T. W. Noh et al. reported that BLT thin films provide a promising alternative for ferroelectrics random access memory (FRAM) applications by the pulse laser deposition (PLD) method [1]. The merits can be deposited at low temperature (< 650℃) and the films were fatigue free on metal electrodes. In order to improve the electrical properties, several deposition techniques were being tried for the growth of BLT thin films. M.C. Kao et al reported that the films showed improvement of electrical properties using the sol-gel method [2]. The excellent fatigue property up to 1010 cycles by the metal organic deposition (MOD) method was reported [3,4]. A.Z. Simoes et al. reported that orientations mainly contributed to electrical properties using metal organic chemical vapor deposition (MOCVD) [5].

N. Zhong et al. reported the effect of La doping on the improvement of structural and electrical properties using chemical solution deposition (CSD) [6]. In this study, we fabricated BLT thin films by the rf magnetron sputtering method and found the improvement on electrical properties of the films fabricated by the rf magnetron sputtering method with a single stoichiometric target. We confirmed the excellent remnant polarization (Pr) and suggested a good method for BLT thin films fabrication.

BLT thin films with a thickness of 200 nm were deposited on a Pt (150 nm)/Ti (50 nm)/SiO2/Si substrate by rf magnetron sputtering. The as-deposited BLT thin films were annealed at temperatures ranging from 650℃ to 750℃ in oxygen atmosphere for 5 min using rapid thermal annealing (RTA). The crystal structure of the BLT thin films were analyzed using X-ray diffraction (XRD, Mac Science M18XHFSRA, Cu target, 1.54 A, Ni filter). The XRD patterns were recorded at a scan rate of 5° per minute for the crystal structure analysis. The surface morphology of the sputtered BLT thin film was observed using a scanning electron microscope (SEM, JEOL JSM6700F). In order to estimate the dielectric and ferroelectric properties, Pt dot electrodes of 0.3 mm2 in diameter were patterned by the shadow mask sputtering process. The leakage current behavior of BLT capacitors was obtained using a Keithley 617 programmable electrometer. The dielectric properties of the BLT capacitors were measured by a multi-frequency LCR meter (Boonton 7200). The ferroelectric polarization versus the electric field (P-E) hysteresis loops and fatigue properties of the fabricated BLT capacitors were measured using an RT66A ferroelectric tester (Radiant Technologies Inc) in the virtual ground mode.

