In this work, standardization trends related carbon nanotubes and international standardization activities in the ISO/TC229 and IEC/TC113 were introduced. The movement toward development of carbon nanotube standard began in the nanotechnology council under the IEEE in 2005. KATS has also run the carbon nanotube standardization committee to support commercialization of product containing carbon nanotube through standards since 2004. The Korean Standards such as KSD2711, 2712, 2717 were established.

Carbon nanotubes are one of new materials which will help mankind's dreams come true. Research and development on carbon nanotubes are expected to overcome the limits of existing material properties, and are associated with recent developments in light weight materials for commercialization of products [1-5].

However, due to difficulties in handling nano materials there is an obstacle to evaluating product characteristics related to safety and quality control. Test method standards are being developed to help get over this barrier and market launch products containing nano materials. Internationally approved terminology is necessary to establish standards and restrictions that are trustworthy and commonly accepted. Standard development for safety evaluation and technology development in the field of carbon nanotubes and their application for products is making progress in international standardization organizations such as ISO/TC229, IEC/TC113. The strategic policy of ISO/TC229 is to support industrialization of technology and products, and simultaneously clarify unknown dangers and develop risk management programs and standards [5-9].

Meanwhile, OECD/WPMN has begun to develop test guidelines for evaluation of toxicity for 14 nanomaterials including carbon nanotubes, Ag, titanium oxide, etc., as well as activities focused on risk management for health and safety in the workplace or laboratory. In this way we are seeing a move in the direction of clearer social responsibility requirements for researchers and manufacturers [9-13].

2.1. Foreign standardization trends

Research on mass production of high quality carbon nanotubes, physical and electron emission characteristics, and applications of nano materials are improving the competitive power of multi-functional nanomaterials.

The movement toward development of carbon nanotube standards began in the nanotechnology council under the IEEE, and they developed IEEE-1650 (Standard Test Methods for Measurement of Electrical Properties of Carbon Nanotubes) to support researchers and manufacturers in 2005. IEEE-1650’s contribution enabled unification of the procedure for reporting and test methods for evaluation of carbon nanotube electrical characteristics. Recently, IEEE-1650 was submitted for review to IEC/TC 113 and will be published as double logo IEEE/IEC.

Our country runs the joint project group in IEC/TC113 for the TS for electrical characterization of carbon nanotube using 4-probe measurement, which was approved as NWIP (New working item proposal) in 2008. The standards under the IEC/TC 113 related to carbon nanotubes are as follows; Technical specification for the determination of metal impurities in carbon nanotubes (CNTs) using inductively coupled plasma-mass spectroscopy (ICP-MS), technical specification for the electrical characterization of carbon nanotubes (CNTs) using 4-probe measurement, and IEC 62565 Ed.1 : Guidelines for single wall carbon nanotube specifications for electrotechnical applications.

In addition to the activities of IEEE, NASA has collaborated with NIST to host the workshop on the standardization of carbon nanotubes. The guideline on purity and dispersion that appeared as issues was suggested to need standardization for carbon nanotubes. Professor, Younghee Lee attended as the Korean representative for carbon nanotube standardization, and has led the carbon nanotube standardization committee established by KATS in 2004 [14,15].

These activities triggered the establishment of new ISO technical committee, ISO/TC229, to develop international

