A fuel cell is an electrochemical device that convert the chemical energy directly in to electrical energy, without an often messy and relatively inefficient combustion step. Due to its potential to reduce the environmental impact and geopolitical consequence of the use of fossil fuels, it emerged as tantalizing alternatives to combustion engines. Many types of fuel cells have been demonstrated so far, polymer electrolyte membrane (PEM) fuel cell is considered viable for personal transportation application due to its high power density, low operating temperature, quick start-up time and virtual zero emissions [1,2]. A typical PEM fuel cell consists of an anode backing, membrane electrode assembly and cathode backing sandwiched between two bipolar plates. Within the fuel cell stack, bipolar plate connects the cells physically, electrically and thermally. The commercialization of PEM fuel cell for automotive and stationary applications is required to reduce cost, weight and volume of fuel cell stack components. The major cost and weight of fuel cell stack come from bipolar plate, cost accounts 45-50% and weight 70% of fuel cell stack [3]. The most commonly used bipolar plates are made from graphite and metal. The advantages of graphite plate are excellent corrosion resistance, low bulk density and electrical resistivity. On the other hand, the disadvantages are difficulties in machining, and its brittleness [4-6].

There are plenty of studies reported in literature to overcome the disadvantages of graphite based bipolar plates and developed graphite ?polymer composite bipolar plates with graphite powder, in these studies systematic approach is not adapted to develop composite bipolar plates. Therefore, in this study authors have tried to develop low density composite bipolar plate by using different particle size of natural graphite (NG) or expanded graphite (EG) with combination of other fillers i.e., carbon black and chopped carbon fibers, to achieve the desired properties as per US Department of Energy (DOE) target (in-plane conductivity >100 S/ cm, through-plane conductivity >20 S/cm, flexural strength >25 MPa, thermal conductivity >20 W/m.K) of bipolar plate.

In this study, two types of conducting fillers were used as major reinforcements, i.e., NG of different particle sizes and EG synthesized from different particle sizes of NG [7]. Carbon black and PAN-based T-300 carbon fiber in a chopped form (diameter 7 μm, 2-3 mm in length) were also used as additional filler materials. Novolac-type phenolic resin-9624 was used as matrix binder. It was procured from Pheno Organic Limited, New Delhi, India.

Composite bipolar plates were developed from different particle sizes of NG and EG with Novolac phenolic resin 60 mm × 20 mm × 4 mm in size by a compression molding technique [8]. In this study, three types of composite series were prepared. In the first series, composite plates were developed from different particle sizes of NG with a fixed content of constituent fillers of carbon black (10 wt%), carbon fiber polyacrylonitrile-based T-300 (5 wt%) and Novolac phenolic (30 wt%) resin as a polymer matrix. In another series, EG-based composite plates were developed from different particle sizes of EG, EG content at 50 wt% with an addition of 10 wt% NG of the same size, and polymeric phenolic resin 40 at wt% in all samples. The surface area of the EG is high as compared to the NG; thus, a higher amount of polymeric resin was used. In another set of experiments, EG composites were developed from EG with a particle size of 150 μm with different percentages of chopped carbon fibers and fiber content varying from 1 to 5 wt%. All of the composite plates were coded with the particle sizes shown in Table 1. All composite plates were characterized for their electrical conductivity (EC), shore hardness, bending strength, air permeability and I-V performance, as reported in earlier studies [9]. The thermal conductivity levels of the composite plates were measured by a laser flash technique with a xenon laser as the source in a Thermo Flash Line 2003 instrument (Anter Corporation, Pittsburgh, PA, USA).

