In this study, a low temperature growth of high-quality carbon nanotubes on glass substrate using a local surface heating without heating damage to substrate was tried and characterized. The local joule heating was induced to only Ni/Ti metal film on glass substrate by applying voltage to the film. It was estimated that local surface joule heating method could heat the metal surface locally up to around 1200℃ by voltage control. We could successfully obtain high-quality carbon nanotubes grown at 300℃ by applying 125 V for joule heating as same as carbon nanotubes grown at 900℃.

Since their discovery in 1991[1], carbon nanotubes (CNTs) have excited many researchers owing to their amazing electrical and mechanical properties. They have various applications such as a tip material for field emission device and scanning probe microscope, an intercalation material for Li ion battery, a hydrogen gas storage material for electric vehicles, and so on. But many technical problems also remained because it is not easy to control them due to their small size [2]. Moreover, commercialization would not become active until the techniques for large-amount and low-cost synthesis are developed. Electronic industries have been significantly using transparent glasses or plastics as substrates for flexible displays or other electronic devices.However, theses substrates commonly have low thermal durability. For examples, temperature for polyimide should not exceed 260℃, and soda-lime glass is also strained at a temperature over 511℃. One of the most attractive applications of CNTs is an electron emitter for flat panel displays and white light sources using its sharp tip. Since the typical growth temperature of CNTs is around 700~900℃ using thermal CVD system [3-5], it is difficult to grow highquality CNTs on glass substrate. In this study, a local surface joule heating by applying voltage to metal film electrode on glass substrate was tried to grow high-quality CNTs on glass without any strains to the substrate.

