Nanocomposites comprised of graphene oxide (GO) nanosheets and magnesium oxide (MgO) nanoparticles were synthesized by a sol-gel process. The synthesized samples were studied by X-ray powder diffraction, atomic force microscopy, transmission electron microscopy, and energy-dispersive X-ray analysis. The results show that the MgO nanoparticles, with an average diameter of 70 nm, are decorated uniformly on the surface of the GOs. By controlling the concentration of the MgO precursors and reaction cycles, it was possible to control the loading density and the size of the resulting MgO particles. Because the MgO particles are robustly anchored on the GO structure, the MgO/GOs nanocomposites will have future applications in the fields of adsorption and chemical sensing.

Magnesium oxide (MgO) nanostructures have drawn special attention because of their important applications in the areas of catalysis, refractory materials, and superconductors [1-3]. Various MgO structures, such as nanocrystals, nanoparticles, nanocubes, nanowires, and nanosheets have been fabricated successfully [4-6]. For the field of surface chemistry, including such areas as catalysis and adsorption, the fabrication of MgO nanostructures with high surface area and robustness is a priority.

Graphene nanosheets, a single layer consisting of sp2-bonded carbon atoms, have attracted considerable scientific interest due to their excellent thermal, mechanical, and electronic properties [7-9]. Building of nanocomposites of inorganic nanoparticles onto a graphene sheet would yield the benefit of large surface area [10]. Research into nanocomposites of graphene and inorganic nanoparticles have mostly used chemically exfoliated graphene and its derivatives, such as graphene oxides (GOs) and reduced graphene oxides (rGOs). Because these materials can act as substrates to support adhered inorganic nanoparticles, the resulting nanocomposites can exhibit enhanced properties for adsorption and sensing applications.

In this study, we demonstrate the growth of MgO nanoparticles on GOs using a sol-gel process at room temperature. Benefitting from the flat, two-dimensional nanosheet structure of the GOs, the resulting MgO/GOs nanocomposites showed MgOs uniformly grown on the surface of the GOs. It was possible to control the average particle sizes and size distributions by varying the growth conditions of the MgOs. Using X-ray diffraction (XRD) and transmission electron microscopic (TEM) analyses, it was demonstrated that the synthesized MgOs show an amorphous phase with an average particle size of about 70 nm.

Natural graphite (325 meshes, 99.8%) was purchased from Alfa Aesar. H2SO4 (97%) was purchased from Matsunoen Chemicals LTD. KMnO4 and Mg (NO3)2·6H2O were purchased from Sigma Aldrich. Other chemicals, such as NaOH (98.0%) and H2O2 (34%), were obtained from Samchun. Deionized water with a resistance of 18 MΩ cm was obtained using a Millipore Simplicity 185 system. All of the chemicals were used without further purification.

2.2. Preparation of graphite oxide

The graphene oxide (GO) was prepared using the modified Hummer’s method [11]. In a typical procedure, 1 g of graphite powder was added to 50 mL of H2SO4 under stirring, followed by stirring at room temperature for 30 min. To this mixture, 6 g of KMnO4 was slowly added. The mixture was stirred for 6 h upon reaching a temperature of 45℃. Subsequently, 80 mL of deionized water was slowly added to the mixture with stirring. The color of the mixture turned to yellowish brown. After 30 min, 200 mL of deionized water and 10 mL of H2O2 were added to the mixture. After 24 h, the resulting suspension was subjected to dialysis and then filtered through a cellulose acetate membrane with a 0.45 μm pore size. After centrifugation and freeze drying, GO powder was obtained.

In a typical procedure, an aqueous solution (1.5 mL) containing Mg(NO3)2·6H2O (0.1 mg/mL) was prepared and mixed with an aqueous suspension of the GO (0.1 mg/mL). The mixture was vigorously agitated for 4 h using a shaker. Then, the dispersion was centrifuged at 15 000 rpm for 5 to 10 min, the supernatant was removed, and water (1.4 mL) was added. This washing step was repeated four times. After washing, NaOH (0.5 M) was added to the dispersion and mixture was allowed to react for 30 min. Again, the resulting dispersion was subjected to centrifugation and washing with water. For the creation of more MgO nanoparticles on the surface of the GOs, the above procedures were repeated several times.

