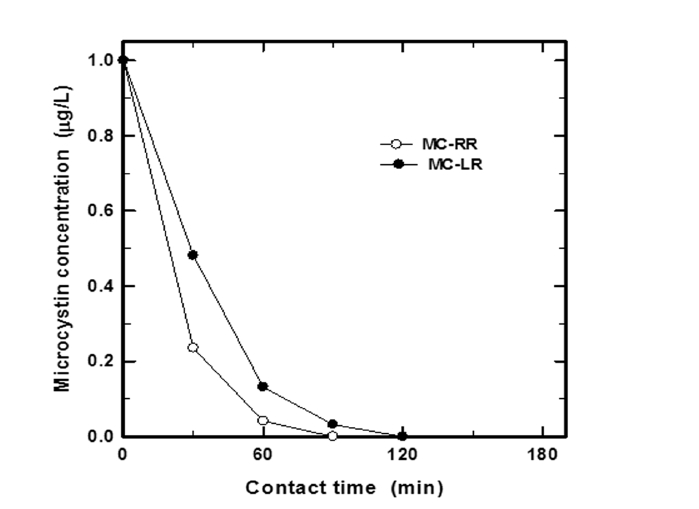

This study examined the special technique of photocatalytic degradation (RPODisk) for removal of taste and odor causing materials, algae, and algal toxin. The RPODisk was effective for removal of these troublesome contaminants. It outperformed the fixed media and the UV irradiation for geosmin removal. The RPODisk performance was comparable to the combination of the UV irradiation with TiO2. The RPODisk performance was affected by the rotating speed. The faster the speed was, the better the performance. The RPODisk was also effective for removal of algae and algal toxin. The algal activity reduced by 80% after 30 mins of the treatment. More toxic microcystin (MC)-LR was more difficult to remove than MC-RR. The times for 50% removal were 23.7 mins for MC-LR and 14.1 mins for MC-RR. Almost 100 mins of the contact time was required to completely remove MC-LR at the rotating speed of 260 rpm.

Recent industrialization and urbanization resulted in eutrophication of most surface waters in Korea. The typical example is the Nakdong river, which serves as raw water source to southeast region of Korea. Eutrophication was more serious at downstream, where hydration occurred.1) Subsequent algal bloom poses a serious threat to water treatment plants, relying on the Nakdong river. Algal bloom causes several problems including taste and odor (T & O), algal toxins, filter clogging. Since conventional treatment is ineffective to handle these problems, advanced processes such as activated carbon and ozonation were introduced to those plants. This study reports the results using the technique rotating photocatalytic oxidation disk reactor (RPODisk).

Geosmin was selected as the representative T & O causing material in this study. The standard solution of geosmin (98%, Sigma-Aldrich, U.S.A.) was diluted in distilled water so that the solution concentration became 10 μg/L. Microcystin (MC)-LR and MC-RR were used as the representative algal toxin. The standard solution (Kanto Chemical, Japan) was diluted to 3.9 μg/L (MC-LR) and 2.9 μg/L (MC-RR) in distilled water.

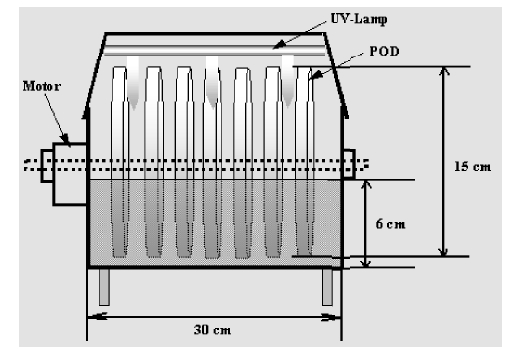

Titanium dioxide powder (Degussa P-25) was used without pretreatment to evaluate the photocatalyitc oxidation performance. When an experiment did not involve the powder form of TiO2, titanium isopropoxide (TTIP; 98%, JUnsei Chemical Co., Ltd., Japan) was used. TTIP was attached into the fixed media such as the hollow glass bead with 2 cm of diameter, glass pellet with 2.5 mm of diameter, and glass disc with 15 cm of diameter. The germicidal lamp of 10 W (254 nm, Sankyo Denki, Japan) was used as the ultraviolet (UV) source. Fig. 1 shows the schematic diagram of the RPODisk used in this study.