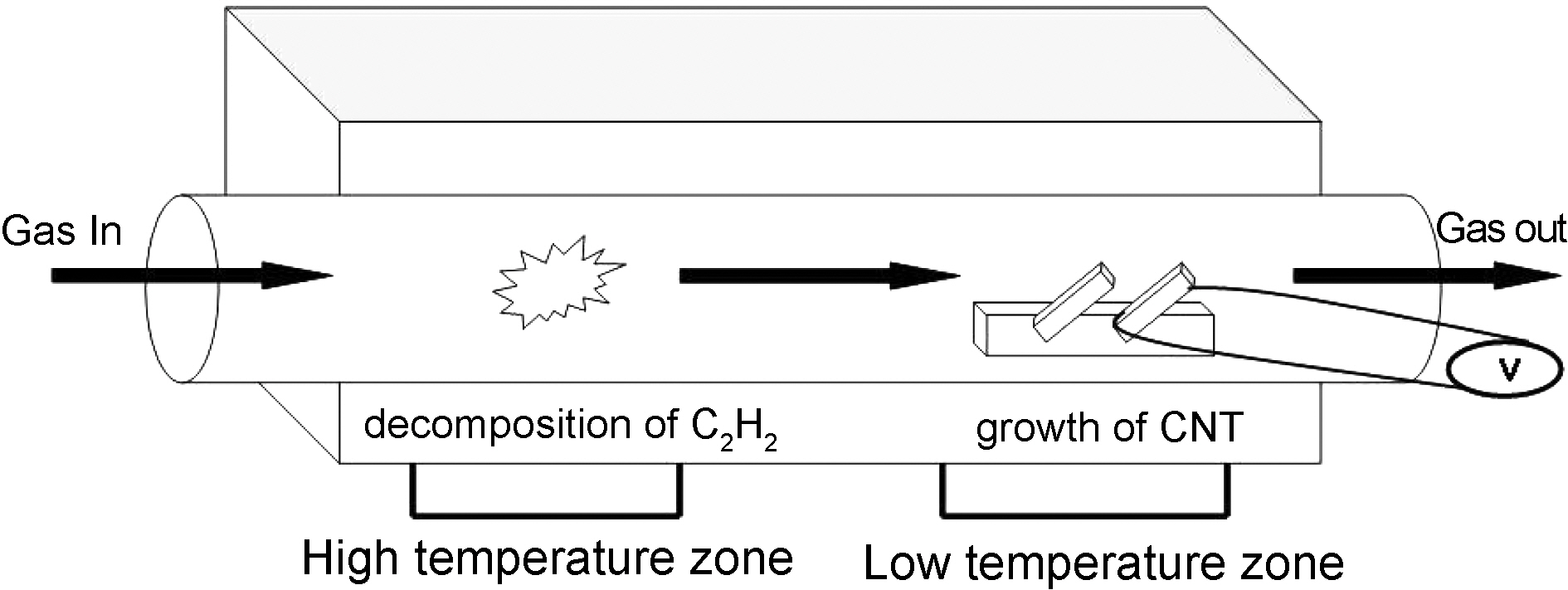

A patterned (20 mm×7 mm) Ni/Ti thin film (20 nm/200 nm) was sputtered on a glass substrate (PD-200) under constant DC power of 50W at working pressure of 5 mTorr. Fig. 1 shows the schematic diagram of a two-temperature zone chemical vapor deposition (CVD) reactor. The first heating zone was maintained at 900℃ for the decomposition of acetylene (C2H2) gas and the second heating zone was controlled at 400~500℃ for the growth of CNTs on glass substrate. Ni film was used as a catalyst for growing CNTs and Ti film as an electrode for carrying electrical current. The Ni-deposited Ti electrode on glass substrate was placed at the second heating zone with an angle of 15° to the quartz boat. The Ni/Ti film was contacted to electrical wires coming through electrical feedthrough for applying voltage.

The chamber was pumped down to around 20 mTorr and Ar gas (200 sccm) was flowed into a CVD quartz reactor in order to prevent the oxidation of the Ni catalytic film during heating of the chamber. Then the Ni/Ti film on glass substrate was pretreated using NH3 gas with a flow rate of 20 sccm for 10 min before growing the CNTs. The NH3 pretreatment causes the continuous Ni catalytic film to be formed as the discontinuous nano-islands and to make Ni

surface activated for CNT growth.

The CNTs were grown using C2H2/NH3 gas with a flow rate of 20/60 sccm for 10 min at an atmospheric condition. After the growth, the reactor was cooled down to room temperature under Ar gas.

