Since Korea’s first nuclear power plant began operation in 1978, nuclear energy has increasingly contributed toward improving the nation’s energy security and providing affordable electricity. Nuclear power generation has lowered Korea’s energy imports. In 2009, the nation’s energy imports reached US$95 billion, which accounted for 97% of its total energy requirements. Taking into account nuclear power as a domestic energy source, it saved the nation about 15% in overall energy imports. Cheap nuclear electricity, with its growing share of electricity supply, has contributed to stabilizing the domestic electricity prices at very low levels, which in turn has led to competitive production costs in domestic industries and bringing down inflation in national economy.

To the world’s surprise, Korea has furthermore grown into a full-fledged nuclear power plant supplier. In early December of 2009, Korea was awarded a bid by Jordan to build the country’s first nuclear research reactor in a contract worth some US$170 million. The contract was signed in March 2010, and called for a 5 MWt reactor to be built by 2014, which will be used for scientific and engineering studies and for medical and industrial isotope production in Jordan. Immediately following this auspicious news, Korea was won another bid to build and operate four nuclear power units for the United Arab Emirates. The world’s third-largest oil exporter is introducing nuclear power in order to meet its soaring electricity demand. The first unit, with an installed capacity of 1,400 MWe, is expected to come online by 2017 and the other three units by 2020. These two contracts marked the greatest achievements in the 50-year history of nuclear energy development in Korea.

This article details how this remarkable accomplishment was achieved. It explores how Korea succeeded in developing an indigenous nuclear power plant model over fifty years. Chapter 1 introduces the objective and background. Chapter 2 offers the conceptual framework. Empirical cases are investigated and analyzed in Chapters 3, 4 and 5. Chapter 6 summarizes the research and lays out the policy implications.

1. Technological Change for Economic Growth

Technological change is widely recognized as one of the primary engines of economic growth. Since the findings of Abramovitz (1956) and Solow (1957), technological progress has been acknowledged to be the major determinant of industrial development (OECD, 1996; Kim, 1999) and national economic growth (Rosenberg, 1982; Nelson and Winter, 1982). Ever greater emphasis has been placed on technological advance as the most important factor in the growth of many economies of both developed and developing countries. Through improvements in capital and labor productivity, and the creation of new goods and services, technological advances have played a significant role in the economic growth (Mitchell, 1999).

Schumpeterian and Neo-Schumpeterian economics views acknowledge technical advancement to be the central force in the economic phenomena. Both theories likewise acknowledge that technological change is one of the endogenous determinants of economic development. However, the two offer different perspectives about the kind of technological change that contributes more significantly to economic growth. Schumpeter focuses on the radical change that underlies the deployment of discontinuity of radical innovation in the expansion of the international technology frontier.

The neo-Schumpeterian concept of technological change is not so much one major event resulting from an original breakthrough of radical innovation as an evolutionary process in which the incompleteness of the original breakthrough is successively improved by a series of complementary innovations in product or process technology. This neo-Schumpeterian approach stresses the importance of incremental change over radical change in understanding technological change as the process of integration of technological discontinuity by radical change with continuous accumulation of incremental change (Kim, 1994). The neo-Schumpeterian view technological change as an evolutionary process of technically-diverse solutions and selection mechanisms to substitute for less-desirable technologies, in terms of cost advantages, technical superiority and evolutionary potential (Nelson and Winter, 1982; Arundel et al., 1998).

2. Technological Capabilities in Developing Countries

By the early 1970s, technological innovation that is, technological change and its resultant contribution to economic growth in developing countries became to attract considerable attention in the study of technological innovation (Bell and Figueiredo, 2012). Technological learning means the process of building-up capabilities for technological change and subsequently the creation of socio-economic value in developing countries. The technological learning school finds the answer to the question of how the imported foreign technology leads to technological change by the recipient in developing countries. The school acknowledges that the technological effort of the recipient could incrementally change the imported technology and, as a result, technological capabilities (TCs) will be accumulated and improved. This school recognizes that, with the active technological effort, developing countries can efficiently import foreign advanced technology and effectively develop TCs, which contribute to their industrialization and economic growth.

This technological learning perspective leads to a distinction between different courses of technological change from those experienced in the supplier countries. This concept of technological learning pays more attention to international technology transfer from advanced countries to developing countries as a starting point of building up TCs in developing countries. This perspective of technological learning recognizes endogenous technological change by internal technological efforts of developing countries. Technological effort is concerned with an argument that TCs is barely obtained in the international technology market. The building-up of TCs is a dynamic and complex process in which TCs are accumulated over time responding in a timely way to the changing technological environment (Teece and Pisano, 1994; Lall, 1998; Kim, 1999; Lee, 2004). The initial acquisition from outside and the subsequent transition of technological capabilities from lower to higher stages are not accomplished automatically or without cost. As for developing countries, these require purposeful technological effort with a successive commitment for considerable time to monitor external environments, to make effective use of imported technology and to accumulate and improve TCs.