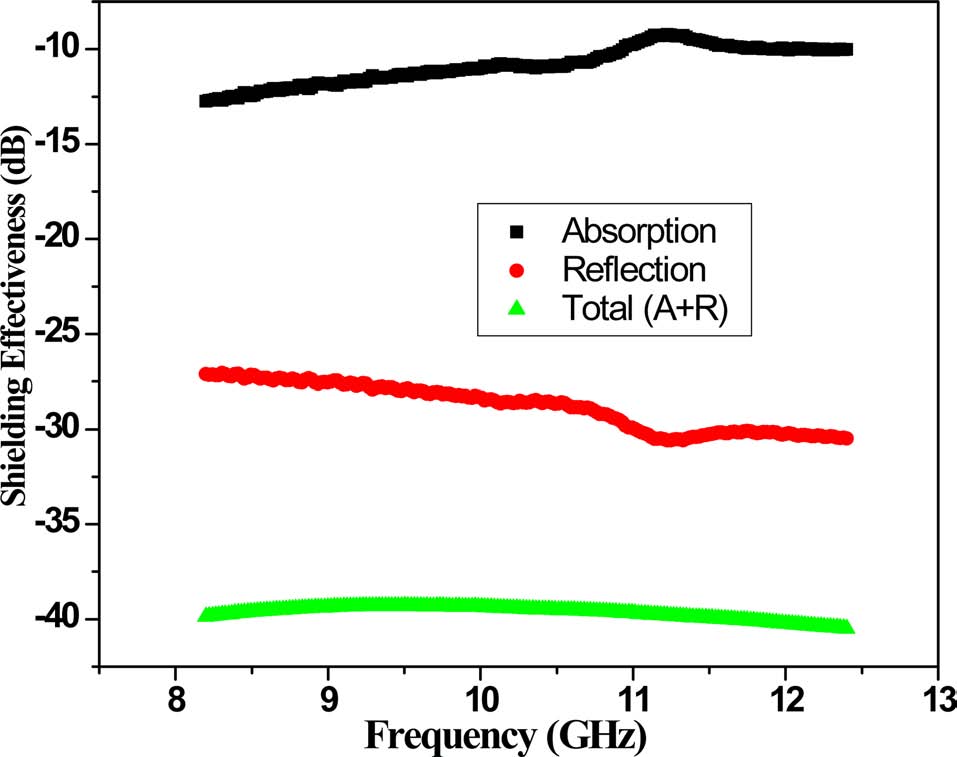

The electromagnetic interference (EMI) shielding effectiveness was measured in terms of the waveguide using a vector network analyzer (VNA, E8263B, Agilent Technologies). Rectangular samples 2.70-2.75 mm thick were placed inside the cavity of a sample holder which matches the internal dimensions of the x-band (8.2-12.4 GHz) wave guide. The sample holder was placed between the flanges of the waveguide connected between the two ports of the VNA.

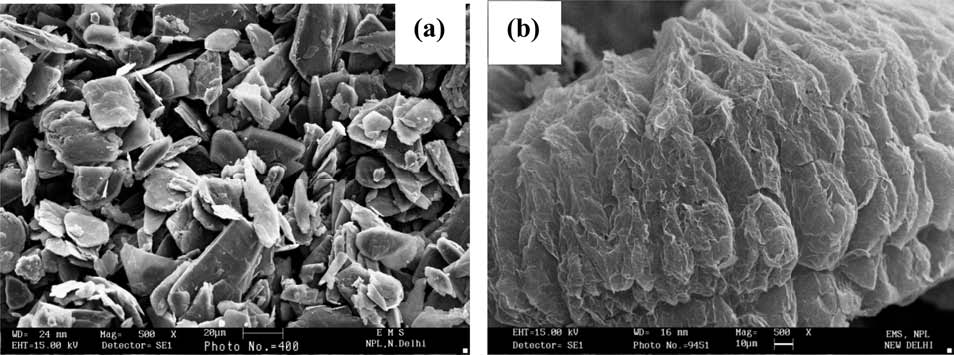

Fig. 1 shows scanning electron microscope (SEM) micrographs of the NG and EG. Fig. 1a shows NG particles of different sizes and shapes. Fig. 1b shows a SEM micrograph of an EG

particle with a vermiform shape and a loose and porous structure [7] and with a high surface area.

