In the field of piezoelectric ceramics, sodium potassium niobate ceramics with lead-free piezoelectric material have been investigated as alternative material for PZT-based ceramics [1-13]. Lead-free ferroelectric materials with perovskite structure have a general formula of ABO3. In this structure, cations based on their valence states and coordination numbers occupy the A- or Bsites. Na1-yKyNbO3, NKN is a material with perovskite structure, and it exhibits high piezoelectric properties because its structure permits spontaneous polarization to rotate along three orientations. Sodium potassium niobate (NKN) is a solid solution of potassium niobate (KN) a ferroelectric and sodium niobate (NN), with an Na/K ratio of ~50/50. The piezoelectric applications of Na0.5K0.5NbO3 (NKN), ceramics produced by hot-pressing, are better than those produced by sintering in air atmosphere. Hotpressed NKN ceramics have been reported to have a high phase transition temperature (Tc ~ 420℃), good piezoelectric properties (d33 ~ 160 pC/N), and a high planar coupling coefficient (κp~45%) [1-4].

However, NKN ceramics are difficult to obtain using the conventional sintering method because their phase stability is limited to 1,140℃ and they are exposed to moisture. Therefore, attempts have been made to improve the sinterability and piezoelectric properties of KNN through the addition and/or substitution of several cationic elements in the A- or B-sites [10-13]

It is known that (1-x)(Na0.5K0.5)NbO3-xLiNbO3, NKN- LNx ceramics are good, lead-free piezoelectric and ferroelectric ceramics. A morphotropic phase boundary between the orthorhombic phase and the tetragonal phase of NKN-LNx was present when x was approximately 0.05 ~ 0.07 mol of LN [8]. Guo et. al., observed that the Curie temperatures (TC) of NKN- LNx ceramics were in the range of 452 ~ 510℃, according to their LN content, which is at least 100℃ higher than that of Pb(Zr, Ti)O3. For (Na0.5K0.5)NbO3, Tc values were observed at 420℃ and 200℃, which correspond to the cubic-orthorhombic and orthorhombic-tetragonal phase transitions, respectively. Two phase transitions were present at x = 0.04, 0.06 mol, similar to the case for NKN, except that the phase transition temperatures were shifted [9]. Many research efforts thus far have been based on the conditions for which a small amount of LN was added to the NKN composition.

In this study, (1-x)(Na0.5K0.5)NbO3-xLiNbO3, i.e., NKN-LNx (x = 0.0, 0.1, 0.2, 0.3, 0.4mol), was synthesized using the conventional solid state method. The purpose of this study is to investigate the phase transition and electrical properties of (Na0.5K0.5)NbO3 in terms of its LiNbO3 content.

Lead-free (1-x)(Na0.5K0.5)NbO3-xLiNbO3, i.e., NKN-LNx ( x = 0.0, 0.1, 0.2, 0.3, 0.4 mol), was prepared by mixing the oxides, K2CO3 (99% purity), Na2CO3 (99% purity), LiNbO3 (99% purity) and Nb2O5 (99% purity) in a molar ratio used in the conventional solid state reaction method. Before being weighed, the K2CO3 and Na2CO3 powders were first dried in an oven at 200℃ for 10 h to minimize the effect of moisture. These powders were then milled with ZrO2 balls for 20 h using ethyl alcohol as a medium and dried. The dried powders were calcined at 850℃ for 2 h. After calcination, the powders were ball-milled again for 20 h and, dried, after which PVA(4 wt%) was added as a binder. They were then pressed into disks with diameter of under 13 mm. After burning off the PVA, the pellets were sintered at 1,070℃ for 2 h. The crystal structures were determined by X-ray power diffraction analysis using CuКα radiation (Philips X’ Pert - MPD system). The remnant polarization Pr and coercive field Ec were determined from the P-E (Polarization - Electric field) hysteresis loops, as measured by a Radiant Precision Workstation. To examine their dielectric properties, the ceramics were polished and painted with silver paste on both surfaces, and fired at 800℃ for 30 min. The real and imaginary dielectric constants were measured using an SI1260 impedance analyzer at temperature ranging from room temperature to ~ 600℃ with heating and cooling rates of 0.2℃/min in the frequency range of 1 Hz to 1 MHz.

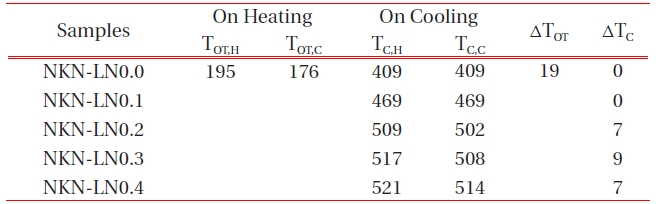

Figure 1 shows the XRD patterns of the (1-x)(Na0.5K0.5)NbO3- xLiNbO3, i.e., NKN-LNx (x = 0.0, 0.1, 0.2, 0.3, 0.4 mol) ceramics. Studies have reported that a phase of K3Li2Nb5O15 (KLN) with a tetragonal tungsten bronze structure starts to appear at x ≥ 0.08 [9]. In this study, it appeared at x ≤ 0.2 but for x ≥ 0.3, the KLN phase and LiNbO3 phase coexisted. This implies that the structures of the NKN-LNx ceramics were transformed, again increasing their LiNbO3 content.

