Nuclear power generation had its beginning in 1954 when the USSR’s Obninsk Nuclear Power Plant produced approximately 5 MWe that was supplied to a power grid [1]. Since this beginning, the global footprint of nuclear power has grown to 437 plants generating approximately 372 GWe of total capacity, providing about 13.5% of the world’s electric capacity [2].

As nuclear fuel reaches the end of its operational life, it is removed from the reactor to pool storage as a safe intermediate step to await further disposition pathways. There are three general pathways for spent fuel; reprocessing, interim dry storage, and disposal. Within these three general pathways, there is a myriad of options that could define a particular fuel cycle. In general, however, existing global reprocessing capability is limited and only two repository sites are currently being licensed or are under construction for the disposal of spent fuel, one each in Sweden and Finland, respectively. There is no current high level waste repository that accepts spent nuclear fuel for disposal.

In the U.S., delay in repository design, licensing, and construction has created a situation where spent fuel storage at utility sites will need to remain in place much longer than originally expected and longer than current regulatory storage time limits allow.

As of May 2012, there was over 67,000 metric tons of uranium (MTU) of used fuel in storage in the U.S.; 49,000 MTU in pool storage and 18,000 MTU in dry storage in the U.S. [3] Current reactor operations in the U.S. will result in an additional 2000 MTU being offloaded to pool storage every year. Site management will require used fuel to be transferred from pool storage to onsite dry storage as a means to manage pool availability for routine operations such as reactor refueling and offloading and cooling of fresh used fuel.

As repository programs continue to experience delays, the safe and secure storage of used fuel becomes more important. Interim storage sites must expand their sizes to accommodate new used fuel, plans for centralized interim storage sites are being considered, and extension of storage licenses for existing storage systems will be necessary pending a disposition resolution. While it is expected that used fuel can be stored safely and securely, a technical bases needs to be developed that demonstrates safe storage beyond the current licensing timeframe.

An important component in these issues deals with evolving reactor operations. In particular the fact that used fuel is being discharged with increasingly higher burnups. Given the high burnups, material property conditions of the fuel cladding may be significantly different from cladding subjected to the average burnups of even ten years ago. Higher burnup fuel is usually considered as fuel that has been irradiated to > 45 GWd/MTU. This affects the technical bases that need to be addressed when considering extension of dry storage licenses.

This paper will discuss a path forward for development of the technical bases that will address technical gaps that need to be resolved for understanding materials degradation issues over extended periods of time. Although all safety components of a storage system need to be considered, this paper will focus on the status of the development of the technical bases associated with used fuel specifically that is in dry storage. The focus will be on the U.S. situation and the Department of Energy program that is sponsoring much of this work.

2. U.S. DEPARTMENT OF ENERGY USED FUEL DISPOSITION R&D PROGRAM

In 2009, the Department of Energy (DOE)/ Office of Nuclear Energy (NE) established the Used Fuel Disposition Campaign (UFDC) as part of the Fuel Cycles Technologies Program that supports overall R&D focused on issues associated with the nuclear fuel cycle. Establishment of the UFDC was recognition that important issues associated with the backend of the fuel cycle needed to be addressed on a national scale. The UFDC focuses on two principal areas; disposal research and R&D associated with the storage and transportation of used nuclear fuel. The storage and transportation R&D relates directly to the issue of extended storage for used nuclear fuel.

The UFDC used fuel storage and transportation R&D has three main objectives:

1. Develop the technical bases to support the continued safe and secure storage of used fuel for extended periods.

2. Develop the technical bases for retrieval of used fuel after extended storage.

3. Develop the technical bases for the transport of high burnup fuel, as well as low and high burnup fuel, after extended periods of dry storage.

Initial efforts in this program centered on a technical data gap assessment to identify the data gaps that need to be addressed in order to develop the technical bases for extended storage. This assessment was done for all safety components of dry storage systems including the fuel, baskets, containment boundary, neutron poisons and shields, closure lids and seals, overpacks, gamma shielding, and the concrete pad. Having identified the gaps, the next step was to prioritize the gaps relative to their importance to making the safety case for extended storage.