III. Opening the ‘Atomic Age’ in Korea

1. Creating Legislative and Organizational Institutions

Korea first got acquainted with nuclear energy in the 1950s when the nation made an all-in bet at overcoming the devastation wrought by the Korean War. Korea was suffering from widespread poverty and hunger with a per-capita gross national income of around US$80 per year. Eisenhower’s ‘Atoms for Peace’ policy triggered this poor country to introduced nuclear energy. The ‘Atoms for Peace’ policy spurred an international technology transfer both bilaterally and multilaterally. Between 1953 and 1962, the US offered forty-five countries a total of US$11.7 million for research reactors and equipment (Johnson, 1978). In response to the US ‘Atoms for Peace’ policy, multilaterally, the UN international conferences on the peaceful uses of atomic energy held in Geneva in 1955 and 1958 contributed dramatically to the international diffusion of scientific and technological knowledge for peaceful applications of atomic energy. In particular, these conferences encouraged small and developing countries to invest in nuclear energy including a nuclear power option (Hewlett, 1985). By the late 1950s, Korea developed a keen interest in the peaceful use of nuclear energy. With domestic energy resources badly limited, Korea expected that nuclear energy could solve the problem of chronic power shortages. The United Nations international conference on the peaceful uses of atomic energy which was held in Geneva in August 1955 provided Korea with the first opportunity to understand nuclear science and technology for peaceful uses, e.g. nuclear power generation, radioisotope use, etc. Three Korean participants collected 1,132 scientific and technological papers from the conference. On returning to Korea, the three Koreans formed an informal so-called ‘Study Group’ and began to study the advanced science and technology of nuclear energy. This Study Group incubated nuclear science and technology in Korea. The group prepared the draft of the Atomic Energy Law and nuclear administrative organization. The group also reviewed the feasibility of a nuclear research reactor and manpower training (KAERI, 1990).

The ‘Agreement for Co-operation between the Government of the Republic of Korea and the Government of the United States concerning the Civil Uses of Atomic Energy’ (‘1956 agreement’) was signed in February 1956. It is the first bilateral agreement that Korea entered into with an advanced country for cooperation in the use of nuclear technology, materials, and information for non-military purposes. After this agreement, Korea started its study on nuclear science and technology at the government level. In the wake of the 1956 agreement, the Korean government established a Nuclear Energy Section (NES) under the Ministry of Education in March 1956. As a result of the NES’s effort, in March 1958, the Atomic Energy Law was promulgated in order to provide the legal foundation for nuclear energy development. The Office of Atomic Energy (OAE) was established as a central government body for nuclear energy development in January 1959. The OAE was consisted of two major subordinate organizations: the Atomic Energy Commission (AEC) and the Atomic Energy Research Institute (AERI).

The introduction of nuclear energy began with the import of a research reactor. Korea selected a TRIGA Mark-II (100 kWth) research reactor with 20% enriched uranium fuel of ZrUH. The reasons were as follows. First, Korea reckoned that the TRIGA reactor satisfied the Korean objectives, i.e. basic nuclear research and nuclear manpower training. Second, instead of technical functions, Korea evaluated its business performance in terms of product sales. Because of the lack of technological capabilities, Korea could not review the technical characteristics of the reactor. At the time, TRIGA was in the lead in terms of share in the world’s research reactor market. Lastly, the purchase price was very favorable to Korea. Under the ‘Atoms for Peace’ program, the US government offered Korea US$ 350,000, which was about half the purchase price (KAERI, 1990). Korea signed a turnkey contract with the General Atomic Division of General Dynamics Corporation (GA), USA, in December 1958.

In the late 1960s, Korea faced insufficient thermal power off the TRIGA Mark-II due to the increasing demand of radioisotopes and high neutron flux. The government augmented the capacity of the research reactor and simultaneously constructed a second research reactor with greater power capacity. From 1967 to 1969, Korea increased the thermal power of the TRICA Mark-II from 100 to 250 kWt. It was achieved mainly by AERI’s own effort. AERI rearranged reactivity control mechanism and neutron detectors in the reactor structure, and installed pumps and heat exchangers in the primary cooling system (KNS, 2009). In December 1968, Korea signed a contract with GA for the purchase of a TRIGA Mark-III. This time, the Korean decision was based on different factors than the ones that presided over the decision on the first reactor. They were not based on the business performance, but on technical performance criteria such as the safety and reliability of the reactor, and nuclear fuel supply as well as research flexibility and reactor reliability. Second, unlike the TRIGA-II, the purchase of the TRIGA Mark-III was not turnkey-based. Even though the foreign company essentially led the project, Korea made an effort to participate in the construction as much as possible in order to accumulate domestic technological capabilities for nuclear research reactor. The construction work began in April 1969 and the reactor reached nominal full power of 2 MWth in March 1972. By introducing and operating its research reactors, Korea accumulated operational and maintenance capabilities while training its manpower. In addition, Korea came to understand the scientific and technological characteristics of nuclear energy and its research facilities.

Meanwhile, since 1958, several universities established new departments devoted to nuclear engineering, or they revised the curriculum of their existing department placing an emphasis on nuclear engineering. Training technical manpower was accomplished through overseas education and on-the-job training, mostly in US universities and national laboratories. Initially, two Koreans went to the US. Since then, many qualified scientists and engineers have travelled abroad to study nuclear science and technology. By 1964, the number of overseas trained personnel had reached 237 (Lee, 1975; KAERI, 1990).

As a result of this effort, Korea’s in-house research had perfected the fabrication of nuclear fuel rods by the late 1960s. On the basis of earlier learning in the US as well as basic research experience with the TRIGA reactor in Korea, Korea organized a department in AERI to research nuclear fuel fabrication in 1965. In the US in the early 1960s, Korean engaged in laboratory-scale experiments to manufacture material test reactor fuel. This experience was applied to the research on the fabrication of nuclear fuel rods using uranium in Korea. The US ANL provided some of the parts and equipment, and technical advice for laboratory experiments for this research. By 1968, AERI succeeded in producing fuel rods while uranium pellets were sintered and inserted into zircalloy tubes that were subsequently manufactured in the laboratory. It was the first time that Korea carried out all the processes involved in nuclear fuel rod fabrication on its own. Moreover, AERI improved the fabrication process including sintering time and temperature even though it was at a laboratory scale.