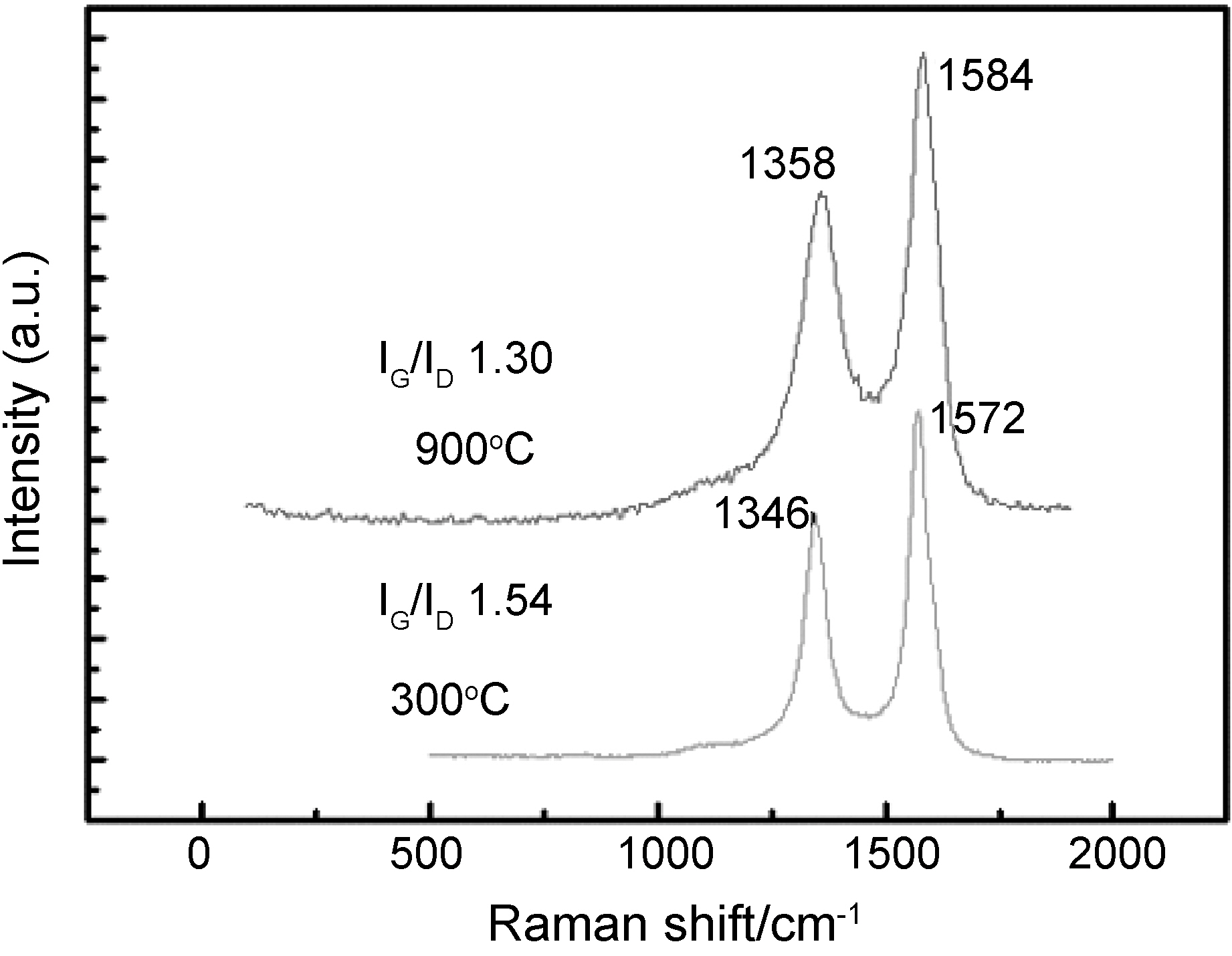

Morphology of Ni catalyst layer and the grown CNTs was examined by a scanning electron microscopy (SEM, JEOL JSM-7000F). Raman spectroscope was used to analyze the crystallinity of the grown CNTs through atom-atom bonding characteristics. The Raman peaks of CNTs normally show D peak (1350 cm?1) and G peak (1590 cm?1). D peak indicates the crystal disorder of graphite such as amorphous carbons and G peak indicates crystalline graphite. The degree of graphitic ordering in the carbon deposits was compared from the peak integrated intensity ratio of the G band to D band of CNTs.

3.1. Temperature estimation of Ni/Ti layer according to local surface joule heating

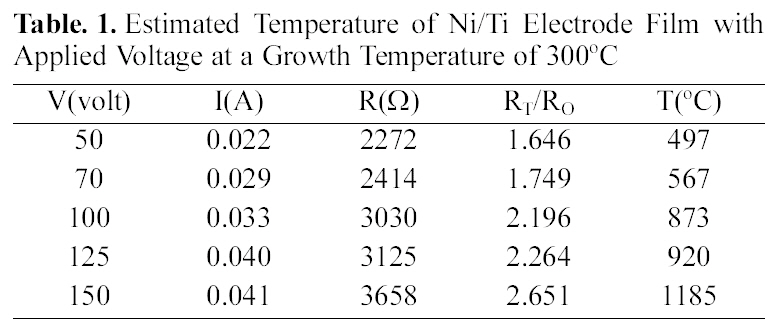

Thermal CVD has become an important technique in the fabrication of CNT emitters, because it enables CNTs to be grown vertically-aligned on a large patterned substrate using lithography technique [6,7]. However, there still exists a critical problem on how to reduce the processing temperature for preventing substrate damage, especially for glass substrate because growth temperature of CNTs is too high for glass.Therefore we tried a local surface heating only on electrode without heating a whole body of glass substrate to grow high-quality carbon nanotubes. When applying voltage to Ni/Ti films for joule heating, it is very difficult to measure the actual temperatures of Ti electrode because the electrode dimension is too small and the applied voltage induces misleading read from thermocouple. Therefore, the surface temperature was estimated as follows. The actual sample of a Ni/Ti film on glass was laid on a hotplate and the electrical resistance of the Ni/Ti film was measured with increasing temperature of hotplate. The empirical equation of temperature vs. electrical resistance was established by curve fitting.

