The ground amorphous powder was consolidated into a dense sintered body with a typical ultrafine Al2O3-GdAlO3 eutectic structure by spark plasma sintering (SPS). Sintered material with ultrafine and dense eutectic structure was obtained by an appropriate combination of rapid quenching and SPS at lower temperature and more quickly than by conventional sintering. The Al2O3-based rare earth eutectic ceramics for solar cell emitters are believed to have a higher efficiency and the Al2O3 based eutectic ceramics with ultrafine grains will be one of the promising materials showing excellent selective emitter characteristics.

1. EUTECTIC NANOCOMPOSITE EMITTERS FOR SOLAR CELL

Thermophotovoltaics (TPV) as an option to convert thermal radiation into electricity has been suggested some 40 years ago. The basic principle consists in utilizing only a selected part of the thermal radiation that is matched to the band gap of the cell. The remaining radiation is kept within the system, which is therefore heated up and kept at a generally rather high equilibrium temperature. Selective filtering of the thermal radiation may be achieved by a combination of a selective emitter and a filter. Thus, a TPV generator consists of a heat source, a selective emitter/filter system and photovoltaic cells [1,2].

Sunlight can be first transformed into low-energy photons. A material is thus needed to absorb the heat from the sun and then thermally emit infrared light into a well-matched photovoltaic cell as shown in Fig. 1. Ideally, the emitting material would convert all absorbed energy into a narrow band of thermal emission that is tailored to an available narrow-band gap semiconductor photocell. Selective emitter is thus the core material to fulfill the energy conversion with high efficiency in the latter case. The TPV system can also be used to recollect the industrial waste heat as mentioned above.

TPV systems have few, if any, moving parts and are therefore very quiet and require low maintenance. These properties make TPV systems suitable for remote-site and portable electricitygenerating applications. Their efficiency-cost properties, however,are often rather poor compared to other electricity-generating technologies. Current research in the area aims at increasing the system efficiencies while keeping the system cost low. In the design of a TPV system, it is usually desired to match the thermal emission's optical properties (wavelength, polarization, direction) with the most efficient conversion characteristics of the photovoltaic cell, since unconverted thermal emission is a major source of inefficiency. Most groups focus on gallium antimonide cells. Germanium is also suitable. Much research and development in TPVs therefore concerns methods for controlling the emitter's properties.

For higher operating temperatures of next-generation turboblades operating at gas temperatures up to 1,600℃, one solution is to develop oxide-based ceramic composites for the high temperature emitter in-situ by directed solidification of melts with

eutectic compositions. The resulting structure is a single-crystal three-dimensional phase lattice with no grain boundary-i.e. a material with coherent interfaces and no vitreous phase. It is known that its thermo-mechanical strength is almost constant up to its melting temperature, whereas polycrystalline ceramics'strength decreases gradually. Moreover, the rupture stress can be increased by reducing the size of both phases-without reducing creep strength. This is the case of perovskite structure oxides, which have high temperature plasticity with eutectic systems (melting between 1,700 and 1,900℃), which combine alumina with rare earth oxides with perovskite (XAlO3; X: Gd, Eu) or garnet(Y3Al5O12; Y: Er, Dy, Yb) structures. Recently, the eutectic ceramics are considered to be candidates not only for the heat-resistible materials but also for other various functional applications, such as TPV generation systems [4-6] , and porous materials [7-9].

Profs. Y. Han, J. Lee at Yeungnam University, Korea, and K.Kakegawa at Chiba University, Japan, have focused on the crystallization process of Al2O3-based rare earth eutectic systems for possible application of TPV emitters, having the ultra-fine eutectic microstructure processed from the eutectic melt from the amorphous phase and optical characterization for thermal radiation power measurement.

1.1 Rapid quenching for the amorphous phase

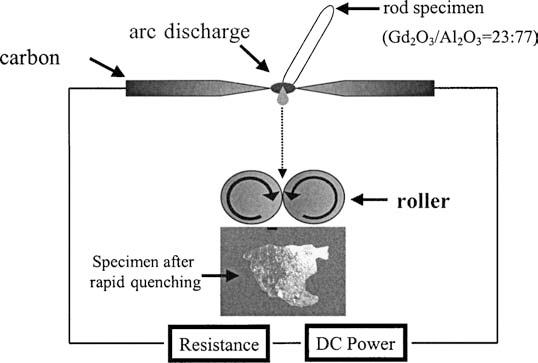

An amorphous powder with a particle size less than 45㎛ ground from the rapid quenched material was used to fabricate a bulk specimen, as shown in Fig. 2. The top of the sintered rod was melted by arc discharge, and the discharge was turned off to produce the sample, which was rapidly cooled by quenching the droplet between rotating aluminum rollers to form an amorphous film. The amorphous films were obtained from heating between 1,000℃ and 1,600℃ for 30 minutes to form eutectic phases, GdAlO3 and Al2O3 [10-12].

From the amorphous phase produced by rapid quenching from the eutectic composition (Gd2O3/Al2O3=23:77), eutectic structure was obtained

1.2 Consolidation of nanocomposites by spark plasma sintering

The amorphous powder obtained from rapid quenching method just before synthesis was complete was chosen for consolidation as being in the optimum state to minimize grain growth and allow full densification at low sintering temperature.