The distribution of the MgOs on the GOs was analyzed using an atomic force microscope (Dimension 3100, Veeco). XRD patterns of all samples were obtained using an X-ray diffractometer (D/Max 2500, Rigaku) with Cu Kα radiation to analyze the crystalline structure of the MgOs. A field-emission TEM (FETEM) was used to visualize the microstructure of the MgOs, for the energy dispersive X-ray (EDX) analysis, and for the selected area electron diffraction (SAED) analysis (FE-TEM, JEM 2200FS, Jeol). Particle size analysis was carried out using imaging analysis from TEM and statistical calculation using data from 300 particles.

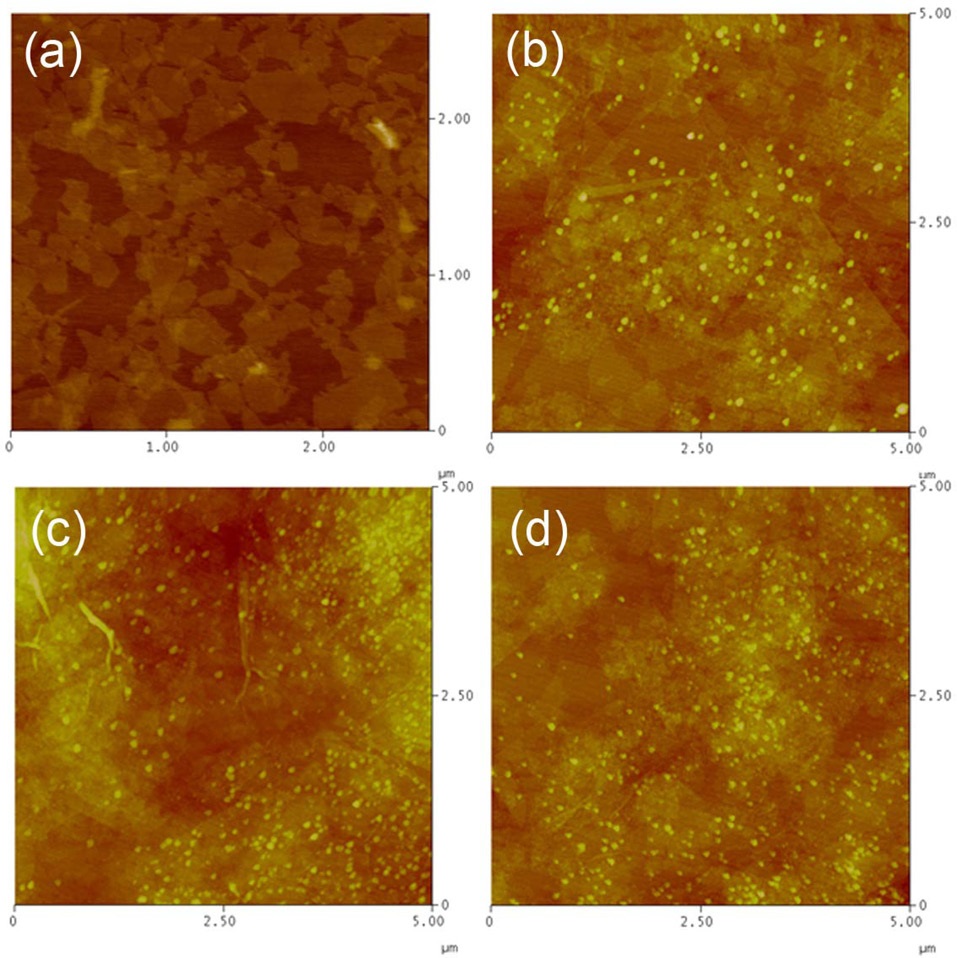

The MgO nanoparticles were grown on the surface of the GOs using magnesium nitrate (Mg(NO3)2·6H2O) as a source material, followed by treatment with NaOH. Fig. 1 shows the atomic force microscopy (AFM) images of the MgO/GO nanosheets when the reaction cycles of the MgO growth are controlled. Fig. 1a shows the GO sheets, revealing lateral dimensions of 10-3000 nm and heights in the range of 1.1-10 nm; this image was obtained by an analysis of a large number of AFM images. Approximately 80% of the sheets displayed a height of 1.1 ± 0.2 nm. The height values are slightly larger than the theoretical height of 0.8 nm; this is thought to be a result of the presence of oxygen-containing functional groups on both faces of the GO sheets [12]. After the reaction cycle of MgO growth, MgO nanoparticles of about 60 nm in size were sparsely distributed on the surface of the GOs (Fig. 1b). When the growth cycle was repeated, the population of MgO nanoparticles increased with the creation of new nucleation sites (Figs. 1c and d). The size distribution of the MgO nanoparticles broadened a bit with the repeated reaction cycles because nucleation and growth occurred simultaneously.