T(℃)=684 ×(RT/RO)+(2.364×10?5) × (RT/RO)2?631

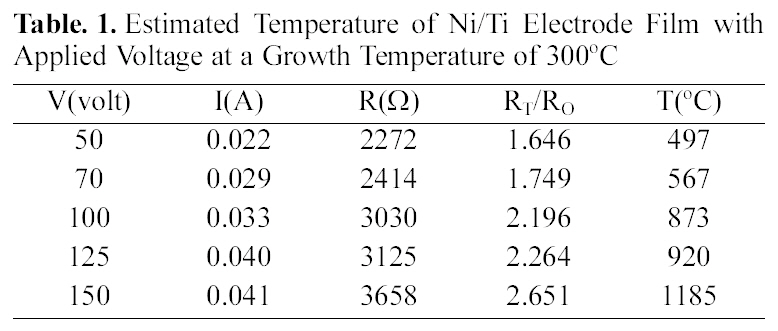

RT is the electrical resistance (Ω) of Ni/Ti electrode at a certain temperature (T) and RO is resistance value at 50℃ as a reference. Then a certain voltage was actually applied to the sample in the CVD growth chamber for surface joule heating during CVD growth. By an applied voltage, a local surface heating on Ni/Ti film occurred, leading to change in electrical current, from which resistance values were obtained. From the measured (RT/TO) value (shown in Table 1) and the above equation, we noticed that the surface temperature of Ni/Ti film could be raised up to as high as 1185℃ by applying a voltage of 125 V, which is the growth temperature region of

Estimated Temperature of Ni/Ti Electrode Film with Applied Voltage at a Growth Temperature of 300℃

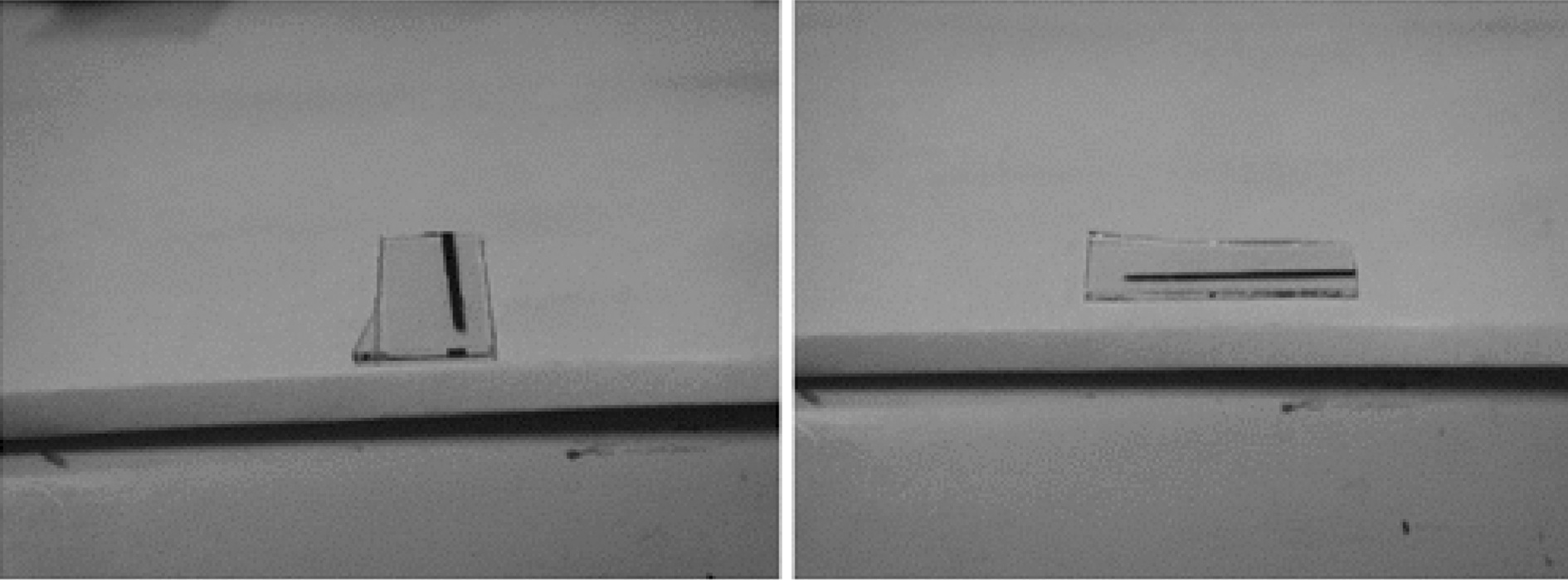

CNTs. However, any deformations or distortions were not found on glass substrate as shown in Fig. 2.

