Commercial PAN fibers were thermally stabilized at 220 or 240oC for 30 min. Those fibers were further stabilized using radio-frequency (RF) capacitive plasma discharge during 5 or 15 min. From Fourier transform infrared spectroscopy results, it was observed that an additional plasma treatment led to further stabilization of PAN fibers. After stabilization, carbonization was performed to investigate the final tensile properties of the fabricated carbon fibers (CFs). The results revealed that a combination of thermal and plasma treatment is a possible stabilization process for manufacturing CFs. Morphology of CFs was investigated using scanning electron microscopy. The morphology shows that the plasma stabilization performed by the RF large gap plasma discharge may damage the surface of the CF, so it is necessary to select a proper process condition to minimize the damage.

DuPont in 1941 produced polyacrylonitrile (PAN) spun fibers for textile purpose under the name of Orlon [1].Initially, precursors for commercial carbon fibers (CF)manufactured by Union Carbide in the late 1950s were Rayon [1]. In 1960s, Shindo [2] developed a process of PAN based CF and the process has been widely used in the industry due to its combination of high tensile and compressive strength in resulting CFs as compared to those of other precursor fibers. Nowadays, ~90% of CFs produced in the world are PAN based CFs. PAN for CF precursors is co-polymer containing acrylontrile (>90%) and various comonomers such as methyl acrylate, methyl metharcylate,metharcrylic acid, vinylacetate, itaconic acid, and sodium methallyl sulphonate [1].

In general, fiber spinning, stabilization, carbonization,graphitization, surface treatment, and sizing processes are involved in CF manufacturing [3]. In stabilization process,the spun fibers undergo heat treatment at 200 to 300oC in air,which leads to thermally stable ladder structure through cyclization, dehydrogenation, and oxidation to avoid melting during carbonization [4]. It is known that nitrile groups in PAN are initiated thermally through a free radical mechanism,leading to cyclized network of hexagonal carbon-nitrogen rings [5]. Further, the nitrile groups in PAN with a large dipole moment provide high cohesive energy density and chain stiffness, which result in excellent tensile strength [6].Stabilization is one of the most important factors to determine mechanical strength of PAN based CFs. Fitzer et al. [4] reported optimization of PAN fibers stabilization and effect of carbonization of resulting fibers on tensile strength.In conventional process, stabilization is performed for more than a couple of hours, which is time and cost consuming process. Therefore, researches on an effective stabilization have been done to reduce a total cost of CF manufacturing,which is an obstacle for extensive applications to various industries.

Recently, novel methods of CF manufacture using plasma technology are being reported. [7,8] By the plasma discharge in the vicinity of the PAN fiber, air or specific gas used for the process can be ionized or dissociated to make reactive oxidative species such as atomic oxygen. Atomic oxygen,smaller than diatomic oxygen molecule, can diffuse inside the fiber more rapidly because of its smaller size and can shorten the total process time needed for oxidation. In addition, the reactive oxidative species diffused into the fiber tow will stabilize the fibers more actively than diatomic oxygen since the dissociation energy of the diatomic oxygen(498 kJ/mol at 298 K) can further be used to activate the reactions [7]. Therefore, the use of plasma in the CF manufacture is promising in cutting down on the process time and price of CF. However, important characteristics of plasma stabilized CF such as tensile strength are not characterized or reported. Because of the lack of the quality analysis of the plasma stabilized CF, the possibility of application of the fiber in the industry is still under question.

In this study, the effect of plasma assisted stabilization on tensile properties of PAN based CFs at different plasma exposure time was reported. Commercial PAN fibers were stabilized using RF capacitive plasma discharge during various residence time. After stabilization, carbonization was performed to investigate the final tensile properties of the fabricated CFs. Also, morphology of CFs was investigated to observe the damage of the plasma on the fiber surface.

Commercial itaconic acid-modified PAN fibers with 3000 filaments in a tow were obtained from Sinosteel Jilin Carbon Co. Ltd. (Jilin, China). Nuclear magnetic resonance of asreceived fibers showed that a content of itaconic acid was~1 wt%. Molecular weight of as-received fibers was found to be ~140000 g/cm-1 by HLC8320GPC (TOSOH, Japan).