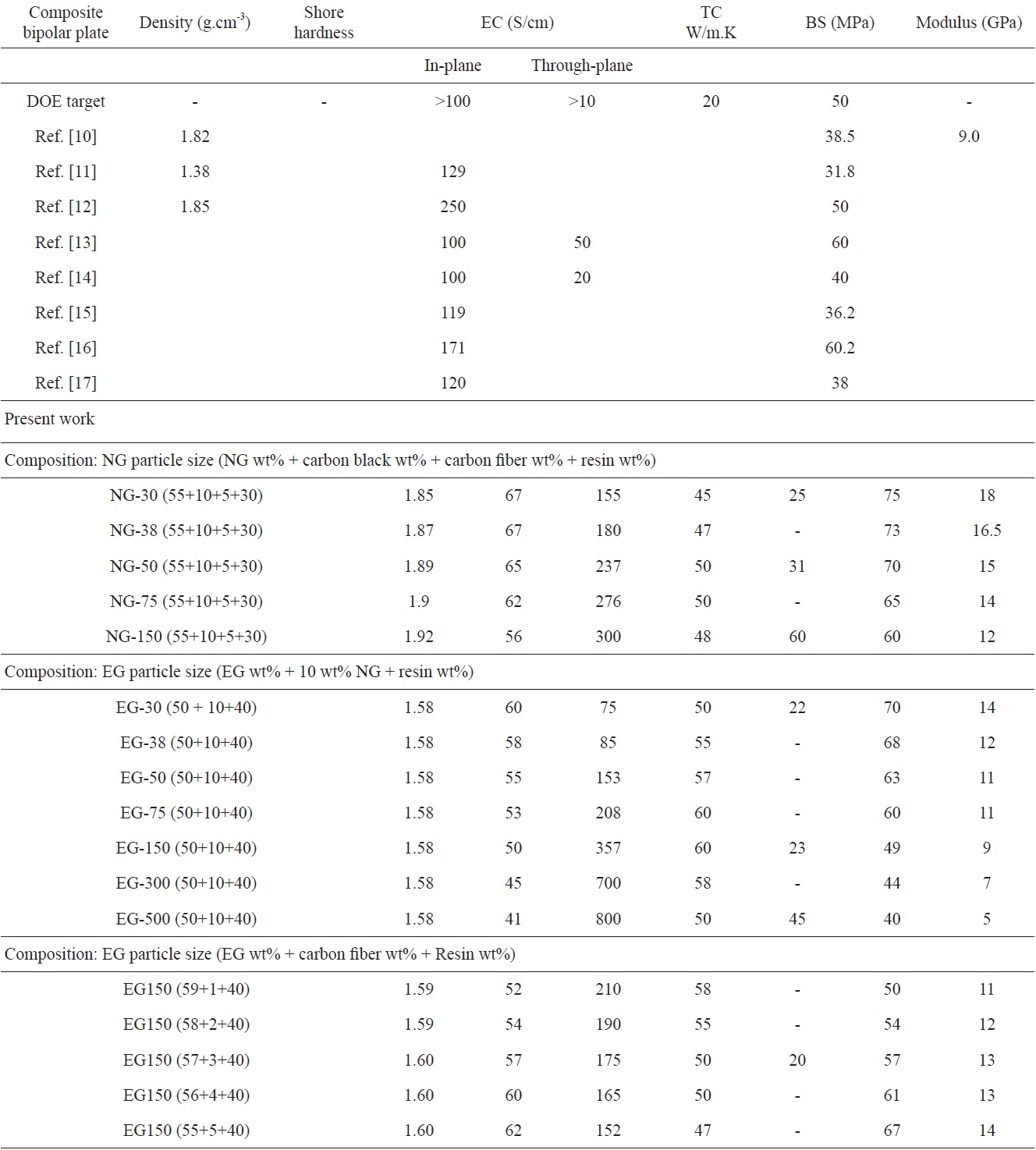

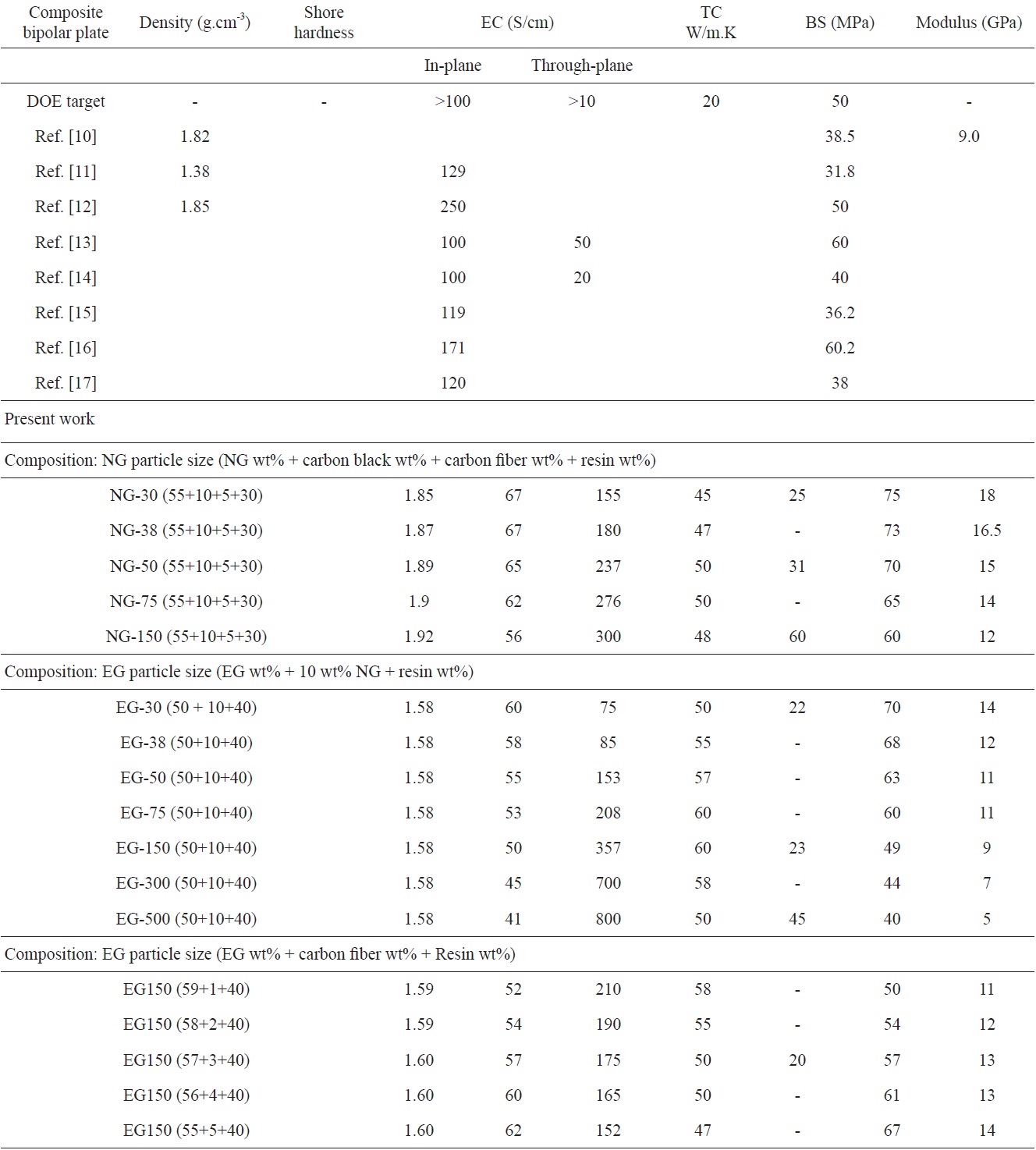

For use in a PEM fuel cell stack, a bipolar plate should have a low density, high EC and adequate mechanical properties. Table 1 shows the properties of a commercially available bipolar plate [10-17] compared to the plate developed in the present work. These previously reported bipolar plates do not satisfy all of the properties necessary for a bipolar plate.