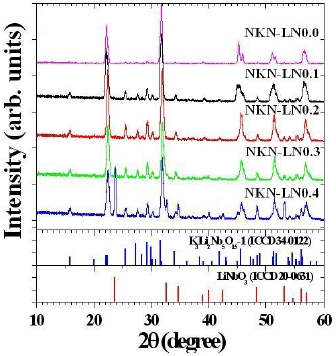

P-E hysteresis loops of (1-x)(Na0.5K0.5)NbO3-xLiNbO3, i.e., NKN-LNx (x= 0.0, 0.1, 0.2, 0.3, 0.4 mol) ceramics measured at room temperature under a driven electric field are plotted in Figs. 2(a)- (f). Generally, the presence of P-E hysteresis loops is considered to be evidence that a material is ferroelectric.

The capacitor is characterized by P-E hysteresis curves. However, the shapes of the P-E loops changed slightly with increasing LN contents. As shown in Fig. 2(f), the value of 2Pr decreases with an increasing LN content below a certain critical level. 2Pr has a minimum value of 5 C/cm2 near x = 0.2, and it first increases and then decreases after reaching this value. The coercive field 2Ec increases for an increase in the amount of LN in the range between x = 0.0 and x = 0.1 mol., and a further increase in the amount of LN above x = 0.2 mol causes an increase in 2Ec.

The tendency of varying 2Pr is similar to that of 2Ec when the range of x is approximately above x = 0.2 mol.

Du et al. [8] reported the dielectric properties of NKN-LNx ceramics for the case that the amount of LN is below x = 0.2 mol; when the amount LN is x = 0.06 mol, Ec achieves its minimum value of 13.4 kV/cm and Pr reaches its minimum value of 20 C/ cm2. They proposed that NKN-LN0.06 ceramics are a promising candidate for lead-free high-temperature piezoelectric ceramics.

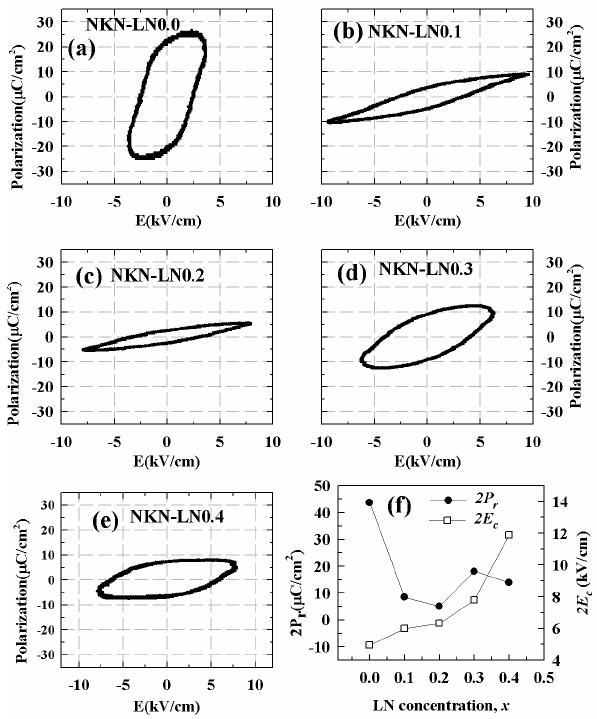

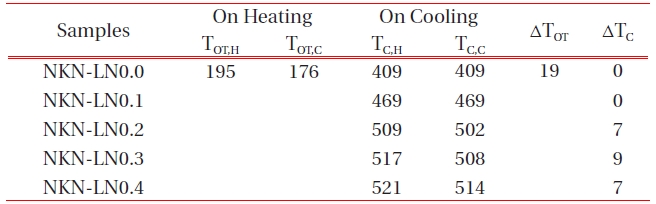

Figures 3(a) and (e) show the real (ε') dielectric constant at 1 MHz as a function of temperature for of (1-x)(Na0.5K0.5)NbO3- xLiNbO3, i.e., NKN-LNx (x=0.0, 0.1, 0.2, 0.3, 0.4 mol) ceramics. In the case of NKN-LN0.0 ceramics, the values of ε' increase with decreasing temperature. At TC (the temperature at which ε' is maximized) = 409℃, ε' beings to decrease, forming a large λ-type peak in the dielectric constant vs. temperature curve upon heating and cooling.

As the temperature decreases, if we assume that the phase

transition temperature is the mid-point of the steepest curve of ε', then the lower transition occurs at TOT,C (low temperature phase transition point) = 176℃ upon cooling and at TOT,H=195℃ upon heating with a thermal hysteresis of 19℃ This result is similar to that reported by Guo et al. [9].