PAN fibers were stabilized using a two-step process.Fibers were thermally treated in a convection oven at 220oC(or 240oC) for 30 min, and then oxygen plasma treatment was performed for various duration times (5 and 15 min).The plasma system is powered by 13.56 MHz radio frequency power source via a matching network and a rotary pump is connected to the sealing reactor to lower the base pressure of the reactor. The pre-thermally treated fibers were loaded in the sealing quartz tube, in which plasma is discharged between two concave electrodes placed outside the reactor. Carbonization of stabilized fibers under nitrogen atmosphere was performed using a tubular furnace (Korea Furnace Development Co. Ltd, Korea). After fiber loading,the temperature was increased to a set point of 1200oC at a rate of 5oC/min, and fibers were cooled down without hold.

FTIR spectra of spun PAN and its stabilized fibers were obtained using a Nicolet iS10 FTIR spectrometer (Thermo Scientific, USA) in a range of 400-4000 cm-1 with an attenuated total reflectance mode. For mechanical testing, a single fiber was loaded to a paper tab with a 25 mm gauge length. An epoxy resin was applied to both ends of fibers,and cured for 24 h at 60oC. Fiber diameters were measured by an optical microscope (Olympus BX51, Japan). The tensile properties were determined using an Instron Universal Tester 5567 (Instron, USA) at 25oC. The crosshead speed was 5 mm/min for all specimens, and twenty replicates were tested at each condition. Surfaces and cross-sections of CFs were observed using scanning electron microscopes (SEMs;Hitachi S-4100 and FE S-4800, Japan).

