It is well-known that basalt fibers do not have toxic reactions with water and are non-combustible. When in contact with other chemicals, basalt fibers do not produce chemical reactions that may damage health or the environment. Furthermore, they have good mechanical and thermal properties and can have various applications as reinforcing materials in structural and constructional composite materials [1].

Accordingly, many studies have been conducted to investigate the mechanical properties of basalt fiber reinforced polymer matrix composites [2-5]. Recently, carbon nanotubes (CNTs) have been used as reinforcing materials in the polymer matrices because the addition of CNTs can improve the mechanical, electrical, and thermal properties of the conventional fiber-reinforced composites [6-8]. For example, Ashrafi et al. [9] investigated the effect of the addition of single-walled CNTs (SWCNTs) on the impact, compression, and fracture toughness of carbon/epoxy laminates. They reported that the addition of SWCNTs significantly improved the impact resistance and fracture toughness of the carbon/epoxy laminates. Furthermore, Kim et al. [10] investigated the effects of CNT modification on the fracture behavior of CNT/epoxy/basalt composites. Their results demonstrated that the fracture toughness of silane-treated CNT/epoxy/basalt composites was ~40% greater than that of the acid-treated CNT/epoxy/basalt composites. However, an important issue for polymeric composites is that their mechanical properties degrade when exposed to seawater. To date, little research has been undertaken to investigate the fracture behavior of seawater-absorbed CNT/epoxy/basalt composites.

In the present study, the effects of seawater absorption on the fracture properties of CNT/epoxy/basalt composites were investigated. Fracture tests were conducted using CNT/epoxy/basalt composites with and without seawater absorption.

The reinforcing materials that were used were woven-type basalt fibers (EcoB4-F260, Secotech, Korea) with an area density of 260 g/m2 and multi-walled CNTs (MWCNTs; CM-95, Hanhwa Nanotech, Korea) prepared via chemical vapor deposition. The epoxy was diglycidyl ether of bisphenol A (YD-115, Kukdo Chemical, Korea), and the curing agent was polyamidoamine (G-A0533, Kukdo Chemical, Korea). The reagents used for the acid treatment were nitric acid (60-62%, Junsei Chemical, Japan), sulfuric acid (95%, Junsei Chemical, Japan), acetone (99.5%, Dae Jung Chemical, Korea), and ethanol (99.5%, Aldrich, USA). The acid treatment of the CNTs and the fabrication of the CNT/epoxy/ basalt composites were performed using the procedure described in the previous article. For the double cantilever beam (DCB) fracture specimens (width 25 mm and length 200 mm), an initial delamination was created through the insertion of a 50 mm Kapton film (thickness: 13 μm) between the fourth and fifth plies. The fracture specimens were constantly immersed in sterile filtered seawater (S-9148, Sigma-Aldrich, USA) for up to six months.

The fracture tests were performed using the DCB fracture specimens (width 25 mm and length 200 mm) at a loading rate of 0.5 mm/min in accordance with the guidelines set in ASTM D 5528-01 [11]. After the initial delamination increased to a predetermined extent, the applied displacement was reduced and then increased again to induce further delamination. This process was repeated more than ten times until the delamination increased to more than 30 mm. A minimum of five flexural and fracture tests were performed to ensure the reliability of the test results.

