In nuclear power plants, zirconium and its alloys are used extensively to store nuclear core material due to their ability to withstand reactor conditions for long periods of time, including neutron irradiation. Despite their excellent properties as structure materials and significant manufacturing progress, radiation-induced phenomena (growth, hardening, creep, and amorphization) are still main concerns.

Radiation-induced growth is one of the most important phenomena which should be avoided in order to maintain structural integrity because radiation-induced growth is a dimensional change of materials without applied stress or volume change under irradiation to materials. Radiationinduced growth occurs only in anisotropic materials, because the defect diffusion coefficient is different between the basal plane and the prism plane [1], interstitial shows this tendency to a much greater degree, i.e., high diffusion coefficient in basal plane and low diffusion coefficient in prism plane [2-4].

Extensive experimentation has been conducted to evaluate growth behavior. Quantitative analysis of three key parameters (fluence, temperature, and materials variables) has explained their influence on growth behavior [5-10].

However, there are some discrepancies between radiation-induced growth phenomena and growth prediction models. Because material microstructure is fundamental to macro-scale behavior, understanding the correlation between microstructure and macrostructure may explain radiation-induced growth uncertainties and discrepancies.

In the case of zirconium and its alloys, microstructure changes dramatically with radiation-induced defects, which can be clustered into two major dislocations. Thus, dislocation can be used conceptually to analyze hardening and growth in zirconium and its alloys.

In the initial stages of the nuclear industry, extensive surveying has revealed the nature of radiation-induced dislocation [11-26]. The dislocation loop is experimentally characterized by geometry, Burgers vector, size, and the proportion of vacancy and interstitial loops. However, until now, compiled experimental and theoretical results have not been presented for radiation-induced dislocation and growth phenomena. Therefore, the aim of this study is to understand the fundamental behavior of dislocation and growth of zircaloy, which is one of the most important zirconium alloys in the historical viewpoint of nuclear reactor application, under irradiation conditions and quantitatively analyzed radiation-induced dislocation and its growth in single crystals and polycrystals of zirconium and zircaloy.

2. RADIATION-INDUCED DISLOCATION

Before material is subjected to neutron irradiation, a certain amount of defects already exist, but many more form upon neutron bombardment. Especially in the case of zirconium and its alloys, which have low stacking fault energies, defects are two dimensional and are known as the dislocation loop and the

By the end of the 1970s, numerous researchers had established typical dislocation characteristics in zirconium and zircaloy [11-26]. A dislocation loop is experimentally characterized by geometry, Burgers vector, size, and the proportion of vacancy and interstitial loops. Experimental results showed that all zirconium defects have the same Burgers vector

and the same habit plane on

[11-12]. Temperature effects on dislocation consist of a decreased density and an increased loop size with a temperature increase. Vacancy loop geometry shows a circular shape with a loop size less than 40 nm, but an elliptical shape with a loop size larger than 40 nm. Interstitial cases tend to show a circular shape regardless of temperature.

Northwood

situated in the prismatic planes.

The influence of temperature on zircaloy also shows the same tendencies as zirconium metal in Northwood’s papers, in that the loop density decreases and the loop size increases with increasing temperature. At 623 K, observed dislocations indicating a mean loop diameter between 8 nm and 10 nm and a loop density between 8.0×1021 n/m2 and 5.0×1022 n/m2, but a higher temperature at 673 K shows a mean loop diameter between 16 nm and 23 nm and a loop density between 4.0×1021 n/m2 and 2.0×1022 n/m2. Above 873 K, no radiation damage was observed [16]. At a higher temperature, the irradiation-induced defects are generally annealed out by relaxation because the internal energy in the material is sufficiently high for atoms to move in a normal lattice site.

The proportion of vacancy and interstitial loops was also examined. At 623 K, the ratio of interstitial and vacancy was balanced at 50%; however, by increasing the temperature (up to 673 K), the vacancy loop proportion increased to about 70%. At higher temperatures (>673 K), the proportion of vacancy loops drops to 20%. For lower temperatures (<573 K), the interstitial loop type is dominant.