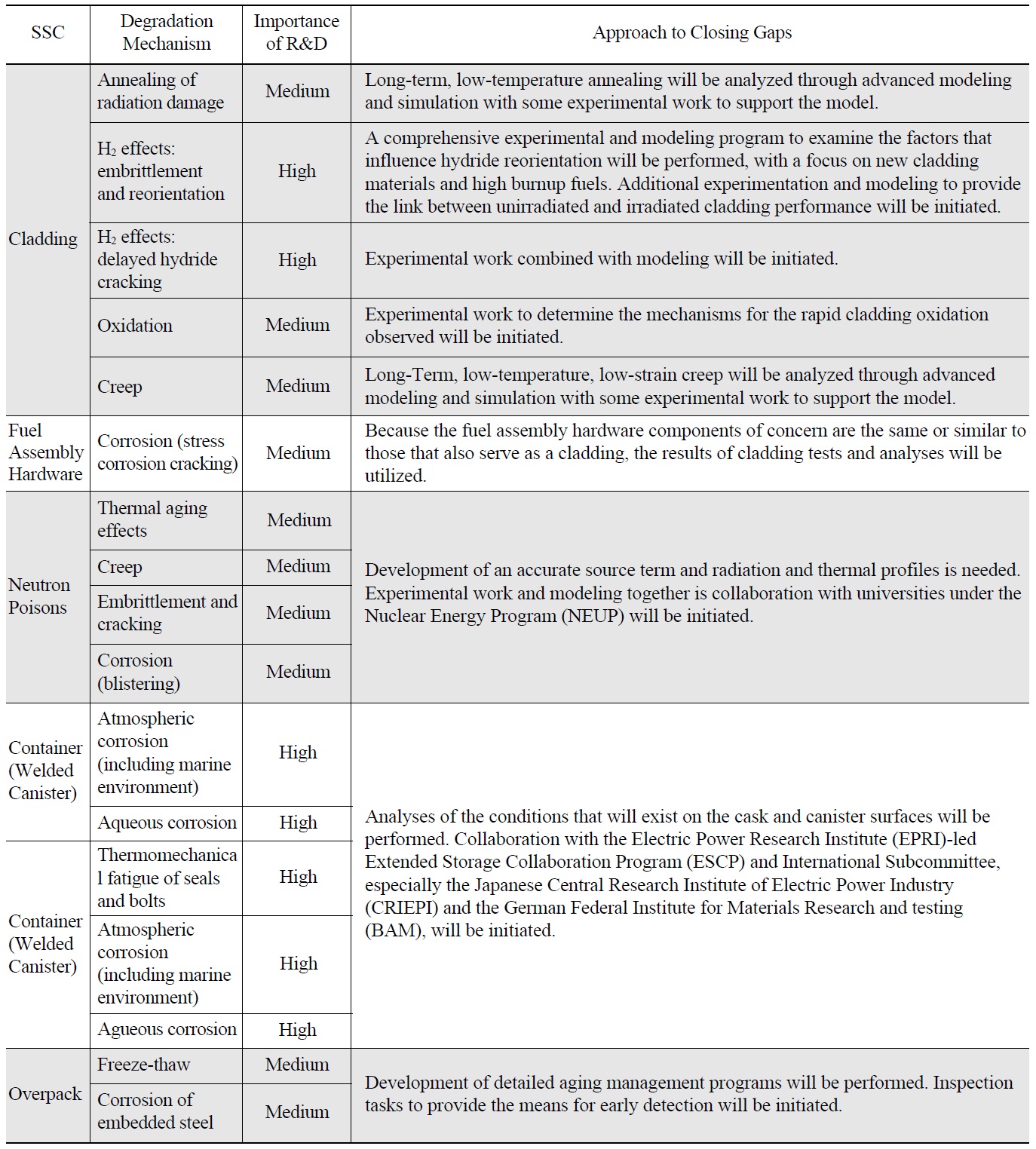

The result of this work is a comprehensive assessment [4] of the R&D that needs to be conducted to develop the technical bases for extended storage. Table 1 lists the high priority technical gaps that need to be addressed in order to develop the technical bases for extended long-term storage. In addition to the prioritized gaps identified in Table 1, cross-cutting gaps such as monitoring, thermal and stress profiles, drying issues, subcriticality and burnup credit, and fuel transfer options were also identified.

By way of example to demonstrate the approach in development of the technical bases, the remainder of this report will focus on the hydride effects in used fuel cladding that is identified as a high priority issue in Table 1.

Several independent gap analyses were conducted in parallel with this study. In particular, the U.S. NRC and the International Subcommittee of the Electric Power Research Institute Extended Storage Collaboration Program (EPRI/ESCP) each conducted studies [5,6] that are relevant to the UFDC study. While there are differences in gaps and the order of priorities for the list of technical gaps, there is general consensus on the importance of hydrogen effects on cladding [7].

