Due to the drastic increasing demand for vehicles and industrial growth, the consumption of oil increases annually in Korea. In 2002, the average per-capita oil consumption in Korea was 2.14 tonnage of oil equivalent (TOE), which was higher than that in Germany, France, the UK and Japan, which had TOEs of 1.56, 1.49, 1.32 and 2.0 TOE, respectively [1].

The number of oil facilities between 2003 and 2006 has also increased from 11,306 to 11,810. In addition, the number of oil contaminated facilities has increased from 325 to 982 locations during the same period. These facilities have the potential to contaminate soil with various organic pollutants, including oil.Leakages from oil pipelines, transportation vehicle accidents and other sources have resulted in the oil contamination of soil.In addition, visually checking for leakages from storage facility and oil pipes can be difficult, as most of these structures are located underground. In such cases, investigations are limited to indirect methods, with soil restoration employed as an initial action.

Techniques for the restoration of oil contaminated soils include: soil vapor extraction, bio purification, incineration, thermal desorption and chemical oxidization methods, etc.[2, 3]. Among these, thermal desorption has both economic and efficiency advantages.

The thermal desorption technique has been proven as a relatively fast and efficient treatment for volatile and semi-volatile pollutants [4]. This technique is known to be highly reliability and applicability for on-site treatment [5], and is also the most economically feasible process for combining with other soil purification technologies [6, 7].

The temperatures applied in the thermal desorption process range from 100 to 400℃ [8]. This operating temperature range was reported as the relevant condition. A removal rate of around 90% within 30 minutes has previously been obtained using the thermal desorption method at 300℃ [9], but the removal efficiency was drastically decreased at lower temperatures and with moisture contents exceeding 20% [10].

Therefore, a pre-treatment process is very important in the remediation of contaminated soil with high water content. Pretreatment devices used with the thermal treatment include: hot wind drying, microwave and direct heating contact methods. Among these technologies, the microwave method has shown high treatment efficiency and can remove moisture quickly. Due to these advantages, it has been widely used as a pre-treatment process [11].

Thermal treatment has been widely applied, main because it requires a lower temperature and less energy consumption compared to direct heating, incineration and other methods [6]. With respect to soil restoration techniques, microwave pretreatment has been shown to be an effective process for the recycling of organic substances from pollutants or for use in combination with a biological process. With thermal treatment, the heat is externally supplied for thermal desorption. Within the process, heat can be transferred at many stages, including inside the soil particles, the capillary tubes in the soil particle layer, and between the soil particle layer and the external environment. In the purification process employing thermal desorption, it is important to consider not only the properties of thermal decomposition of the pollutant ingredient absorbed onto the soil, but also the thermo-dynamic parameters, such as the water content, soil ingredients and particle size, etc. [12].

In this study, the optimal conditions for the microwave pretreatment combined with thermal desorption process.

2. Experiment Materials and Experiment Device

2.1. Experiment Materials and Method

The soil samples were collected from contaminated areas in Incheon City, Korea. This area has been used as a military oil storage base since the 1940s. The soil sampling followed the sampling process outlined in soil protection law[13]. The initial average total petroleum hydrocarbon (TPH) concentration of the synthesized soil sample was 34,457 mg/kg, while maintaining the 30% moisture content present during the collection stage. This contaminated soil samples were classified using the sieve classification method, and found to have diameters of 11.8, 4.72 and 2.35 mm, with the treatment efficiency according to the soil diameter tested. According to the Unified Soil Classification System [14], soils with diameters of 11.8 mm or bigger are classified as gravel, and those with diameters of 4.75 and 2.35 mm as sand.

