Carbon nanotubes (CNTs) can be used as multi-functional reinforcement materials within polymer matrixes due to their superior mechanical, electrical, and thermal properties [1-3]. As such, a number of studies have been performed to characterize the tensile, flexural, and fracture behaviors of CNT-reinforced polymer composites [4-7]. In recent years, new attempts have been made to develop multi-scale composites composed of a mixture of micro-scale fibers and a nano-scale CNT-reinforced polymer matrix [8,9]. It is believed that multi-scale composites may have a greater synergetic effect on the mechanical properties of these composites compared to typical fiber/polymer composites. Basalt fiber, which is made from basalt rock, exhibits superior thermal performance, mechanical strength, and chemical resistance. Furthermore, basalt fiber can be produced at a much lower cost than carbon fiber. For this reason, several studies have investigated the mechanical behavior of basalt-fiberreinforced composites [10,11]. However, few attempts have been made to develop CNTreinforced CNT/basalt/polymer multi-scale composites.

In this study, the surfaces of CNTs were modified with silane to improve their interfacial strength with epoxy matrix and the effects of this process on the flexural behavior of CNT/epoxy/basalt multi-scale composites were investigated. Flexural tests were performed on epoxy/basalt composites, oxidized, and silanized CNT/basalt/epoxy composites. The fracture surfaces of the composites were examined via field emission scanning electron microscopy (FESEM) to determine the dispersion of the CNTs and the fracture mechanisms with respect to the surface modification of the CNTs.

The materials used in this work were commercial woven-type basalt fibers (EcoB4-F260; Secotech, Korea) 260 g/m2 in size and multi-walled CNTs (MWCNTs) synthesized by catalytic chemical vapor deposition (CM-95; Hanhwa Nanotech, Korea). We employed 3-aminopropyltriethoxysilane (99% purity; Aldrich, USA) as a silane functionalization agent. Nitric acid (60-62%; Junsei Chemical, Japan), sulfuric acid (95%; Junsei Chemical), distilled water, acetone (99.5%; Dae-Jung Chemical, Korea), and ethanol (99.5%; Sigma-Aldrich) were used for the acid treatment. The epoxy was diglycidyl ether of bisphenol A (YD-115; Kukdo Chemical, Korea), and the curing agent was polyamidoamine (G-A0533; Kukdo Chemical). The acid-treatment and silane-treatment processes are described in earlier research[12]. Oxidized and silanized MWCNTs were each added to a mixture of epoxy resin and a hardener (2:1 v/v) at a concentration of 1 wt%. Eight plies of basalt fabrics were stacked with the oxidized and silanized MWCNTs with the epoxy resin in a hand lay-up method. A vacuum bag mold of the CNT/basalt/epoxy composites fabricated by the vacuum-assisted resin transfer molding (VARTM) method, after which it was cured in an autoclave under a pressure of 3 kgf/cm2 at 130℃ for 2 h. Flexural tests were conducted with a universal testing machine (Model:8871; Instron, USA) following the ASTM D638 specification at cross-head rates of 1 mm/min.