IV. Introducing Nuclear Power Generation

1. Importing Nuclear Power Plants

Korea launched its first five-year plan of economic development in 1962. Driven by the nation’s industrialization and economic growth, nuclear power was initially considered very promising alternative for the stable electricity supply. Korea organized the ‘Survey Committee on Nuclear Power Generation’ led by the OAE in 1962 and undertook a preliminary feasibility study to introduce nuclear power into electricity generation. The IAEA supported this study while visiting Korea in October 1963 and June 1965 (Ha, 1982, KAERI, 1990). This preliminary feasibility study suggested a nuclear power reactor with the capacity of 200 to 300 MWe because of the relatively small size of the Korean electricity grid at the time (Lee, 1975). The results of this study showed that, in economics terms, it was not the appropriate time to introduce a nuclear power plant in Korea. Nuclear power units of over 600 MWe were generally being validated for construction by the mid-1970s. Also, the maximum size of a single nuclear power plant is limited to about one-tenth of the total installed capacity of one electrical transmission network (Poneman, 1982). Otherwise, an unplanned outage of the plant could result in a blackout throughout the electrical grid. However, the total installed capacity of electricity generation was no larger than 770 MWe in Korea in 1965 (KHNP, 2011).

By the late 1960s, as the domestic economy recovered, energy consumption increased and was expected to continue doing so in the future. The total energy demand of Korea was projected to rapidly increase to the equivalent of 48 million tons of coal (TCE) in ten years, compared to 25 TCE in 1966. In particular, Korea estimated that the demand for electricity would increase six-fold for the same time (Ha, 1982). Therefore, a more reliable energy supply for the national economy became one of the most important elements of Korea’s third economic development plan (1971-1976). In the country, anthracite coal and hydropower were the major domestic energy resources. But they were not sufficient to cope with the increasing energy demands. The only domestic fossil fuel was anthracite coal of low calorific value below 4,000 kcal/kg. Proven anthracite reserves were estimated to be 1.5 billion tons – about half of this was economically recoverable – and would be depleted in twenty-five years. The country’s hydroelectric potential was about 3,000 MW, which was not adequate for domestic demand in either the near- or long-term future. Moreover, uranium deposits were identified as low grade and not worth exploiting economically (Ha, 1982; Choi, 1996). Taking advantage of nuclear energy came to be considered a reliable energy supply to cope with the ever-growing energy demand and overcome poor energy security.

In addition, nuclear power was evaluated to be very effective at reducing the heavy dependency on imported oil. In the 1960s, Korea’s power generation program was centered on oil-fired plants. The share of fossil-fired generation reached 80% in the late 1960s. As the import of petroleum sharply increased, Korea worried about its heavy dependency on foreign oil. Korea was also concerned with the uncertainty of global oil supply. Thus, the country conceived the idea of so-called ‘diversification of energy resources’ and then decided to introduce nuclear power generation. Korea recognized that the overall economics and low operating cost together with the high energy density of nuclear power generation was well suited to base load electricity generation system. For Korea, the cost of nuclear power generation at 530 MWe was calculated to be 6.42 mills/kWh, which was slightly lower than 6.83 mills/kWh from an oil-fired thermal plant (Ha, 1982). Nuclear energy also has high energy density. Compared with fossil fuels, much less volume of nuclear fuel needs to be used to produce the same amount of electricity. This energy density coupled with high economics provided nuclear power with a competitive advantage against other energy resources. Hence, Korean nuclear power development has been inextricably linked with national economic development and industrialization. In 1967, Korea conducted again a feasibility study for the introduction of a nuclear power plant. The OAE reviewed the unit size of nuclear power plant again and concluded that the economic growth in Korea would favor a nuclear power plant with a unit size exceeding 500 MW(e) in 1974 (Lee, 1986). Again, Korea consulted with the IAEA on the overall nuclear power program including plant sites and financial arrangements for the construction. Then, the Korean government established the first ‘long-term nuclear power development plan’ in 1968 and decided to construct two nuclear power plants (2 x 500 MWe) by 1976 as part of the third five-year economic development plan (1971-1976).

In June 1968, KECO, a government-owned company, issued letters of tender guidance for the first nuclear power plant. Based on technical criteria in terms of operation experience of nuclear power reactors such as plant availability, the Korean government decided the construction of an imported US PWR (Pressurized Water Reactor) with a 587 MWe capacity. Korea’s plan to construct two units of NPP was changed into one after looking at financing sources. Korea followed a conventional approach to finance its first NPP project. It requested potential suppliers to provide funds together with their bids. Approximately US$157 million was financed through the ECA (Export Credit Agency) loan by foreign suppliers. Although it was over 50% of the total investment, the international loan granted was enough for only one PWR after the course of the negotiations. Another limited commercial loan was also supplied by the Bank of America with a short-term repayment term. As a result, the Korean plan to construct two NPP units was reduced to one (Ha, 1982; KAERI, 1990; KAERI, 2007; KHNP, 2011).

In June 1970, Korea signed a turn-key contract with the Westinghouse Electric International Company (WEICO) for the construction of the first Korean NPP in June 1970 (KEPCO, 1990). In September 1970, the site preparation for the construction of the first Korean nuclear power plant with 587 MWe capacity began at Kori, Jangan-eup, Yangsan-gun, some 50 km northeast of Pusan, at the southern end of the Korean peninsula. As per the contractual agreement, commercial operation was expected to start by the end of December 1975. However, it was delayed for about two and a half years. The lack of technological capabilities of NPP projects at home and the oil crises in 1970s abroad were mainly responsible for the delay (KHNP, 2011). The construction permit (CP) and operating license (OL) were simultaneously issued to the Kori Unit 1 in March 1976 (KAERI, 2007).

So far as technological capabilities are concerned, Korea evaluated that the construction of a nuclear power system was beyond its present capabilities because of its technical complexity and capital intensity. By that time, Korea had only participated in feasibility studies for the introduction of a nuclear power plant, carrying out safety analyses, etc. Such experience did not amount to enough capabilities to be responsible for the construction of NPPs. So, Korea decided to choose a turnkey contract, i.e. a plant-based approach. Under the turnkey contract, a foreign company served as the prime contractor and assumed the overall responsibility for completing all phases of the project ranging from project management, quality management, manufacturing equipment, construction, commissioning and licensing of the plant, as well as training of personnel (KAERI, 2007). While participating in a limited way in civil engineering and installation, Korea got to learn the basics of how to do the undertake such tasks as project management and test operation of the completed power plants. The human resources plan for the first Korean NPP was focused on securing the appropriate capability for the operation. Due to a lack of domestic capabilities, it was evaluated that about 1.8-times as much manpower as that of the US was needed. This number of trainees was supplied from domestic universities, which had already been graduating nuclear engineers for some years. Korea began to train engineering and operations staff members for the first and subsequent nuclear power plants with the help of WEICO and IAEA amongst others. At home, AERI launched a basic training course for nuclear power plant operation including nuclear engineering theory in 1968 (KHNP, 2011).