3.2. Synthesis of carbon nanotubes by local surface heating

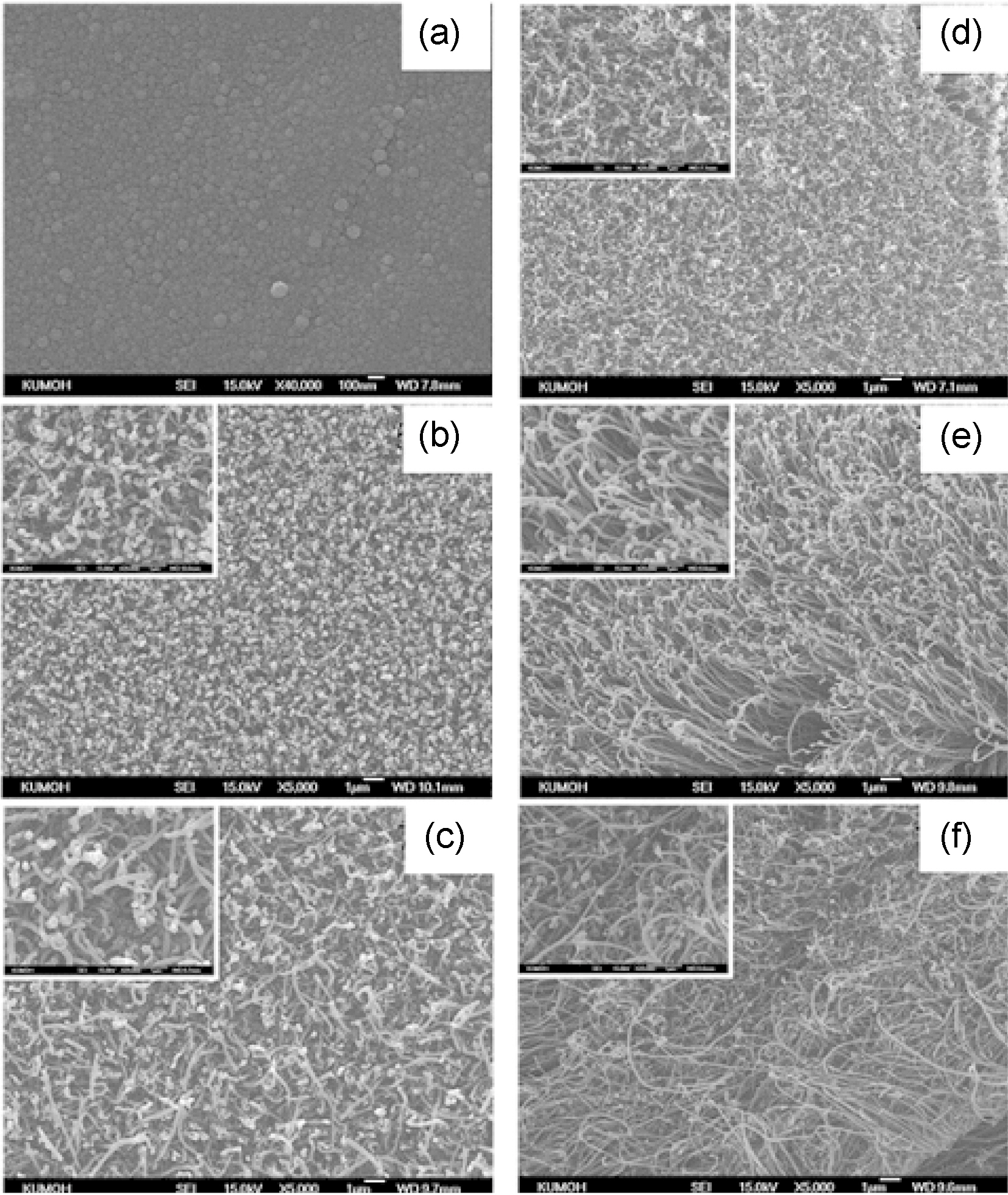

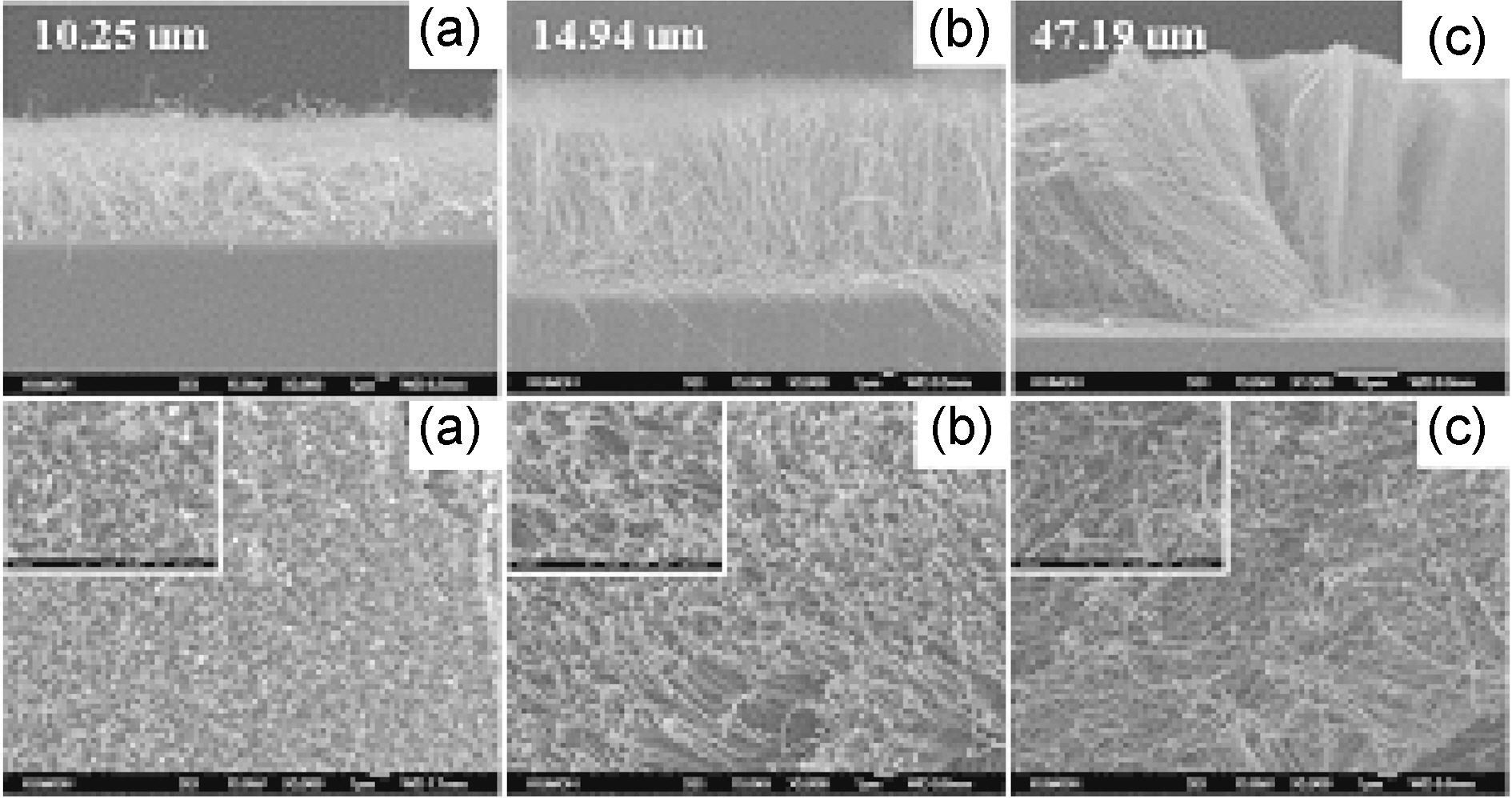

Fig. 3 shows the growth of carbon nanotubes at a growth temperature of 300℃ with an increase in applied voltage for local heating. Whereas carbon nanotubes did not grow when no voltage was applied as shown in fig. 3(a), it can be seen from fig. 3(b)~(f) that as the applied voltage was increased,

carbon nanotubes were grown more soundly and densely, and the length and diameter of CNTs were increased with good uniformity. We proved that carbon nanotubes can be grown at low growth temperature as low as 300℃ using extra local surface heating.

Fig. 4 shows changes in the length and density of carbon nanotubes with increasing applied voltage. CNT length and density were larger at higher voltage. It could be seen that big differences in the length of CNTs between 100 V and 150 V might result from temperature difference, which is estimated to be around 700℃ as shown in Table 1. Temperature difference in Ni catalyst metal surface affects the diffusion rate of activated carbon species dissociated from C2H2 into the catalyst metal, resulting in CNT growth rate.