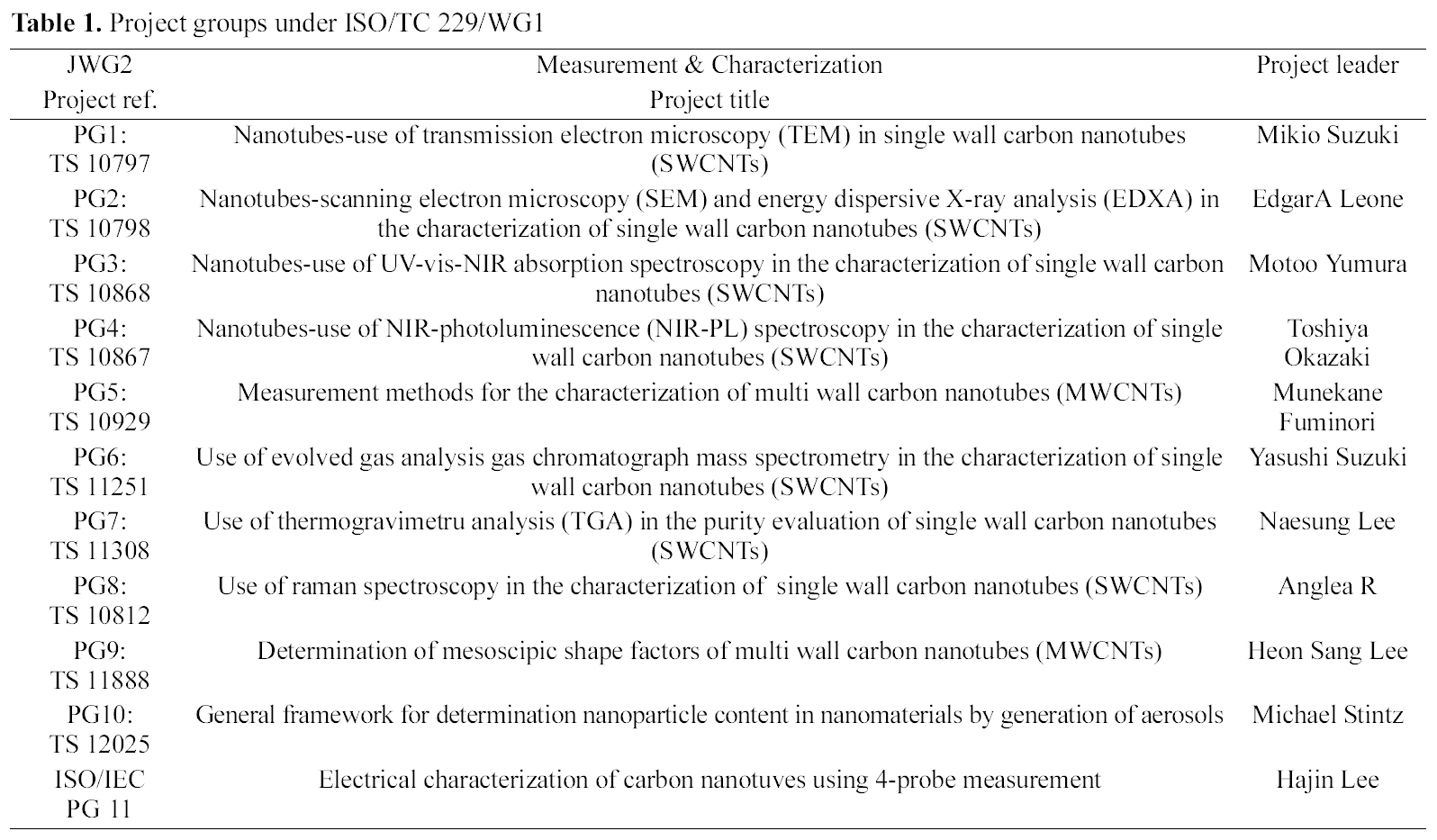

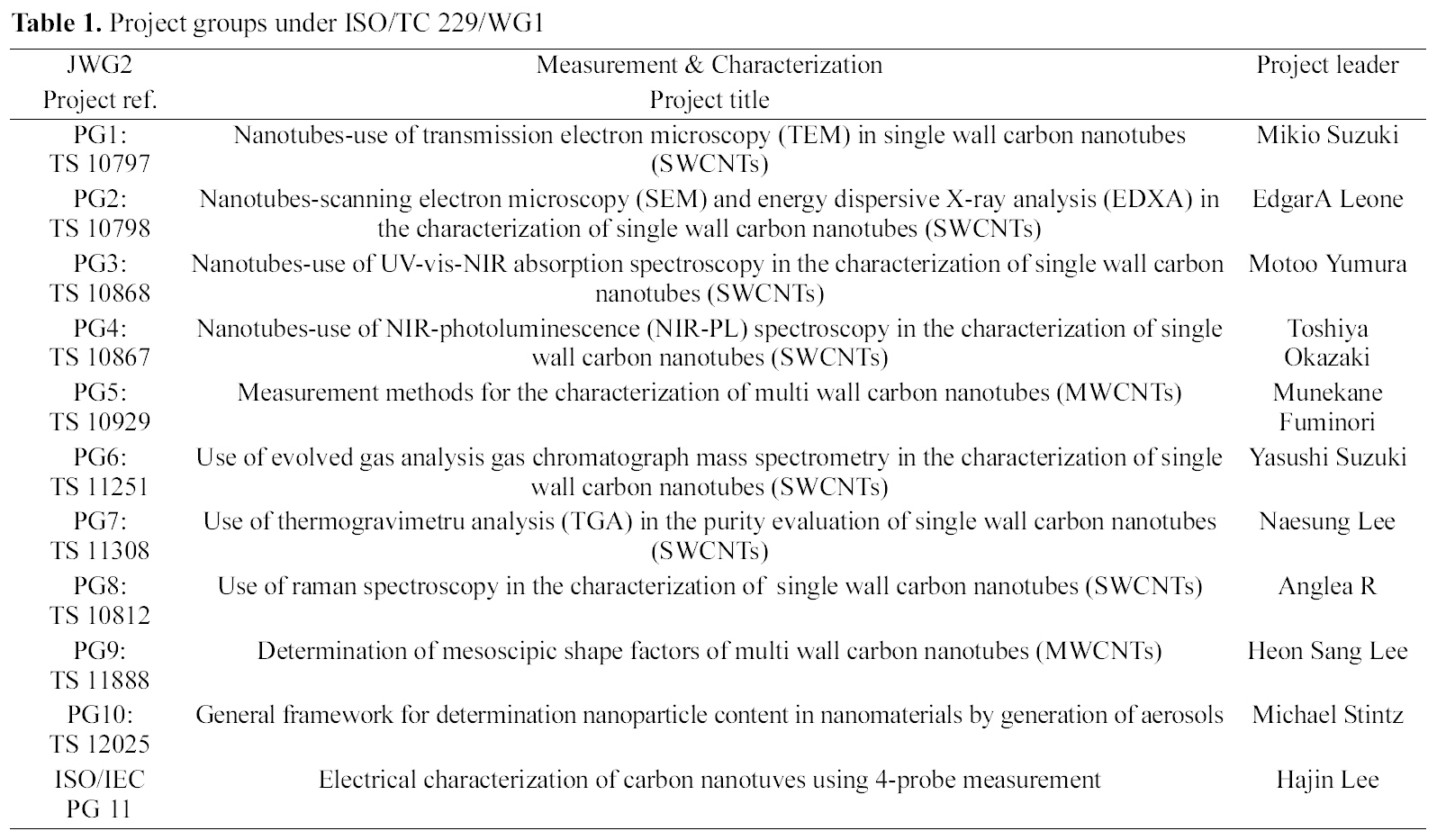

[Table 1.] Project groups under ISO/TC 229/WG1

Project groups under ISO/TC 229/WG1

standards for nanotechnologies. Its inaugural meeting was held in 2005 and this year, the 8th general meeting will be held in Seattle. At present, the national standard institutes of 30 ISO member countries are participating, and eight member countries have observer status. Its working group structure is as follows, WG1, Terminology and nomenclature, WG2, Measurement and characterization, WG3, Health, safety and environment, WG4, Nanomaterial specification. Each working group is developing several documents related to carbon nanomaterials. Exposure evaluation and inhalation toxicity testing of carbon nanotubes and products containing carbon nanotube will start in near future because the safety issue of carbon nanotube is at the center of controversy. Considering the important demand for carbon nanotubes applied in energy storage devices and as a light source in the electronic and display industries, the development of standards for the reliability of products has been assigned to IEC/TC 113, and product safety evaluation corresponds to the activities of ISO/TC229.

