The two main air pollution problems in Korea at present are sick building syndrome and high temperature CO gas occurred in subway accidents, in the later case we and also accompanied animals shall outfit with civilian gasmasks composed of AC-immobilized adsorption filter packs. News also announced that the most of the outfits are defected. So a novel idea is suggested to overcome these problems.

So called high BET-surface area over 3,000 m2/g in the activated carbons were patented by A. N. Wennerberg, US Patent 4082694[1] and F. J. Derbyshire, US Patent Documents 6057262[2] with coal cokes based activated carbons in abroad and 2,800 m2/g reported by H.K. Jin with coconut shell based activated carbons in inland [3]. But they all have studied with solid-solid contact reaction(Film Model) composed of Carbon-KOH(anhydrous). However in this study we have prepared it carefully with solid-liquid diffusion controlled reaction (Penetration Model) composed of Carbon-KOH(strong elec-trolyte saturated solution, 97 g/100H2O).

We have also prepared a thermostable PE-nonwoven fabric for the moderate temperature (320) usage by means of continuous 3 steps different thermal treatment processes, impregnated it with a AC-QS(Activated Carbon-Quinoline Solubles of Petroleum Isotropic Pitch [4]) slurry mixtures and dried at the temperature 240℃, followed by the reactivation process at the higher temperature (400~700℃) in order to enhance the surface area and the micro pores ranges in the targeted adsorption filters. For the higher temperature over 700℃ we have applied Sigri-Thermospelz (nonwoven fabrics of pitch fibers made by Sigri, Germany), immobilized with super AC by means of isotropic pitch binder and reactivated up to 30%-burn off with hot steam-activation at 900℃. These are named a novel idea of AC-Immobilized Adsorption Filters in this study.