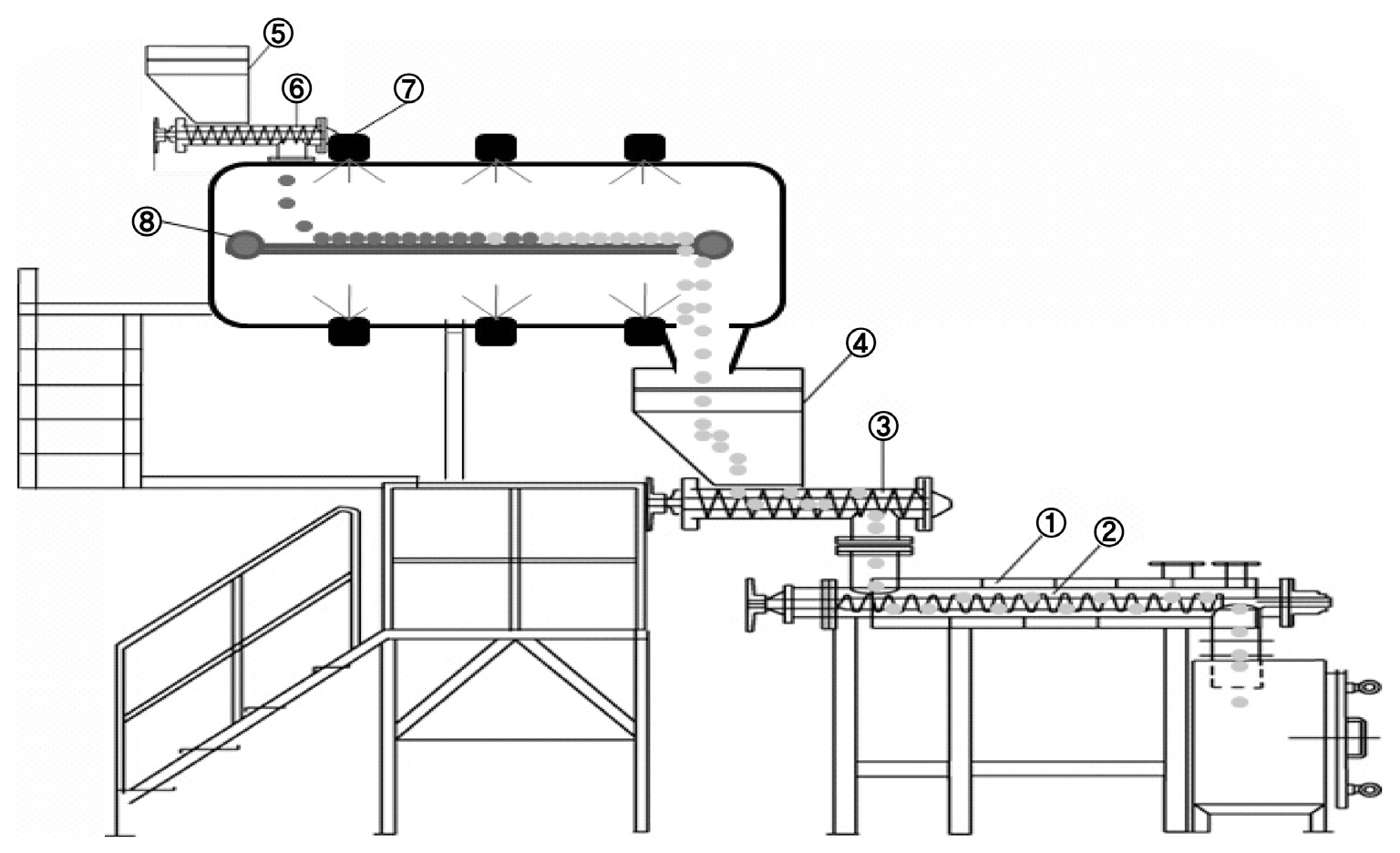

The consecutive process, comprised of the combination of microwave and low temperature thermal desorption, is shown in Fig. 1. In the case of soil with low moisture content, the soil was directly injected into the thermal desorption device, without the microwave pre-treatment. As shown by the schematic in Fig. 1, the contaminated soil was injected via a screw injector through the hopper ⑤. The contaminated soil was transferred using a conveyor motor ⑧ into the microwave process. The operation of the microwave required 1 kW of power during the transfer of the contaminated soil. After the microwave pretreatment process, the contaminated soil was injected into the thermal desorption furnace ① through the inlet port ②. In addition, the contaminated soil was transferred, using a screw belt, to the thermal desorption device. The decomposition process occurred via direct contact with hot air, with the soil finally discharged via the outlet port.