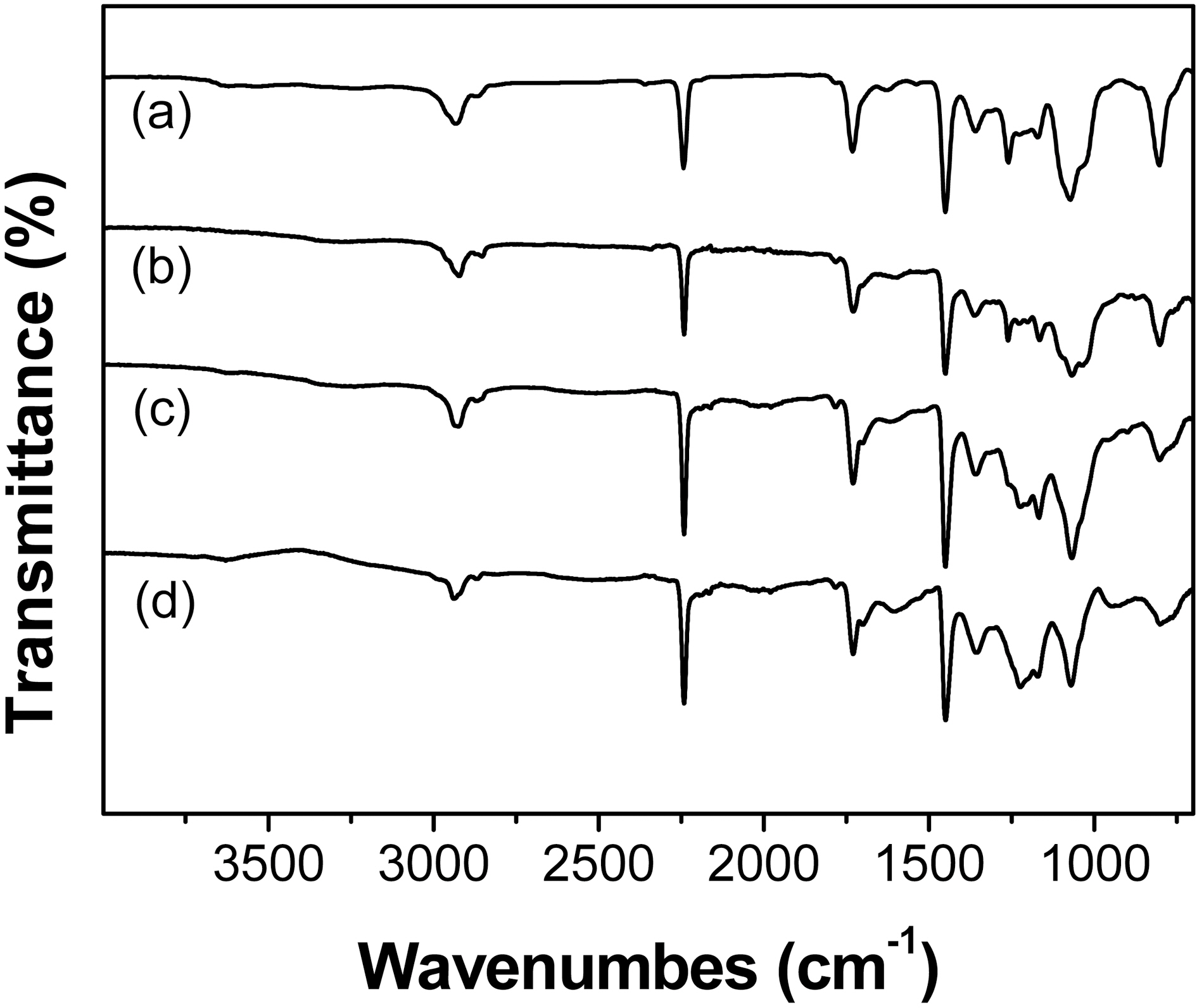

Fig. 1 shows Fourier transform infrared (FTIR) spectra of pure PAN fibers, thermally stabilized fibers at 220×C, and additionally plasma treated fibers. In the spectra of pure PAN fibers, distinct absorption bands appeared at 2939,2243, 1720, 1454, 1360, and 785 cm-1 assigned to νC-H in CH2, νC≡N in CN, νC=O in COOH, δC-H in CH2, δC-H in CH,and δC-C in C-CN, respectively (Fig. 1(a))

In the spectrum of stabilized fibers experienced an additional plasma treatment for 5 min, the intensity of the band at 1595 cm-1 assigned to conjugated C=N stretching increased in Fig. 1(c). The peak was stronger with a longer plasma treatment (Fig. 1(d)). A band at 2243 cm-1 assigned to C≡N stretching decreased with an additional plasma treatment. The degree of cyclization or extent of reaction (EOR), which ranges from 0 to 1 for no cyclization to complete cyclization, was quantified using the intensity of the peak at 1595 and 2243 cm-1 assigned to C=N and C≡N, respectively, in FTIR spectra[EOR=