Table 1 shows the mechanical and electrical properties of different types of bipolar plates made from different sizes of NG and EG particles in the present study. The bulk density of the NG-based plates varies from 1.85 to 1.92 g. cm-3, while the density of the EG-based composite plate is in the range of 1.57-1.61 g.cm-3. It was found that with an increase in the particle size of the NG, the bulk density of the composite plate increases. This increase is in accordance with particle size gradation theory and is in fair agreement with accumulation theory. With an increase in the particle size of graphite, larger particles are not closely accommodated in the same volume as compared to smaller particles. This leads to fewer contact boundaries in the case of a composite based on larger particles in the same volume as compared to composite plates based on a smaller particle size. As a result, a lower shore hardness was noted for the composite plates based on larger particles as compared to those based on smaller particles. On the other hand, the shore hardness of the EG-based plates is 10-15 % less than that of the NG-based plates. A high level of in-plane EC is an essential feature of proton exchange membrane fuel cell (PEMFC) bipolar plates. A percolating conducting path is necessary to achieve a high EC [18]. The EC (in-plane) of composite plate increases with an increase in the NG particle size (Table 1). In a composite based on a larger particle size, the conductivity is controlled by the number of contact boundaries between NG particles; larger NG particles lead to fewer contact boundaries. As a result, a higher percolating conducting path for electrons exists. On the other hand, the value of the through-plane conductivity becomes quite less compared to the in-plane conductivity, with maximum values of ~50 S/cm for a composite based on a particle size of 50 to 75 microns. However, in the case of an EG-based composite plate, the trend of the conductivity value is identical as that of NG-based plates. However, the ultimate value of the in plane EC is higher (800 S/cm) for a composite plate based on larger particles (500 μm). Nonetheless, the through-plane EC is 50 S/ cm for composite plates based on smaller particles and 60 S/cm for composite plates based on larger particles. Upon an addition of carbon fibers to EG-based composite plates, both the in-plane and through-plane EC deceases due to the much lower conductivity

[Table 1.] Electrical and mechanical properties of NG- and EG-based composite bipolar plates

Electrical and mechanical properties of NG- and EG-based composite bipolar plates

of carbon fibers as compared to EG. This clearly shows that the smaller particles are oriented in all three directions as compared to larger particles, which are preferably oriented in the x-y direction due to their size.

In addition, the higher value of the through-plane EC of the G-based plate is due to the lower modulus (comparatively more flexible than an NG plate), which can help to reduce the contact resistance.

The thermal conductivity is also a requisite property of a bipolar plate for heat dissipation during the functioning of the fuel cell stack when it is operated above a temperature of 70℃. The thermal conductivity values of composite plates with larger and

smaller NG particles are 65 and 26W.m-1K-1, respectively, while the EG is 45 and 22 w/m.K for plates based on larger and smaller particles, respectively (Table 1). The higher value of conductivity is due to the fewer contact boundaries in the plate based on a particle size of 300 μm as compared a plate based on a particle size of 30 μm. The number of contact boundaries is much higher in plates based on smaller particles, and these contact boundaries restrict the conduction of heat.

