A zero-shrinkage sintering process in which the shrinkage of x-y axis is controlled to be zero is in great demand due to the trend of high integration in the ceramic modules. Among the zero-shrinkage sintering processes that are available, the proposed glass infiltration method where the viscous but fluidic glass infiltrates of the Al2O3 particles in the structure of Al2O3/glass/Al2O3 during firing is one of the applicable methods. However, the above proposed glass infiltration method has the problem of the warpage-like delamination. This occurred at the outermost surface of the multiple-bundle substrate. It is thought that the decomposed gas rapidly expands in low viscous glass to create vacant space. To solve this problem, the vacant space was tamped with Al2O3 particles to lead to the actual improvement of the sintered properties. With 15 wt% of tamping Al2O3 particles in glass, most of the vacant space disappeared. Fully densified zero-shrinkage substrate without delamination can be obtained.

In recent years, the demands for miniaturization, high-speed, and multi-functionality of both the systems and the components of the communication devices are led by the rapid development of information technology with wireless communication [1,2]. As today's trend of miniaturization and weight-reduction is embedding certain specific functions found in the electronic circuit into a single module. Low temperature co-fired ceramic (LTCC) technology is focused as one of the applicable methods. The need for zero-shrinkage sintering process is one of the most important issues in LTCC in order to reduce the dimensional uncertainty of ceramic substrate during the firing process and to improve the precise matching between the ceramic layers [3,4].

We have suggested the glass infiltration method in the previous study [5] including the structure of Al2O3/glass/Al2O3. During firing, the viscous but fluidic glass is thought to infiltrate into Al2O3 particles in both the upper Al2O3 sheet and the lower one. But there was a problem in this method. Delamination occurred on the Al2O3/glass interface. To solve this problem, we have suggested the use of Pb-B-Si-O glass without TiO2 modified from the original Pb-B-Ti-Si-O glass. The lamination into a bundle of Al2O3/glass/Al2O3 structure produced a very dense zero-shrinkage LTCC in the previous study [6]. However, we had to solve an additional problem of warpage-like delamination which occurred at the outermost surface of multiple-bundle substrate.

In this study, delamination phenomenon in the multiple-bundle substrate with glass infiltration method for zero-shrinkage LTCC was investigated. The reason was analyzed to prohibit this phenomenon.

In this study, the commercial raw powders such as Al2O3 (particle size of 0.5 μm, AES-11, Sumitomo, Japan) and Pb-B-Ti-Si-O glass (particle size of 2.53 μm, density of 4.87g/cm3,

The each slurry of the glass and Al2O3 with viscosity of 800~1,000 cPs was made by mixing toluene and ethanol with glass and Al2O3 powders for 24 hours. Then, every mixture was again mixed with PVB binder and plasticizer. Subsequently, the slurry was cast into green sheets with a thicknesses of about 10~50 μm through a comma coater.

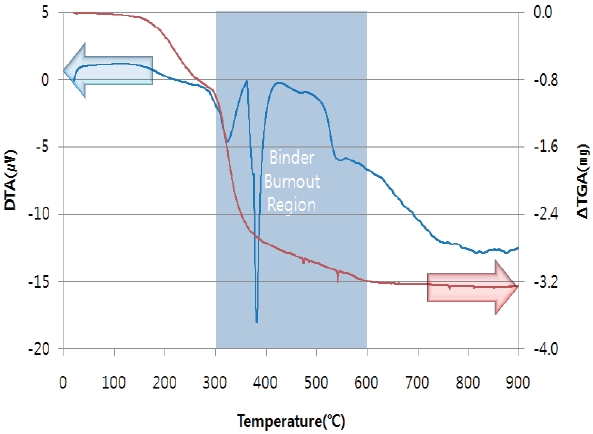

Prepared green sheets of both Al2O3 and glass were pre-laminated into a sandwich structure of Al2O3/glass/Al2O3 at 1,000psi, 60℃ for 5 minutes. Pre-laminated green sheets were pressed warmly and iso-statically at 250bar, 80℃ for 30 minutes. After WIP (warm iso-static pressing), stacked green sheets were cut into size of 15 mm ×15 mm. Organics in the prepared samples were burned out at 450℃ for 1 hour with a heating rate of 2℃/min. Following the binder-burnout process, samples were sintered at 900℃ for 20 minutes with a heating rate of 1℃/min. Then, they were slowly cooled in the furnace.

Density of sintered specimen was measured by Archimedean method. Its shrinkage was evaluated after the observation of a size difference between green and sintered one with an optical microscope (Icamscope-G, Icamscope, Korea). For microstructure observation, polished samples were observed by field emission scanning electron microscope (FE-SEM; JSM-6700F, Jeol, Tokyo, Japan). Dielectric constant and loss was measured with an impedance analyzer (E4991A, Agilent, U.S.A.) at 1 GHz.