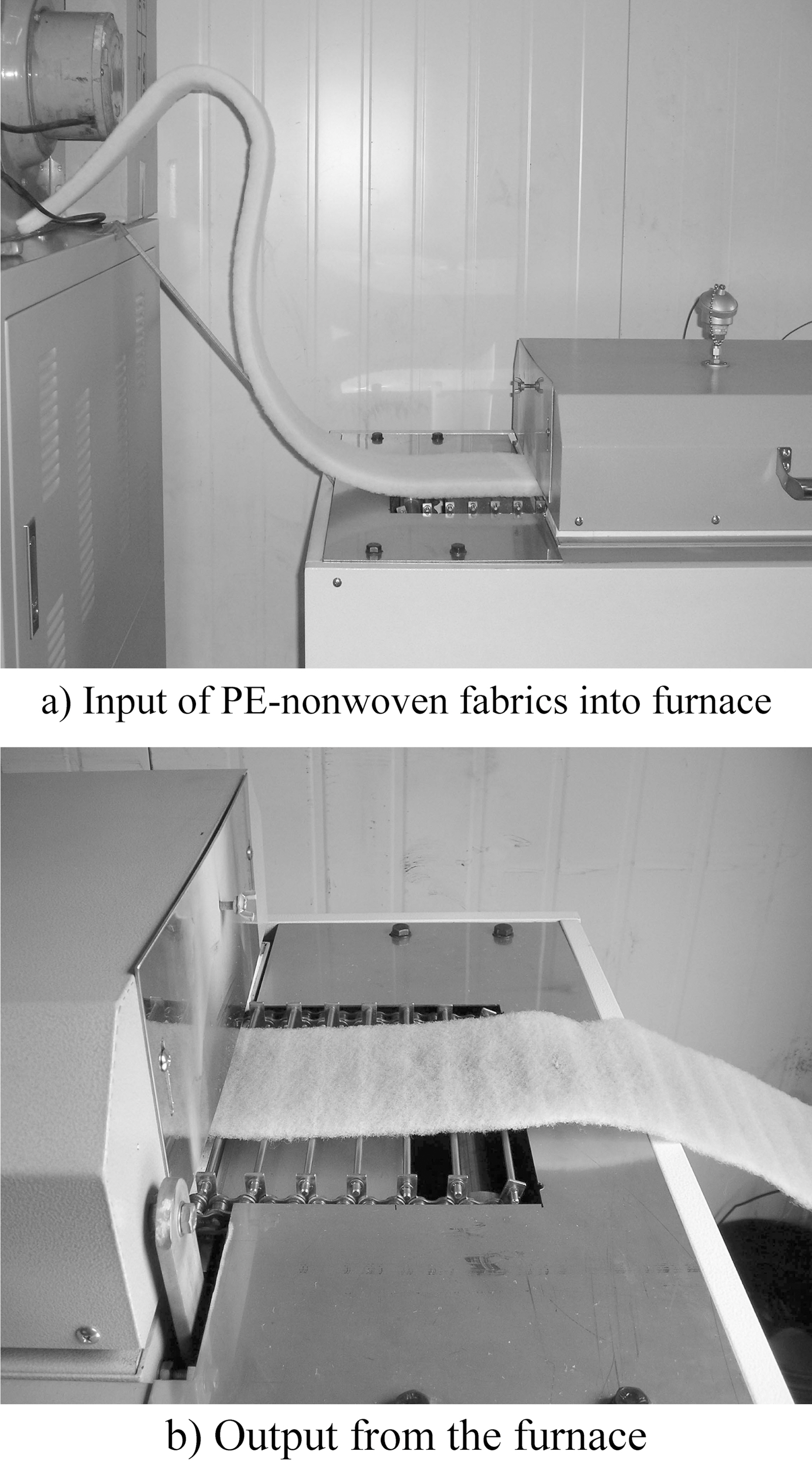

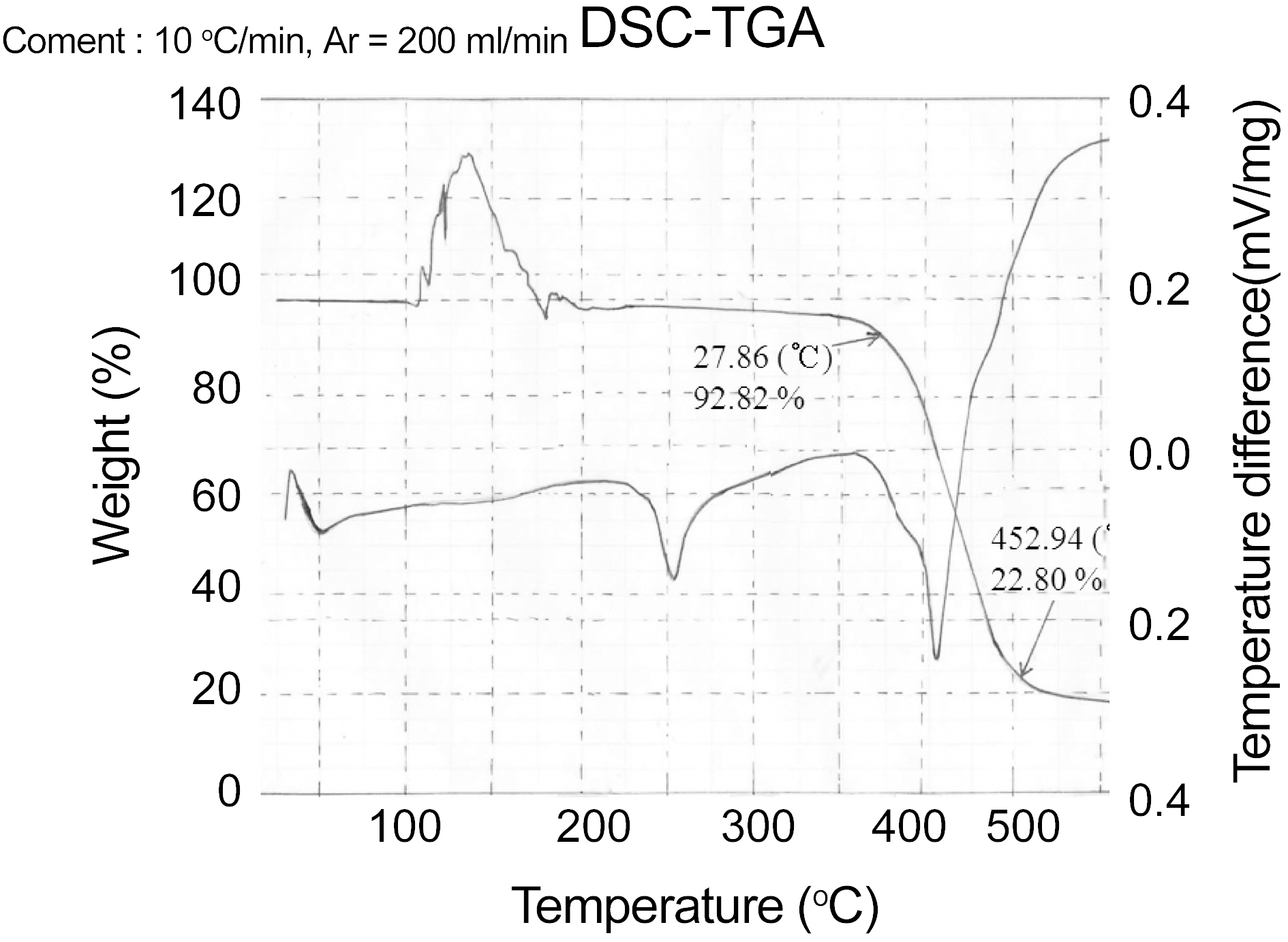

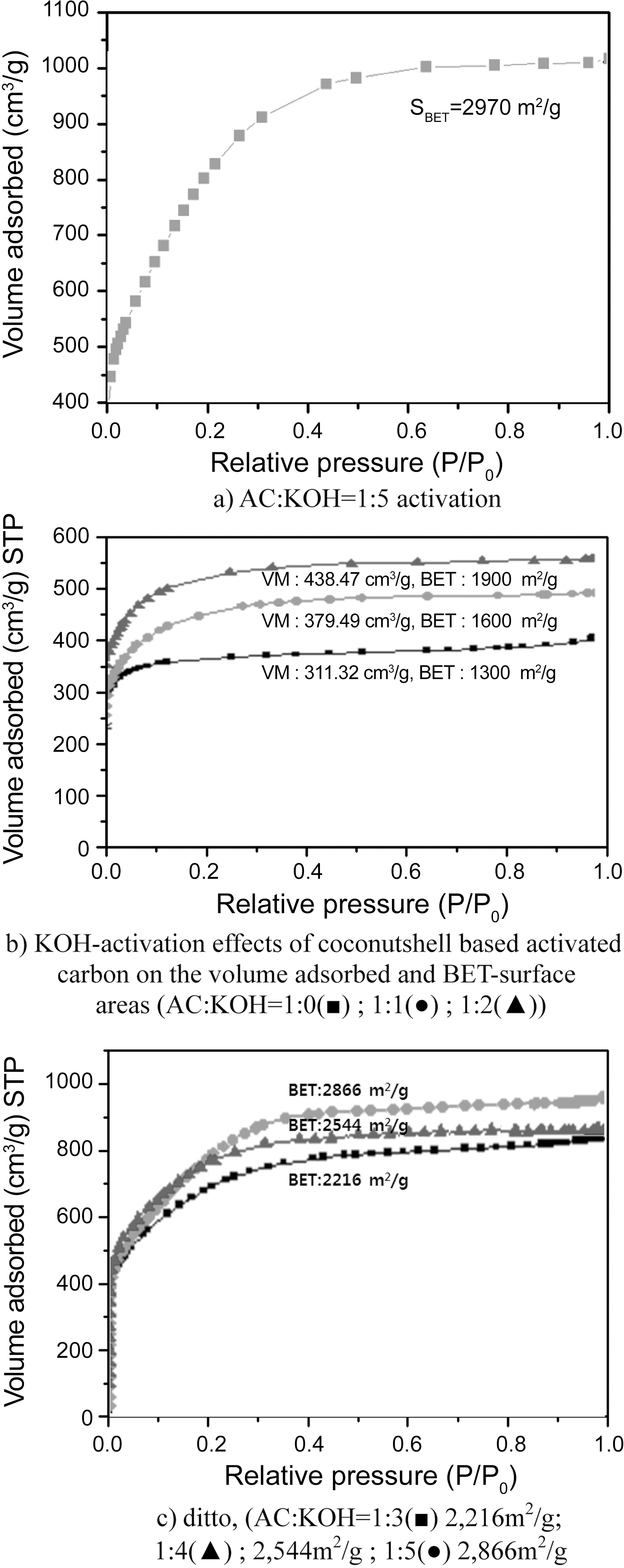

Super activated carbons were prepared with coconut shell based AC made of the commercially available coconut shell char, as the precursor, by impregnation with saturated solution of KOH into AC followed by dehydration under 320℃ and chemical activation at high temperature (900℃) with increasing additions from 1/1 to 1/5 of AC/KOH-mass ratios. For the thermal-stable PE-nonwoven fabrics and the KOH-activation, we have developed two heating and holding time programs [see, a) mechanism of KOH-activation, b) & c) 2 temperature programs] and constructed a continuous 3 zone

thermal treatment furnace as shown in Fig 1 a) Input of white color PE-nonwoven fabric into first zone and b) Output of brown color thermal stable fabric from the third zone in accordance to the thermal analysis as Fig. 2.(DSC-TGA diagram).

