Transparent conducting films based on carbon nanotubes (CNTs) have received considerable attention in various fields, including the display technology, solar cell, flexible electronic device,automobile, and optical device fields [1-10]. CNT-based conductive-coating technologies have many potential applications in areas such as electrostatic dissipation, electromagnetic-interference shielding, and corrosion protection, as well as in the development of transparent film heaters and new electrode materials. To improve the mechanical and interfacial properties of CNT-based conductive films on a substrate, the CNT films should be passivated or hybridized with binder materials such as a polymer, a silane compound, or a titanium compound. During the development of high-quality films with controlled transparency and conductivity, it is also important to consider the long-term stability of the CNT/binder coating solution. The conductivity of transparent CNT-based conducting film can be controlled by material properties such as the purity, diameter, defects, metallicity, and the degree of dispersion of the CNTs [11]. Another factor is the tunneling effect through the insulating layer around the nanotubes [12]. At present, for a transparent conductive coating based on CNTs, membrane filtration and spraying methods are typically used. A spray application, when applied over a large and irregular area, is advantageous for fast throughput fabrication. In this case, the wettability of the CNT/binder coating solution on the substrate should be controlled to fabricate highly transparent and conductive thin films, as the film thickness should be less than several hundred nanometers. In this respect, compatibility between the coating materials and the substrate is a defining factor which affects surface properties and interfacial interactions related to adsorption, wetting, and adhesion [13].

In this study, we investigated the effect of coupling agents on the optoelectrical properties of transparent CNT/binder films prepared on glass substrates. First, the functionality of the CNTs in the preparation of a coating solution was optimized by a HNO3 treatment. We matefound that a coupling agent is very effective in the creation of a uniform film, as it decreases the sheet resistance of the films.

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/3.0/) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Few-walled CNTs (FWCNTs) with an average diameter of 3-5 nm and a length ranging from hundreds of nanometers to micrometers (obtained from Hanwha Nanotech Inc., Incheon, Korea) were used in this study. Epoxy acrylate resin was obtained from Nippon Kayaku Co. (Niigata, Japan), and the crosslinking agent used in this study was dipentaerylthritol hexaacrylate, as supplied by San Nopco Co. (Shanghai, China). It was used as received. Acryloxypropyltrimethoxysilane was obtained from Shinetsu Chemical Co. (Tokyo, Japan) and was used as received.

2.2 Preparation of CNT/silane sol hybrid films

To optimize the acid-treatment condition, oxidation of FWCNTs was done using the method described in Table 1. The FWCNTs were immersed and refluxed in nitric acid to attach carboxyl groups onto their side walls. The samples were then extracted several times by vacuum filtration using an alumina filter until the solution reached a pH value of 7. Finally, 20 mg of the filtered FWCNTs were dispersed in 200 mL ethanol for 2 h in an ultrasonic bath. The epoxy acrylate resin and a crosslinking agent were then added to the CNT solution at a certain concentration. The fabrication of the CNT/epoxy resin hybrid film was achieved using an automated spray-coater (NCS Co., NCS200) with a nozzle diameter of 1.2 mm at 70℃. The prepared FWCNT/epoxy resin hybrid films were then heated under a vacuum for 3 h (at 150℃) to remove the remaining chemicals,after which the binder resin was cured with a UV lamp.

The Raman spectra were measured to characterize the disordering of the FWCNTs after an acid treatment at room temperature using a high-resolution Raman spectrometer (LabRAM HR800 UV; Horiba, Kyoto, Japan) under excitation at wavelengths λ of 633 nm. Corresponding images of the prepared films were obtained by scanning electron microscopy (SEM,