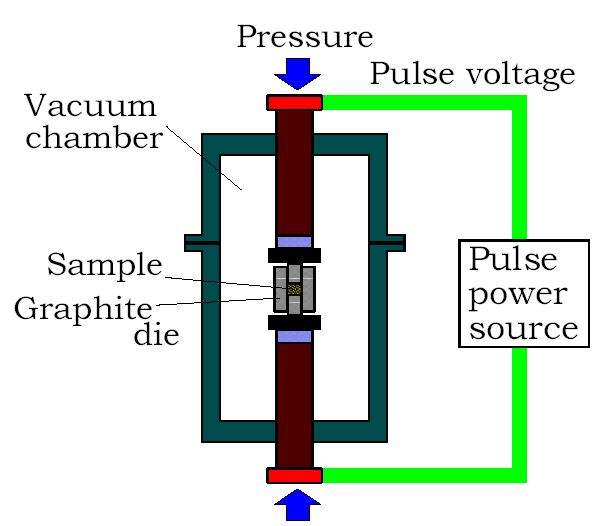

As shown in the overview of spark plasma sintering (SPS) in Fig.3, which is located at Chiba University, the mixture was loaded and pressed under 30 MPa in vacuum, and an 1,500 A DC electric current was applied until a temperature of 1,400℃ was reached on the surface of the graphite mold with no holding time, which means that the power was switched off and the chamber allowed to cool.

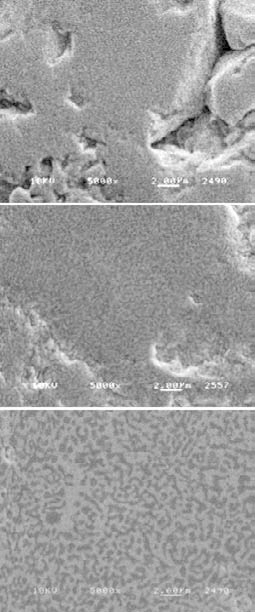

The scanning electron microscope (SEM) micrographs in Fig. 4 show significant microstructural change with increasing sintering temperature from 1,300 to 1,500℃. An ultrafine microstructure is established after sintering at 1,500℃, which looks like a very typical microstructure of binary Al2O3-GdAlO3 (GAP). It is evident that a proper combination of rapid quenching and SPS can synthesize a sintered material with ultrafine and dense eutectic structure. An GAP sintered body with eutectic microstructure can be successfully consolidated from amorphous state material by rapid quenching and the SPS technique.

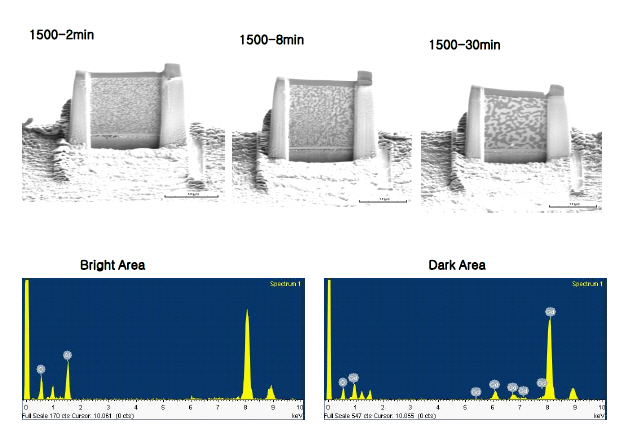

In Fig. 5, the eutectic composites sintered at 1,500℃ for 2 minutes, 8 minutes, and 30 minutes, are compared with crystalline dark Al2O3 and bright GdAlO3, which were analyzed by the focused ion beam (FIB)-SEM and high-resolution transmission electron microscopy (HR-TEM) for higher resolution characterization.

The bright area is GdAlO3 and the dark area is Al2O3. Most of the Al2O3 component has crystallized from the amorphous phase along with GdAlO3 after a heat treatment at 1,500℃ for

2 minutes, which can be explained well, based on the previous results by Kakegawa et al. [10,13]. The completely crystallized components appeared after a heat treatment of 8 minutes. A similar, crystallized microstructure is present in the sample sintered for 30 minutes according to the FIB-SEM micrographs that show apparently fine, eutectic-like microstructures; these microstructures having an appearance of a “cantaloupe skin” are intertwined GdAlO3 and Al2O3 crystals,

1.4 Optical characterization for thermal radiation spectrum

For the thermal emissive power measurement, the plate specimens used for emissive test will be fabricated with the dimensions of the test specimen, 20 x 20 x 3 mm from Mr. Furudate at Prof. Kakegawa’s lab in Chiba University, Japan. Figure 6 shows the experimental apparatus, which is operated and tested by Mr. Jung, a graduate student for Ph.D., at Prof. JH Lee’s Group, Yeungnam University in Korea, for thermal radiation spectrum measurements equipped with a Fourier transform infrared (FT-IR) spectrometer. A specimen installed at the sample holder, which is constructed of SiC and Pt plates were heated by a natural gas burner. The intensity of thermal radiation was normalized by a

standard black body furnace. The emission from specimen was detected by FT-IR spectrophotometer. The emission spectrum measured is converted into an emissive power spectrum with the apparatus coefficient [6].

After melting and rapid quenching a mixture of Al2O3-GdAlO3 (GAP), the result is an amorphous film. Using SPS, this ground amorphous powder was consolidated into a dense sintered body with a typical ultrafine GAP eutectic structure. Sintered material with an ultrafine and dense eutectic structure was obtained by an appropriate combination of rapid quenching and SPS at lower temperature and more quickly than by conventional sintering.

The Al2O3-based rare earth eutectic ceramics for solar cell emitters are believed to have a higher efficiency and the Al2O3-based eutectic ceramics with ultrafine grains will be one of the promising materials showing good selective emitter characteristics. For actual use for the TPV system, however, the selective emitter characteristics of the Al2O3-based rare earth eutectic ceramics must be improved more.

![Schematic of the solar thermophotovoltaics (TPV) [3].](http://oak.go.kr/repository/journal/10324/E1TEAO_2010_v11n6_249_f001.jpg)