In order to increase the TOF the ACs were impregnated with 0.188 wt% PdCl2 and 0.577 wt% CuCl2, 3 wt% KMnO4, respectively[5,6]

a) Mechanism of KOH-Activation:

b) Continuous Process: Temperature Program of Thermal Treatment with PE-nonwoven fabrics:

c) Batch process: Temperature Program of KOH-Activation

Thermostable PE-nonwoven fabrics for the moderate temperature were prepared with the polyester nonwoven fabrics which are available in the market by means of 3 stepthermal treatment program from 100℃ via 180℃ to 320℃ in atmospheric environments continuously. For high temperatures above 700℃, Sigri-Thermospelz, which are available in Germany market were applied without pretreatments.

AC-immobilized adsorption filters were prepared with the thermostable nonwoven fabrics and also Sigri-Thermospelz by coating AC-epoxy resin binder (degree of Polymerization ca.300) mixture and AC-QS (Quinoline Solubles of Isotropic Pitch binder, B.Pt. ca. 360℃) mixture, respectively and drying at 240℃ followed by reactivation at 900℃ in order to disclose coated surface areas and micro pores in the Thermospelz-filters. Particularly, isotropic pitch binder was developed from petroleum pitch [4] and dissolved by Quinoline, namely QS and AC were impregnated into the thermostable PE-nonwoven fabrics followed by drying and reactivation to product AC- immobilized filters.

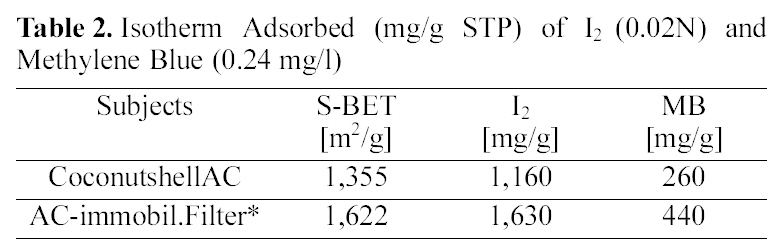

Enhancement effects of isotropic pitch binders to the surface area and adsorptivity of AC-immobilized adsorption filter were tested by BET-analysis, Iodine- and methylene blue MB-adsorption as the model pollutant using the