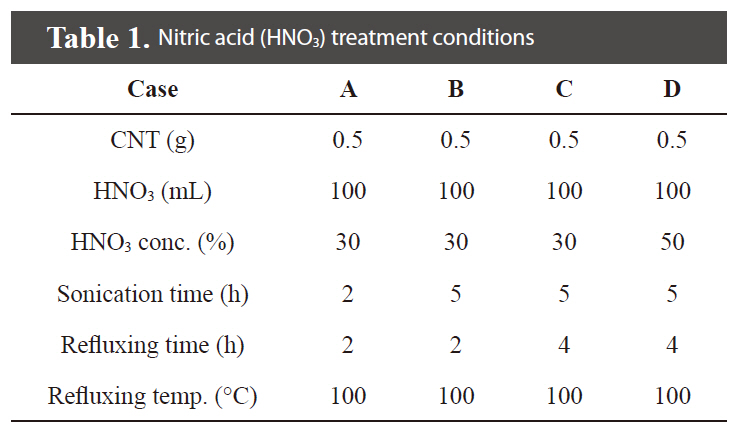

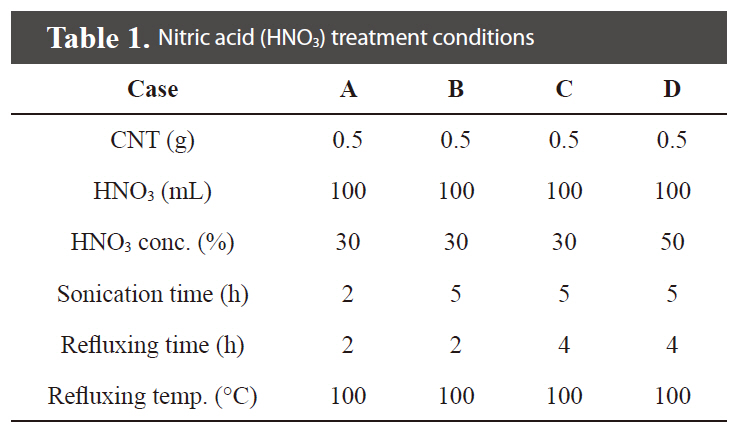

[Table 1.] Nitric acid (HNO3) treatment conditions

Nitric acid (HNO3) treatment conditions

HITACHI S4800; Hitachi, Tokyo, Japan) and optical microscopy (OM). The sheet resistance was measured using a fourpoint probe tester (MCP-T610; Mitsubishi, Tokyo, Japan). The transmittances of the films were measured using a Varian Cary winRV spectrometer (Varian, Palo Alto, CA, USA).