When it came to construction capabilities, most of the materials and technology were supplied by foreign contractors. Domestic industries only provided civil materials such as rebar, cement and sand. Nevertheless, domestic capabilities of construction could supply general technicians and craft workers as much as needed thanks to several petro-chemical plants and thermal power plants, which were under construction ahead of the NPP. Korea had been constructing 250 MWe fossil fuel plants at the time. However, special welders and engineers were supplied mostly from abroad (KHNP, 2011). The manufacturing capabilities were not ready for the first NPP despite the fact that the Korean government policy to develop heavy and chemical industries drove the localization of equipment and facilities for the industries. The Korean NPP projects used codes and standards of the supplier country such as 10CFR, Reg. Guide and Standard Review Plan of USNRC.

Domestic laws and regulations were not appropriately set up for the construction and operation of nuclear power plant. The ‘Atomic Energy Act’ was first passed in March 1958 without substantial consideration of constructing and operating NPPs. In supporting the feasibility study of the first NPP in Korea, the IAEA recommended establishing national nuclear legal institutions before the completion of the first nuclear power plant. For the introduction of the first NPP, the Atomic Energy Act was revised to accommodate the nuclear safety regulations as well as energy promotion (KHNP, 2011). In addition, the Korean government entrusted the nuclear regulation tasks for the construction of the Kori Unit 1 to the Atomic Energy Research Institute (AERI) under the Office of Atomic Energy. The first Korean NPP came on line in July 1978.

In October 1973, an oil crisis swept the world. It happened in the wake of the outbreak of war in the Middle East. OPEC member countries used oil resources as economic weapons and nationalized them. Oil prices, which had hovered below US$3 per barrel in 1972, nearly quadrupled to US$11.20 in 1974. While scrambling to devise self-rescue measures, major energy consuming countries, including Japan and France, began to treat energy security at the highest level of national agenda and to expand nuclear power plants. Korea, an energy-poor country, followed this trend; it decided to expand its nuclear power generation capacity. Judging that nuclear power plants could be the best alternative as an oil substitute, the Korean government decided to construct two additional nuclear power installations, Kori Unit 2 (a 650 MW(e) PWR) and Wolsong Unit 1 (a 679 MW(e) PHWR). Like Kori Unit 1, both Kori Unit 2 and Wolsong Unit 1 were implemented on a turnkey basis. Korea Electric Power Corporation (KEPCO) signed another contract for Kori Unit 2 with WEICO again in November 1976. Thanks to technological learning, although limited, from the construction of the first nuclear power plant, although it was very limited, the second nuclear plant was completed in a much shorter period of time than the first one. The Korean government also established a nuclear architecture/engineering (A/E) company named Korea Nuclear Engineering (KNE) to develop designing and engineering capabilities in November 1976. It was largely spun off from KAERI. KNE studied the methods of localizing parts and equipment.

2. Expanding Nuclear Power Plants

In late 1970s, this government decided a further expansion of NPP in order to meet the surging electricity demand due to domestic economic growth and the uncertainty of global energy supply in the wake of oil crisis. Six NPPs were constructed in the 1980s. Korea began to build 950 MWe-class Kori Units 3 and 4 in January 1978. They were planned to be terminated by September 1984 and September 1985, respectively. From the Kori Units 3 and 4 (2 x 950 MWe PWRs), there were small changes of the terms of contract regarding international technology transfer. Under the government policy, Korea began to adopt a non-turnkey method with a view to increasing the domestic share in constructing, manufacturing and architectural engineering. Through non-turnkey and component-based contracts, the project was divided into many packages based on the owner’s technological capabilities and strategies for the project. A large number of domestic subcontractors became involved to carry out and guarantee their works (KAERI, 2007).

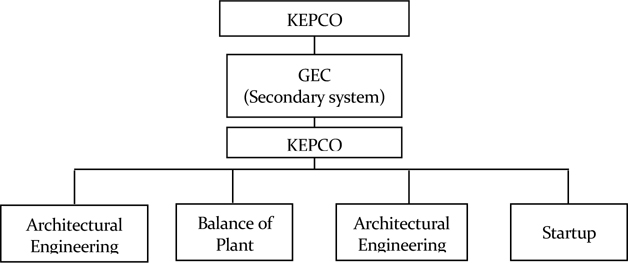

The Korea Electric Power Corporation (KEPCO) assumed overall responsibility. However, foreign firms were still engaged as the prime contractors for designing and supplying core equipment and machinery. Westinghouse was responsible for the supply of NSSS and fuel, Bechtel Power of the US for A/E, design and procurement BOP (balance of plant) area, and GEC for turbine electricity generators. As for domestic participation, Korea was able to participate in more works for the project as subcontractors of foreign main contractors. Hyundai Engineering and Construction, a domestic builder, took charge of construction. Civil engineering was undertaken by domestic firms primarily under their own responsibility. Unlike turnkey contracts, domestic manufacturers, as subcontractors, began to participate in fabricating or assembling selected equipment except core technologies. Korea Nuclear Engineering Company (KNE, currently KOPEC) participated in the detailed design for the project in support of Bechtel Power of the US and was able to accumulate A/E technology.