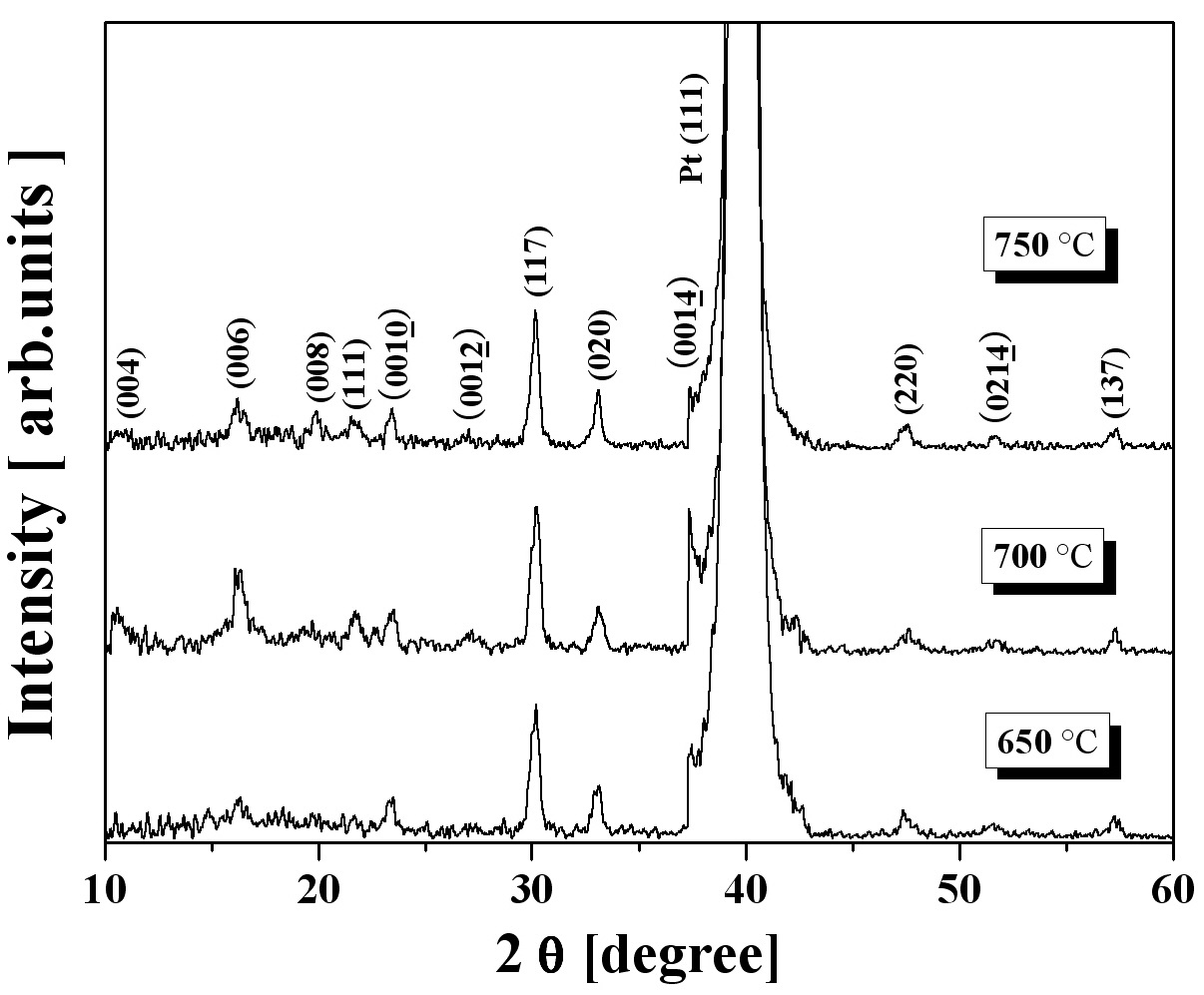

Figure 1 shows the X-ray patterns for BLT thin films deposited on the Pt/Ti electrode annealed by RTA at various temperatures ranging from 650℃ to 750℃. BLT thin films annealed at 700℃ had the strongest (006) peak intensity in the XRD pattern of BLT thin films. With further increase in annealing temperature, (117) peaks became increasingly sharp and increased for temperatures from 600℃ to 700℃ and decreased at 750℃. The Lotgering degree of a-axis and c-axis orientation was evaluated according to the following equation, respectively [7]:

where I006 and I117 are the measured XRD peak intensities of (006) and (117), respectively. As the result of Lotgering evaluation, the degree of a-axis orientation for 650℃, 700℃ and 750℃ are estimated to be 77.3%, 57.7% and 54.7%, respectively. These results indicate that the BLT thin films annealed at 650℃ have an enhanced a-axis orientation. The c-axis orientation growth of BLT thin films is mainly determined by the interfacial energy state of BLT thin films and the substrate. The interfacial energy is related to the atomic plane density in the interface between the BLT thin films and substrate [6]. The degree of c-axis orientation for 650℃, 700℃ and 750℃ are estimated to be 22.6%, 44.3% and 45.2%, respectively. It is found that the c-axis orientation of the BLT thin film above 700℃ has the highest atomic plane density and the lowest interracial energy.

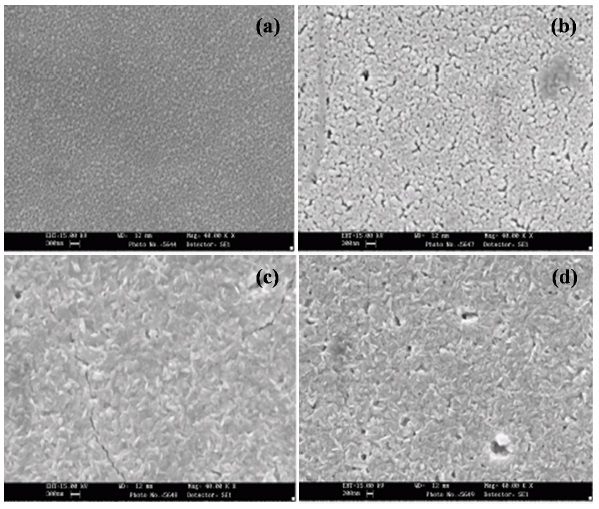

Figure 2 presents the SEM surface micrographs of the sputtered BLT thin films after 5 min RTA annealing with different temperatures. The surface micrograph is shown to be highly sensitive to the RTA annealing temperature. As-grown BLT thin film in Fig. 2 (a) shows the fine-grained thin film due to the poor crystallization. As the annealing temperature increased from 650℃ to 750℃, the crystallized fraction of the films increased as well. Also, the average grain size of the BLT thin films increased with annealing temperature. With increasing RTA temperature at 700℃, we observed the plate-like grain morphology and uniform grain sizes. These results indicate that the ferroelectric properties of the BLT thin films can be improved by increasing the annealing temperature [2].