The effect of fluence is also conserved at a constant temperature; before

Parameters such as dislocation size and density show a tendency of being proportional or inversely proportional based on conditions (temperature and fluence). However, dislocation also shows common characteristics in that all loops have a Burgers vector

which is parallel to the a-axis and habit on the prismatic planes

Moreover, these types of loops are observed to coexist between vacancy and interstitial types in the prism plane.

Historically,

along the c-axis. The loop type was observed to be only vacancy [20].

Holt and Gilbert [21] used high fluence (8.6×1025 n/ m2) in order to reveal

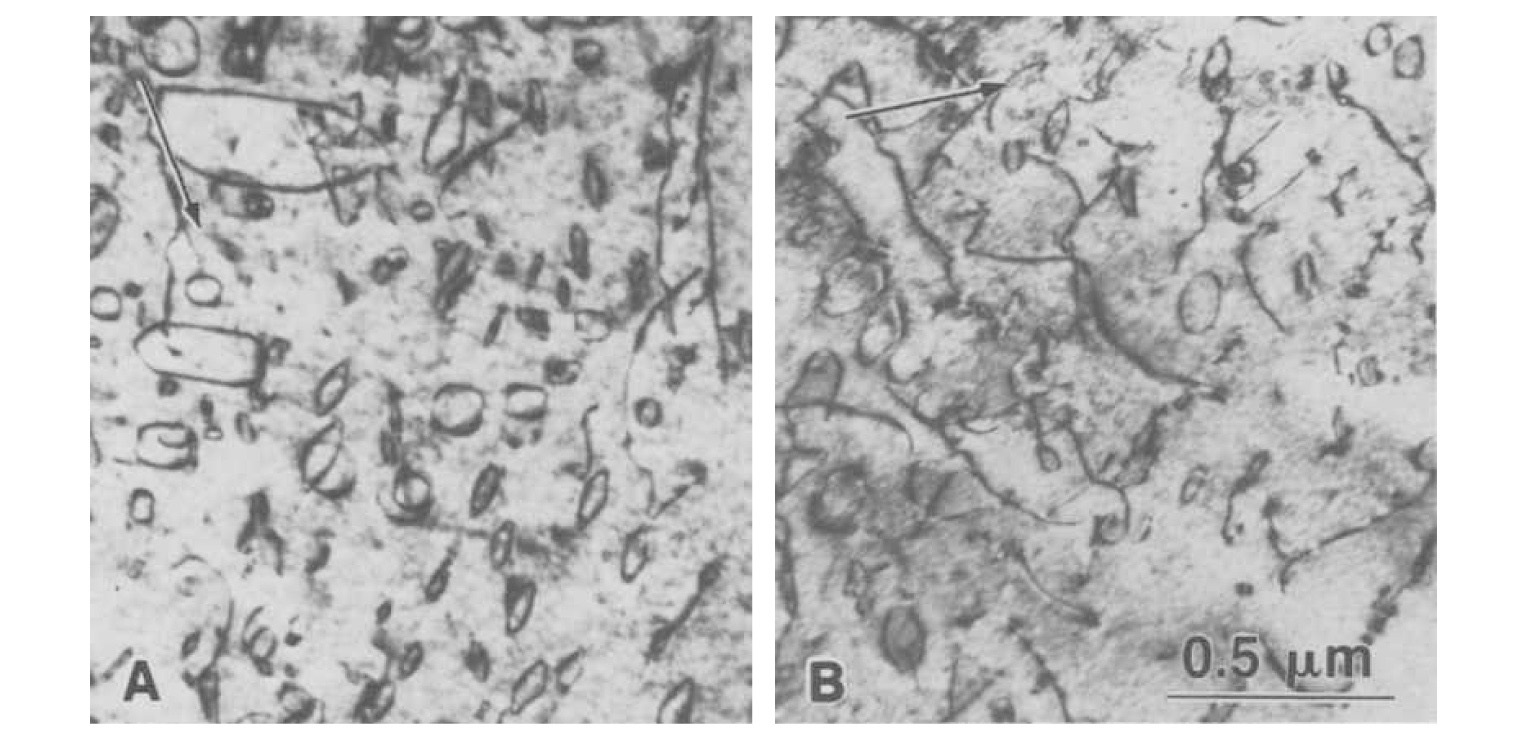

[Fig. 1.] Type Dislocation in an Annealed Zirconium Microstructure at 700 K: (a) 1.1×1025 n/m2; (b) 1.5×1025 n/m2. Diffracting Vectors are g = 10?1 [24].