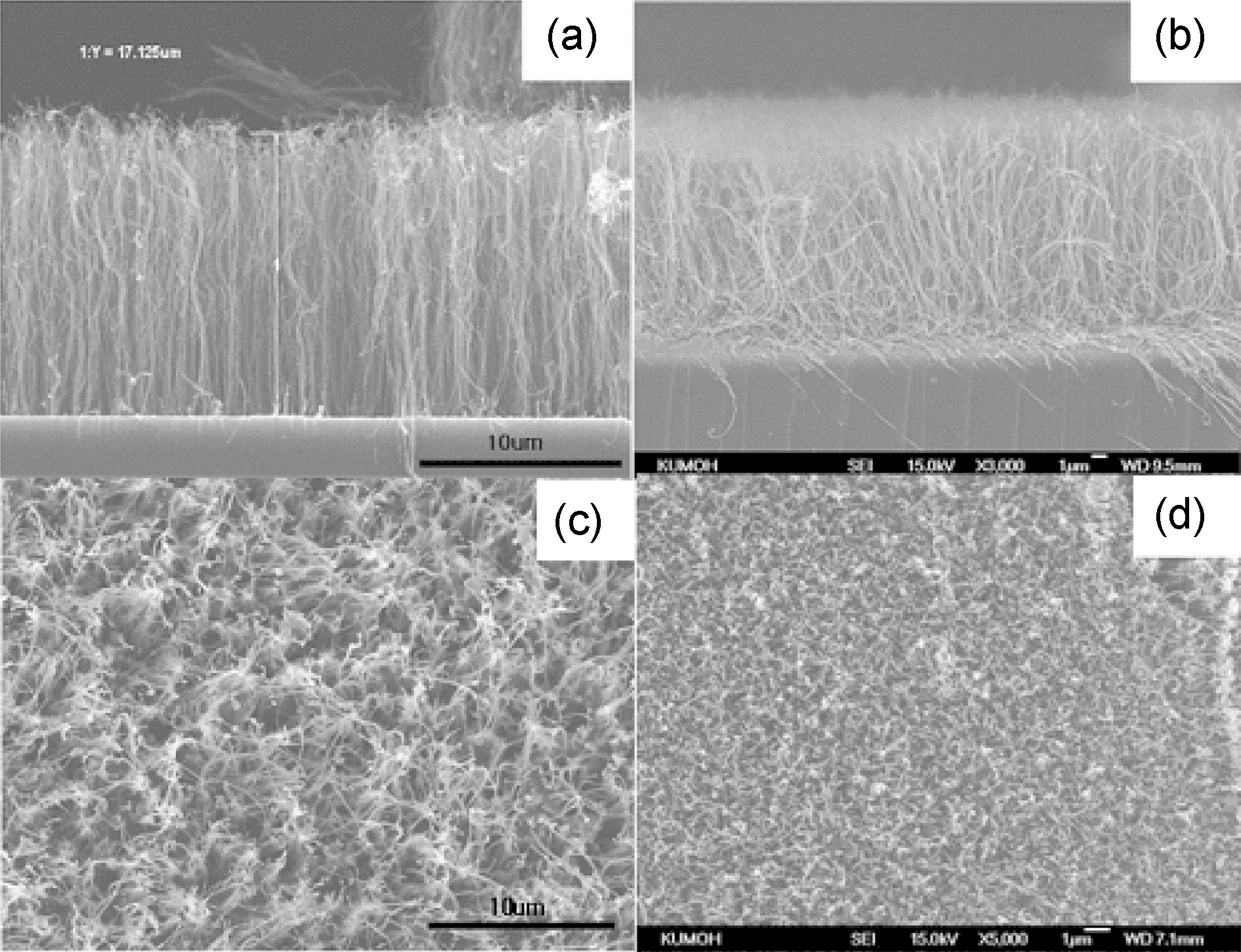

Fig. 5(b, d) are photos of carbon nanotubes grown at 300℃ with local surface heating and fig. 5(a, c) are photos of carbon nanotubes grown at 900℃ by conventional thermal CVD method for comparison. CNT growth occurred on Ni catalyst metal of 20 nm thickness under the condition of NH3 /C2H2 (20 sccm/60 sccm) mixture in this experiment. Little differences in CNT morphology could be found between them.

Fig. 6 shows the comparison result of Raman spectra for crystallinity of CNTs made by the two growth methods. As shown in the figure, there were not many differences in crystallinity. The crystal quality of CNTs using local heating from IG/ID ratio comparison is surprisingly a little bit higher than that of CNTs by the conventional CVD growth method.