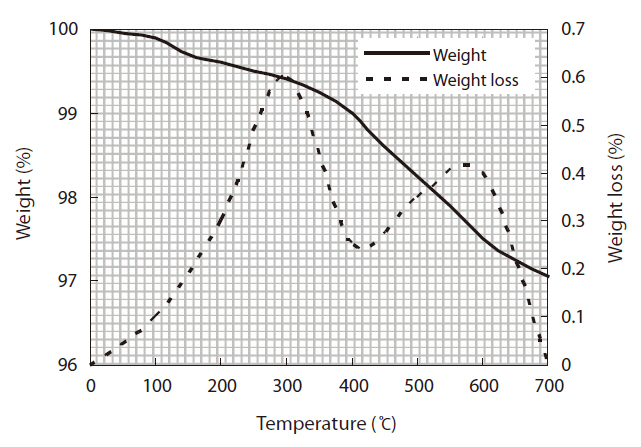

The removal of oil from the samples was identified by comparison of the gross weight of the hydrocarbons. The initial average concentration of the hydrocarbons in the sample was 45,014 mg/kg, with a moisture content of 10.3%. In order to maintain 30% moisture content, the TPH concentration in synthesized soil sample had to be 34,457 mg/kg. The characteristics of the thermo gravimetric analysis curve, shown in Fig. 2, were analyzed to determine the optimal temperature condition for the thermal desorption. From the curve, the weight can be seen to dramatically change in the temperature range 300-550℃. The observed decomposition characteristics led to the identification of the temperature conditions for thermal desorption as well as the percentage of water in the sample.

The efficiency of the microwave process was determined via the energy transfer, target substance characteristics, temperature and density, etc. The characteristics of the target substance

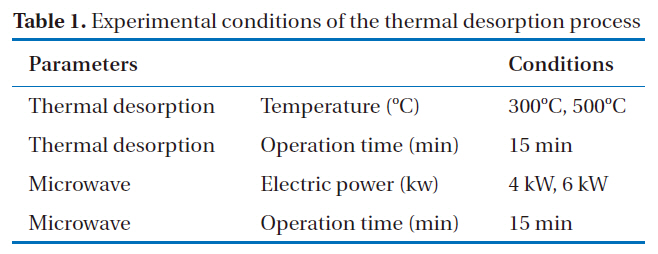

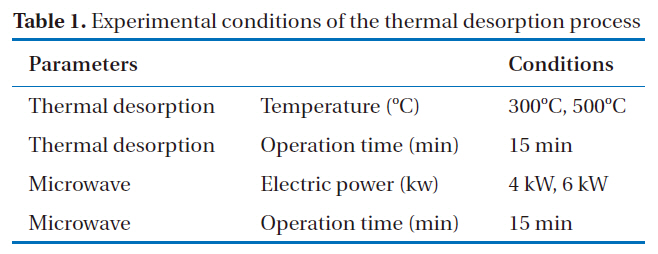

[Table 1.] Experimental conditions of the thermal desorption process

Experimental conditions of the thermal desorption process

were expressed as absorption, reflection, penetration, the semiconductor,insulator and absorber body types [15-18]. Therefore, the optimal conditions in this study were considered in relation to the particle size, temperature and moisture content.

The operational conditions of the process are shown in Table 1. Thirty kilograms of contaminated soil was injected as the sample. The operation times were fixed at 15 minutes in both the microwave and thermal desorption processes. The microwave process was operated at powers of 4 kW and 6 kW, with temperatures of 300 and 500℃ applied during the thermal desorption process.

