This study examined the separation characteristics of particles in the rainfall runoff from paved roads using a φ7.5 cm hydrocyclone. The volume fraction and total suspended solids concentrations in the overflow and underflow from the hydrocyclone, as well as the separation efficiency were determined. The results indicated that the overflow volume increased with increasing operational pressure, but decreased with decreasing ratio of underflow outlet to inlet sizes (Du/Di), while the underflow to overflow volumes showed contrary behavior. The total suspended solid (TSS) concentration ratio between the overflow and inflow (TSSover/in) decreased as a function of the operational pressure, while the corresponding ratio of underflow to inflow (TSSunder/in) increased. There was no visible difference in the TSSover/in with increasing Du/Di ratio, but the TSSunder/in decreased sharply. The particle removal efficiency was mainly affected by the particle size.

Hydrocyclones are a type of industrial centrifugal separator, which have been used for more than 100 years. They are classified as continuously operating devices that utilize centrifugal force generated by the rotation of the slurry entering the hydrocyclone tangentially, which accelerates the settling rate of particles and their separation according to density and weight. They perform this separation based on size, geometric shape and the characteristics of treated water.1) Due to their many advantages, such as reductions in equipment size and weight, costs saving, enhanced separation efficiency, simplicity of operation, lack of moving parts and environmental friendliness, they have become one of the most important pieces of equipment for solid-liquid separation.

Besides a large number of applications in mineral processing, this separation technique has recently been applied to environmental engineering, food engineering, electrochemical engineering, bioengineering and pulping process, etc.2) Due to their wide practical applications, much attention has been paid towards hydrocyclones, with previous investigations having mainly concentrating on geometric modification by means of experiments and computational fluid dynamics. Souza et al.3) analyzed the influence of the filtering medium on the behavior of the filtering hydrocyclone, with the results indicating that filtering hydrocyclones promote an increased feed flow rate. Zhao et al.4) compared three different inlet structures (conventional tangential signal inlet, direct symmetrical spiral inlet and converging symmetrical spiral inlet), and the results indicated that a symmetrical inlet significantly increased the removal efficiency. Martinez et al.5) experimented on the optimal length of the vortex finder; the results indicated the optimal length of the vortex finder was 10% of the total length of the hydrocyclone. Many investigations have studied the performance of hydrocyclones by the means of computational fluid dynamics.6-8)

Highway sediments, as typical non-point pollutants, are particulate matters generated from traffic (transportation activity), and collected by vacuum cleaning vehicles or washed-out with rainfall runoff directly to a receiving water body. The sediment components, such as tire and brake debris, road materials, metals, de-icing salts, some dead vegetation, and other garbage, are recognized as major sources of nutrients, oils and heavy metals in paved urban areas, which can have temporary or chronic impacts on aquatic eco-systems when washed into receiving water bodies;9) thus, having a clear understanding of the particle size distribution and amounts of pollutants associated with different particle size ranges is important; the removal of sediments from highway runoff then become necessary and meaningful.

Although many studies have focused on hydrocyclones, detailed descriptions of the performance and experimental operational data are rare, especially for their application using the capacity of the actual waterhead in the treatment of highway runoff under bridges. The objective of this research was to evaluate the operational performance and particles removal efficiency of a hydrocyclone, which will allow determination of the optimal conditions, resulting in a concentrated underflow and a clean overflow in the best management practice (BMP) of highway runoff.

The highway sediment samples used in this study were collected from the transfer station of D Branch Office of the Korean Express way Corporation during October, 2008. The particle size distribution and pollutants contents were determined based on Standard Methods.10)