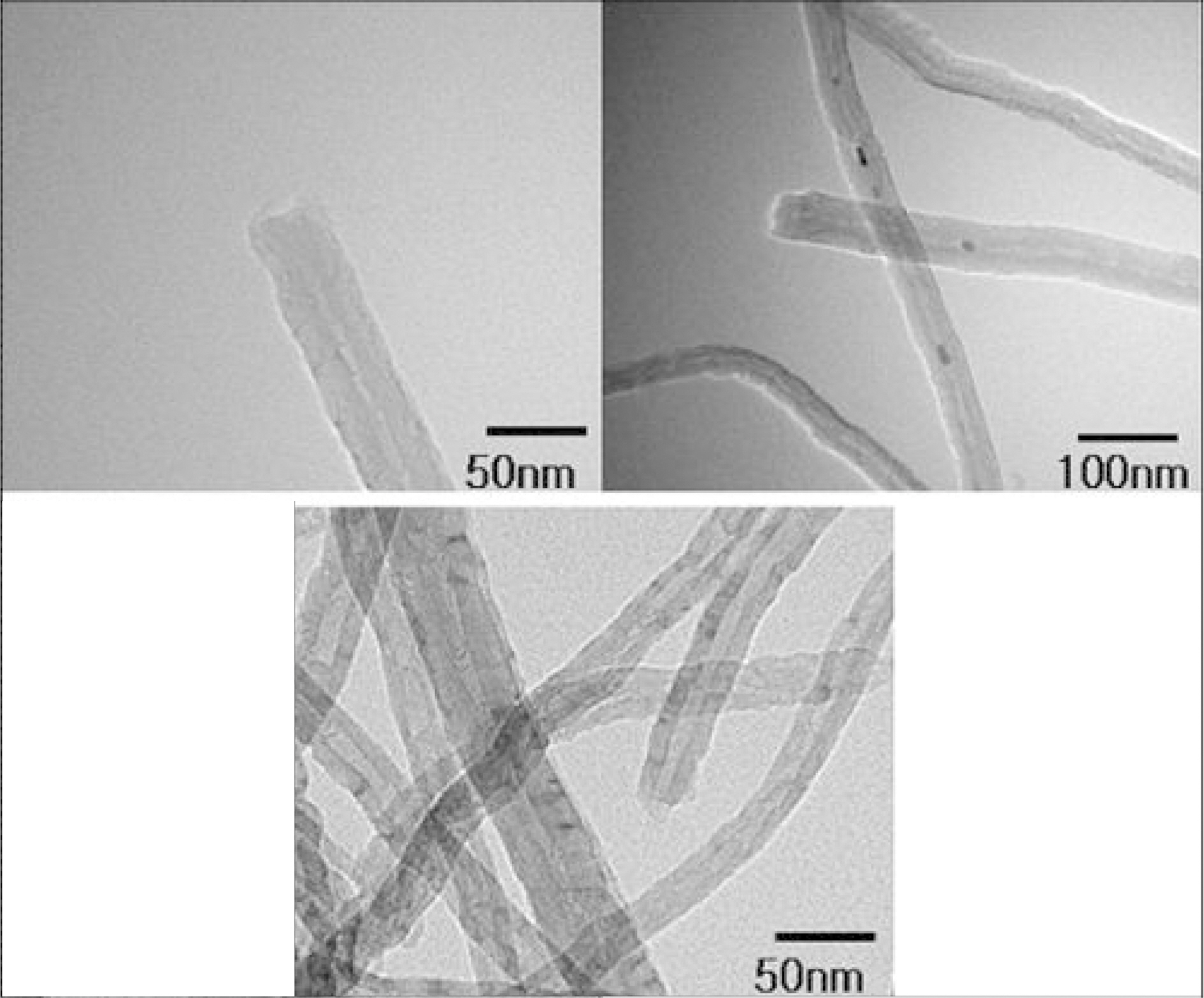

Finally, CNTs grown by CVD with a local heating method were observed by transmission electron microscopy as shown in Fig. 7. Typical CNT morphologies were observed and sometimes Ni catalyst metal particles (black dots) were found inside CNT tubes around base regions of CNT tubes. This base growth mechanism may be from the enhanced adhesion of Ni particles to Ti film due to interdiffusion of Ni and Ti during local surface heating. The diameters of the carbon nanotubes were around 20~50 nm.

It is expected that carbon nanotubes can be grown under temperatures lower than 300℃ by applying higher voltage and that CNT growth on plastic substrate will work well in the next experiment.

From the above results, we successfully grew high-quality CNTs on glass substrate using conventional CVD method even at a temperature of as low as 300℃ through surface heating method. It was possible to heat locally the metal film surface up to around 1200℃ with an applied voltage of 150 V without any distortions to glass substrate. It is expected that this results give possibility to grow CNTs even on flexible plastic substrate.