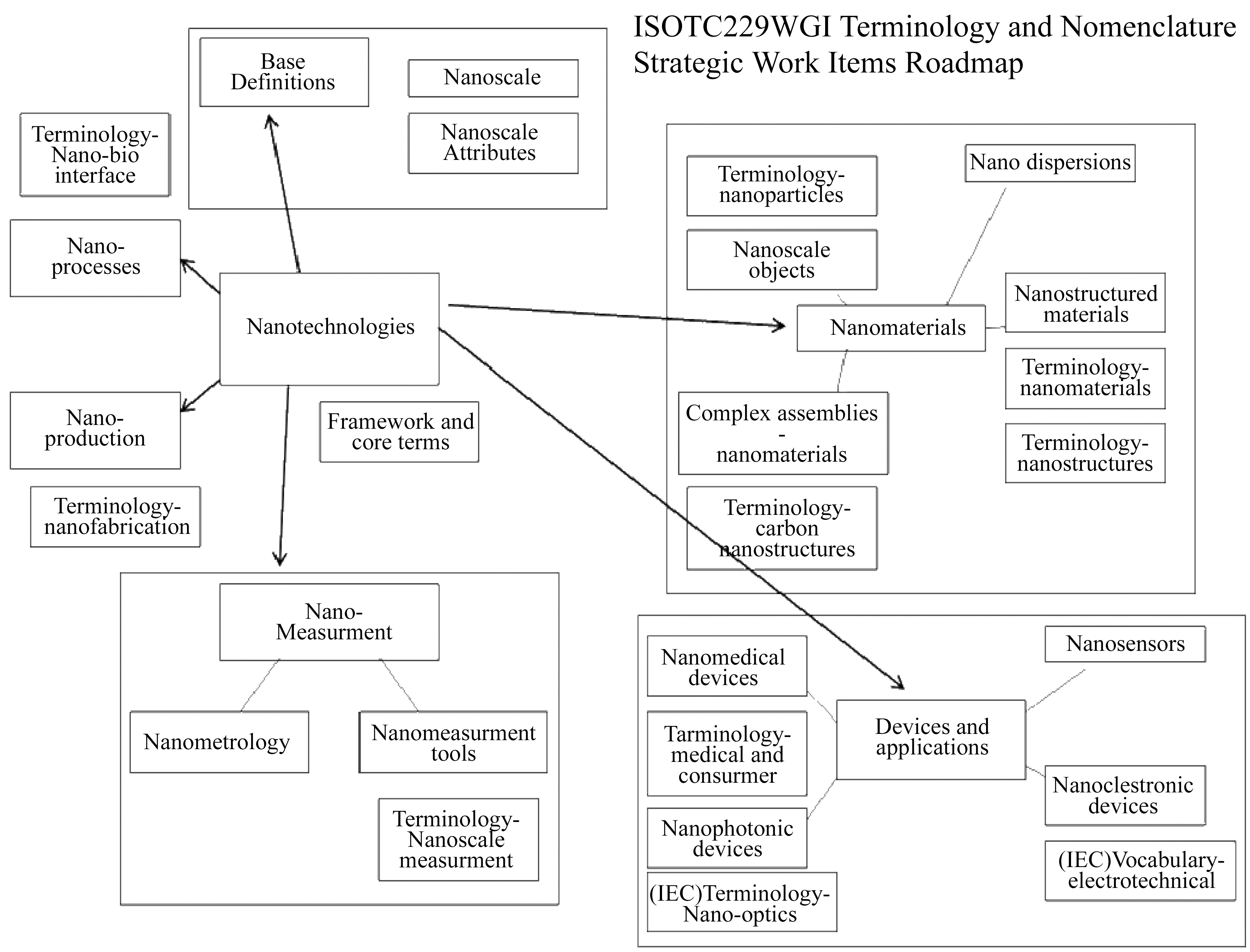

2.1.1. ISO/TC 229/WG1 (Terminology and nomenclature)

In 2008, ISO/TC229/WG1 published ISO/TR 27687, Nanotechnologies-Terminology and definitions for nano-objects, nanoparticle, nanofiber and nanoplate, in which we defined nano scale as a range between approximately 1 and 100 nm. Included was terminology describing nano tube, nano horn, nano fiber, nano material. At present, the standardization of terminology is basic, and so ISO/TC 229 JWG1 is making progress on development of standards for nano objects and key terminology describing carbon nanomaterials, nano-structured materials, bio-nano interfaces, nanoscale measurement and instrumentation, nano-production and nano-fabrication. It is significant to note that the international standard on terminology is expected to become the basis of regulation.

2.1.2. ISO/TC 229/WG2(Measurement and characterization)

The nanomaterial standardization priority in ISO/TC229/JWG2 is the carbon nanotube. 11 documents associated with purity evaluation and characterization of carbon nanotubes using SEM, TEM, UV-VIS-NIR-TGA, etc., are in progress. Our country submitted three documents to ISO/TC 229, and runs project groups, PG7, PG9 and PG11 under JWG2.

PG7 handles the purity evaluation of single walled carbon nanotubes using TGA. PG leader, Professor Nsesung Lee, jointly with the ANSI (American National Standardization Institute) has prepared the FWD (Final working draft) and it will be circulated to country members as a CD (Committee draft) for balloting. PG9 deals with measurement of mesoscopic shape factors of carbon nanotubes and PG11 is associated with measurement of electrical properties of carbon nanotubes. Both are being prepared for WD (Working draft). Usually, the international standard process follows each sequential stage as such: NWIP, WD, CD, DIS, FDIS and IS.