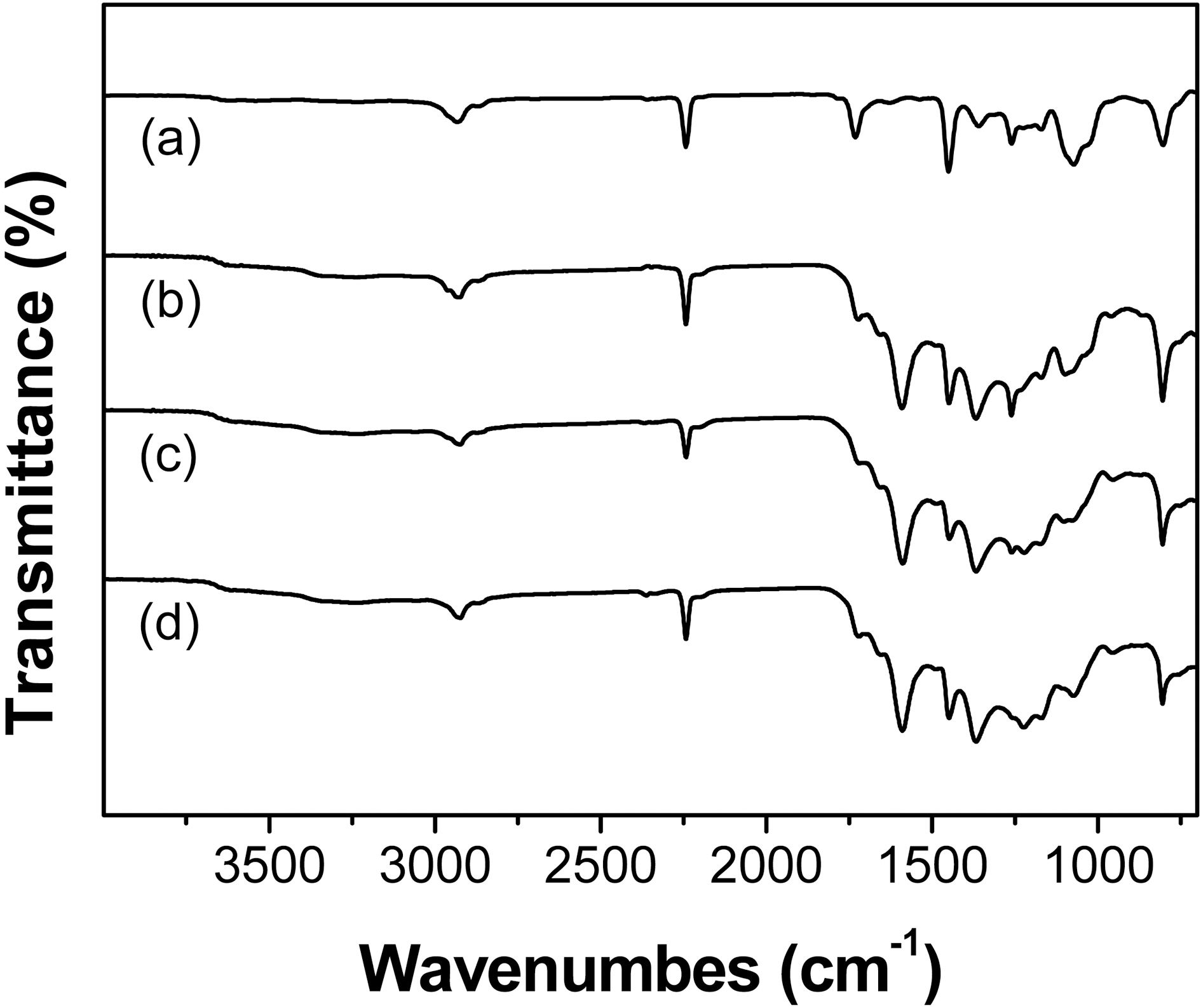

Fig. 2 presents FTIR spectra of thermally stabilized fibers at 240oC for 30 min and additionally plasma treated fibers.Compared to PAN fibers or stabilized fibers at 220oC for 30 min, a strong band at 1595 cm-1 and a decrease of band at 2243 cm-1 were observed, indicating that stabilization took place significantly. However, there was no significant change with the plasma treatment fibers in Figs. 2(c) and (d).

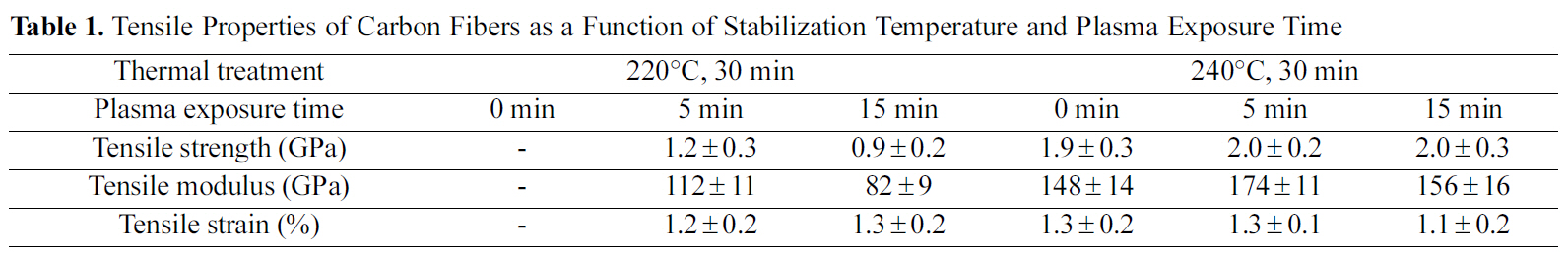

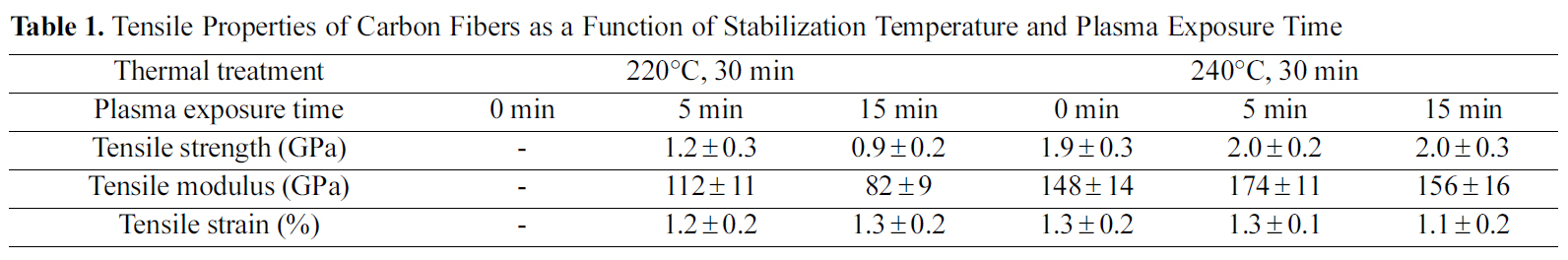

Tensile Properties of Carbon Fibers as a Function of Stabilization Temperature and Plasma Exposure Time