As regards financing the Kori Units 3 and 4, Korea budgeted US$811 million US$ in principal financed at home and US$1.32 billion from abroad. The main source of the international loan was arranged by the US EXIM and the commercial loan arrangement was initiated through direct consultations from the Hong Kong-based bank Chase Manhattan Asia Limited (CMAL). From the Kori Units 3 and 4 project, commercial loan arrangements began to be supplemented with the main sources of funding. All the loans organized by US EXIM and the CMAL syndicate became effective in February 1979, and the construction of the two units began in April 1979. Work was completed in September 1985 for Kori Unit 3 and in April 1986 for Kori Unit 4 (KAERI, 2007).

In March 1979, there was a severe accident at the Three Mile Island (TMI) nuclear power plant 2 in the US The Korean government reinforced the safety requirements for the Yonggwang Units 1 and 2. Both units were constructed for the first time in Jeolla Province to meet electricity demand for the west coast. The pressurized light water reactors had a capacity of 950 MWe each. Yonggwang Units 1 and 2 were completed in August 1986 and June 1987, respectively. Despite the bolstered safety regulations, Korea was able to cut construction periods and save costs in building nuclear power plants by utilizing domestic materials and experience gained from Kori Units 3 and 4.

Korea imported French technology for constructing the first Ulchin units with the gross capacity of 900 MWe. Korea evaluated that the French P4 PWR’s standardized design carry the advantage to reduce the interface in the design between construction procedures and the entire workload of construction compared with previous types. The primary assembly mechanism was imported from France’s Framatom. The secondary loop mechanism, including turbine electricity generators, was supplied from Alstom. Korean entities shared fairly large portions of assemblies and structures for the construction and manufacturing equipment of Ulchin Units 1 and 2. Dong Ah Engineering and Construction carried out civil engineering work, and KHIC (Korea Heavy Industries and Construction) was responsible for the installation of electrical facilities. Site preparation began in January 1981. Construction and installation for the Ulchin NPP 1 and 2 were completed by September 1988 and September 1989, respectively (KAERI, 2009b).

Influenced by the TMI accident and the increasing number of Korea’s NPPs, the Atomic Energy Act was amended to strengthen the safety provisions in 1982. A two-step licensing system, or Construction Permit (CP) and Operation License (OL), was formally incorporated into the law. This 1982 Atomic Energy Act was the basis for the current structure of legal institutions for nuclear energy development in Korea (KHNP, 2011). Besides, the Nuclear Safety Center (NSC) was organized as a specialized department in the KAERI in December 1981. This was the predecessor of today’s Korea Institute of Nuclear Safety (KINS). The majority of important codes and standards applicable in the vendor countries (US and France) were still applied to the licensing of the six NPPs with only minor modifications.

V. Building-up of Indigenous Technological Capabilities

1. Adaptation with Joint Design

The global oil shock of the 1970s led Korea to realize the need for technological independence in nuclear energy. There was a growing concern that if Korea failed to develop its own independent energy supply line, it might fail to ultimately escape from a ‘least developed country’ syndrome. For Korea, which lacked natural energy resources, localizing nuclear power technology turned out to be a major agenda of national security. In September 1984, the Korean government set up the overall target of localizing 95 percent of NPP technologies by 1995. To be specific, the government planned to localize 95 percent of the design, 97 percent of the manufacturing and 100 percent of the construction by 1995 (KAERI, 2009b; KHNP, 2007). The objective of technical self-reliance policy was to develop indigenous technological capabilities and to catch up with the advanced countries from to constructing and manufacturing to designing work. One of the main targets was to develop its own design of nuclear steam supply system (NSSS) while improving the economic and safety performance of conventional NPPs. The so-called technology self-reliance plan was applied to the Yonggwang Units 3 and 4. The plan called for the completion of the Yonggwang Unit 3 by March 1995 and Unit 4 by March 1996. This daring plan was largely the result of the government policy based on the series of successes in nuclear power construction.

For the successful implementation of the self-reliance policy, the government adopted major strategies such as joint R&D as a way of learning and standardization as an integrated technical path for economics and safety. In general, standardization meant constructing plants of the same standardized specifications in series to gain economies of scale while adapting a new technology to enhance the safety and performance of the NPP. Modularization of the components and equipment was employed to increase the efficiency of standardization. As such, standardization provided a shortening period, saving costs and enhancing the safety of NPP construction and operation (KAERI, 2007; KHNP, 2007).

The standardization was successfully implemented and learnt in the YGN Units 3 and 4, and then the experience was transferred to the UCN Units 3 and 4. Korean-Standard Utility Requirements Document (K-SRED) and Korean-Standard Safety Analysis Report (K-SSAR) were researched and prepared in order to get the licenses of the standardized NPP while elaborating existing technologies including design and analysis methods, sub systems, components and structures (KAERI, 2007).

The strategy of joint design was adopted as a response to the changing environment of the global nuclear power business. In the mid-1980s, the world’s nuclear industry already faced a slowdown in growth and, accordingly, some suppliers began to face difficulties in managing an NPP business (KIM, 2011; NEA, 2008). This trend was accelerated fatally by the Chernobyl disaster. The worst nuclear accident took place in April 1986 in Ukraine. Many countries decided to reduce or stop NPP businesses and the world’s nuclear industry entered a dark age. In spite of the slowdown in the nuclear power industry in the US and Europe, Korea could not help but continue to promote the nuclear power generation business in response to its increasing electricity demands. Therefore, foreign suppliers became more fiercely competitive against each other to win contracts in this promising market, which created a ‘buyers’ market’ for Korea until the signing of the contract and the start of the project in April 1986 (Kim, 2011). Korea turned this global situation into an opportunity for its domestic industry.