The strategic policy of WG2 is to develop technical specifications (TS) rather than international standards (ISO)

in consideration of the urgency of distributing guidances. The development period of TS is shorter than that of ISO.

2.1.3. ISO/TC 229/WG3 (Environmental/Health/Safety)

WG3 has set targets on development of safety evaluation standards for the market entry of nanomaterials and nanomaterial containing products.

ISO/TR 12885 (Nanotechnologies - Health and safety practices in occupational settings relevant to nanotechnologies) was published in 2008. It provides a guideline for health and safety in the workplace.

In WG3, documents such as endotoxin test for nanomaterial samples for in vitro systems, and generation and characterization of nanoparticles for inhalation toxicity testing have being created. The USA is leading the document on the evaluation of physical and chemical characteristics of nanomaterials to back up toxicity evaluation.

WG3 established a roadmap for the standardization of safety for nanotechnologies and suggested Toxicological Screening Techniques, Occupational Exposure Controls, and Toxicological Assessment Techniques as priority items. Recently, development of a framework for nanomaterial risk management and evaluation has begun. In conclusion, a risk management program is being requested to be developed in parallel with the technologies.

2.1.4. ISO/TC 229/WG4 (Nanomaterial specifications)

WG4 was established for the standadization of nanomaterial specications, At present, NWIPs for specifications of titanium oxide and calcium carbonate were submitted, and these are in the WD stage. In the case of carbon nanotube specifications, IEC/TC 113 is handling the guideline for single wall carbon nanotube specifications for electrotechnical applications. It is currently in the CD stage.

2.2. Domestic standardization trends

In agreement with the necessity of standardization in the filed of carbon nanotubes, the Carbon Nanotube Standardization Committee, which consists of experts from industries, universities and institutes was established in 2004. First, the committee started to develop standards on purity evaluation of carbon nanotubes, established as Korean Standard, KSD 2711 (Evaluation of carbon nanotube soots and non carbon content - Thermogravimetric methods) and KSD 2712 (Evaluation of content of single walled carbon nanotubes using UV-VIS-NIR absorption spectroscopy) in 2006. KSD 2717(Evaluation of metallic/semiconducting ratio of single-walled carbon nanotubes using UV-VIS-NIR absorption spectroscopy) established in 2008, was developed in collaboration with the carbon nanotube standardization committee too. Until the present time, the Carbon Nanotube Standardization Committee has contributed to international standardization activities and development of domestic standards involving carbon nanotubes.

The domestic roadmap on nanotechnology standardization covering nanomaterials/environment/energy, nanobio, nanodevice, and nano measurement/process/instruments was developed in 2007 by the standardization committee for roadmap. In the roadmap on nanotechnology standardization prepared by KATS, detailed standardization items such as the carbon back light unit and carbon nanotube transparent electrode were chosen as priority target items.

In parallel with the development of standards to support commercialization such as KSD2711, 2712 etc., KATS (Korean Agency for Technology & Standards) has already developed a guideline based on ISO/TR 12885 (Nanotechnologies - Health and safety practices in occupational settings relevant to nanotechnologies) with references to guides issued in the USA and UK, and reviewed its adaptability considering the situation for Korean workplaces and laboratories. The guidance will be established as a KS in April 2009. Moreover, KATS started developing a guideline on nanomaterial exposure risk management and tracking the real conditions in workplaces and laboratories with nanomaterial exposure assessment. One of the target materials is carbon nanotubes.

Nanotechnology development has innovative potential energy to transform our quality of life. From agriculture, medicine, food to energy, in the process of industrialization of novel products, the significance of standardization will increase.

Standardization in the field of nanotechnologies includes measurement of characteristics and safety evaluation, and construction of systems by mutal agreement to evaluate advantages and dangers to humans and the environment. Standardization will support commercialization of nano products and help attain wider social acceptance of nano products. ISO/TC229(Nanotechnologies) and IEC/TC 113 (electrical and electronic standardization on nanotechnologies) are making progress in standardization which will provide the basis for technological development, commu-nication tools for nanotechnologies, securing Intellectual Property rights and evaluation of the effect of nanomaterials including carbon nanotubes.

In addition to those pervasive benefits, standardization on environment, health and safety issues can lay the groundwork for risk evaluation. Standardization for nanomaterial specifications, including carbon nanotubes, will enable planning for the performance and quality control of nanoproducts.

Due to these high stakes, the USA, Japan, and Korea are competing for selection of their native standard and technologies as models for international standards.