In the case of NKN-LN0.1, a low temperature anomaly was not observed at TOT upon heating or cooling.

At high temperatures, the complex dielectric response of NKNLN0.1 was found to be similar to that of NKN-LN0.0. The sharp peaks around TC for the NKN-LN0.0 and NKN-LN0.1 samples show a second-order phase transition without thermal hysteresis.

In the case of NKN-LNx (x ≥ 0.2), the ferroelectric phase transition temperature TC shifted to a higher value with an increase in the LN content, whereas the dielectric peak broadened. The temperature anomaly of the real dielectric constant appeared at TC in all the samples upon heating and cooling with a small thermal hysteresis, which corresponded to at weak first-order phase transition. A low-temperature dielectric anomaly was not observed upon heating and cooling. In NKN-LNx samples with 0 ≤ x ≤ 0.07, Guo et al. [9] reported that the phase transition of NKNLN0.0 was observed at 420℃ and 200℃, which corresponds to the cubic-orthorhombic (at TC) and orthorhombic-tetragonal (at TOT) phase transitions. Also, LiNbO3 has lithium niobate structure, which can be described as a heavily distorted perovskite or an ordered phase derived from the corundum structure with space group R3C (C3V 6 ). So, it is evident that two effects on the structure of NKN ceramics have been observed in NKN-LiNbO3 ceramics. At lower LiNbO3 concentrations, Li mainly replaces Na and K in the A sites of ABO3 perovskite structure (i.e. form a solid solution), leading to a linear shift of the Curie point (TC) to higher temperature [9]. However, the structure of solid solution transforms from orthorhombic to tetragonal symmetry due to the large distortion caused by Li+ [9].

The phase transition temperatures also shifted increasing the

LN content. TC shifted to a higher value, and TOT, to a lower value [11]. Thus, we expect that a low-temperature phase transition of this sample should appear at room temperature because these phase transition temperatures decrease with an increase in LN contents.

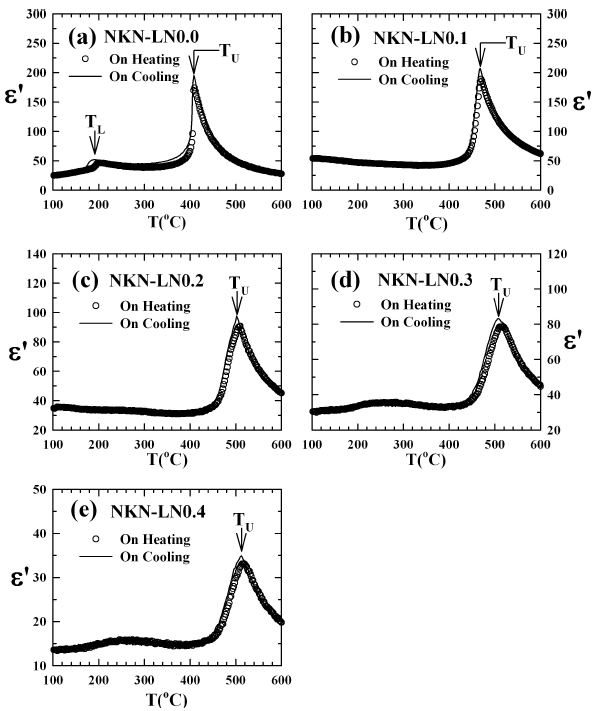

The values of TOT, TC, and ΔT obtained for all the samples are presented in Table 1. Here, ΔT indicates the degree of the firstand second-order phase transition of NKN-LNx. These results indicate that the phase transition of NKN-LNx ceramics occurs when TC changes from a second-order to weak first-order phase transition with increasing LN contents. Our results also show the possibility that the concentration of x = 0.2 may be the critical concentration for a first- to second-order-ferroelectric phase transition.

In conclusion, (1-x)(Na0.5K0.5)NbO3-xLiNbO3, i.e., NKN-LNx (x=0.0, 0.1, 0.2, 0.3, 0.4mol) ceramics, were synthesized using the solid state reaction method. The effects of LN mixing on the ferroelectric properties of these two ceramics were studied through dielectric and P-E measurements. The value of Pr increased with increasing Nb content. (1-x)(Na0.5K0.5)NbO3-xLiNbO3 ceramics exhibited a minimum remanent polarization of 2Pr=5 μC/cm2 at an LN content of x ~ 0.2. These results indicate that LN doping can change the ferroelectric properties of NKN-LNx ceramics. The phase transition temperature, TC, increased with increasing LN contents. The ferroelectric phase transition of NKN-LNx (x ≤ 0.1), is a second-order transition without thermal hysteresis, and NKN-LNx (x ≥ 0.2) is a weak first-order transition with small thermal hysteresis. Thus, our results demonstrate the possibility that the concentration of x ~ 0.2 may be the critical concentration for a first-to-second-order-ferroelectric phase transition.