3.1. Variation in the TPH Concentration with Soil Layer Thickness During the Microwave Process

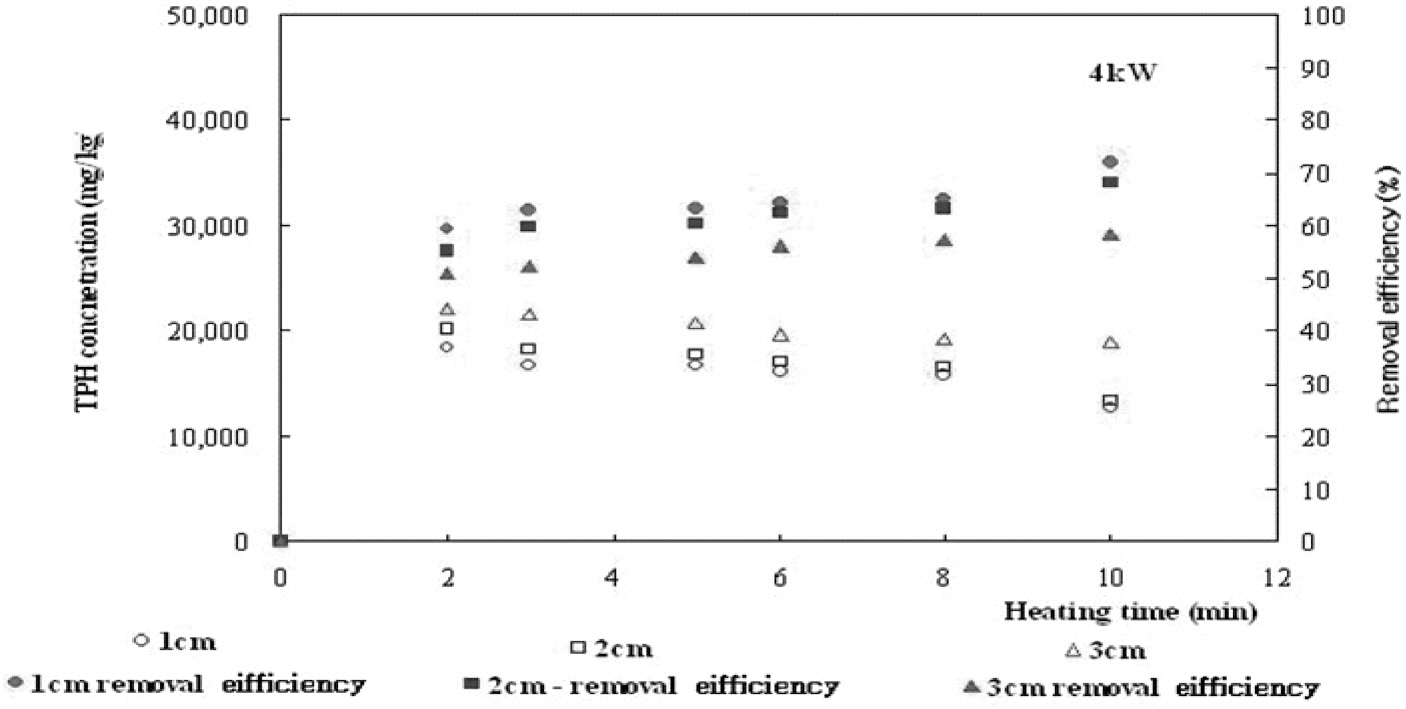

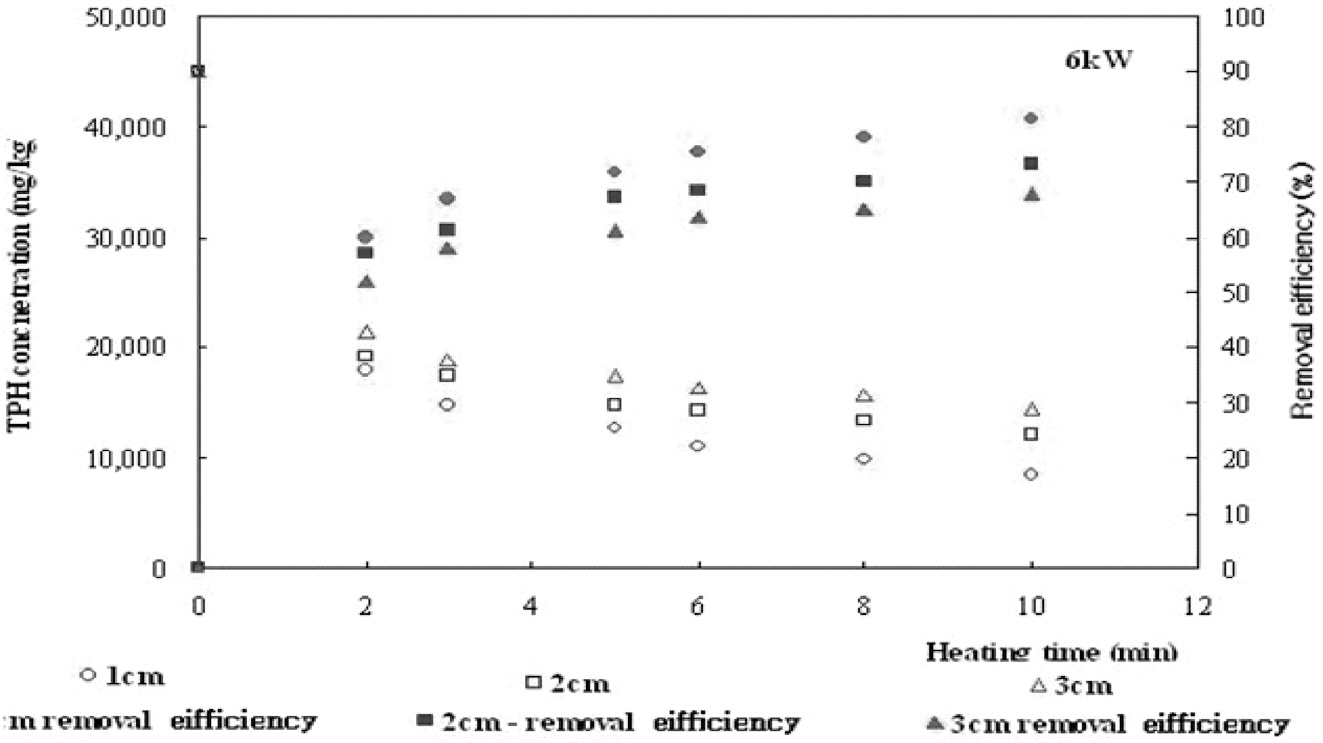

As mentioned earlier, the conveyor belt transferred the contaminated soil to the thermal desorption process with the applied condition of 4 kW and 6 kW. The TPH was removed as a result of heat transfer due to the thickness of the contaminated soil layer. Contaminated soil layer thicknesses of 1, 2 and 3 cm were tested experimentally. The optimal soil layer thickness was also tested with different quantities of supplied power during the transfer of the contaminated soil.

In Fig. 3, the removal efficiencies of TPH with 1 and 2 cm soil thicknesses were shown to be very similar with 4 kW of power. However, that with a 3 cm thickness was low. The results indicated that the heat was effectively transferred from the inside to the outside of the soil when the soil thickness was 2 cm with 4 kW of power. As the microwave started to heat the center of the soil layer [18], the temperature decreased at the surface of soil layer due to the "core effect." The removal efficiency decreased with soil thicknesses over 3 cm. In addition, no increase in heat transfer resulted from an increase power. Therefore, the heat transfer was dependent on the optimal soil layer thickness.

Fig. 4 shows the TPH concentrations and removal efficiency with 6 kW of power under the same sample and operation time conditions as those used with 4 kW of power. However, the TPH removal efficiency was approximately 10% higher at 6 compared to 4 kW. At 6 kW, the TPH removal efficiency was 80% with a 1 cm contaminated soil thickness, but around 70% with 2 and 3 cm contaminated soil layer thicknesses. Therefore, the removal efficiency was affected by the soil layer thickness and the amount of power applied. In addition, the heat could be transferred more with a soil layer thickness of 3 cm at 6 compared to 4 kW.