2.2. Apparatus and Instruments

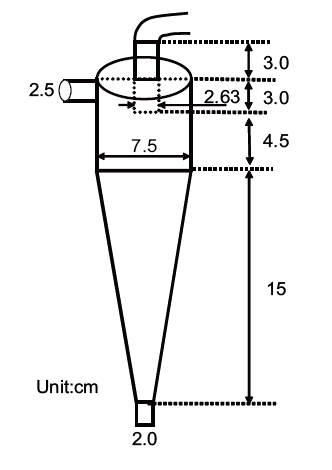

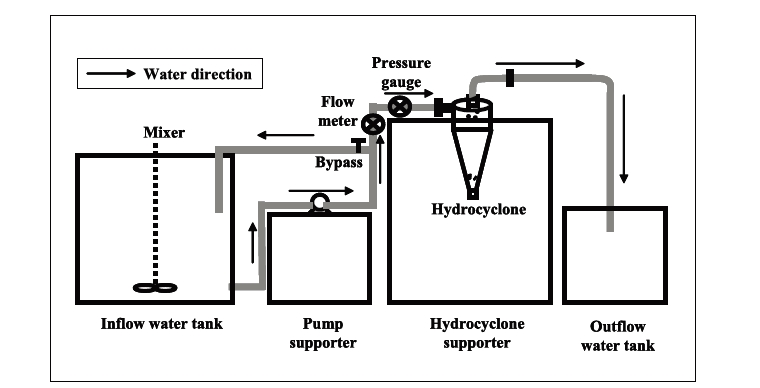

The hydrocyclone used in this study had a φ7.5 cm diameter, which was designed according to the Rietema criterion, with minor modifications.11) The geometric parameters of the unit are illustrated in Fig. 1, with the experimental instrument and apparatus system arranged as shown in Fig. 2.The inflow was pumped The inflow was pumped from the water storage tank to the hydrocyclone. The flow rate was measured and controlled by adjusting a by-pass valve. The pressure inside the hydrocyclone was measured using a pressure gauge.

2.3. Artificial Highway Runoff

The experimental work was performed using a laboratory scale device. The artificial runoff was obtained by mixing water and highway sediments, where the suspended solids concentrations in the inflow varied within the range 120 to 400 mg/L.

Experimental work was performed on a laboratory set-up with the φ7.5 cm hydrocyclone. Four ratios of Du/Di (0.2, 0.4, 0.6, and 0.8) and different pressures (55, 103, 152, and 200 KPa) were applied and their effects on the performance of the hydrocyclone operation observed. Other experiments were performed using uniform particles (63, 125, 250, 500, and 850 μm) to study the relationship between the particle size and the removal efficiency. The artificial runoff was prepared from water and solids collected from the highway surface. Samples were taken from the overflow and underflow at the same time intervals, with the total suspended solids and water volumes measured; the particles size distribution was also immediately analyzed.

3.1. Highway Sediments Analysis

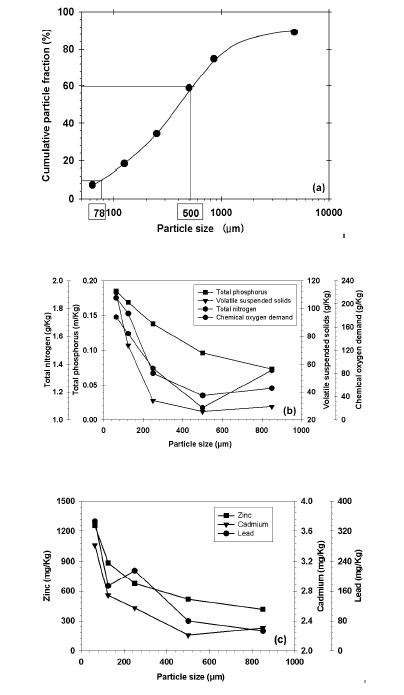

The results of the particle analysis are presented in Fig. 3. The D10 and D60, indicating particle sizes at which the cumulative mass fractions of 10 and 60%, were 78 and 500 μm, respectively, where the value of D60/D10 (U) represents the uniformity coefficient, which was 6.4 (Fig. 3(a)); thus, the particle size distribution can be defined as being non-uniform (5

84% of the pollutants were associated with particles less than 850 μm (easily removed with highway runoff), and accounted for around 75% of the total particles. Therefore, the removal of solids is important for the BMP of highway runoff.