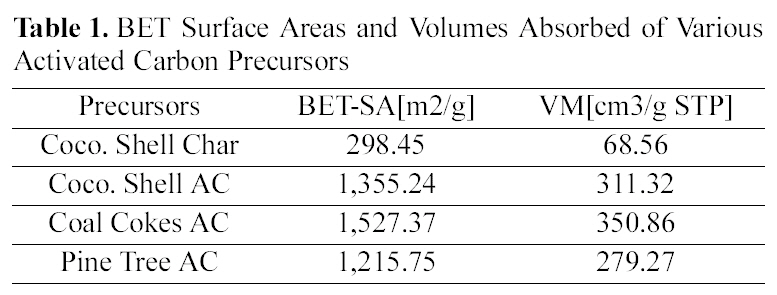

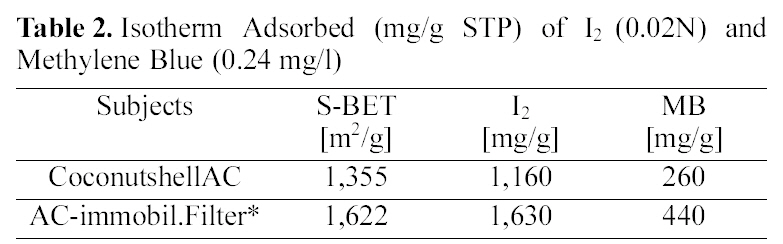

[Table 1.] BET Surface Areas and Volumes Absorbed of Various Activated Carbon Precursors

BET Surface Areas and Volumes Absorbed of Various Activated Carbon Precursors

correlativity between SBET, I2- and MB-adsorptions [7]. Adsorptive tests for the Betrex of this developed filter will be reported in the second publication.

Table 1 shows the results of BET-analysis of the activated carbon including of coconut shell char (S-BET: 298 m2/g)

which were used to convert into activated carbon (1,355 m2/g) and applied to the KOH-activation in this work. After KOHactivation shows the increasing BET surface areas of coconut shell AC in accordance to addition of AC/KOH mass ratio [Fig.3 a) increasing SBET=1,300~1,900 from 1/0 to 1/2; b) 2,200 ~ 2900 m2 from 1/3 to 1/5 with mass ratios of C/KOH] It was confirmed that increasing rate of BETsurface area was 300 m2/g and limited max. 2970 m2/g was in case of the mass ratio 1/5 of AC/KOH with the coconut shell activated carbon.