The technical self-reliance project started with international technology transfer of the ABB-CE system 80+. The ABB-CE NPP with a capacity of 1000 MWe had been in operation in Palo Verde, USA. In 1987, Korea looked at it as a reference for localizing NPPs, taking into account its high technical performance including safety, but also the terms and conditions of the technology transfer. Korea selected ASEA Brown Boveri-Combustion Engineering (ABB-CE) of USA for learning NSSS, General Electric (GE) for turbine generator and Sargent & Lundy (S&L) of USA for architect engineering. Three criteria were applied to the selection – the method of joint design between supplier and recipient, the contents of technologies and technical capabilities transferred from the suppliers. Korea paid particular attention not only to ABB-CE’s global competitiveness in NSSS technologies, but also to the company’s willingness to transfer such sophisticated technology as NPPs to Korea (Kim, 2011). Taking advantage of a buyer’s market, Korea set up its principle on international technology transfer from the foreign suppliers as a prerequisite condition of contract. By 1987, Korea signed a ten-year contract with ABB-CE for the international transfer of commercial NPP technologies. Korea wanted the foreign suppliers to provide technical information, patents license, classroom training (CRT) and on-the-job training (OJT), R&D participation and consultations. Furthermore, the royalty-free conditions for the export case were agreed upon under the strong request of Korea (KAERI, 2007; Kim, 2011). Grasping the golden opportunity offered by a ‘Buyer’s Market’, this was the way of learning the capability of designing CE system 80+ (SYS-80) NPP technologies.

The project of YGN 3 and 4 was financed with more favorable terms than the previous ones. This was attributed to the successful growth of the national economy. In the late 1970s, Korea’s economy had grown very fast. KEPCO had easier access to international commercial banks. The company secured 85 percent of the required foreign capital through commercial loans. In June 1987, KEPCO borrowed US$ 100 million on its own credit line from international commercial banks, i.e., Banker’s Trust Company, on more favorable terms of financing than before (KAERI, 2007: 108). Among the terms and conditions of the loan, the interest rate was Libor +1.25% with a 5-year grace period and 5-year repayment period (KAERI, 2007).

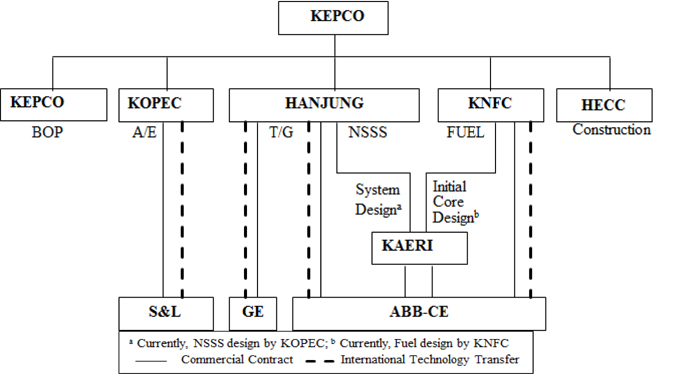

The organizational structure of the Yonggwang Units 3 and 4 was set up to facilitate international technology transfer between foreign suppliers and domestic recipients. At first, the Korea government defined the domestic division of labor among Korean participants on the basis of professional expertise. Then, domestic entities were subcontracted with foreign companies for the efficient transfer of technology. ABB-CE, S&L and GE supported the domestic organization for engineering and equipment and related technologies (KAERI, 2007). Therefore, the NSSS team was comprised of ABB-CE, KHIC (now Doosan Heavy Industry Company, DHIC), and KAERI. ABB-CE and KAERI worked together to jointly design the NSSS and the nuclear reactor core. ABB-CE and KHIC supplied the NSSS and components. KHIC manufactured the Reactor Coolant System (RCS) components, with the exception of reactor coolant pumps and motors. The Korea Nuclear Fuel Company (KNFC) using the ABB-CE design and components manufactured 16-by-16 nuclear fuel. The Korea Power Engineering Company (KOPEC) and S&L provided architect engineering services. KHIC supplied the turbine generators in technical cooperation with General Electric (GE). However, the construction project management was totally undertaken through domestic capabilities. KAERI was also responsible for assisting the government in its licensing and regulatory activities for securing nuclear safety. KAERI carried out safety inspections and technical assessments through all stages ranging from site selection, design, manufacturing, construction, operation to decommissioning. Universities supported science and technology R&D and tests and ran academic programs to foster nuclear manpower.

As for technological capabilities, at that time the domestic prime contractors did not have appropriate capabilities so that they could not warrant the project performance for the construction of NPPs. Therefore, KEPCO signed special subcontracts with foreign suppliers, namely, ABB-CE and S&L. They were asked to assume the warranty responsibilities even though foreign companies were subcontractors. ABB-CE had the largest share of warranty obligations including thermal output performance at the steam generator outlet, delivery schedule, system design accuracy, interface data correctness, regulatory licensing from the Korean authority, and fuel cycle cost. Both sides agreed that completion of the YGN project would be measured by proving all warranty conditions. The project was completed for commercial operation by March 1995 (Kim, 2011). Through this international technology transfer through a joint design, Korea obtained about 4,700 technical documents and 110 computer codes while a total of 500 Koreans were trained in classroom (300) and on-the-job (200). In localizing BOP and A/E for the YGN 3 and 4 project, the S&L transferred technical documents and computer programs to KOPEC. At the beginning, the design was performed by S&L. After the Korean company built up its capabilities, it took responsibility for the final design. Through international TT, the Korean company obtained about 1.3 million pages of technical documents and 300 computer codes and trained 650 persons through classroom (550) or on-the-job (100) (KAERI, 2007).

In the localization of NPP, the ABB-CE’s 1300 MWe of System-80 was scaled down to 1000 MWe for the YGN units. The scaling-down of plant capacity caused some difficulties in licensing the YGN units. After the design safety was intensively reviewed and verified not only by an in-depth review of the project organizations, but also with the assistance of the USNRC and the IAEA, the regulatory body issued construction permissions to the YGN Units 3 and 4 in December 1989 and operation licenses for YGN Unit 3 in September 1994 and Unit 4 in June 1995 (KAERI, 2007). By 1995, Korea estimated that technical self-reliance of NPP had been achieved as planned.