special characteristic. High density

The correlation between

Griffiths [24-25] reviewed microstructure evolution in zirconium and its alloys and also compiled

Radiation-induced growth indicates anisotropic dimensional change, i.e. expansion in the a-direction and contraction in the c-direction. Contrasted to swelling and creep, the growth phenomenon is not accompanied by increasing volume and application of stress. Nevertheless, even in the absence of stress and volume expansion, growth is a complex phenomenon itself because it is dependent on many fundamental parameters. Therefore, we had to consider many material parameters and metallurgical conditions (texture, grain size, dislocation density, alloy component, heat treatment, degree of cold work) and experimental conditions (fluence and temperature).

To recognize the importance of these parameter effects on growth, some important experiments were completed. To discern the sink effects (grain boundary and network dislocation induced by cold work) on the growth mechanism, the researchers performed single crystal growth

experiments. After these data were analyzed, polycrystalline and zircaloy were also researched systemically.

3.1 Radiation-induced Growth in Single Crystals

Carpenter reviewed single crystal zirconium growth behavior [5-6] by a Northern Research Laboratories (NRL) program as underlying the study of radiation-induced growth in zirconium and its alloys. Fig. 3 shows Carpenter’s growth strain results at 553 K and a fluence up to 7×1025 n/m2.

Zirconium metal could be divided into two large groups based on the manufacturing process, iodide- and zone? refined. In the case of the iodide growth strain, results show three regions. First, the transient stage is observed to elongate rapidly along the a-axis, showing saturation growth strains are approximately 10-4 at fluences below 2.5×1025 n/m2. Growth remains in the stationary stage until a fluence of 3×1025 n/m2. After the stationary stage growth breakaway, accelerated growth is observed. At a fluence of 7×1025 n/m2, the growth strain reaches 5.25×10-4.

In the case of zone-refined zirconium, the transient stage region is larger than that of iodide and increases almost linearly at a rate of 4.5×10-30 m2/n up to 1.5×10-4 growth at fluence up to 1.5×1025 n/m2. Reaching a strain of 3.25×10-4 at ~ 5.9×1025 m2/n. However, in the stationary and breakaway stages, growth strains shown are hard to distinguish from iodide-refined zirconium. In both cases of iodideand zone-refined zirconium, the c-axis growth could not be identified in this fluence range.

3.2 Radiation-induced Growth in Polycrystals

In order to understand the element effect on the zircaloy growth mechanism, another pioneering group using polycrystalline zirconium specimens also researched growth phenomena in an NRL program. Polycrystalline growth

behavior research is meaningful because it could reveal the growth dependence of an alloy’s individual elements. Rogerson’s growth strain results for iodide zirconium in the temperature range of 352 to 553 K are illustrated in Figs. 4 and 5 [7].

Specimens tested had different grain sizes: 5 μm, 40 μm, and 75 μm. The intent was to study the growth dependency on grain size and different textures. Annealed, polycrystalline, iodide-refined zirconium shows a linear increase in a texture-dependent growth strain until 6×1024 n/m2 at 353 K. In these figures, texture is expressed by

3.3 Radiation-induced Growth in Zircaloy-2 and Zircaloy-4

Before high fluence facilities were built, zircaloy was researched with low fluence for practical applications. Adamson is a pioneer in the area of zircaloy growth. Adamson adopted traditional approaches making use of three key parameters: material properties, fluence, and temperature to assess growth phenomena [8]. Experiments were completed at a reactor temperature of 555 K and a fluence up to 3.5×1025 n/m2. To observe growth dependency on the cold work parameter, the experiment was controlled such that specimens tested had similar texture and irradiation conditions. In the case of annealed zircaloy-4, the growth strain saturated at fluence near 1.0×1025 n/m2, whilst 78% cold work zircaloy-4 showed an almost linear increase with fluence, as shown in Fig. 6. However, at fluence below about 0.2×1025 n/m2, the effect of cold work parameters on growth dependency was negligible.