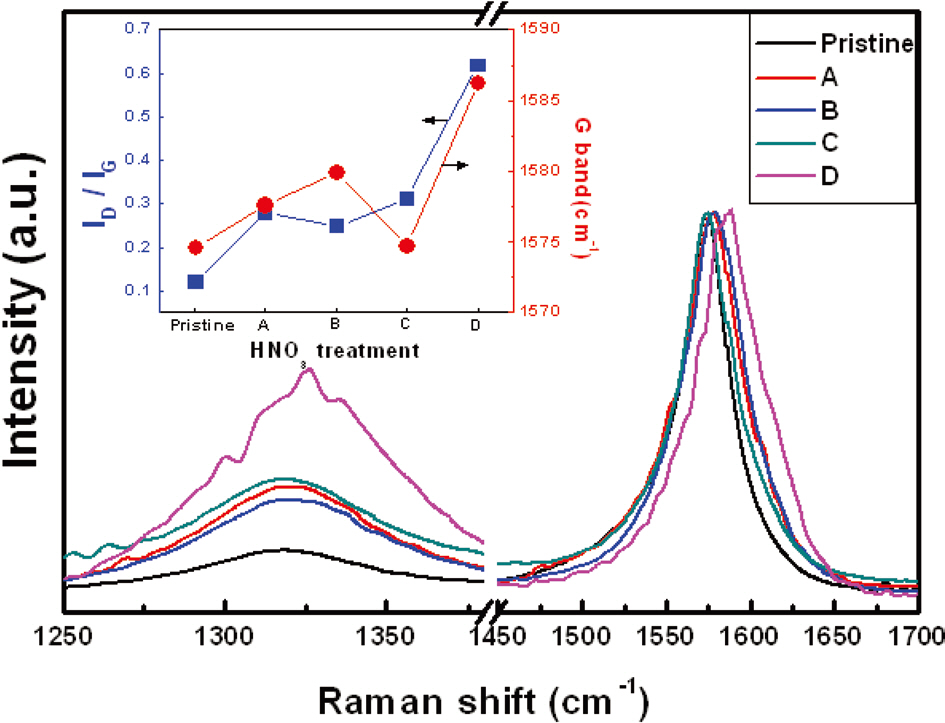

To fabricate CNT/binder hybrid thin films by spraying or spin-coating, first the CNTs must be well dispersed in an organic solvent. The stability of the dispersion should be maintained by mixing with binder materials or additives. The wettability of the components in the CNT/binder mixture solution on the target substrate should also be considered. Here, interfacial engineering concepts can be applied to balance the interaction at the interface of all of the components, including the CNTs, solvent and additives, binder materials, and substrates (Scheme 1). It is well known that carboxyl groups after a HNO3 treatment cause a reduction of the van der Waals interactions between the CNTs, which is useful for the dispersion of CNTs in aqueous or organic solvents [14]. For a stable dispersion of FWCNTs in a binder mixture solution, the FWCNTs were treated with nitric acid by varying the HNO3 concentration, sonication time, and refluxing time to optimize the dispersion condition, as shown in Table 1.Fig. 1 depicts typical G and D bands of the Raman spectra at an excitation wavelength of 633 nm for pristine and acid-treated FWCNTs. The ratio of the D-to-G peak intensity (ID/IG) gradually increased as the refluxing time and HNO3 concentration increased.Considering the electrical and dispersion properties of the FWCNTs, we selected the FWCNTs treated under condition C for further study.

Next, we prepared the FWCNT dispersion solution in ethanol via a bath sonication method and added epoxy acrylate as a binder material. We observed that the dispersion of the FWCNTs in a vial was stable after the addition of the binder mate-

Scheme of (a) interfacial engineering for high-performance carbon nanotube (CNT)/binder hybrid films, (b) a dewetted film, and (c) a uniform film.