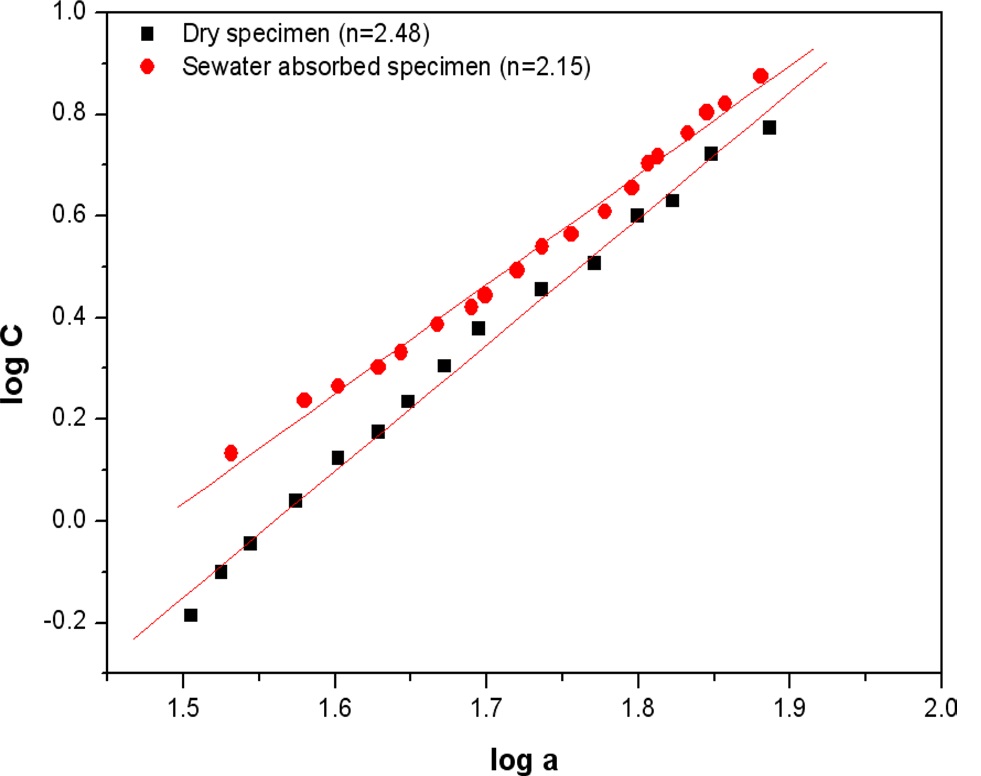

The mode I fracture toughness (

where

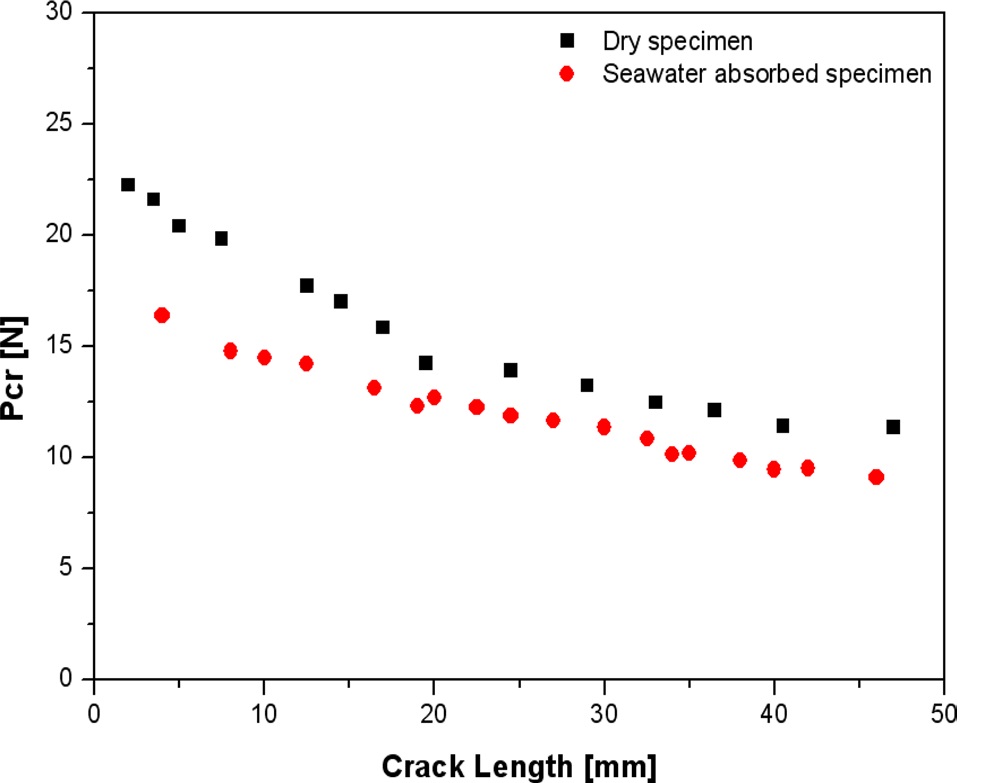

Fig. 2 shows the

The mode I fracture toughness (

values of

This study investigated the effect of seawater absorption on the fracture toughness of CNT/epoxy/basalt composites. Overall, the fracture properties of the CNT/epoxy/basalt composites were significantly affected by seawater absorption. The compliance of the seawater-absorbed CNT/epoxy/basalt composites was larger than that of the dry CNT/epoxy/basalt composites at the same crack length, while the fracture load exhibited the opposite behavior. The fracture toughness of the seawater-absorbed CNT/epoxy/basalt composites was approximately 20% less than that of the dry CNT/epoxy/basalt composites. The decrease in the fracture toughness of the seawater-absorbed CNT/epoxy/basalt composites was attributed to the weakening of the interfacial bonding between the CNTs and epoxy due to the swelling of the epoxy matrix.