Fig. 7 represents the temperature and texture parameters’ influence on radiation growth in annealed zirconium. For an f-factor around 0.1, the growth strain is shown to be increasing with fluence up to 1.0×1025 n/m2, but after the linear growth range, strain shows a tendency to saturate at 523 K. In the case of an f-factor around 0.33, a relatively low growth strain is shown, as compared with other ffactor values. This is likely because texture is randomly distributed. Growth strain dependency on f-factors is observed more clearly at lower temperatures (<339 K). For fluence below about 0.5×1024 n/m2, the growth rate dependency on the f-factor is not affected by temperature.

In the case of high fluence regions, zircaloy growth behavior was also analyzed, and the research confirmed the influences of cold work and temperature dependency on growth. Annealed zircaloy-2 was used as a control group [9-10]. Fig. 8 shows the growth strain at 353 and 553 K and fluences up to 1.7×1027 n/m2. At low temperatures, zircaoy-2 is rapidly saturated at a low fluence of 0.5×1024 n/m2,

[Fig. 8.] Irradiation Growth Strain at 353 and 553 K in Annealed and 25% Cold-worked Zircaloy-2 [7].

whilst at 553 K, initial transient growth was relatively slow. However, after the transient stage, high temperatures show much greater growth strain. The growth behavior of 25% cold work zircaloy shows a breakaway range and higher growth strain than annealed zircaloy-2. Annealed zircaloy at 353 K shows re-saturation at a fluence of 4×1025 n/m2.

4. THE PREDICTION MODELS OF RADIATIONINDUCED GROWTH

As seen in the previous section, radiation-induced growth experiments have been extensively conducted. To consider the growth dependency on various parameters, Rogerson [7] extensively reviewed many zirconium types, including single crystal, polycrystalline, and zircaloy-2 growth behavior, and Fideleris [17,27] analyzed zircaloy growth behavior in more detail by using parameters such as grain size, texture, cold work, temperature, fluence, and alloy elements. This work confirmed not only the fundamental parameter effect on growth but also built the foundation of an experimental and theoretical formula.

4.1 Experimental Growth Analysis

Radiation-induced growth behavior was first observed and analyzed by Beckly, who estimated growth quantitatively [28]. He established that growth behavior is in proportion to the anisotropy factor,

εd ∝ 1 - 3Fd = Gd

Where

εd ∝ 1 - Fd - 2Ad = Gd

where

Where

4.2 Theoretical Growth Analysis

Simultaneous to experimental work, theoretical approaches have been taken to explain radiation growth. In contrast with the experimental approach, the theoretical approach had to consider fundamental parameters such as atomic volume, vacancy relaxation volume, binding energy, formation energy, diffusion coefficient, alloy components, etc. Nevertheless, significant progress has been made.

Radiation damage theory (RDT) is dealing with parameters related to radiation-induced damage quantity and is focused on the explanation of all kinds of radiation-induced phenomena. RDT was developed in the 1940s, when the first fission reactor was built. Many models were generated to understand radiation-induced phenomena, such as hardening, creep, and swelling [32-33]. However, until the early 1990’s, RDT was based on an incorrect framework that only point defects are generated by neutron damage. Many disagreements between RDT and experimental observation had been shown [34-35].

These problems were solved by adopting the concept of radiation damage morphologies [36-38]. In the 1990s, Woo and Singh modified the incorrect framework by adopting the cascade concept that radiation damage produced not only point defects but also clusters [39-40]. They called this modified model the production bias model (PBM). In this framework, self-interstitial atom clusters show immobile cluster characteristics. After adopting PBM, RDT was significantly improved and successfully explained radiation-induced phenomena. For example, the old growth prediction model [14,40] could not explain that growth displays a sharp increase in the high temperature region [21]. However, after the adoption of PBM, the temperature dependence could be explained [42].