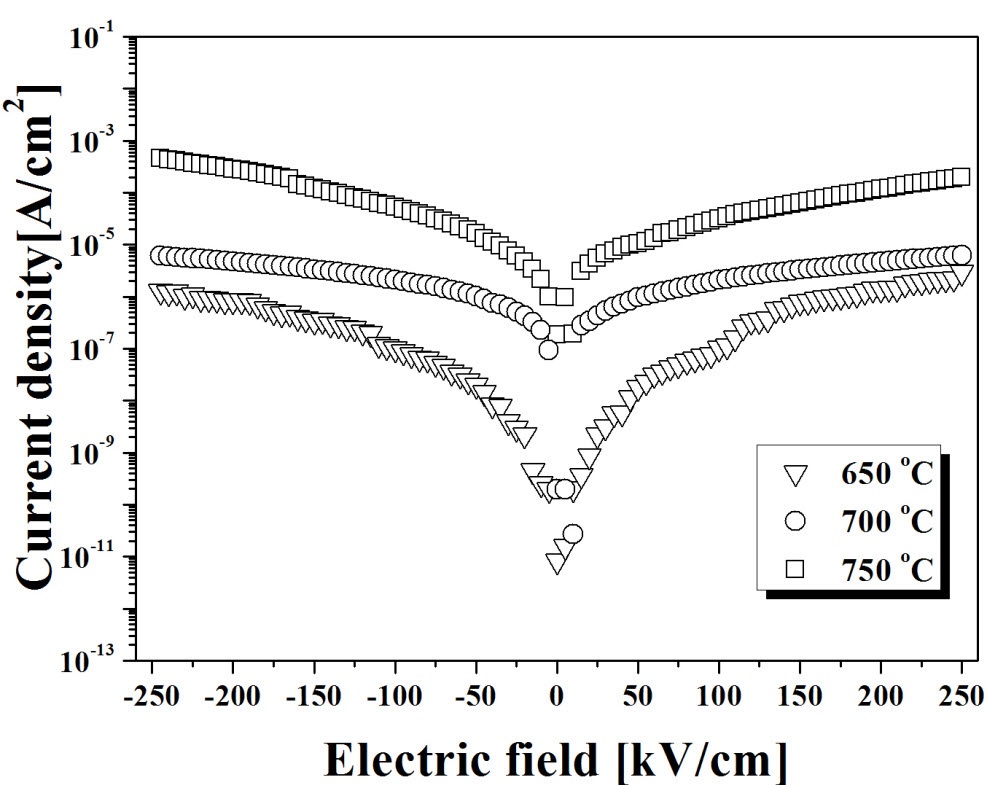

The leakage current density of the BLT thin films was studied at different temperatures. The leakage current against electric field curves of the BLT capacitors was shown in Fig. 3. The leakage current density of the annealed BLT thin films at 650℃, 700℃ and 750℃ were measured with 3.56 × 10-7 A/cm2, 2.62 × 10-6 A/cm2 and 4.83 × 10-5 A/cm2 at the 125 kV/cm, respectively.

The leakage current of BLT thin films at 650℃ exhibit asymmetry. When the annealing temperature was increased, the leakage current densities were increased. The increase of leakage current density is due to several defects such as bismuth vacancies and oxygen vacancies [8].

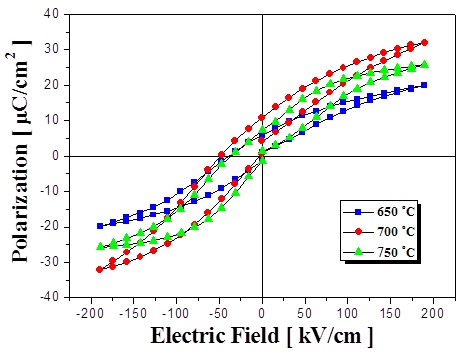

Figure 4 shows the P-E hysteresis curves of BLT thin films with various temperatures. As is known, the dielectric and ferroelectric properties are strongly influenced by grain size, porosity, film thickness and growth conditions of BLT thin films. In general, the dielectric constant and remnant polarization increases while the coercive field decreases for thin films with large grain size. The remnant polarization values (Pr) of the samples post-annealed at 650℃, 700℃ and 750℃ were measured with 5.42 μC/cm2, 10.92 μC/cm2