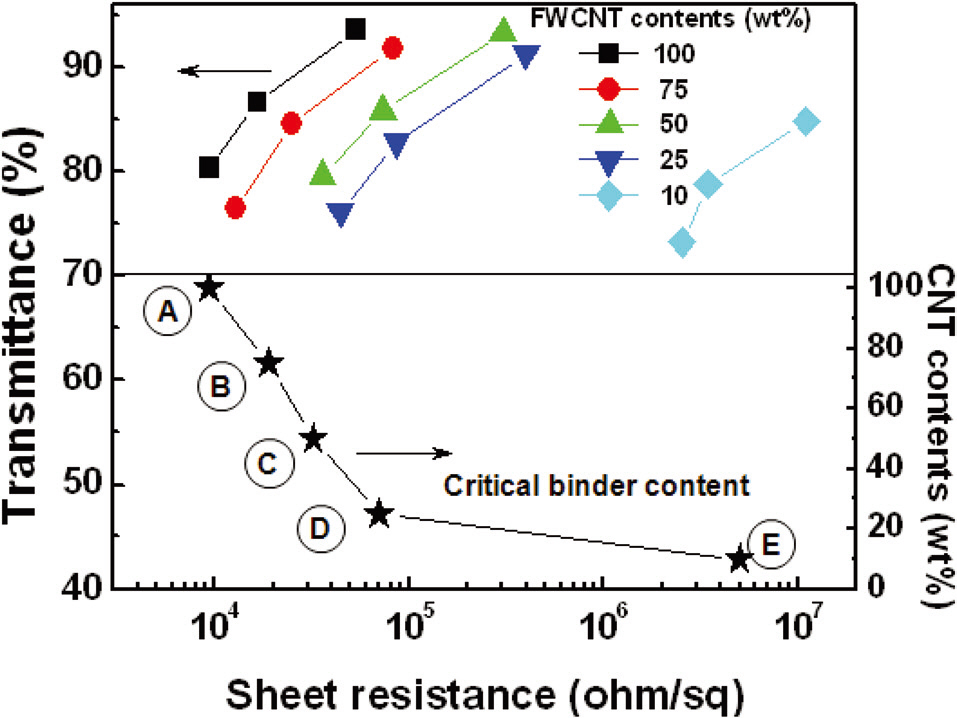

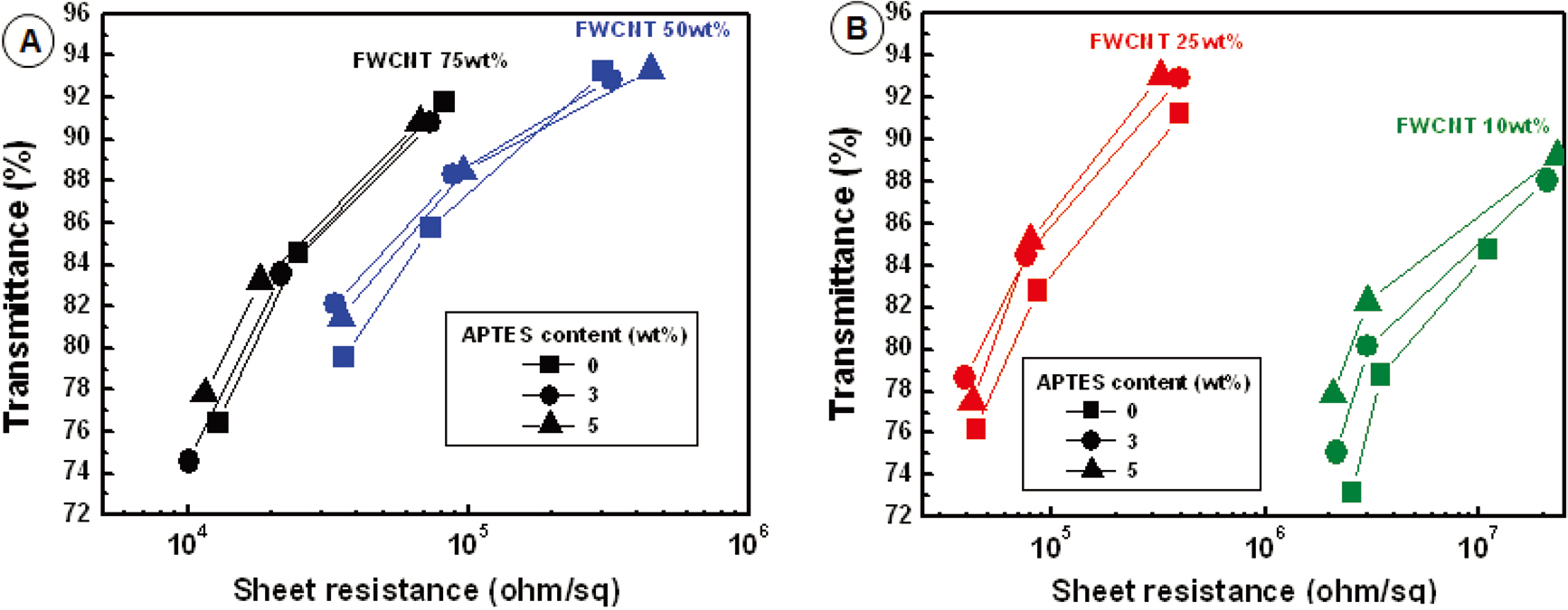

rial. The transmittance and sheet resistance of the spray-coated CNT/binder films depend on the amount of deposited CNTs and binder material and on the ratio of the CNT and the binder. From a plot of the sheet resistance as a function of the binder content,it is evident that a critical binder content (Xc) exists above which the sheet resistance increases dramatically [12,15]. To determine the value of Xc, the effects of varying the binder content in the FWCNT/silane hybrid films on their optoelectrical properties were investigated. We used a simple spray-coating to fabricate FWCNT/epoxy resin thin films with a transmittance at 550 nm of 70-95%. FWCNT/epoxy resin solutions with various epoxy resin contents (0, 25, 50, 75, and 90 wt%) were deposited on UVO-treated glass substrates. Fig. 2 shows a plot of the transmittance vs. sheet resistance of the FWCNT/epoxy films with various binder contents. Both parameters were found to decrease with an increase in the amount of spray-coated CNT/binder solution.Note that the sheet resistance increases dramatically at a certain binder content. In this system, the critical binder content,