Most recently, Golubov et al. [43] developed a growth prediction model which was based on the recently updated RDT, including PBM. He adopted RDT to explain single crystal radiation growth, and by using a very simplified framework of his own, showed theoretically the volume conservation phenomenon and cold work effect on growth. Calculated results agreed well with experimental results. Regrettably, further work has yet to be completed.

In line with the recent trend, Christen made a prediction model of single crystals by adopting cluster dynamic modeling without the PBM framework [44-45]. However, he showed that theoretical modeling from fundamental parameters agreed well with experimental results [46].

Radiation-induced dislocation and its growth have been examined and reviewed. In the case of zirconium and zircaloy, microstructure changes are eventually translated to and

Due to design or operating conditions, zircaloy can be located in various radiation conditions. Reactors could be divided into two large groups, such as research reactors and commercial reactors. Commercial reactors are operated with relatively high temperatures and low fluence conditions compared with research reactors.

Therefore, different approaches are needed to analyze a safety assessment of the radiation-induced growth phenomena between commercial reactors and research reactors. In the case of research reactors, defect diffusion frequency in the material is lower than in commercial reactors because the coolant is at a lower temperature. Therefore, if the material is subjected to the same fluence, growth in a research reactor will be suppressed when compared to commercial reactors. However, research reactors receive a higher fluence than commercial reactors in the same period. Considering all conditions, growth phenomena is a much more important issue in the research reactor.

Typically, dislocation and growth are researched together and growth phenomena are categorized systematically by single crystal, polycrystalline, and zircaloy growth [47-48]. However, dislocation and growth are not organized systematically with theoretical work because growth prediction models have not been wholly established until today. Therefore it is very important to compare theoretical models and experimental results to complement growth prediction modeling.

In the case of single crystal zirconium, much more theoretical work has been successfully completed as compared to polycrystalline zirconium because the single crystal model can be simplified by several assumptions [46]. Christien [45] used a clustering dynamics model to build a growth prediction model by assuming that all cluster defects are immobile. The result was very successful in that the calculated growth result well suited experimental growth. His paper also shows that only interstitial dislocation can survive in the prism plane.

In contrast to Christien’s framework, Gloubov used the assumption that interstitial clusters are mobile. And, in his work, the PBM concept was adopted in the growth modeling. Therefore, the interstitial cluster could be considered the most important parameter to build a growth model [43]. Although contrary to assumption, the result from two growth prediction models shows that both works agree well with experiment results.

Therefore, it is very important to compare theoretical modeling and experimental results in order to understand radiation-induced growth phenomena. Unfortunately, however, very limited experimental results exist since the radiation-induced microstructure damage to single crystals has not been extensively studied experimentally. Also, theoretical approaches for polycrystalline and alloy are quite different from that of single crystal, because the problem lies in the complexity of fundamental growth prediction modeling. There is no general or extensive prediction growth model in polycrystalline and alloy, although microstructure experimental results are more numerous than for single crystals. Therefore, both single crystal and polycrystalline need more fundamental research with respect to the development of radiation damage theories.

Radiation-induced growth phenomena depend on many parameters such as texture, temperature, grain size, point defect trapping effect, vacancy mobility, intra-granular effect, and anisotropy diffusion. For example, radiationinduced growth can be controlled by texture control, which can be quantified by Q factor. Q factor is the fraction of the change of outer diameter over the change of the thickness of the cladding resulting from the pilgering manufacturing process. Therefore, modeling which usually begins from fundamental parameters to explain experimental results is challenging, and this study requires a series of steps to achieve the final goal of the explanation of the radiationinduced the growth phenomenon. Despite this, there has been several significant modeling works to explain the micro-scale phenomenon. Especially at a low temperature range, vacancy mobility is one of the most important key parameters to predicting the growth phenomenon, but no certain value has been revealed until now. Moreover, there exists not only dislocation loops, but other defects which form by neutron damage, such as network dislocation and liner dislocation. This merits more significant consideration. As well, primary neutron damage behavior and relaxation such as thermal cascade and intra cascade are not clear. For this research area, multi-scale analysis of all types of defects is needed to create a computer simulation of radiation damage.