The glass disc was washed with potassium dichromate before coating. TTIP was mixed with ethyl alcohol and HCl at the ratio of 10:100:1. The TTIP mixture was then coated into the dried

glass disc. The titanium coated disc was then heated at 100℃. The temperature increased at the rate of 10∼20℃ /min up to 500℃, at which it stayed for 4 hrs. This process was repeated 20 times before the disc was placed into the reactor.2)

The RPODisk used in this study was a batch reactor with a capacity of 3 liter. Two germicidal lamps were placed above the disc. A reflecting glass was put above these lamps so that the UV light heading the reactor roof can be directed into the disc. Seven discs with titanium coating (POD) were connected by a horizontal axis. It was rotated at 24∼260 rpm. While POD was rotating, it would contact with water and air, alternatively. Photocatalytic capacity of the titanium oxide would be enhanced through the rotation.

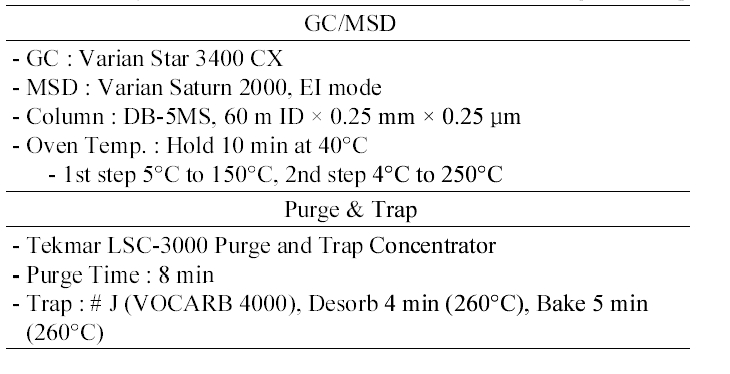

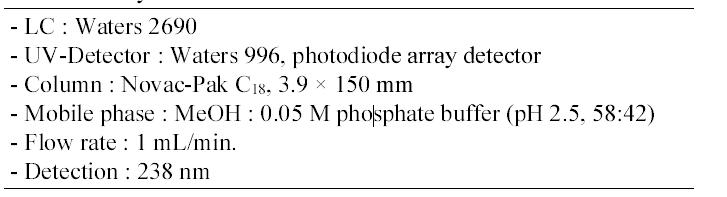

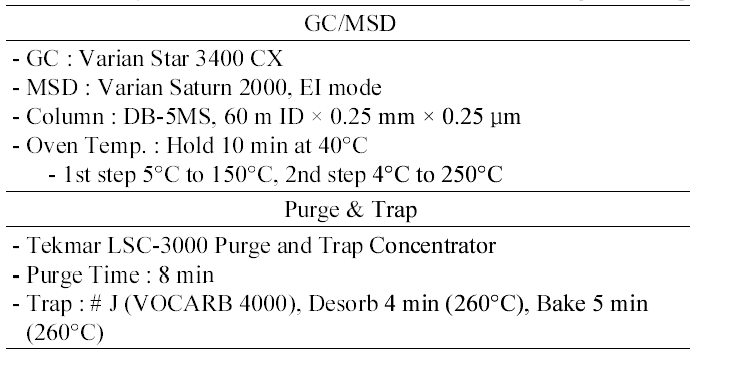

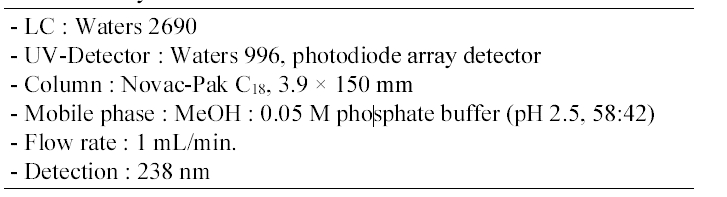

Geosmin and 2-MIB were analyzed by GC/MSD with twist pretreatment. For the microcystin analysis, sample of 500 mL was pretreated using solid phase extraction (Autotrace SPE Workstation, Tekmar, U.S.A.) so that microcystin could be adsorbed onto the sep-pak catridge (C18). It was