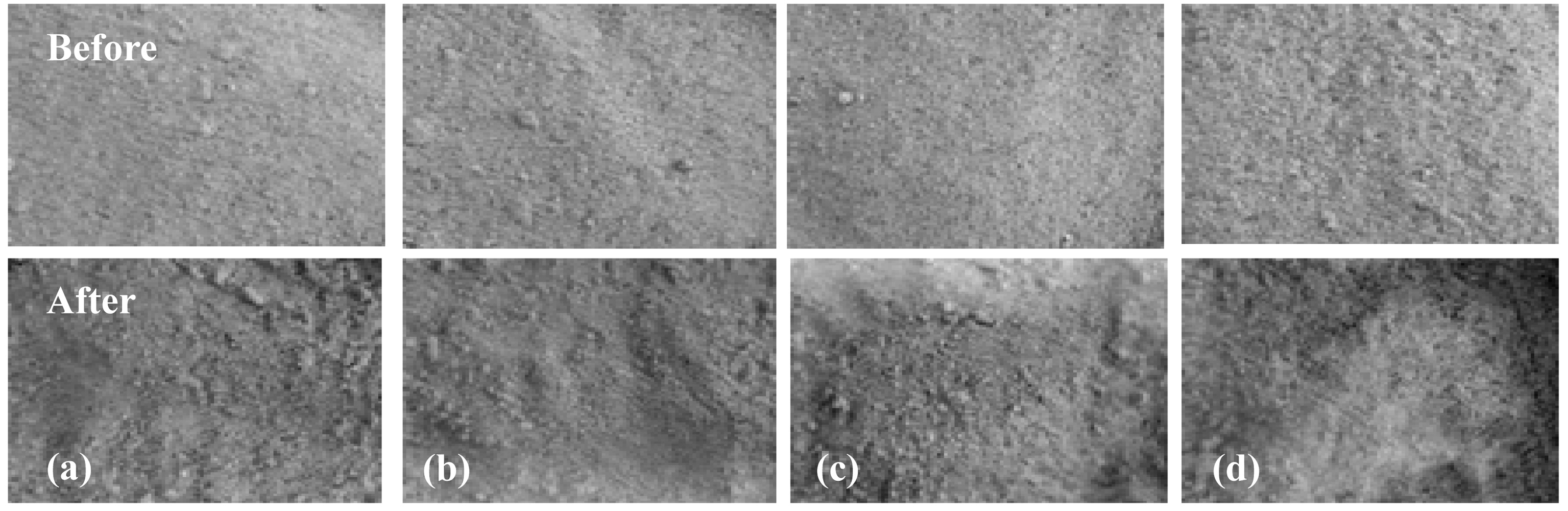

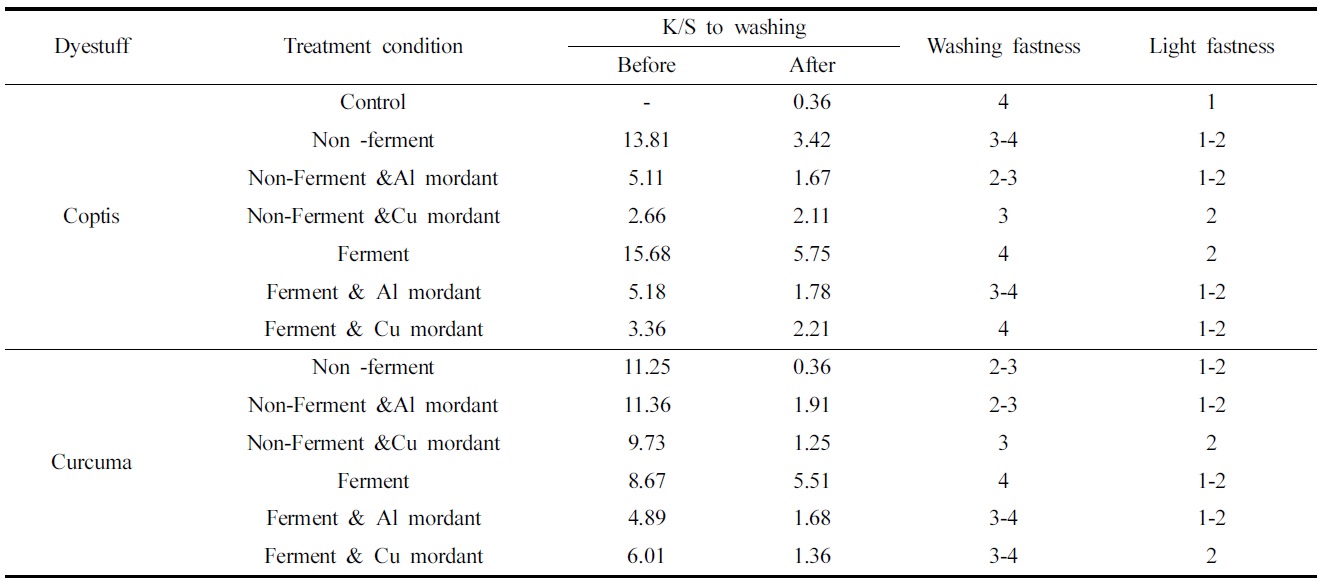

3.6. Effect of fermentation and mordant to washing fastness by K/S

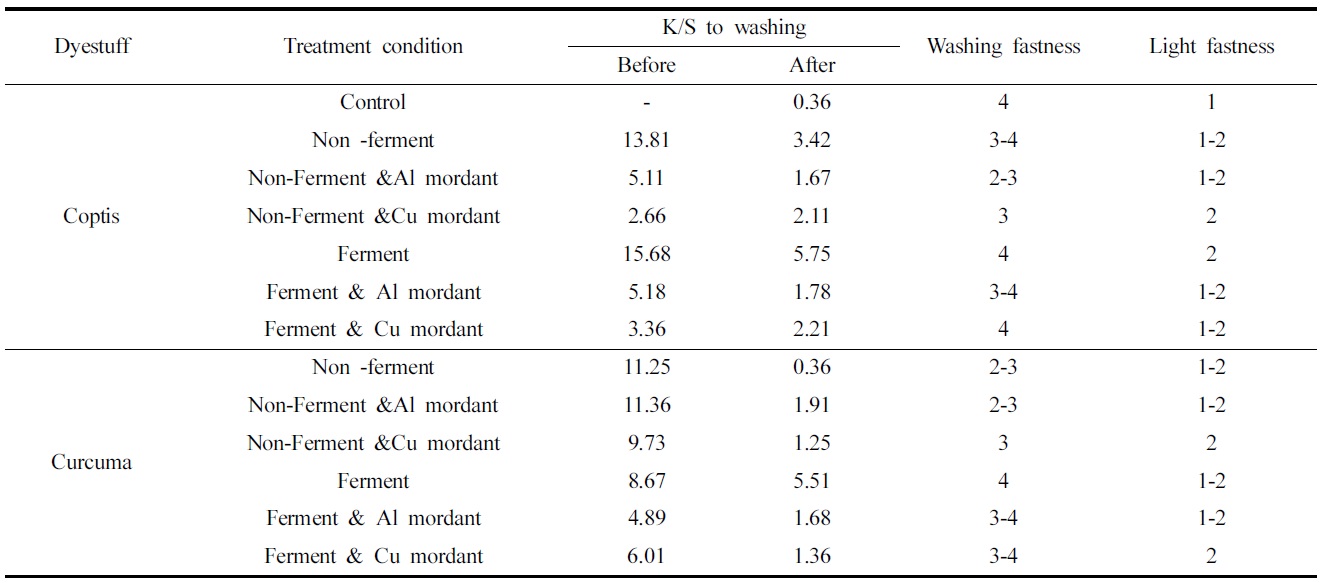

Table 3 presents the durability of silk according to changes in the surface color. In Table 3, the K/S of before and after washing on silk dyed with

Generally, the poor light fastness of fabrics is the main problem with natural dyes, though the dyes fabrics look deep colored in appearance. The silk fabric has physico-chemically better durability or dyeability than cotton, but naturally not durable to light. Therefore, continuous exposure to light weakens silk faster than

K/S to before and after washing and the fastness to washing and light of Coptis and Curcuma dyed silk fabrics under various conditions

either cotton or wool.

The light fastness of the unmordanted and mordanted silk fabrics dyed with

This study evaluated the microorganisms used for the fermentation of dyes,