3.2. Tensile properties of CFs

Tensile test of a single filament was conducted after carbonization at 1200oC without tension. Table 1 displays tensile properties of CFs. CFs, which experienced thermal stabilization at 220oC for 30 min, were very brittle. A single filament was not separated from a CF tow, and tensile test was not available. It is recalled that FTIR spectrum of thermally stabilized fibers at 220oC for 30 min represented the low degree of cyclization. However, CFs with an additional plasma treatment for 5 and 15 min showed 1.2± 0.3 and 0.9±0.2 GPa of tensile strength, respectively. Tensile modulus was found to be 112±11 and 82±9 GPa for CFs with an additional plasma treatment for 5 and 15 min, respectively (Table 1). It is worthy to note from tensile properties that an additional plasma treatment for only 5 min led to an extent of stabilization of PAN fibers, which were suitable for carbonization. Furthermore,tensile properties of CFs depended on the plasma exposure time, indicating that the plasma treatment should be optimized for our system to enhance tensile properties.

After carbonization of thermally stabilized fibers at 240oC for 30min, tensile strength was 1.9±0.3 GPa. This indicates that an increase of stabilization temperature (220 to 240oC) affects tensile properties of CFs significantly. Thermally stabilized fibers at 240oC for 30min were plasma-treated for 5 or 15min, and carbonized. CFs with an additional plasma treatment for 5 and 15min showed 2.0±0.2 and 2.0±0.3 GPa of tensile strength,respectively. For tensile modulus, a small increase was observed with CFs experienced 5 min plasma treatment, compared to CFs without plasma treatment (148 ± 14 to 174 ± 11 GPa).However, it is likely that the longer plasma exposure such as 15 min led to a decrease of tensile modulus of CFs (Table 1).

From tensile test results, the thermal stabilization at 240oC led to the higher tensile strength and modulus of CFs than that at 220oC with plasma treatment did. We believed that since plasma treatment is not optimized, CFs stabilized with the thermal and plasma treatment did not show a high enough tensile properties, which are from CFs stabilized with a conventional thermal treatment. However, it is suggested that a combination of thermal and plasma treatment is a possible stabilization process for manufacturing CFs with reducing stabilization time and temperature.