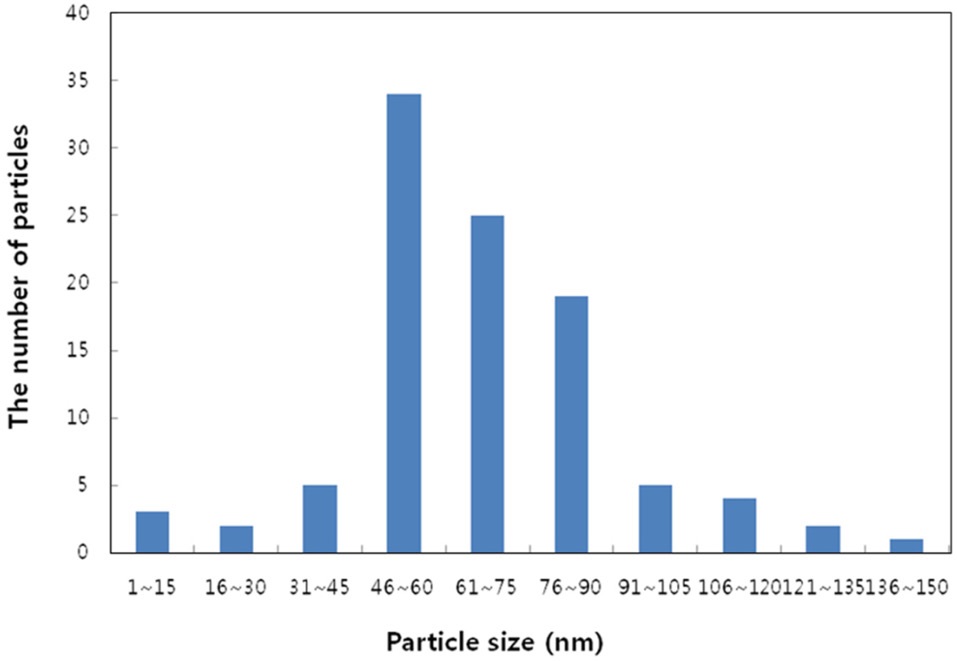

Fig. 2 shows the particle size distribution for the samples after MgO growth of up to 3 cycles. The average particle size was about 73 nm, with standard deviation of 24 nm. Because our process did not involve any heat treatment during the MgO growth, the size distribution of the MgO nanoparticles did not change significantly for

up to 3 cycles. If we add a brief heat treatment for the MgO growth process, the growth speed will be activated and the average particle size for the same growth conditions will increase to 142 nm, with standard deviation of 40 nm.