washed and eluted into 20% methyl alcohol before filtration through 0.2 μm membrane filter (Sartorius Minisart RC4, Germany). HPLC was used for the analysis. Table 1 and 2 summarized the analy-tical conditions.

[Table 1.] Analytical Conditions of the GC/MSD and the Purge and Trap

Analytical Conditions of the GC/MSD and the Purge and Trap

[Table 2.] Analytical Conditions of the HPLC

Analytical Conditions of the HPLC

For chlorophyll-a analysis, sample of 500 mL was first filtered through GF/C filter paper. The paper was then soaked into the 90% acetone solution of 20 mL. After storing in a dark room at 0℃ for 12 hrs, it was sonicated for 1 min, and put back into the storage for another 12 hrs. Centrifuge supernatant was then analyzed UV- absorption at such wavelengths as 750, 664, 647, 630, 480 nm based on the Jeffrey and Humphrey method (CARY 100 conc, Varian, Austrailia).3)

For the algal activity measurement, sample was added into the BOD bottle with 1 mL of NaH14CO3 (55.0 mCi/mmol) at the concentration of 10 μci/mL. After being incubated for 3 hrs, its radioactive concentration was measured using Liquid Scintillation Analyzer (Packard 2500TR/AB, Canberra, U.S.A.) for algal substrate uptake.4)

Fig. 2 shows the SEM picture of the POD surface. According to Fig. 2(a), the coating thickness was 480 nm. Fig. 2(b) shows

that TiO2 particles packed the glass disc surface.