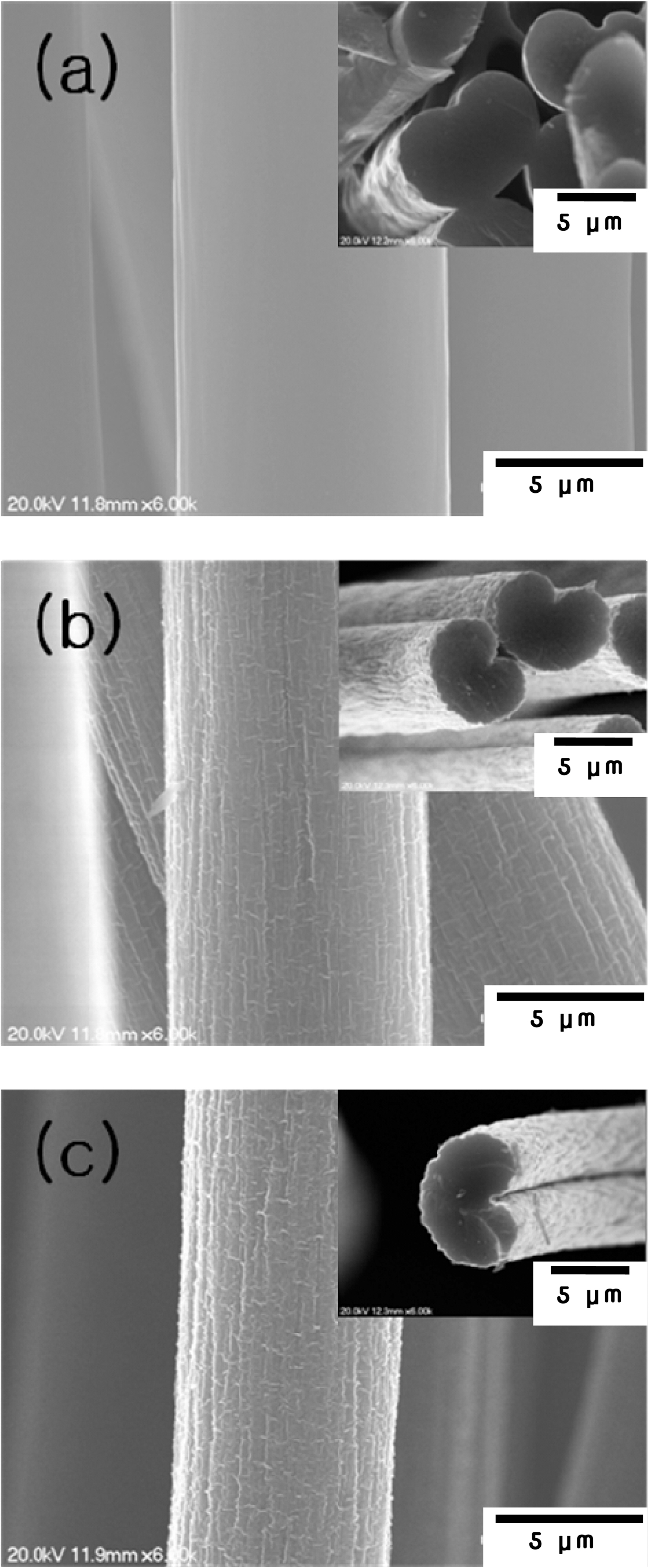

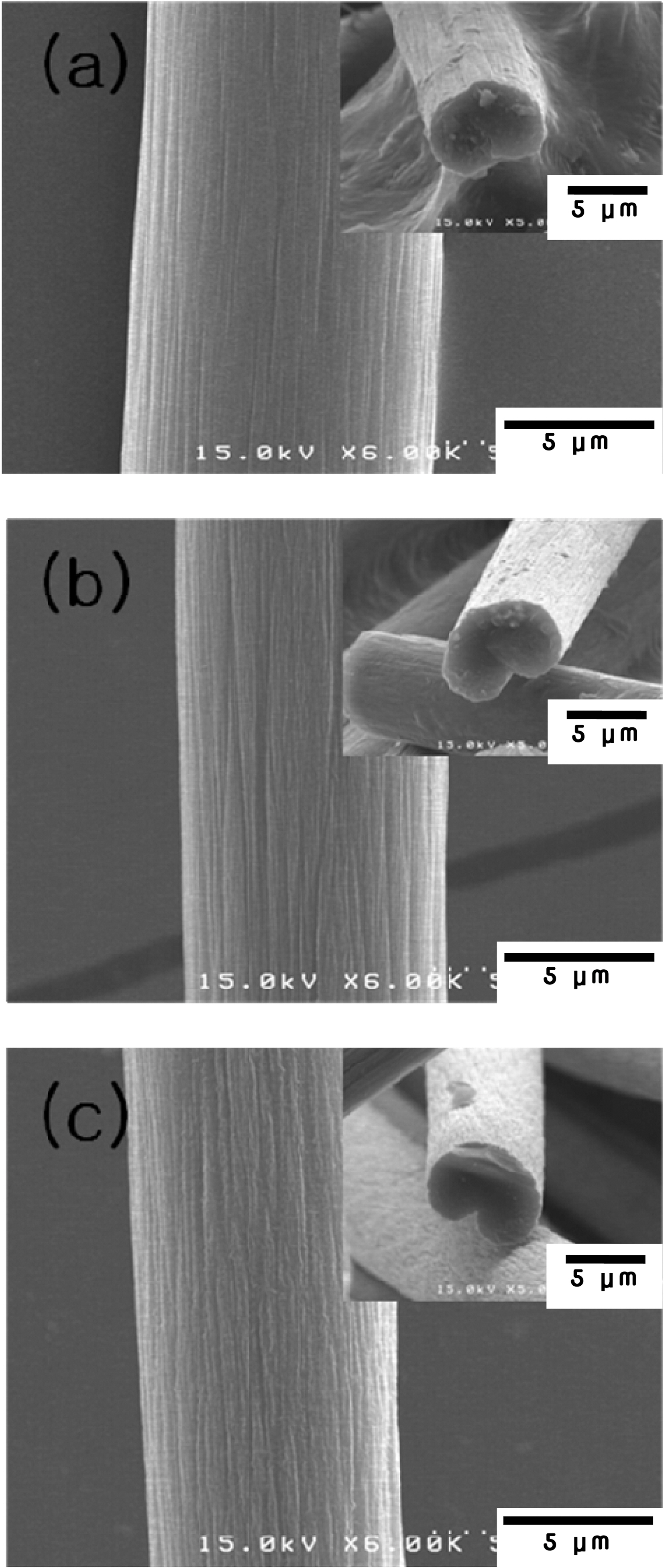

Fig. 3 shows SEM micrographs of CFs: (a) thermal

stabilization of 220oC only, (b) the additional plasma stabilization for 5 min, and (c) 15 min after the thermal stabilization. The surface of CF with no plasma stabilization is relatively smooth as shown in Fig. 3(a). However, Figs.3(b) and (c) show that the plasma stabilization process roughened the surface of the CF. The axial and azimuthal fissureness on the surface that appeared after 5 min plasma stabilization (Fig. 3(b)) became more apparent after 15 min

plasma stabilization (Fig. 3(c)).

A cross-sectional micrograph of the CF is placed on the right upper corner of each micrograph. The bean shape was observed with all fibers in the cross-sectional micrographs.The comparison of the cross-sectional image of Figs. 3(a-c)reveals that the further plasma stabilization after 30 min of thermal stabilization at 220oC had a significant effect on morphology of CFs. In the cross-sectional view of CF of Fig. 3(a), fibers were fused together so that a single fiber was not separated for tensile test. It is evident that thermal stabilization at 220oC for 30 min was not effective to carbonize PAN fibers. However, when the CFs are RF plasma stabilized after the heat stabilization, a CF filament is divided from another for tensile test.

SEM micrographs of CFs carbonized after thermal stabilization at 240oC for 30 min, the additional plasma treatment of 5 min, and 15 min following the thermal stabilization are in Fig. 4. The cross-sectional SEM images of CFs are placed on the right upper corner of each figure. In the Fig. 4(a), a little striation on the surface is shown even without plasma stabilization. Compared to CFs stabilized at 220°C (Fig. 3(a)), The surface of the CF seems to be a little shrunk after stabilization because of higher temperature. The deeper axial grooves on the surface of the CF are present after additional plasma stabilization of 5 min (Fig. 4(b)). The roughness of the surface of the CF increased after 5 min of an additional plasma stabilization. The longer plasma stabilization time