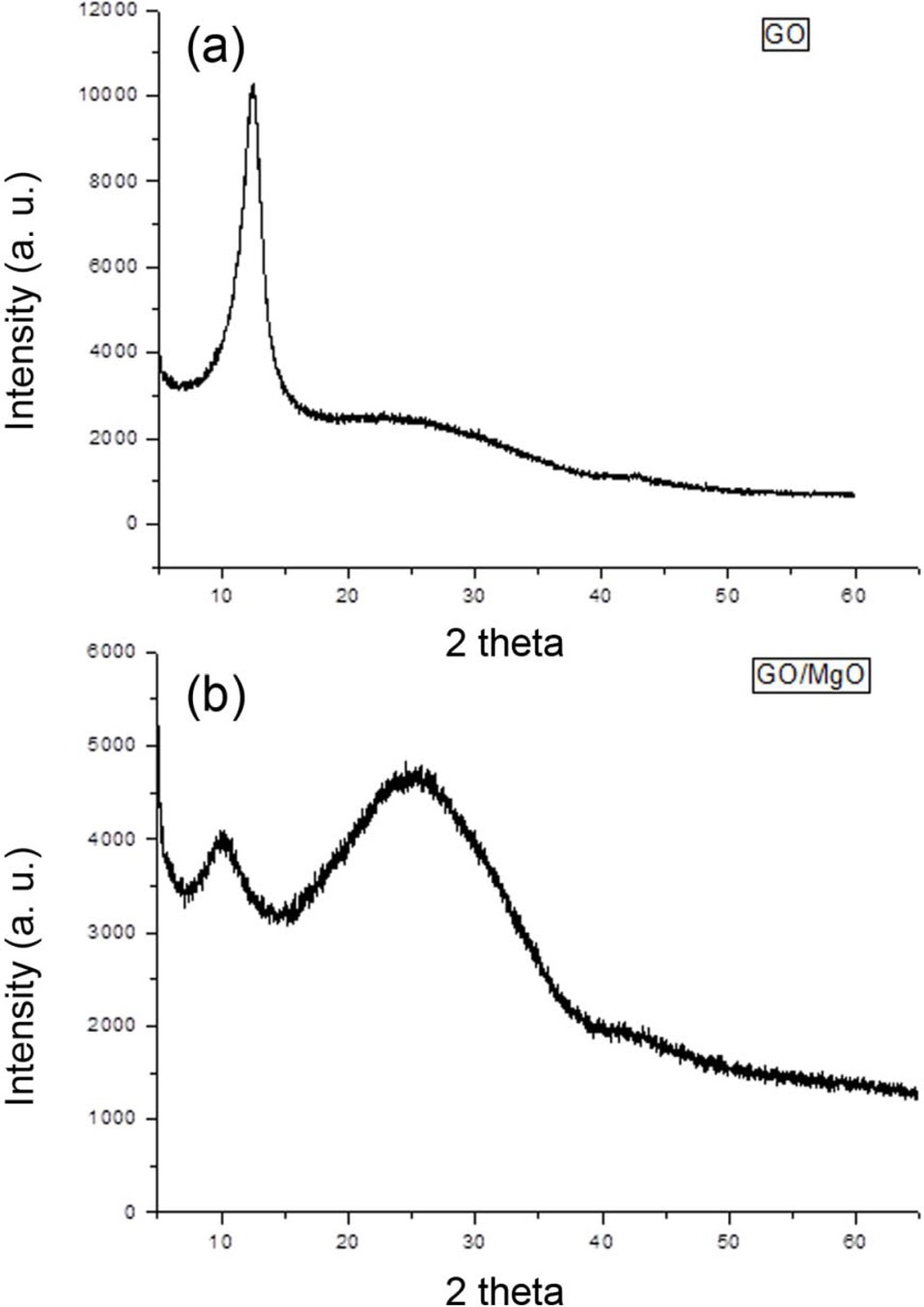

The XRD spectra from the as-prepared GOs and the MgO/GOs are presented in Fig. 3. For the GOs, there is a strong and sharp peak located around 11.8°, corresponding to an interlayer distance of 0.76 nm (d 002). The MgO/GOs shows a broad peak centered on 25°, revealing the presence of the amorphous phase of the MgO nanoparticles, with almost no crystalline structure. Because the growth of MgO took place at room temperature, most of the grown MgO nanoparticles are naturally amorphous, without any crystalline phase. When we increase the growth temperature, we can detect the development of the crystalline phase by XRD analysis. The nominal shift of the (002) peak of the GOs is related to the sodium hydroxide treatment for MgO nanoparticle growth, possibly removing a small amount of oxide groups on the surface of the GOs.