2.2 Experimental and Analytical Work

As high priorities, hydrogen effects on the material properties of used fuel cladding, and how these effects result in performance to regulatory loadings during storage and subsequent transport scenarios, are significant factors in the development of the technical bases for extended storage and transportation.

For the past three years, the UFDC program has funded Argonne National Laboratory to conduct ring-compression tests on de-fueled cladding to better understand the effect that hydrides and hydride orientation in the cladding have upon degradation of the mechanical properties of the cladding. The effect that hydrogen concentration and hydride orientation has on cladding can be significant. Reduction in ductility and fracture toughness are two significant issues that need to be better understood in the storage and transportation environments for these materials. Significant progress has been made for PWR cladding materials (i.e., Zircaloy 4, ZIRLO™, M5®) [8].

Figure 1 highlights the hydrogen in the used fuel cladding. When used fuel is removed from the storage pool to a dry storage system, the fuel goes through a drying process which results in a thermal spike. As the fuel cools after drying, the hydrides may reorient from a circumferential to a radial orientation, thereby further embrittling the cladding. The degree of reorientation is a function of the increase in temperature and resultant cool down rate, as well as the internal pressure in the fuel rod. It is therefore very important to benchmark the hydride characteristics in the fuel cladding when it is placed in dry storage.

The ring compression tests provide load-deflection and failure mode data as a function of temperature and hydrogen concentration. These data are then used to compare

Summary of High- and Medium-Priority Degradatoin Mechanisms that Could Impact the Performance of Structures, Systems, and Components during Extended Storage [4]

response between the different cladding materials under similar conditions.

Figure 2 shows the ductile-to-brittle-transition temperatures (DBTT) developed from the ring-compression tests for Zircaloy 4, ZIRLO™, and M5® cladding. The DBTT parameter is important in order to understand potential fuel response to storage and transportation loading conditions that may be imposed. When used fuel is transferred from

wet to dry storage, the temperatures are high enough that the cladding remains ductile. Over time, as the cladding cools in the dry storage environment, it may change to a lower-shelf, brittle material. This condition makes the material vulnerable to fracture when subjected to regulatory storage and transportation mechanical loadings. Given this understanding of the effect of hydrides on the DBTT, it will be possible to estimate the response of the used fuel over time to specific loadings.

A parallel analytical approach that combines a modified Potts and Phase Field diffusion approach is also being pursued to provide a more efficient way to address hydride effects in cladding [9]. Once the analytical approach is verified and validated to empirical data such as that developed from the experimental program [8], it can be used on a variety of cladding materials with varying operational burnup histories. The resulting tool will be computational and will integrate experiments and theory with computational sciences to develop a predictive capability that can be broadly applied to the claddings found in the current and future used fuel stockpile. Development of this approach will provide much more flexibility in the ability to understand hydride behavior in used fuel cladding.

Another hydride issue that has been investigated by Kim [10] and others is that of low temperature delayed hydride cracking. As the temperature of the cladding decreases below about 180 ℃, stress induced hydride phase transportation from γ to δ at the crack tip may cause cracking of the cladding. This phenomenon has been identified as a priority in both the DOE and NRC data gap reports [4,5].

Given the dramatic effect that hydrides may have on cladding materials, it is important to understand the hydride mechanisms that occur during the operational life of the used fuel in order to predict how the cladding will perform under long-term storage. This understanding of the cladding properties will allow for estimations of fuel performance subjected to regulatory loading conditions.

Linking the understanding of hydride effects to performance in long-term storage is essential in order to predict performance under extended storage periods and subsequent transportation. An understanding of how the used fuel cools in these environments and predicting when or if the used fuel drops below the DBTT will drive operational decisions for the management of these materials. A confirmatory storage demonstration will provide the necessary validation to confirm the long term material performance understanding that was developed from the earlier experimental and analytical work.

3. CONFIRMATORY STORAGE DEMONSTRATION

Several cask storage demonstration projects have been performed in the U.S. over the past several decades. While some of these were conducted to evaluate specific cask designs, one program of note was a storage demonstration conducted by the DOE in collaboration with the Electric Power Research Institute and the Idaho National Laboratory (INL) to evaluate degradation effects on used fuel in storage [4]. BWR and PWR fuel from the Cooper, Surry, and Turkey Point reactors was stored in five different dry storage casks, Figure 3. The period for storage was approximately 15 years.

After the storage period, the casks were opened and the fuel was inspected. NDE techniques, such as profilometry, were used to observe the general condition of the fuel. This program identified no serious material degradation issues and provided the technical basis for the NRC to issue a rule change to allow for the licensing of storage systems for low burnup fuel for up to 40 years, with one allowable 40-year extension.