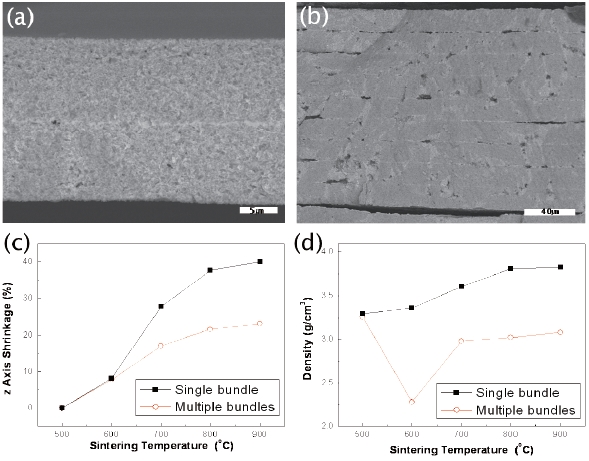

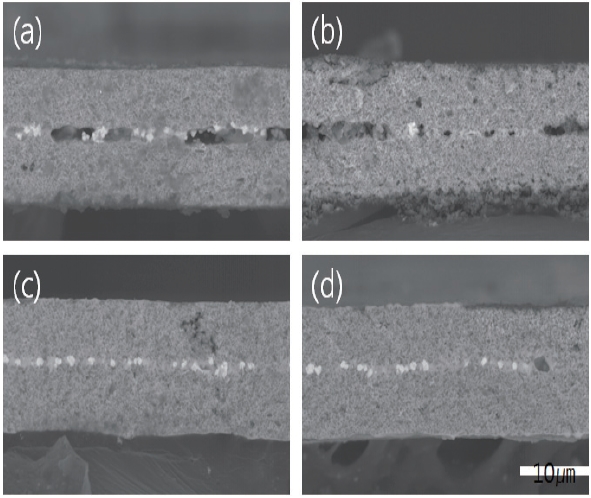

Ti-free glass was prepared into a green sheet and then, laminated with a Al2O3 sheet. In Fig. 1(a), the microstructure of a single bundle (the word ‘bundle’ indicates a set of Al2O3/glass/Al2O3 with every single sheet) is shown. Full infiltration without any remarkable problem can be seen in [6], but in (b) of multiple bundles, delamination and warpage bulged in the image. Warpage-like delamination occurred at the glass region between layers. Serious warpage appeared at the outermost surface of the substrate. Just macroscopic shrinkage and density could be measured. They are shown in (c) and (d). Compared to a single bundle, the z-axial shrinkage and the density values of multiple bundles are much lower than those of the single bundles. Especially, density decreased stiffly from 500℃ to 600℃, then again increased stiffly to 700℃ but it was saturated above that temperature. Despite the variation in glass amount, there was no remarkable change in the warpage state. Any other variation in process factors, such as the kind of binder, sintering schedule

and so on, did not affect the warpage state.

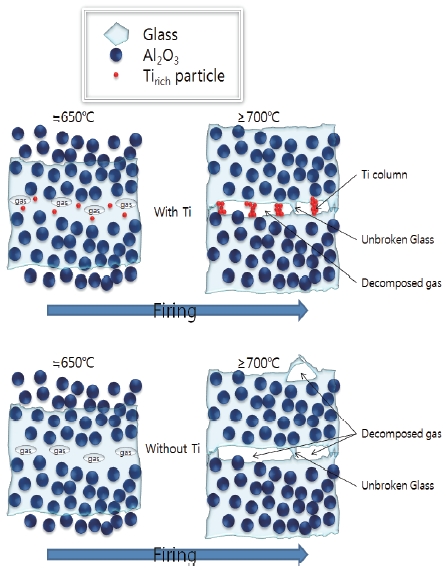

It is thought that too low

warpage at the outermost surface does not occur, while without Ti, gas expansion makes serious warpage. Gas decomposition above

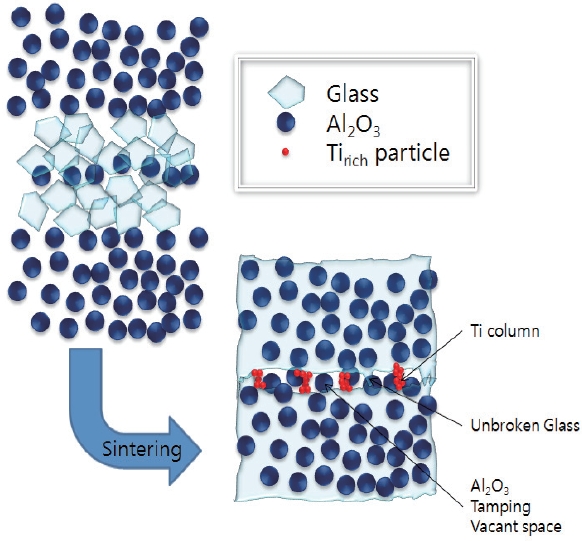

The warpages at the surface made the measurement of the dielectric properties difficult, as the measurement requires a exact contact between the probe and the specimen. And any other variation in the process factor could not improve the state. Then, the tamping of the vacant space in case of glass with Ti was suggested, as shown in Fig. 4. After sintering, decomposed gas diffuses out to make a vacant space in the body [7], so tamping that space with other particles would be a good trial. And so, Pb-glass powder with Ti composition was mixed with Al2O3 powders from 0 to 20 wt%.