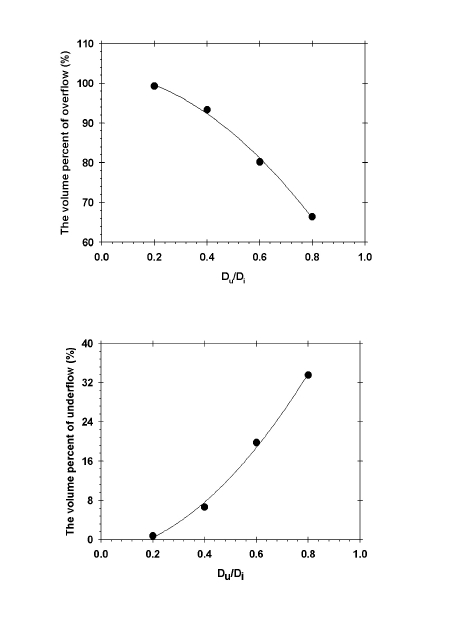

The geometry of the hydrocyclone, and the relative size of the outlet, allow the greatest part of the water and part of the finest particles to exit as overflow, while most particles with less water exit as underflow. The behavior of the hydrocyclone is regulated to a great extent by the Du/Di ratio. As shown in Fig. 4, the percentage of the overflow volume decreases with increasing Du/Di ratio, while the percentage of the underflow volume increases.

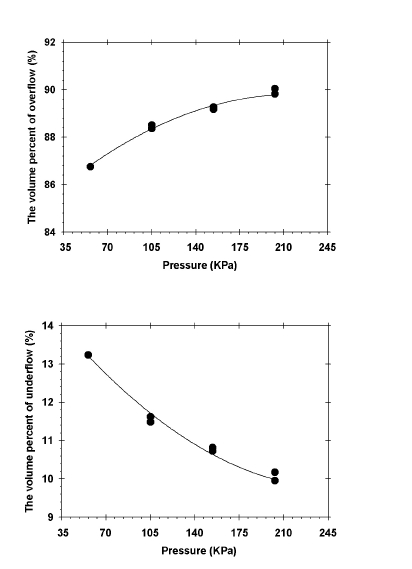

Fig. 5 shows the relationship between the percentage outflow volume and the operational pressure. It is clear that the percentage

overflow volume increases with increasing pressure, but the percentage volume of the underflow decreases. It is known that overflow is obtained by the vortex flow produced by pumping of the inflow inside the hydrocyclone, and the inflow is related to the operational pressure; thus, a high pressure can contribute to a powerful vortex flow, where a concentrated underflow is then indirectly obtained.

The effects of the Du/Di ratio and operational pressure on the percentage outflow volume have meaningful implications in the treatment of highway runoff using a hydrocyclone, as they can contribute to a concentrated underflow and clean overflow at their optimal levels.

3.3. Total Suspended Solid Concentration in Outflow

It is difficult to create a constant total suspended solid (TSS) concentration in the inflow for every operational cycle due to the sedimentation of solids; therefore, the ratio of TSS was used to describe the behavior to avoid differences in the inflow concentration.

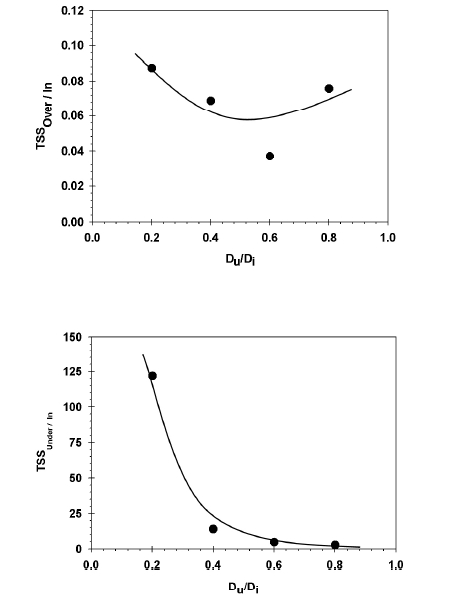

Fig. 6 shows the relationship between the Du/Di ratio and TSS concentration; however, there was little difference in the TSSover/in (0.04?0.09) values as a function of increasing Du/Di ratio, while the TSSunder/in values decreased sharply (ranges from 2.8 to 122), which has important implications for the concentration of the underflow in the treatment of wastewater or highway runoff.