3.4. Transmission electron microscopy

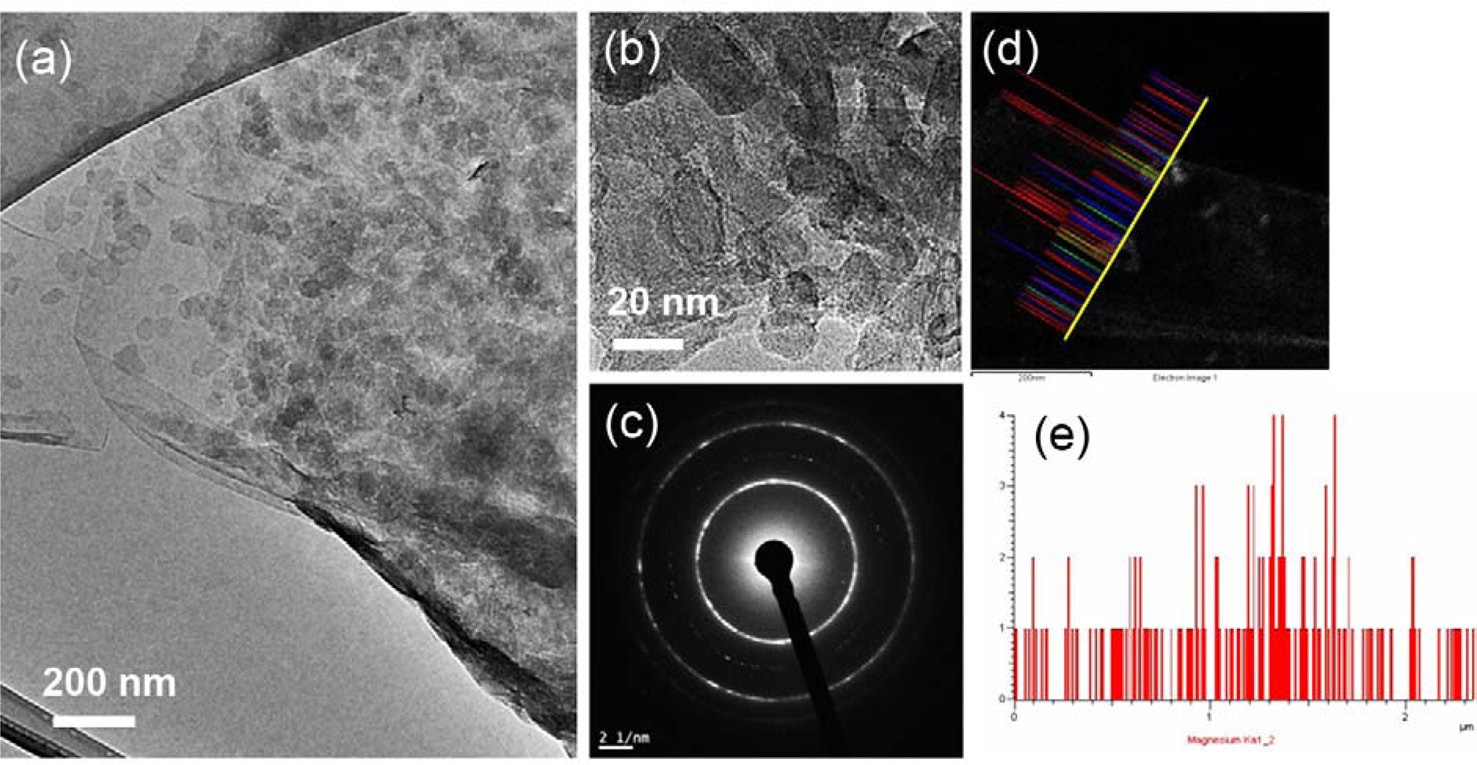

With the aim of obtaining a deeper characterization, TEM and EDX spectroscopy were performed on the MgO/GOs (Fig. 4). These processes revealed densely distributed MgO nanoparticles

on the surface of the GOs (Figs. 4a and b). From the dark field image and the following SAED analysis, we were able to conclude that the morphology of the MgO nanoparticles is amorphous (Fig. 4c). It seems that the GOs do not have any influence on the crystallinity of the grown MgOs because of the low growth temperature and relatively defective structure of the GOs. From the EDX analysis, it is clear that the MgO nanoparticles were successfully synthesized on the surface of the GOs (Figs. 4d and e).

Easy and controllable growth of MgOs on the surface of GOs with uniform distribution was achieved using a simple sol-gel process. It was possible to control the loading density and particle size distribution through the repetition of the MgO growth cycles. Without any heat treatment, MgO nanoparticles with average particle size of around 70 nm were successfully synthesized on the GOs. The MgO nanoparticles grown on the GOs show high surface reactivity, and high chemical and thermal stability, which makes MgO a promising material for applications in fields of sensors and catalysis. The role of MgO/GOs as an efficient catalyst for many useful reactions, for example, the methanation of carbon dioxide, will be the subject of our future work.