Surprisingly, as a result of the joint design, the ABB-CE’S 1,300 MWe-class NPP was reduced to 1,000 MWe for YGN 3 and 4 in consideration of the nation’s total grid size. In addition, Korea brought about 100 modifications to the ABB-CE design for the Yonggwang Units 3 and 4 to prevent more effectively severe accidents than the System 80. In conducting standardization, Korea also included additional safety margins beyond design basis accidents on top of conventional safety feature. Furthermore, it incorporated ergonomic factors specifically designed to suit Korean operators who are relatively smaller than their Western counterparts. In the middle of YGN 3 and 4 project, the KINS was separated from KAERI and established as the nuclear regulatory expert organization of Korea in 1990. YGN Units 3 and 4 went into commercial operation in March 1995 and 1996. Since then it became the reference plants for the KSNP model (now OPR 1000) (KAERI, 2007).

2. Adaptation with Genuine Self-Reliance

As Korea became to take up the full warranty obligation of NPP construction from Ulchin Units 3 and 4 (UCN 3 and 4), the Ulchin Units 3 and 4 were called the first Korea Standard Nuclear Plant (KSNP). KAERI (later KOPEC) was in charge of the full warranty obligation for the NSSS design of OPR and KOPEC for the rest of the design and architecture engineering. DHIC was responsible for supplying the main equipment including the reactor facilities, turbine generator and KNFC for nuclear fuel. The ten-year technology transfer agreement with ABB-CE was extended in the form of technology cooperation for another ten years in May 15, 1997 (Kim, 2011; KAERI, 2007). Thanks to technological capabilities accumulated in the earlier stages, KEPCO was able to finance UCN 3 and 4 project at the lowest interest rate (KAERI, 2007). For UCN 3 and 4, a total of 3,980 billion won was financed some 3,500 billion won from domestic capital and US$554 million from abroad. Korea started the construction of the first KSNPs in May 1989. The construction of Ulchin Units 3 and 4 was successfully completed in 1998 and 1999, respectively, which marked a historical milestone in the nation’s nuclear power development.

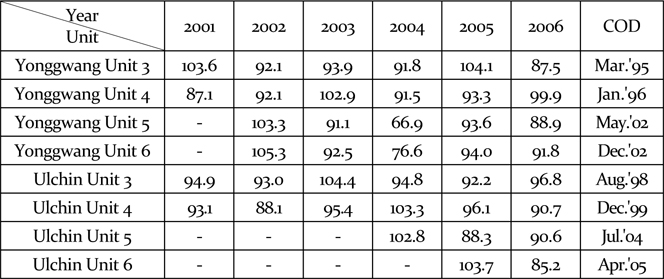

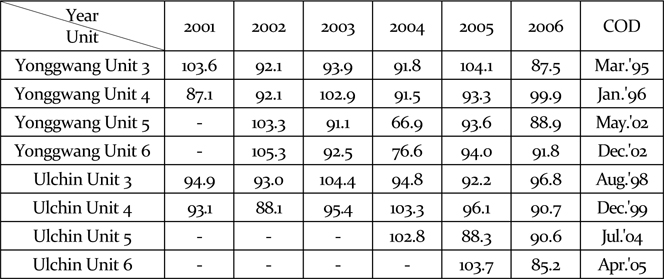

As UCN 3 and 4 were being operated successfully, the KSNP were replicated in constructing eight more units including YGN 5 and 6 and UCN 5 and 6 with embedded incremental improvement (KAERI, 2007). In the meantime, the KSNP was rebranded OPR-1000 in 2005. While continually constructed, the KSNP had been incrementally innovated. Yonggwang Units 5 and 6 were improved to enhance the safety while incorporating some safety feature such as level control in CVCS, digitization and duplication of the process control system, human factors in the remote shutdown system, PSA for low power and shutdown operation, and the filtered vent system, among the features. YGN 5 and 6 project was permitted for construction in June 1997 and UCN 5 and 6 in May 1999. The design of Ulchin Units 5 and 6 was incrementally innovated with special features such as digital plant protection system and engineered safety feature (ESF) actuation system. As a result of the incremental innovation, the OPR series have been operating seamlessly to post outstanding records to this date.

Korea has developed a conventional PWR with its own brand and indigenous fuel fabrication services. Best of all, Korea’s nuclear power plants have produced very cheap electricity with world-class performance in safety and availability of NPP. Nuclear power has reached the lowest cost of all energy sources in Korea; coal is 40% more expensive than nuclear power, for instance. Korea is leading the global standards for NPP Safety, with a 10% higher safety margin than the world average. Its average capacity factor representing system excellence was 1.2 times higher than the global performance in 2009. As of the end of 2010, ten OPRs were in operation: Ulchin 3 and 4, Yonggwang 5 and 6, Ulchin 5 and 6 Shin-Kori 1 and 2 and Shin-Wolsong 1 and 2 (KAERI, 2007).

[Table 1] Capacity factor of OPR1000 in the years 2001~2006 (KHNP, 2007)

Capacity factor of OPR1000 in the years 2001~2006 (KHNP, 2007)

The development of technological capabilities to use nuclear energy began in Korea in the mid-1950s. At the very beginning, US nuclear policy – ‘Atoms for Peace’ policy - provided Korea with the opportunity for understanding the benefit of nuclear energy in terms of energy density and security which was very attractive to the energy-poor Korea with increasing energy demand for the development of a national economy. At the onset of the atomic age, Korea trained technological manpower and conducted basic research of nuclear science and technology, which ranged from nuclear physics to neutron radiography. Korea opened its eyes to the underlying principles of scientific and technical mechanisms relevant to nuclear energy and its applications.