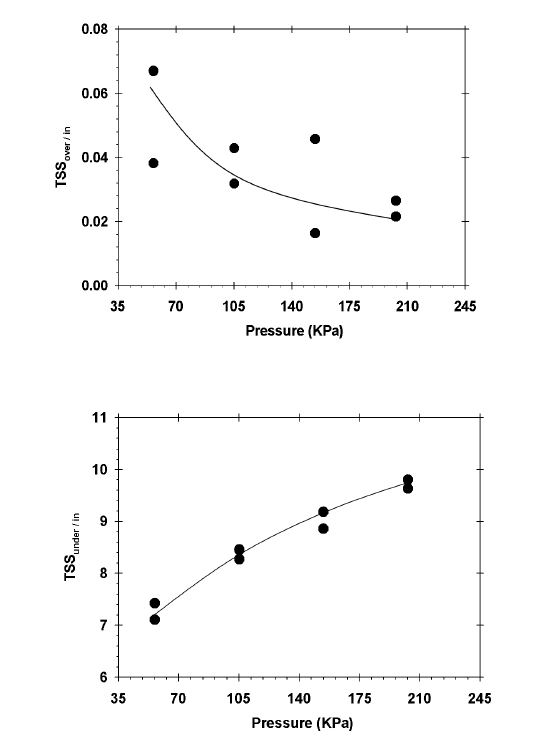

The results of the ratio of the TSS concentration in the overflow and underflow is a relevant indicator of the pressure; the TSSover/in decreases as the pressure increases, but the TSSunder/in increased, which means that a higher pressure will contribute to a clean overflow and concentrated underflow (Fig. 7).

The removal efficiency of the hydrocyclone was evaluated by means of the following indicator:

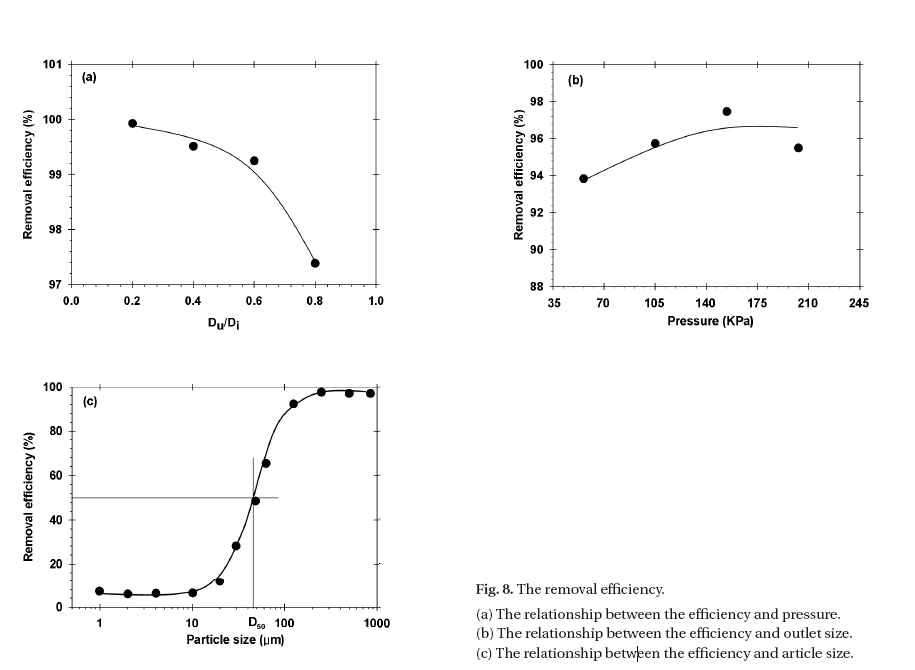

where Mu and Mi are the particle masses in the underflow and inflow, respectively. Fig. 8 shows the variation in the removal efficiency with respect to the outlet size, operational pressure and particle size. The removal efficiency decreased slightly with decreasing outlet size (Du/Di) ratio, as shown in Fig. 8(a). When the underflow outlet is reduced, the flow rotation inside the unit will be enhanced due to the detention of much more slurry; consequently, more particles are separated to the underflow, which explains why the removal efficiency decreases as the Du/Di ratio increases. However, if the underflow outlet is too little, it may clog with coarse particles during practical application; therefore, a balanced outlet size ratio should be designed. When manufacturing a system with respect to the effectiveness of Du/Di for separation, the 0.4 is recommended as the optimal Du/Di ratio.

Conversely, the effect of the Du/Di ratio showed a weak increasing trend for the removal efficiency with increasing pressure (Fig. 8. (b)). The removal efficiency remained at more than 90%; irrespective of the pressure, which was in agreement with Ditria and Hoyack,12) who showed that an increase in pressure corresponded to a marginally improved removal efficiency.