Growth mechanisms are triggered from the absence of stress application. This is an opportunity to get clues for interpreting other radiation phenomena such as creep, swelling, hardening, and embrittlement. In particular, in the case of hardening and embrittlement, modeling based on the interaction with extended defect stress fields and defect behavior will advance radiation damage theory. Therefore it is necessary that extensive and intensive research on radiation-induced dislocation, growth, and radiation damage theory be conducted. After this research is established, nuclear power plants could become more reliable in this paradigm.

This review has brought up to date the extensive work on the radiation-induced dislocation and its growth of zirconium and zircaloy. Dislocation formed by neutron irradiation in both zirconium and zircaloy is composed of two types of loops:

in the prism plane in the type of both interstitial and vacancy. Other Burgers vectors are observed to be

in the basal plane in the type of vacancy only.

2. Dislocation shows temperature dependence on size and density parameters.

Radiation-induced growth phenomena in single crystal and polycrystalline of zirconium and zircaloy can be summarized as follows.

1. Single crystal growth is rapid at the beginning and slows down until reaching a low, stationary growth rate at a fluence of up to 5×1025 n/m2. After the stationary stage, growth breakaway or accelerated growth is observed.

2. In the case of polycrystalline, growth tendencies show a similar behavior to single crystals, but a larger growth strain results. It is shown that dislocation and grain boundaries have an important role in growth phenomena as positive effects of growth.

3. Zircaloy-2 and -4 growth behavior is indistinguishable from polycrystalline growth behavior. Transient, stationary, and breakaway growth was observed. In the transient stage, growth has a high dependency on gain size; however, in the stationary stage, grain size has no influence on growth behavior.

Understanding radiation-induced dislocation and growth mechanisms can provide detailed clues for interpreting other radiation-induced phenomena such as creep, swelling, hardening, and embrittlement. And it is very important to correlate theoretical models and experimental results to complement growth prediction modeling. However, it is questionable whether the research on radiation-induced dislocation and growth has been well organized systematically with theoretical work so far based on the current review study. Therefore, it is necessary that extensive and intensive research on radiation-induced phenomena such as dislocation and growth, radiation damage theory, and modeling be conducted together with experimental work.

![<a> Type Dislocation in an Annealed Zirconium Microstructure at 700 K: (a) 1.1×1025 n/m2; (b) 1.5×1025 n/m2. Diffracting Vectors are g = 10?1 [24].](http://oak.go.kr/repository/journal/12390/OJRHBJ_2013_v45n3_385_f001.jpg)

![<c> Type Dislocation in Annealed Zircaloy-4 at 560K: (a) 8.5×1025 n/m2 in BWR, (b) 7×1025 n/m2 in a PHWR. Diffracting Vectors are g = 0002 [24].](http://oak.go.kr/repository/journal/12390/OJRHBJ_2013_v45n3_385_f002.jpg)

![Irradiation Growth Strain at 553K in Annealed Iodide and Zone-refined Zirconium Single Crystals [5].](http://oak.go.kr/repository/journal/12390/OJRHBJ_2013_v45n3_385_f003.jpg)

![Irradiation Growth Strain at 353 K in Annealed Polycrystalline Iodide Zirconium [7].](http://oak.go.kr/repository/journal/12390/OJRHBJ_2013_v45n3_385_f004.jpg)

![Irradiation Growth Strain at 553 K in Annealed Polycrystalline Iodide Zirconium [7].](http://oak.go.kr/repository/journal/12390/OJRHBJ_2013_v45n3_385_f005.jpg)

![Irradiation Growth at 555 K in Cold Worked Zircaloy-4 [8].](http://oak.go.kr/repository/journal/12390/OJRHBJ_2013_v45n3_385_f006.jpg)

![Irradiation Growth Strain in Recrystallized Zircaloy-2 and 4 [8].](http://oak.go.kr/repository/journal/12390/OJRHBJ_2013_v45n3_385_f007.jpg)

![Irradiation Growth Strain at 353 and 553 K in Annealed and 25% Cold-worked Zircaloy-2 [7].](http://oak.go.kr/repository/journal/12390/OJRHBJ_2013_v45n3_385_f008.jpg)