In the process of moisture vaporization using microwave, the energy was used to remove the moisture. The large energy of vaporization per volume of water indicated a fast rate of moisture removal.

In addition, volatile and semi-volatile characteristics affected the removal efficiency. The microwave energy consumption influenced the average microwave frequency and treatment time.However, this energy consumption was inversely proportional to the volume of moisture vaporized [20]. As the power was increased with different contaminated soil layer thicknesses, the energy generated in the contaminated soil also increased, which resulted in increased rates of heat transfer and moisture volatilization.

Mon et al. [21] investigated the affect of the soil layer thickness on the removal efficiency using 6, 12 and 18 mm soil layer thicknesses. The thicker soil layer had higher removal efficiency. The liberation or retention of the moisture from inside the soil led to the removal of pollutants. However, in this research, a thicker soil layer was observed to result in lower removal efficiency with 6 kW of power. When sufficient heat was transferred from the inside to outside of the soil layer via the microwave pretreatment, the thicker soil layer retained the energy, resulting in moisture evaporation and more efficient removal.

Osepchuck [22] showed that an increase in the applied power with insufficient power, effected the amount of energy retained in the contaminated soil layer.

In this study, the increase of power in the 1, 2 and 3 cm thick contaminated soil layers resulted in increased TPH removal efficiencies with over 4 kW of power.