From Fig. 8. (c) it is obvious that the removal efficiency is associated with the particle size. D50, known as the cut size whose separation probability to the underflow is equal to that to the overflow, is determined according to the hydrocyclone geometric dimension and operational conditions.1) The D50 of the hydrocyclone used in this study was about 45 μm (103 KPa operational pressure, Du/Di=0.4), which means it can effectively separate solids coarser than 45μm from rainfall runoff. Although fine particles (less than 45 μm) can not be removed efficiently, the rapid and efficient removal of coarse particles (especially coarser than 100 μm) is also very important, as coarse particles will become finer over time, and these are much more difficult to remove, as discussed above.13)

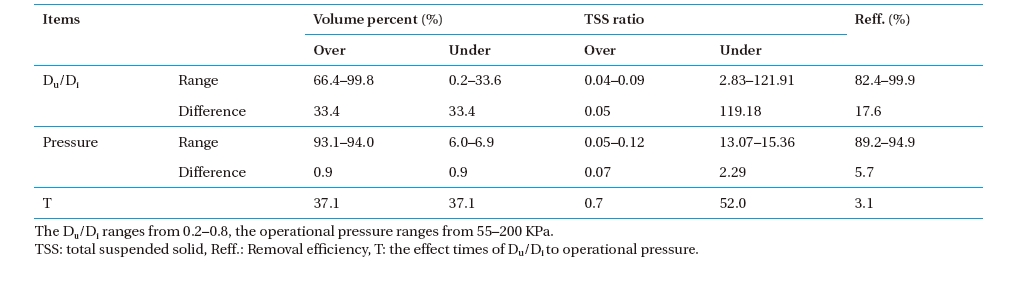

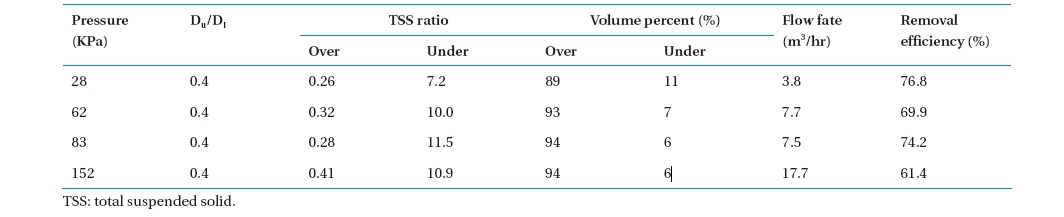

Table 1 compares the effects of the Du/Di ratio and operational pressure on the operational behavior of the hydrocyclone. The Du/Di ratio generally plays a more important and decisive role than the operational pressure in determining the hydrocyclone behavior. The effect of the Du/Di ratio is 37.1 times that of the

[Table 1.] The effects of Du/Di and operational pressure to hydrocyclone behavior

The effects of Du/Di and operational pressure to hydrocyclone behavior

pressure for the percentage volume (overflow and underflow); the corresponding values of the TSSover/in and TSSunder/in are 0.7 and 52, respectively. Thus, it can be concluded that the Du/Di ratio is the main parameter to be considered in the application of a hydrocyclone to obtain a concentrated underflow and clean overflow.

With respect to the removal efficiency, the effect of the Du/Di ratio was only 0.68 times that of the operational pressure, and the difference between the effects of the Du/Di and pressure were weak (2.5 and 3.7 for Du/Di and pressure, respectively). Conversely, the removal efficiency was evidently related to the particle size, as discussed above (Fig. 8(c)). Thus, it can be inferred that the operational conditions, such as the Du/Di and pressure are not decisive parameters with respect to the removal efficiency, although they do both have an affect to some different degree.