and 7.76 μC/cm2, respectively. The coercive field (Ec) of the BLT films increases with the increase of annealing temperature from 650℃ to 700℃, and then decreases with the increase of annealing temperature from 700℃ to 750℃. The annealed BLT thin film at 650℃ demonstrates a coercive field of 56 kV/cm, while a coercive field decreases to 46 kV/cm in the annealed BLT thin film at 700℃. These results indicate that domains can switch more easily in BLT thin films annealed at temperatures above 700℃. It can be described in terms of the effect of the grain size and the stress induced by the substrate.

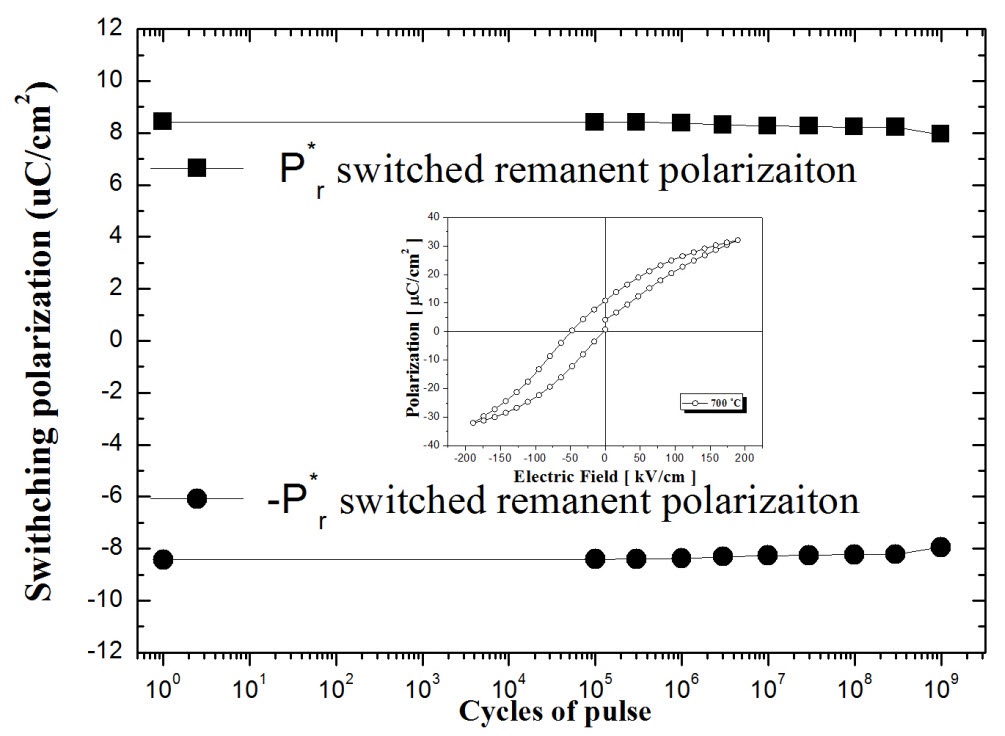

The fatigue property is an important parameter to characterize the ferroelectric random access memory. The fatigue property of the ferroelectric thin films is characterized by the loss of switchable polarization with repeated switching cycles. The loss of switchable polarization constrains the life time of the ferroelectric memory. The loss of switchable polarization reduces the ability to differentiate the two remanent polarizations until they become indistinguishable [9].

Ferroelectric fatigue characteristic of BLT thin films postannealed at 700℃ was illustrated in Fig. 5. There were no significant losses in remnant polarization up to 1.2 × 109 cycles and the measured results were in agreement with those of other fabrication methods.

In this study, BLT thin films were successfully fabricated on Pt/Ti/SiO2/Si by the rf magnetron sputtering method. It was observed that sputtered BLT thin films showed lower leakage current and higher ferroelectric properties compared to other fabrication methods. The thin films showed to be fatigue free, maintaining the value of the remnant polarization (10.92 μC/ cm2) up to 1.2 × 109 cycles. From these results, we suggested a method for the application of next-generation memory devices by rf magnetron sputtering.