This demonstration did not address high burnup used fuels. As identified in Table 1, addressing the hydrogen effects in the cladding of high burnup fuel is a high priority. Since the fuel for the INL demonstration was placed in storage, utility reactor operators in the U.S. have gone to increasingly higher burnups. As fuel stays in the reactor for longer periods of time, the hydrogen up-take in the

Zircaloy cladding increases along with the internal gas pressure. These operation conditions may likely affect the long term performance of the used fuel cladding in dry storage and transportation due to hydride embrittlement and higher cladding circumferential stresses. The INL demonstration program did not address these high burnup used fuel issues.

Another aspect lacking in the INL demonstration program was that there was no characterization of cladding material properties and morphologies before the used fuel was placed in storage. Acquiring these properties prior to used fuel emplacement allows for a baseline material property database by which to make comparisons later in the storage period to assess the rate of degradation mechanisms. Low burnup used fuel in the INL demonstration program will exhibit upper shelf ductile behavior during the term of the storage period. However, as shown in Figure 2, it is very likely that certain types of high burnup used fuel cladding may be operating on the lower shelf in the brittle fracture regime. This potential of changing from ductile to a brittle behavior for the cladding is critical in the assessment of high burnup fuel and its ability to maintain its integrity during long-term storage and subsequent transportation.

Recently, the U.S. DOE has issued a contract to industry to initiate a long term storage confirmatory demonstration program [11]. This program will focus on dry storage of high burnup PWR and BWR used fuels of different cladding types. Intermittent inspections are planned to confirm fuel integrity and validate understanding of material degradation mechanisms developed from the experimental program.

4. INTEGRATING SEPARATE EFFECTS NEARTERM TESTING WITH A LONG-TERM STORAGE DEMONSTRATION PROJECT

Knowledge and data obtained from both separate effects testing and a long term confirmatory demonstration project are necessary, but not sufficient, to make a convincing argument that high burnup used fuel will maintain its integrity for extended periods of time in storage. These two aspects must be well integrated so that the proper technical bases can be developed.

Obtaining initial high burnup cladding properties (e.g., hydride morphologies, internal pressure, DBTT, ductility, modulus, etc.) will provide the important initial conditions by which the used fuel will then be compared when it is periodically inspected during the confirmatory dry demonstration. Hydride morphologies will be linked to analytical assessments of thermal profiles to estimate the time at which cladding types of various burnup levels may transition from a ductile to brittle behavior.

This linkage of initial cladding properties to long term performance confirmation will provide the technical basis for demonstrating behavior of high burnup used fuel in long term storage environments.

Extended long-term storage of used nuclear fuel is a reality for many nations that generate nuclear power. When regulatory frameworks were developed, current thinking at the time envisioned the ability to dispose of the fuel within several decades. Due to many factors, repository development has not proceeded as planned and long-term dry storage of fuel in existing systems must remain the first option for managing this material. To allow confidence in the safety and integrity of these systems for periods past their original regulatory licensing timeframes, an integrated combination of near-term separate effects tests and a confirmatory storage demonstration project must be implemented to demonstrate that materials used as engineering components of the storage system behave over the long term in a manner that is well understood.

Done separately, neither separate effect tests nor a confirmatory storage demonstration project can produce the data to properly demonstrate the safety of long-term storage and subsequent transportation of high burnup used fuel.

![Summary of High- and Medium-Priority Degradatoin Mechanisms that Could Impact the Performance of Structures, Systems, and Components during Extended Storage [4]](http://oak.go.kr/repository/journal/12585/OJRHBJ_2013_v45n4_421_t001.jpg)

![Circumferential and Radial (Note Arrow) Hydrides in Zircaloy-4 Cladding from 64 GWd/MTU High Burnup Fuel after drying Treatment [8]](http://oak.go.kr/repository/journal/12585/OJRHBJ_2013_v45n4_421_f001.jpg)

![Ductile to Brittle Transition Temperatures for Zircaloy 4, ZIRLO™, and M5® Cladding [8]](http://oak.go.kr/repository/journal/12585/OJRHBJ_2013_v45n4_421_f002.jpg)

![NAC-128, CASTOR V/21, REA 2023, MC-10, VSC-17, and TN-24P Dry Storage Casks used for the Storage Demonstration Project at the Idaho National Laboratory [4]](http://oak.go.kr/repository/journal/12585/OJRHBJ_2013_v45n4_421_f003.jpg)