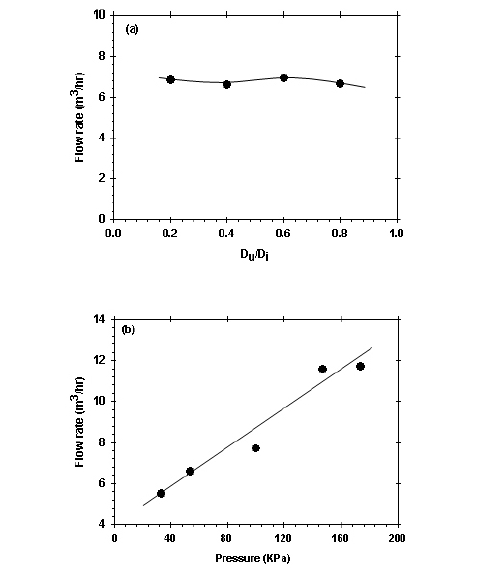

The treatment capacity of a hydrocyclone is important in its practical application, which has to be related to the local highway runoff or other waste water load with respect to obtaining optimal efficiency. The results indicated that the flow rate was hardly affected by the Du/Di ratio, which was around 7.0 m3/hr within the Du/Di range 0.2 to 0.8 (Fig. 9(a)). The flow rate was also found to be positively related to the operational pressure, with significance (r=0.975, p<0.01) (Fig. 9(b)). Thus, it can be concluded that the flow rate is mainly affected by the operational pressure, and the available waterhead (pressure) should be considered when choosing the scale of a hydrocyclone for practical application.

3.6. Particle Size Distribution

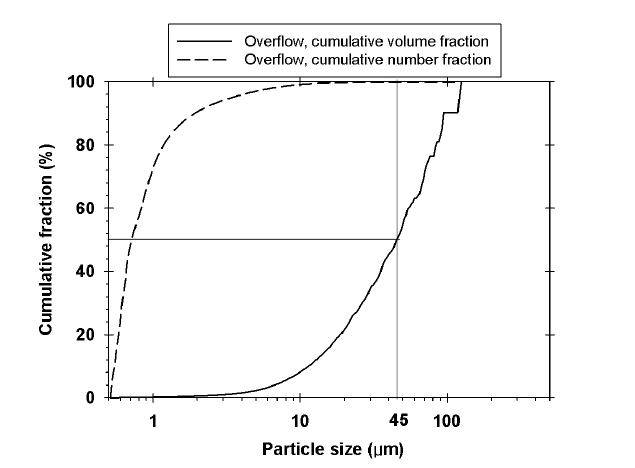

Fig. 10 shows the particle size distribution within the overflow (103 KPa operational pressure, Du/Di=0.4). The results indicate that more than 99.98% of the solids were finer than 45μm, based on the particles number fraction, with the corresponding value being about 50% in this particle size range based on the particles volume fraction; thus, it can be inferred that there are some solids where the number is negligible and has a relative large volume fraction (50%) in the overflow. This can be explained by the short-circulation of some coarse particles, which move along the boundary layer over the vortex finder and; hence, directly join the overflow without being separated to the underflow.

The fraction of non-settleable suspended solids in highway runoff particles is typically between 1?30 μm,14) which explains why some fine particles (especially less than 45 μm) can not be separated to the underflow. Conversely, it is known that the separation of solids-liquid is due to the different densities of solids

from that of the liquid; therefore, some solids can not be separated to the underflow, including some coarse solids, but have a low density; therefore, occupy a relative large volume fraction, such as some vegetation and debris. This explains why the cumulative volume fraction of particles in the overflow less than 45 μm was only 50%.

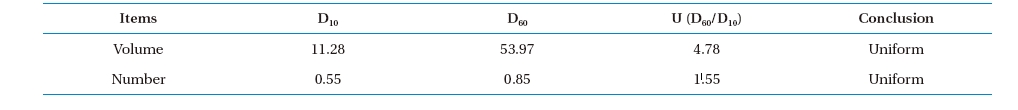

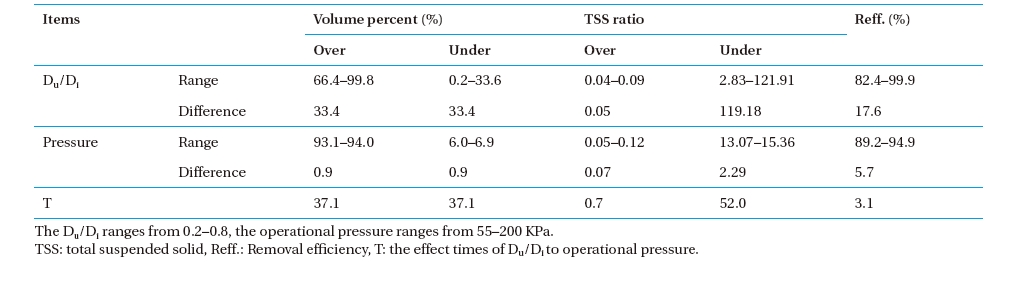

The results from the uniformity analysis are presented in Table 2, where D10 and D60 are 11.28 and 53.97 μm by volume, respectively. The corresponding values for number are 0.55 and 0.85 μm, respectively. The D60/D10 value representing the uniformity coefficient is 4.78 for volume, but 1.55 for number. Consequently, it can be concluded that the particles in the overflow, as expected, were uniform, which is in agreement with the above discussion, where most of the particles were less than 45 μm.