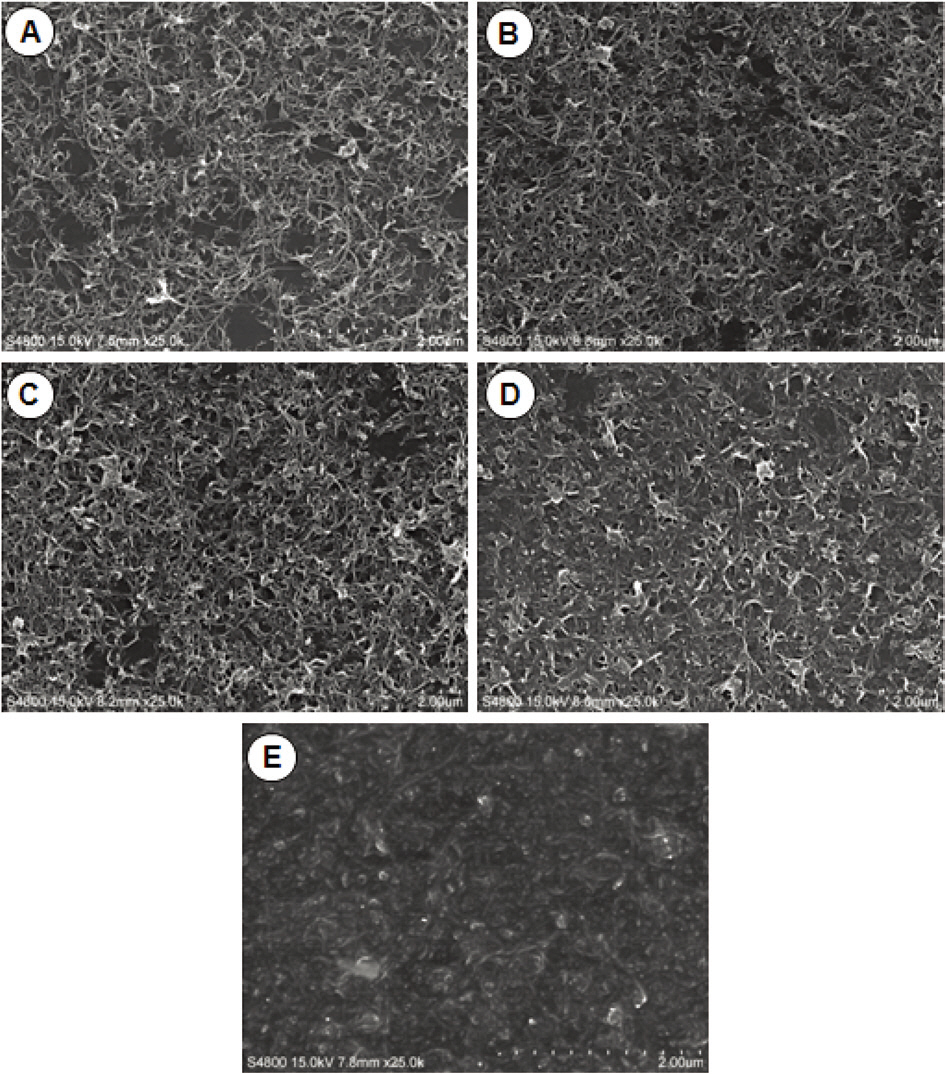

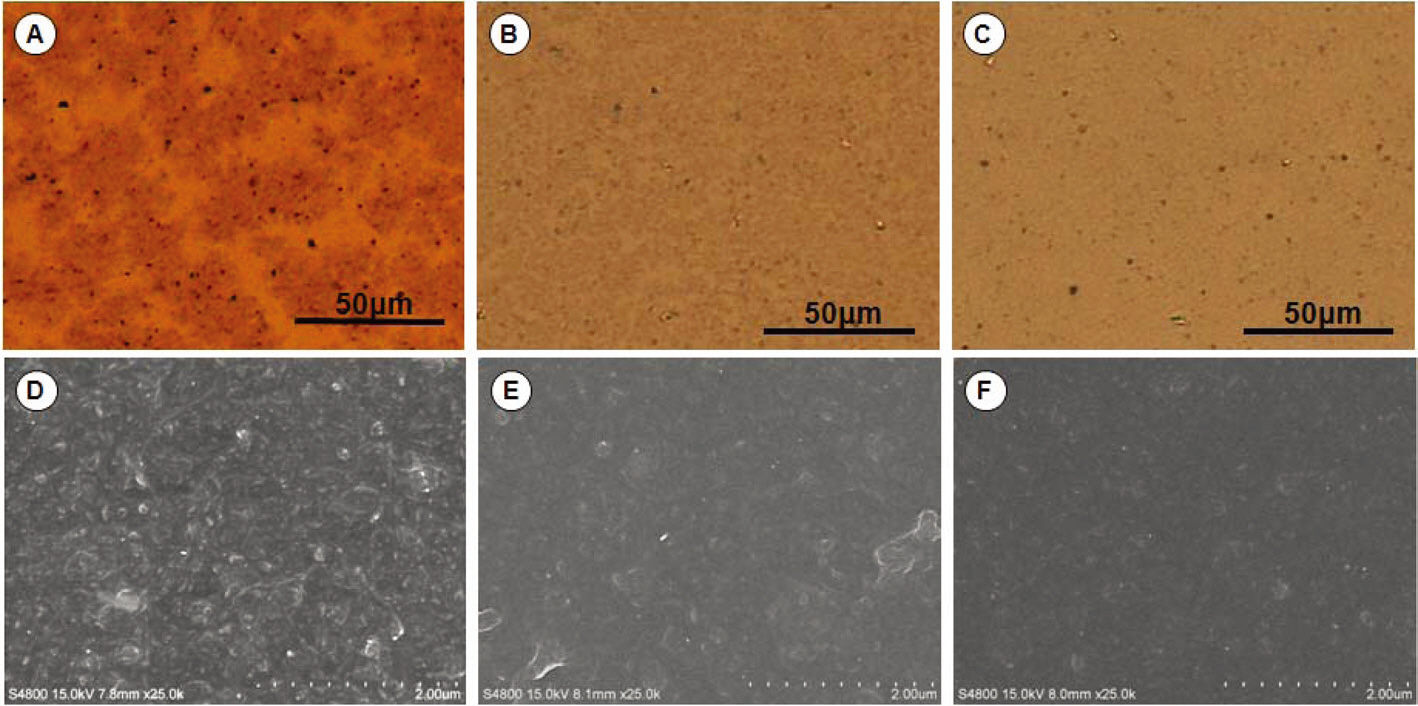

Xc, is approximately 75 wt%. Fig. 3 shows SEM images of the FWCNT/epoxy resin hybrid thin films fabricated on glass substrates. It was found that above a critical binder content, the FWCNTs were fully covered with epoxy resin, thus increasing the contact resistance between the FWCNT network and the probe and decreasing the tunneling between the FWCNTs through the insulating binder layer between the FWCNT bundles.

Silane coupling agents have been used to modify or strengthen the interface between filler particles and matrix materials in the fabrication of reinforced composite materials. In this study, to study the silane coupling agent effect, we added a UV-curable silane agent with an acryloxyl group to the FWCNT/epoxy resin solution and spray-coated it onto UVO-treated glass substrates. Fig. 4 shows the sheet resistance-transmittance curve of FWCNT/binder hybrid films containing various amounts of the silane coupling agent (0, 3, 5 wt%) over a wide range of film thicknesses. It was found that the sheet resistances of the films gradually increased when increasing the amount of the coupling agent. Note that the coupling agent effect was dominant on the films containing epoxy resin above the Xc value. As shown in Fig. 5, OM and SEM images of the FWCNT/binder hybrid films containing coupling agent molecules clearly show that they are more homogeneous than that of films without coupling agent molecules. In particular, without coupling agents, a dewetted pattern is clearly formed after spray-coating, which may explain the high sheet resistance of the film. These results indicate that the sheet resistance and the transmittance depend on the wettability of the binder materials on the substrate.

Our results have important implications for the fabrication of highly transparent and conductive films from CNT and binder

mixed solutions. Our strategy can be applied to various substrates and coating solutions prepared with different solvents and binder material. Moreover, we suggest that the transparency of CNT/binder films with high sheet resistance can also be manipulated with the addition of a coupling agents, which can control the CNT density and aggregation states during a film formation process because the conductivity and transparency depend primarily on the CNT density.

In this study, we systematically investigated the effect of a coupling agent on the optoelectrical properties of FWCNT/binder hybrid films. To do this, we first optimized the acid-treatment condition of the FWCNTs considering the dispersion stability of the coating solution. The transparent and conductive CNT/binder hybrid thin films were fabricated in a spray-coating process onto hydrophilic glass substrates, after which the Xc value was determined by varying the amount of the binder material.Significantly, we found that the uniformity of the films was enhanced by introducing acryloxyl silane coupling agents, which improved the wettability of the FWCNT/binder solution and thus the optoelectrical properties of the films.