The microstructures of the sintered samples obtained by the tamping of Al2O3 particles are shown in Fig. 5. As Al2O3 amount increases, vacant spaces gradually tamped and they were fully done at 15 wt%. Ti-columns also exist, but the packing state of Al2O3 with glass appeared much better than before.

It is suggested that a certain amount of crystalline phase in the glass matrix restrains pore occurrence as well as its movement [8]. Without the crystalline phase, small pores can easily move to coalescence together and a resultant large pore has larger volume than the summation of the small pores because of low viscosity. But with the crystalline phase to some extent, pore movement is hindered by the crystalline particles themselves and also by the high viscosity caused due to their existence.

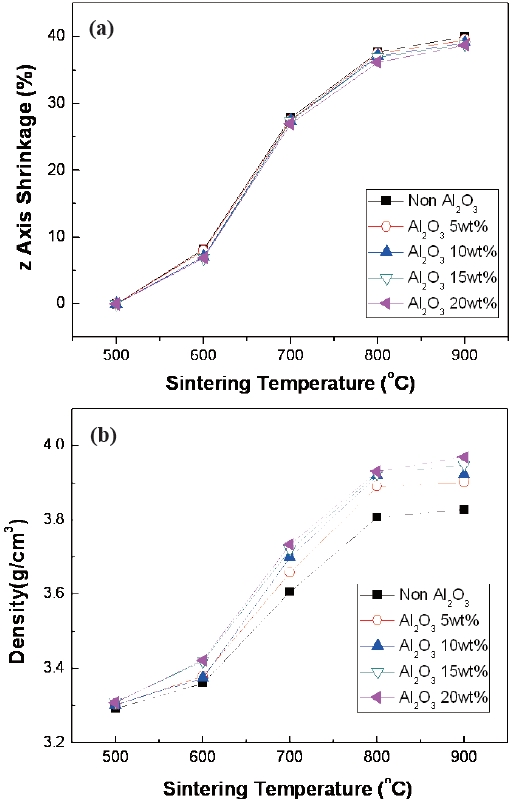

Z-axial shrinkages and measured densities are compared in Fig. 6. In (a) and (b), as tamping amount increases, shrinkage showed no remarkable difference among the values at the same temperature, while there exist remarkable ones in the density plot, despite the addition of low-density material of Al2O3. It is considered that the replacement of the Al2O3 particles with vacant space increases in density. The resultant shrinkage in x-y plane was below 0.1%, and that along the z direction was about 40%.

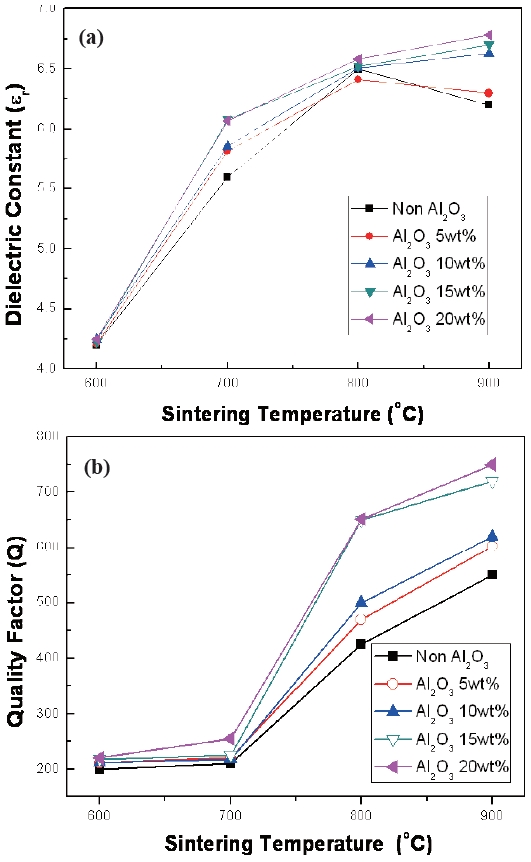

Dielectric properties of a tamped substrate are shown in Fig. 7. As the tamping amount increases, both the dielectric constant and the quality factor increased. It is thought believed that the tamped Al2O3 particles with the dielectric constant about 10, instead of the vacant space, made an increase in the dielectric constant. And also, reduced vacant space showed higher quality factor.

In this study, delamination phenomenon in multiple bundles of glass infiltration method for zero-shrinkage LTCC substrate was investigated and the reason was analyzed to prohibit this phenomenon. Warpage-like delamination occurred at the glass region between layers and serious warpage appeared at the outermost surface of the substrate. This space in the glass region between the layers arises due to the gas expansion. This is derived from the decomposition of the remnant carbon during firing (300-600℃) without a sufficient binder burnout because of low