With an increase in the NG particle size, both the bending strength and modulus of the composite plate decreases. The bending strength of a composite plate based on a particle size of 30 μm made of NG, carbon black, chopped fiber and polymeric resin is 75 MPa. In our earlier studies, it was found that a NG-resin composite plate made with 100 μm particles results in a bending strength of 30- 35 MPa [19]. Thus, the higher strength value is due to the strength imparted from the high-strength T-300 carbon fibers. Moreover, the accommodation of smaller carbon black particles between the NG particles increases the number of contact boundaries within the same composite volume. On the other hand, the bending strength of an EG-based composite plate is lower as compared to that of a NGbased plates, and with an increase in the particle size, the bending strength decreases, but these values satisfy the DOE target. Upon an addition of carbon fiber to a composite based on a 150 μm particle size, the strength of bipolar plates increases with an increase in the fiber content. The increase in the strength is due to the fiber strength imparted by the EG-based composite plate.

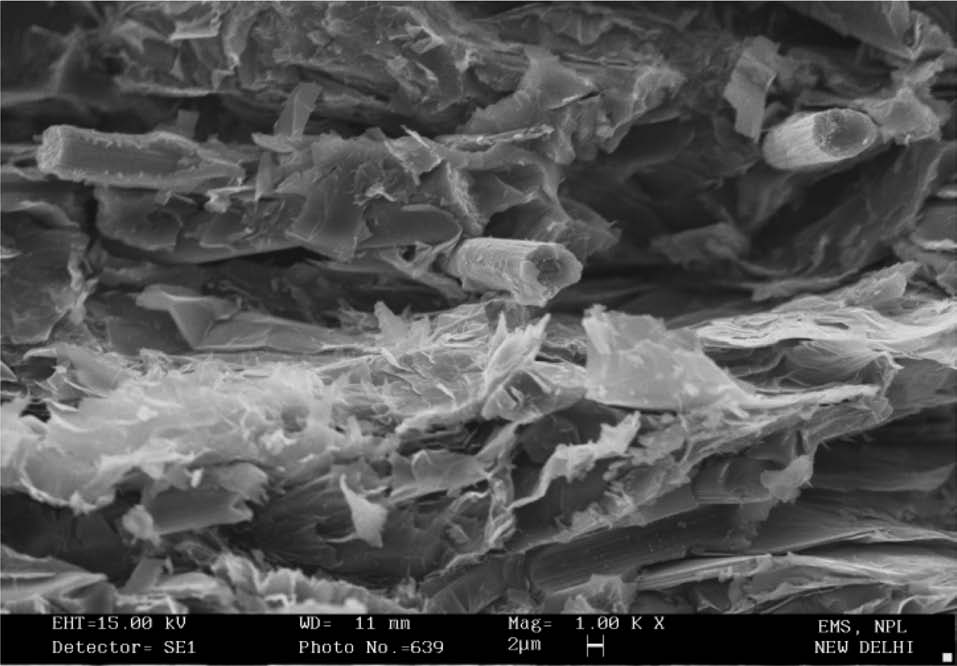

Fig. 2 shows a SEM micrograph of carbon fiber incorporated in an EG-based composite plate. The individual fibers are dispersed between the EG particles. This helps to improve the load-bearing capacity of composite plates.

The thermal stability of both types of bipolar plates (NG- and EG-based) was measured by a thermogravimetric analysis in an air environment, showing that all of the plates are thermally stable at temperatures above 200℃. A gas permeability test was also performed on all of the bipolar plate samples. It was found that all of the NG- and EG-based plates are impermeable to air, even at a pressure of 0.86 MPa (8 Kg.cm-2).