Korea opened its ‘Atomic Age’ with the import of nuclear research reactors in 1962, which resulted from the interaction between the change of external environment and Korea’s technological efforts. Among the external factors were a US policy change, global technological change, domestic energy security, economic growth, and government policy for industrial and economic growth. Technological efforts consisted of nuclear policy formulation, organizational structure, managing research reactor project, active learning at home and abroad, and international cooperation. By the early 1970s, Korea accumulated elementary TCs to the extent that the country operated two research reactors and fabricated nuclear fuel rods.

Technological learning for nuclear power development began in the late 1960s. The first national plan for nuclear power construction was formulated in 1968. Due to a lack of TCs for constructing NPP, the introduction of the first two pressurized water reactors, Kori Units 1 and 2, were entirely reliant upon foreign contractors for the whole range of plant constructions. Under the turnkey contract, the involvement of domestic industries as subcontractors was limited to some civil and architectural works for service facilities. The major goals for technological learning were to find the items to be localized for the next NPP projects. With elementary TCs accumulated in the previous experience, Kori Units 3 and 4, Yonggwang Units 1 and 2 and Ulchin Units 1 and 2 were constructed based on a component basis contract with foreign contractors. Although foreign companies supplied the primary system of the plant through a component approach, a domestic utility, KEPCO, carried out the project management with the assistance of foreign Architect/Engineering (A/E) companies. The roles of domestic firms were expanded to supply equipment and construction in the secondary system. In this stage of absorbing foreign technologies on NPPs, Korea’s TCs building was concentrated on the operation of NPP and the partial participation in BOP construction. Most of the design was not made by Koreans.

As Korea wanted to expand nuclear power capacity, it decided to develop indigenous TCs building in NPPs and localize the design and manufacturing of NSSS, which was formulated under the so-called ‘Technical Self-reliance Plan’ in September 1984. The Korean government set the strategic target to localize 95 percent of nuclear power plant by 1995. Indigenous TCs building was carried out in a different way from the earlier turnkey-type and component-basis projects. With the support of a technology license from foreign subcontractors, Korean organizations took overall responsibility for the project. In order to speed up technological self-reliance, joint design was adopted as a major way of learning under the contract of international technology transfer. Thanks to joint design led by a government research institute (GRI) dedicated to nuclear energy development, KAERI, Korea absorbed the technology of NSSS and fuel, and adapted it to local circumstances in an efficient and effective manner. When YGN 3 and 4 were connected to the grid in 1995, Korea achieved the complete success of its strategic goal of the TCs building for conventional NPPs as planned.

In 1991, Korean was responsible for providing warranty service for the project of the Ulchin Units 3 and 4 and challenged the authentic technical self-reliance of conventional NPPs. Korea took overall responsibility in all aspects of the NPP project while the role of the foreign suppliers was reduced to mainly consulting work. The construction of the first KSNPs (Korean Standard Nuclear Power Plant), namely, Ulchin Units 3 and 4, was started in May 1992. By 1999, domestic technological efforts were successful in build-up indigenous TCs for constructing 1000-MWe-class PWR model, called the Korean Standardized Nuclear Power Plant (KSNP). The Ulchin Units 3 and 4 was replicated in constructing eight more units of OPR with incremental improvement embedded (KAERI, 2007) in particular in terms of safety and economics. The KSNP was rebranded OPR-1000 in 2005. As of the end of 2012, ten OPRs were in operation with world class performance in terms of economics and safety. In 2012, a total of 22 nuclear power units including ten OPRs were in commercial operation which produced 151 TWh of electricity accounting for 29.6 % of Korea’s power generation (MKE, 2013).

By the late 2000s, Korea has succeeded in technological catching-up for constructing and operating a 1000-MWe-class nuclear power plant. This remarkable success was attributed to the nation’s fifty-year commitments for the peaceful use of nuclear energy. The dynamics of TCs building of NPPs in Korea generally complied with the conventional literature of technological learning. However, there was significant difference in this case from the existing knowledge. When Korea developed its indigenous TCs building, it did not follow the conventional path of building-up TCs, which was generally recognized that technological learning in developing countries, namely, technological catching-up, takes place step by step. In other words, the existing literature conceptualizes that adapting imported technologies to local circumstances was not started until their absorption was completed.

This research is concerned with how technological capabilities for the peaceful use of nuclear energy have been indigenously developed in Korea. To answer this question, the theoretical concept of technological learning is elaborated to examine the Korean experience while taking a qualitative approach through longitudinal analysis. Korea succeeded in absorbing and adapting foreign technology at the same time. This dynamic history of TCs building of NPPs in Korea generally complied with the conventional stage model. Starting with the imitation of foreign technology, TCs were accumulated incrementally from absorption to adaptation. Nevertheless, there were some differences in technological learning in Korean cases from the conventional stage model.

The building-up of indigenous TCs for nuclear power generation was greatly affected by global factors, such as global conditions of energy supply, global technological change and resultant global competition in NPP market under the ever-increasing trend of domestic electricity demand. In particular, Korea benefited from global competition in the NPP market, namely, the ‘Buyer’s Market’ in the mid-1980s (Kim, 2011). Nevertheless, it was domestic technological efforts, among them, the strategic planning under government policies and national R&D that led Korea’s unique path of technological catching-up in a conventional NPP model. The government directed technical self-reliance of domestic industry. It established the strategic target of the plan which was to localize 95 percent of nuclear power plant by 1995. The government also defined the domestic division of labor among Korean participants on the basis of professional expertise. From the beginning, the national R&D led by KAERI has played a crucial role in importing, understanding, absorbing and adapting foreign sciences and technologies for the construction and operation of such a complex technology as NPP. In particular, the national R&D was instrumental to develop indigenous TCs and achieve technical self-reliance of nuclear power generation. Thanks to national R&D, Korea could challenge the so-called joint design as a central way of technological learning. The joint design was assessed very effective and efficient in absorbing and adapting foreign technology in the same project while finding indigenous technical solutions to scale down the ABB-CE’s 1300 MWe of System-80 to 1000 MWe for the YGN units.