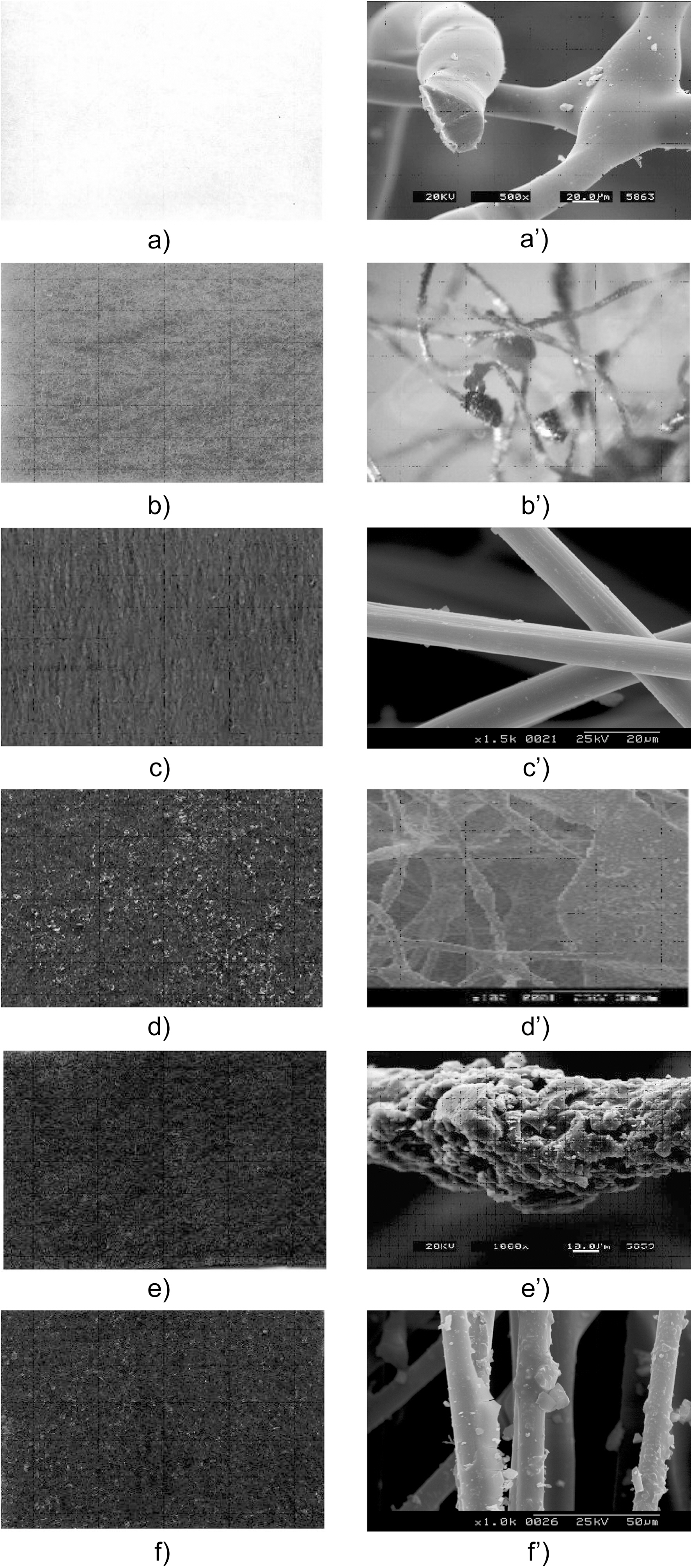

Fig. 4 shows photos from white color PE-nonwoven fabrics(a), its brown color thermostable PE-nonwoven fabrics(b) and black color of Sigri-thermospelz(c) to their SEM picture are (a’), (b’) and (c’). Pictures (d), (e) and (f)

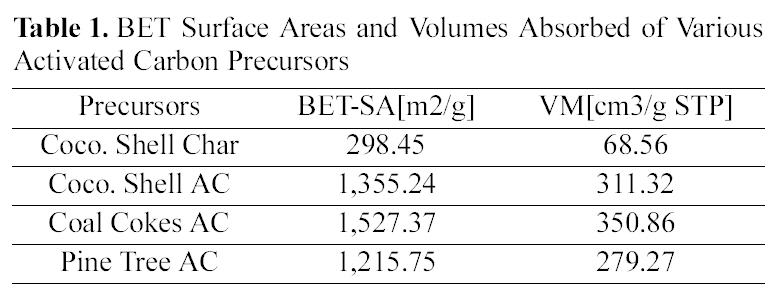

[Table 2.] Isotherm Adsorbed (mg/g STP) of I2 (0.02N) and Methylene Blue (0.24 mg/l)

Isotherm Adsorbed (mg/g STP) of I2 (0.02N) and Methylene Blue (0.24 mg/l)

are the AC-Immobilized adsorption filters by means of epoxy resin and isotropic pitch binders, and their magnifications (d’), (e’), and (f’), respectively.