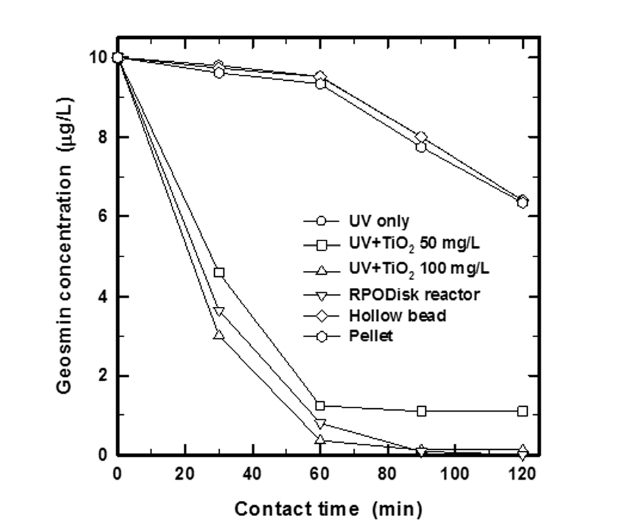

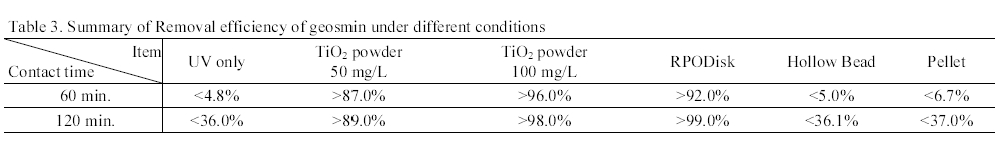

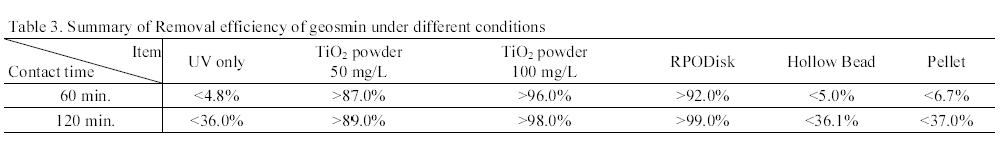

Photocatalytic removal of geosmin was evaluated using powder form of titanium oxide, the titanium fixed media, and the RPODisk. Fig. 3 and Table 3 show the results. The wavelength of 254 nm was used for the UV irradiation. TiO2 powder was suspended in the solution without pretreatment. The solution was continuously mixed using a magnetic bar so that the powder and the media were kept in suspension. The RPODisk was rotated at 260 rpm.

distribution, the photocatalytic reaction failed to occur all over the solution. However, the RPODisk promoted the photocatalytic reaction both in air and water, which resulted in the better removal efficiency. The RPODisk could be more beneficial than the combination of the UV irradiation with TiO2 for application to water treatment plant because the UV-TiO2 combination process needs one more step to separate the TiO2 particle. After the photocatalytic reaction, the TiO2 particles should be separated from water by filtration. On the other hand, the RPODisk does not need an additional step.

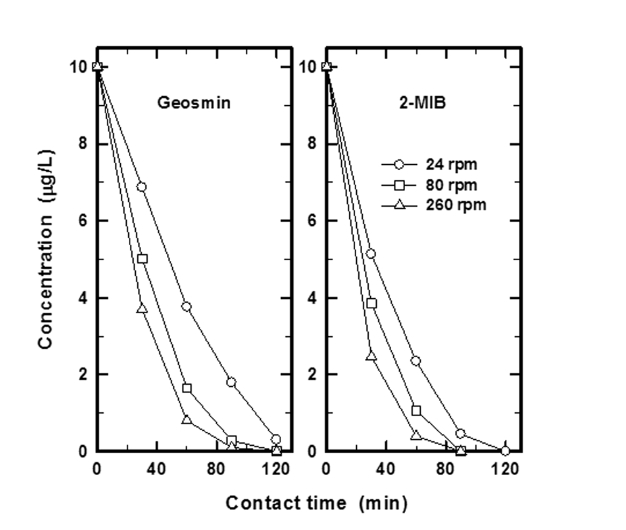

Fig. 4 shows the effect of the rotating speed of the RPODisk on the removal of gesomin and 2-MIB. While the The rotating speed varied to 24, 80, and 260 rpm, the removal of geosmin and 2-MIB were monitored. According to Fig. 4, the best performance was obtained at the highest speed (260 rpm). The fast rotating possible reduced the boundary layer thickness, which encourage the better contact between the POD and the contaminants. The removal efficiency was different with the contaminant type. Geosmin was more difficult to remove than 2-MIB. The time needed for 90 removal was 105 mins for geosmin and 83 mins for 2-MIB at 24 rpm. It was 58 and 52 mins at 260 rpm.