3.2. Removal Characteristics by Combined Process

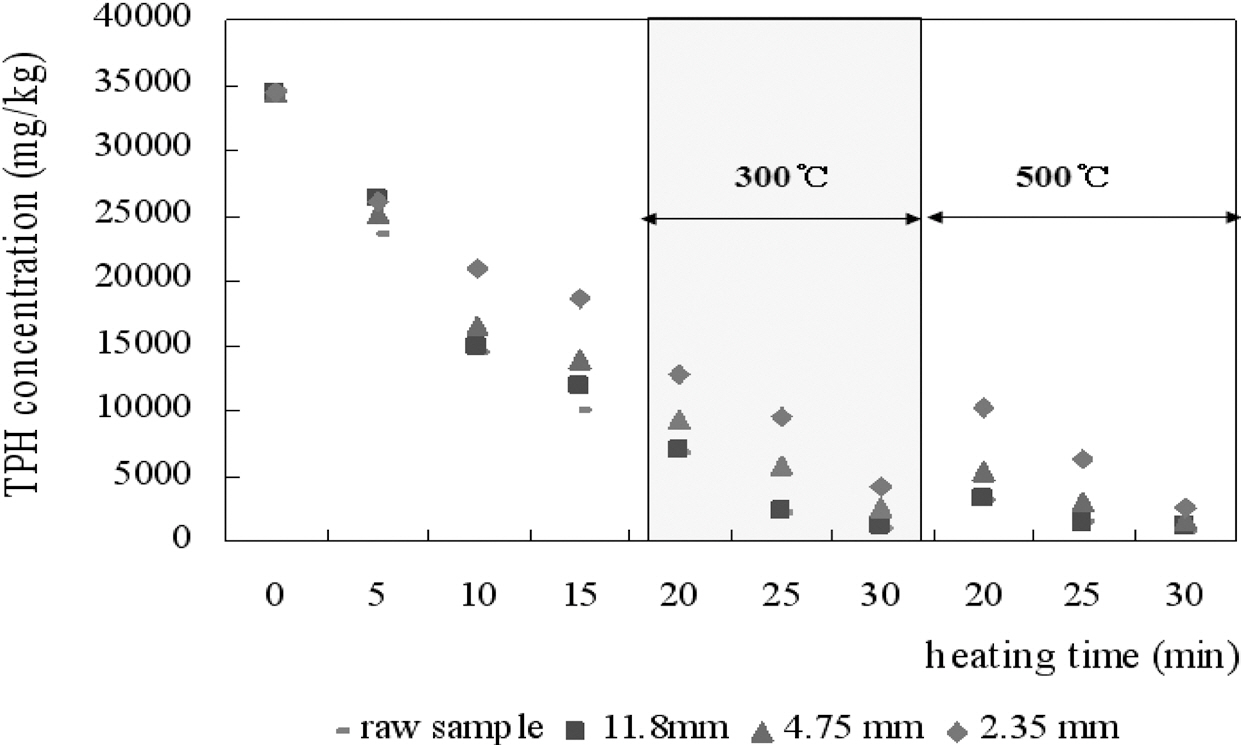

The removal of TPH was conducted using microwave thermal pre-treatment at 4 kW, with the thermal desorption process performed at 300 and 500℃, as shown in Fig. 5. The TPH removal efficiency with microwave pre-treatment was generally over 70%. The rates of TPH removal were analyzed with respect to various contaminated soil particle diameters. Soil particles with a diameter of 2.35 mm had the lowest TPH removal efficiency. However, the diameter of the soil particles in the original sample had the highest removal efficiency.

The TPH removal efficiency was studied with respect to the particle diameter in the combined microwave and thermal desorption process. No significant changes were observed during the initial 5 minutes of operation. However, with increasing operational time, the removal efficiency decreased with the smaller particles in the contaminated soil. McAdams [23] reported that the minute particle of contaminated soil showed the lowest removal efficiency, but did not consideration the soil composition.

The minute particles had a low heat capacity; therefore, discharged the heat. Therefore, the larger particles had sufficient energy for the removal of TPH with increasing operational time.

In Fig. 5, various minute soil particle diameters are shown to have no influence on the TPH removal efficiency with 4 kW of power during the initial 5 minutes of microwave pre-treatment.However, the raw sample and that with a particle diameter of 11.8 mm showed similar removal efficiency. However, the 4.75 and 2.35 mm soil particle diameters influenced the TPH removal efficiency. After the microwave pre-treatment with 4 kW of power, the removal efficiency was independent of the soil particle diameters when the contaminated soil was directly contacted with the hot air for 15 minutes during the thermal desorption process at both 300 and 500℃.

After 15 minutes of operation, the removal efficiencies were 92 and 98% at 300 and 500℃, respectively, at the outlet point of the thermal desorption process.