such as 15 min didn’t much roughen the surface of the CF more. However, plasma treated fibers after thermal stabilization at 240oC did not show the significant damage on the surface observed in Figs. 3(b) and (c). It is evident that since the thermal treatment at 240oC is a more effective stabilization than that at 220oC, an additional plasma treatment for 5 or 15 min in our system did not affect morphology and tensile properties significantly. Therefore, it is necessary to select a proper type of plasma discharge and process condition to minimize the damage since the striation on the surface of the CF shows that the plasma stabilization performed by the RF large gap plasma discharge may damage or shrink the surface of the CF.

Commercial PAN fibers were thermally stabilized at 220 or 240oC for 30 min. Those fibers were further stabilized using RF capacitive plasma discharge during 5 or 15 min.From FTIR results, it was observed that an additional plasma treatment led to further stabilization of PAN fibers. After stabilization, carbonization was performed to investigate the final tensile properties of the fabricated CFs. Since CFs thermally stabilized at 220oC for 30 min were fused together,tensile test using a single filament could not be performed.However, CFs with the additional plasma treatment for 5 min showed 1.2± 0.3 GPa of tensile strength. We believed that since plasma treatment is not optimized, CFs stabilized with the thermal and plasma treatment did not show a high enough tensile properties, which are from CFs stabilized with a conventional thermal treatment. However, it is suggested that a combination of thermal and plasma treatment is a possible stabilization process for manufacturing CFs with reducing stabilization time and temperature. Morphology of CFs was investigated using SEM. The morphology shows that the plasma stabilization performed by the RF large gap plasma discharge damaged the surface of the CF. Compared to thermally stabilized fibers at 240oC, the damage was more significant in the fibers thermally stabilized at 220oC, so it is necessary to select a proper process condition to minimize the damage.