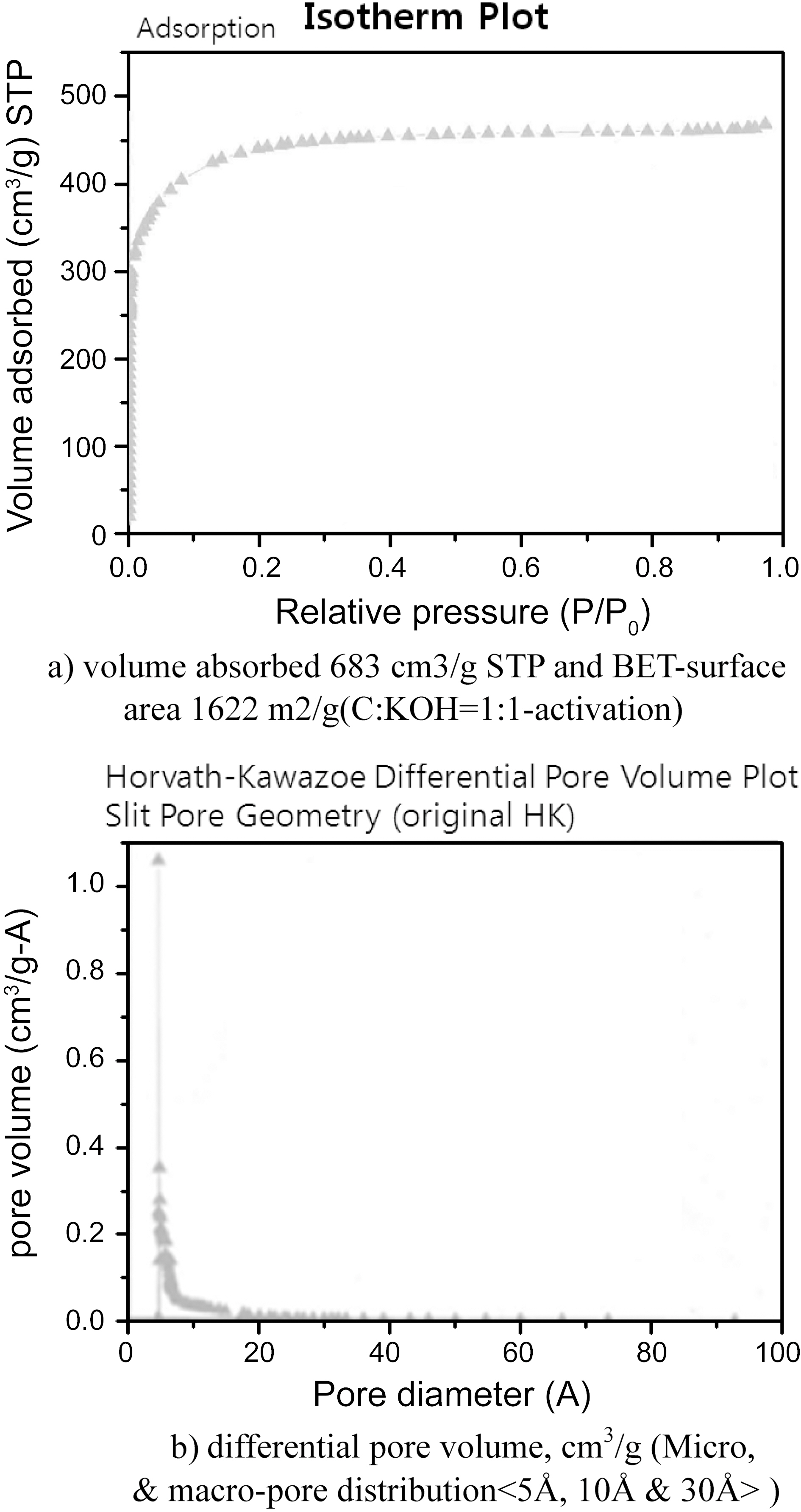

Fig. 5 shows Enhancements of BET-surface area increased by 270 m2/g) and micropore promotion (<5 A~30 A>) after reactivation of the AC-Immobilized Adsorption Filter developed in this work by means of isotropic pitch binder.

In the Table 2, we can confirm that the enhancement effects on the adsorptivity of iodine and methylene blue were each 1.4 times promoted by surface area increase of 266 m2/g.

In this work we have developed AC-immobilized adsorption filter with thermostable PE-nonwoven fabrics for the moderate temperature and with Sigri-thermospelz for high temperature by means of isotropic pitch binder which enhanced not only surface area, also adsorptivity of Iodineand Methylene blue as the model pollutant. The applied AC was coconut shell based activated carbon which has surface area of 1355 m2/g, and enhanced to 2970 m2/g by reactivation after the KOH-activation with mass ratio1/5 of C/KOH.