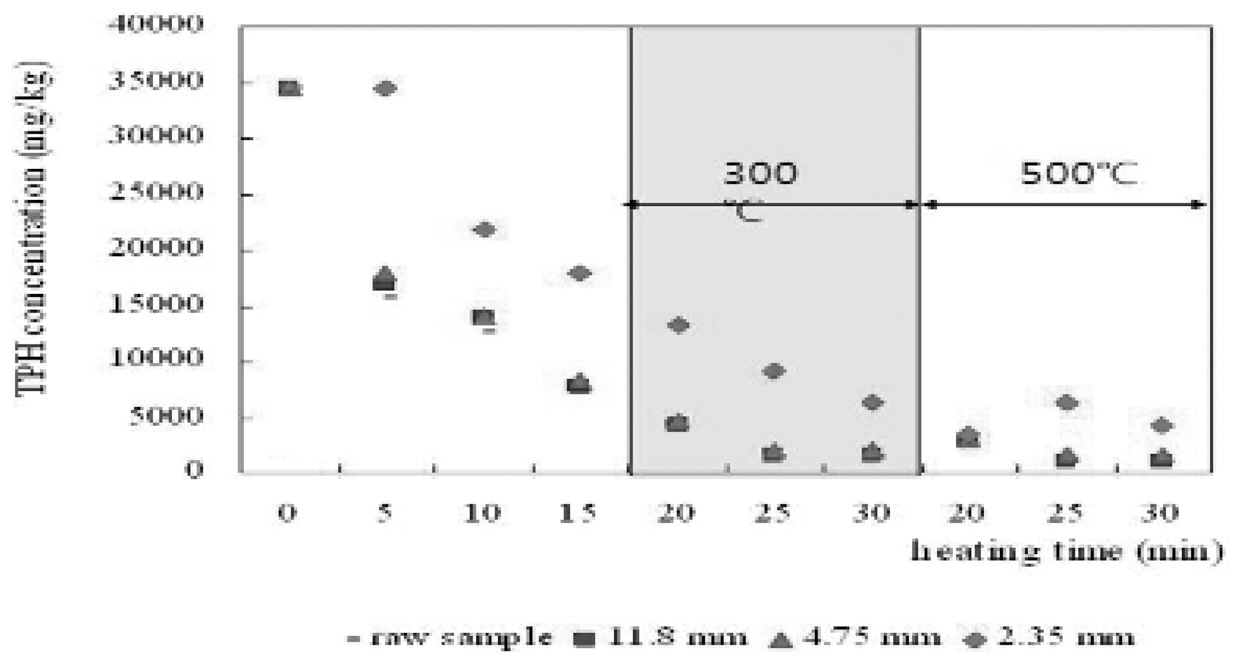

Fig. 6 shows the operational results with respect to the contaminated soil particle diameters using microwave pre-treatment at 6kW and thermal desorption temperatures of 300 and 500℃. A particle diameter of 2.35 mm showed the lowest TPH removal efficiency. However, no differences were observed in the TPH removal efficiencies with other particle diameters in the thermal desorption process.

3.3. Economical Efficiency of the Combined Process Conditions

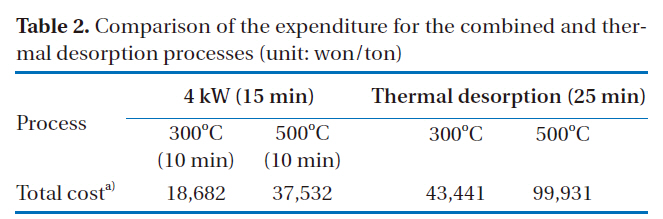

In the case of 30% moisture in the soil, 20% of the TPH was removed using only the thermal desorption process for 25 minutes at 300℃, i.e. not using the combined processing. Under the same conditions stated above, the TPH removal was 70%

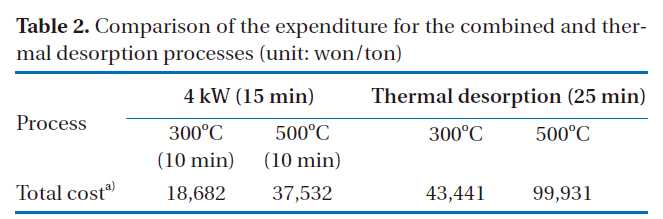

Comparison of the expenditure for the combined and thermal desorption processes (unit: won/ton)

at 500℃. The operational condition of 500℃ was required with high soil moisture contents. The optimal conditions for economic efficiency were 4 kW microwave power, with 300℃ during the thermal desorption.

As only the thermal desorption process was operated for 25 minutes, the costs were 43,441 and 99,931 won/ton at 300℃ and 500℃, respectively, as shown in Table 2. The optimal conditions required to expend only 18,682 won/ton were 4 kW microwave power and low thermal desorption at 300℃. Gabriel et al. [18] also reported that the combined process gave better energy consumption and temperature increases than either the microwave or dry process alone.

During the microwave pretreatment in the combined process, both 1 and 2 cm soil layer thicknesses were shown to remove 80% of the TPH with 4 kW microwave power. However, the removal efficiency with a 3 cm soil thickness was reduced by 10% compared to 1 and 2 cm soil thicknesses, possibly due to the core effect. With a microwave power of 6 kW, the thickness of the soil influenced the removal efficiency. A thicker soil layer was found to give better removal efficiency.

When the contaminated soil samples were classified by soil particle diameter, those with diameters of 2.35 mm showed the lowest removal efficiency. Without considering the removal efficiency, the most economic conditions would be 4 kW microwave power, with thermal desorption at 300℃. The removal efficiency of polymers, such as diesel oil or TPH, in the contaminated soil was higher with the 6 kW microwave process. After treatment at 6 kW, the temperature of the hot was air did not influence the removal efficiency.

Therefore, the optimal conditions for the most efficient removal were 6 kW of power for the microwave pre-treatment and 300℃ for the thermal desorption