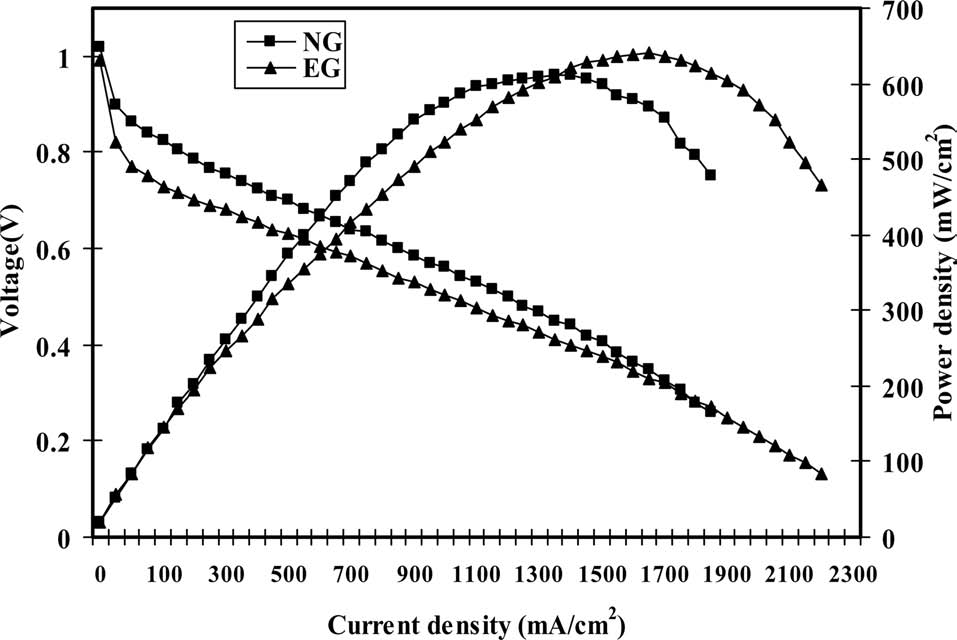

Fig. 3 shows a comparison of the I-V performance levels of NG- and EG-based composite bipolar plates. The NG-based plate provides a maximum power density of 600 mW.cm-2 for a current density 1400 mA.cm-2. However, the EG-based composite

plate under identical conditions results in a power density that exceeds 600 mW.cm-2 for a current density 1600 mA.cm-2.

The I-V performance of a bipolar plate was measured three consecutive times in a unit fuel cell stack. It was found that there was little variation in the voltage and current density values during the first run and last run. Thus, the combination of a low density (1.55 g.cm-3) and a high EC for an EG-based bipolar plate can ultimately reduce the weight and volume of a fuel cell stack without compromising the performance.

Another application of a composite bipolar plate is as an EMI shielding material for electronic equipment to protect the equipment from electromagnetic radiation.

Fig. 4 shows the EMI shielding effectiveness of an EG-based composite bipolar plate with 30 % EG. It provides electromagnetic shielding effectiveness of 40 dB in the x-band frequency region (8-12.4 GHz). The shielding effectiveness is mainly dominated by reflection (27 dB) due to the EC of the bipolar plates. Increasing the EG content further increases the shielding effectiveness to 65 dB with an EG content of 50%. This shows that these bipolar plates can be utilized as EMI shielding materials to protect electronic equipment.

It was observed that the particle size of a reinforcement material significantly influences the mechanical and electrical properties of composite bipolar plates. EG-based composite bipolar plates provide the desired mechanical and electrical properties as per the DOE targets with a bulk density of 1.55 g.cm-3 as compared to 1.85 g.cm-3 for a NG-based plate. These plates are thermally stable at temperatures over 200℃ and impermeable to air up to a pressure 8 Kg.cm-2. An addition of carbon fiber to EG-based composites helps to improve the mechanical properties of a composite plate. However, due to the low conductivity of fiber, a decrease in the value of the conductivity of a composite plate arises, though the result nonetheless satisfies the DOE target for a bipolar plate. The I-V performance of an EG-based plate is slightly better than that of a NG plate, although the bulk density of the EG plate is ~20 % less than that of the NG plate. The modulus of an EG plate is less than that of a NG plate; this is attributed to the fact that EG-based plates are flexible, which can reduce the contact resistance between the components of a fuel cell stack, resulting in an improvement of the performance of the fuel cell. The EG bipolar plate can also be useful as an EMI shielding material.