3.3. Removal of Algae and Algal Toxin

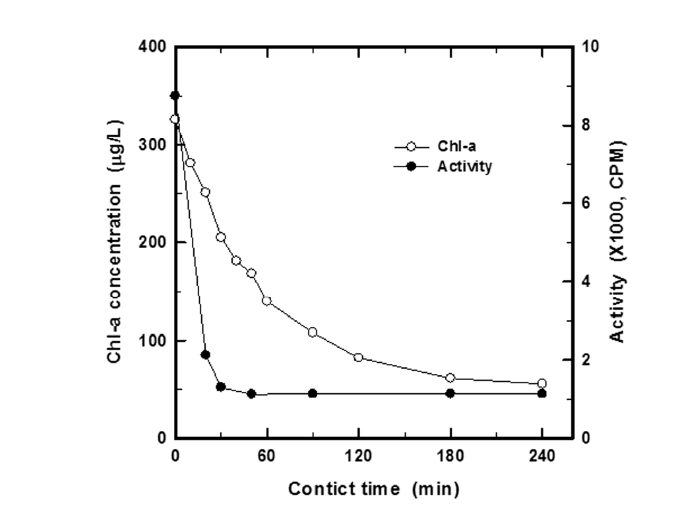

The use of the RPODisk was extended for removal of algae. It was rotated at 260 rpm. Microcystis sp. was directly added into raw water. Fig. 5 shows the results. According to Fig. 5, the algal activity reduced rapidly. The reduction was complete after 30 mins. The chlorophyll-a concentration was slower than the algal activity. It slowly decreased. The 83% reduction was obtained after 4 hrs.

[Table 3.] Summary of Removal efficiency of geosmin under different conditions

Summary of Removal efficiency of geosmin under different conditions

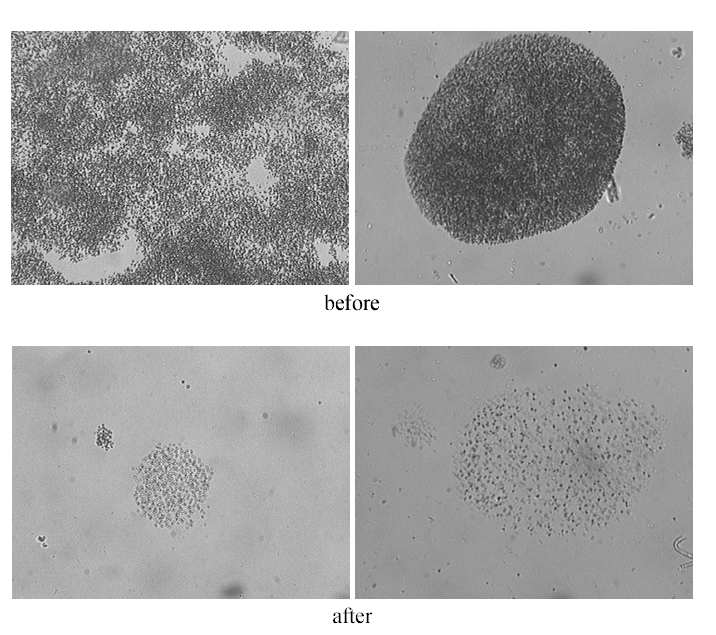

Fig. 6 shows the results of algal toxin removal. According to Fig. 6, more toxic MC- LR was more difficult to remove than MC-RR. MC-RR was almost completely removed after 90 mins of contact time, but MC-LR required 120 mins. The time required to remove 50% of these algal toxin was 14.1 mins for MC-RR and 23.7 mins for MC-LR. Fig. 7 shows the pictures of Microcystis sp. It formed colony originally. However, after 90 mins of contact time, the colony was completely dispersed.

The RPODisk removed geosmin effectively. It outperformed the fixed media and the UV irradiation. The RPODisk performance was comparable to the combination of the UV irradiation with TiO2. The RPODisk performance was affected by the rotating speed. The faster the speed was, the better the performance. The speed of 260 rpm gave the best results in this study. The RPODisk was also effective for removal of algae and algal toxin. The algal activity reduced by 80% after 30 mins of the treatment. The chlorophyll-a concentration was slower than the algal activity. It took 4 hrs to reduce the chlorophyll-a concentration by 83%. More toxic MC-LR was more difficult to remove than MC-RR. The times for 50% removal were 23.7 mins for MC-LR and 14.1 mins for MC-RR. Almost 100 mins of the contact time was required to completely remove MC-LR at the rotating speed of 260 rpm.

![SEM photograph of TiO2 immobilized on a glass disk. [×100k]](http://oak.go.kr/repository/journal/10047/E1HGBK_2009_v14n3_170_f002.jpg)