It is known that most coarse particles are separated to the underflow; however, they are difficult to sample for obtaining the particle size distribution due to rapid sedimentation; thus, the particle size distribution of the underflow was not analyzed.

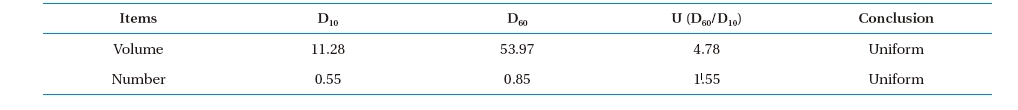

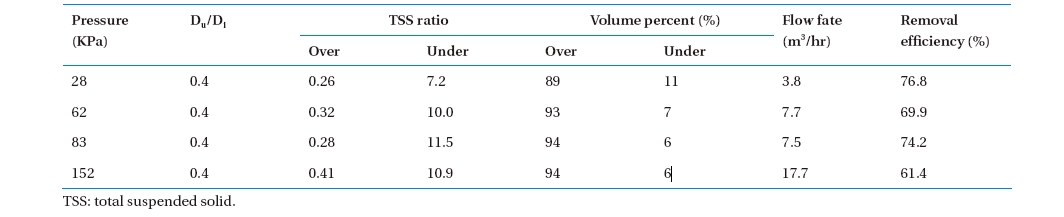

3.7. Experiments with Actual Highway Rainfall Runoff

The artificial feed water was known to be different from the actual highway runoff with respect to the particle size distribution and other component parameters. Experiments were conducted

[Table 2.] The uniformity analysis of particle size distribution

The uniformity analysis of particle size distribution

[Table 3.] The experiments results using actual highway runoff

The experiments results using actual highway runoff

using actual highway runoff collected from a highway on March 11, 2009 in order to determine the practical removal efficiency of the φ7.5 cm hydrocyclone. The results showed that the particles removal efficiency was greater than 60%. The TSSover/in (0.26?0.41) was higher than the results obtained experimentally using artificial water, while the TSSunder/in (7.2?11.5) was within the range of the corresponding values (Table 3); this difference can be explained by the following: the actual highway runoff contains many more fine particles than the artificial water, according to the above discussion (Fig. 8(c)), and more fine particles, especially less than 45 μm, were separated to the overflow. The percentage volumes (overflow and underflow) and flow rate were in agreement with the results obtained experimentally using artificial water.

The operational behavior of a φ7.5 cm hydrocyclone designed according to the Rietema criterion, with some modifications, was measured. The percentage overflow volume decreased with increasing Du/Di ratio, while that of the underflow volume increased; these parameters showed reversed behavior with respect to the operational pressure. There was no evident difference in the TSSover/in with increasing Du/Di ratio, while the TSSunder/in decreased sharply; the TSSover/in decreased as a function of the operational pressure, while the TSSunder/in increased. Therefore, the Du/Di ratio plays a more important and decisive role in the operational behavior of a hydrocyclone.

The particles removal efficiency was mainly affected by the particle size, whereas the Du/Di ratio and operational pressure had only weak effects. The D50 of the hydrocyclone used in this study was about 45μm, which means particles coarser than 45 μm would be separated to the underflow. Priority should be give to the Du/Di ratio when designing and applying a hydrocyclone to obtain a concentrated underflow and clean overflow. The removal efficiency of actual highway runoff was lower than that of artificial water. The treatment capacity was mainly affected by the operational pressure.

The particle size analysis of the overflow indicated that 99.98% of the particles, based on numbers, were finer than 45 μm and accounted for 50% of the mass. The uniformity coefficient analysis indicated that the particle size distribution was uniform based on both the particle number and mass.