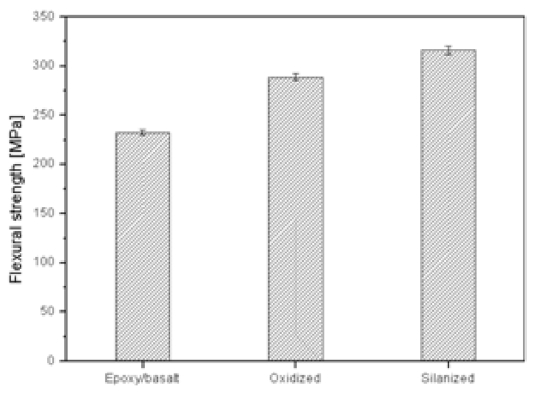

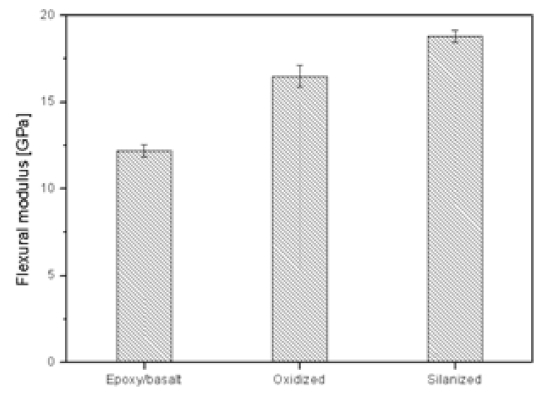

The flexural strengths of the epoxy/basalt composites were compared to those of surface-modified CNT/epoxy/basalt multiscale composites. The flexural strength in each case was defined as the maximum stress in the corresponding load-displacement curve. A comparison of the flexural strengths of the three composites is shown in Fig. 1. The flexural strength of the epoxy/basalt composites was improved by the addition of surfacemodified CNTs, while the flexural strength of the CNT/epoxy/basalt multi-scale composites showed a slight improvement after silane modification of the CNTs. The flexural strength of the silanized CNT/epoxy/basalt multi-scale composites was ~34%, which was ~9% greater than the strength of both the epoxy/basalt composites and the oxidized CNT/epoxy/basalt multi-scale composites. The flexural modulus of the epoxy/basalt composites was also compared to that of the surface-modified CNT/epoxy/basalt multi-scale composites. The flexural modulus in each case was determined by measuring the slope in the linear region of the corresponding load-displacement curve. A comparison of the flexural moduli of the three composites is shown in Fig. 2. The flexural moduli of the epoxy/basalt composites improved significantly upon the addition of surface-modified CNTs. Silane modification of the CNTs improved the flexural moduli of the CNT/epoxy/basalt multi-scale composites. Specifically, the flexural moduli of the silanized CNT/epoxy/basalt multi-scale composites were determined to be ~54% and ~13% greater than the moduli of the epoxy/basalt composites and the oxidized CNT/epoxy/basalt multi-scale composites, respectively.

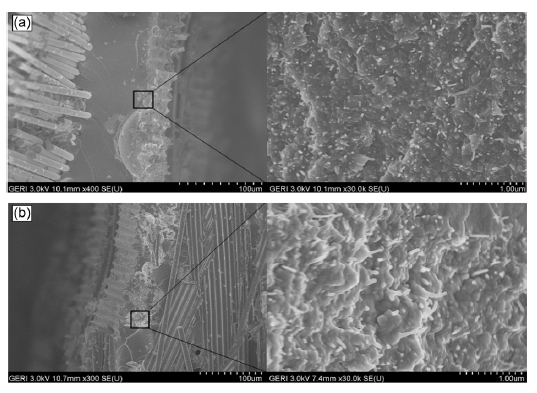

The fracture surfaces of the surface-modified CNT/epoxy/

basalt multi-scale composites are shown in Fig. .3For the oxidized CNT/epoxy/basalt multi-scale composites (Fig.3 a), CNTs were impregnated in the epoxy resin. For the silanized CNT/epoxy/basalt multi-scale composites (Fig.3 b), the dispersion and impregnation of the CNTs in the epoxy resin both showed improvements when compared to the oxidized CNT/epoxy/basalt multi-scale composites. In addition, the pulling out phenomena of the CNTs decreased and the basalt fibers were harmonized with the epoxy matrix. Such a finding may be due to the homogeneous load support of the basalt fibers resulting from the improved dispersibility and interfacial interactions between the CNTs and the epoxy matrix.

In conclusion, the flexural properties of epoxy/basalt composites can be improved by adding surface-modified CNTs to the epoxy matrix. The improvement in the dispersibility and interfacial bonding between the epoxy and the silane-modified CNTs enables an effective stress transfer between the epoxy and the basalt fibers. This in turn leads to better flexural strength and flexural moduli of the silanized CNT/epoxy/basalt multi-scale composites when compared to the moduli of oxidized CNT/epoxy/basalt multi-scale composites.