In recent decades, high power light-emitting diodes (LEDs) based on III-V compound semiconductors have attracted attentions for their use in solid-state lighting and many other applications [1]. In the LED industry, the growth of nitride layers on heteromaterials, such as sapphire or silicon substrates, using metal-organic vapor phase epitaxy (MOVPE), has been considered as the most important process to obtain highquality blue and ultraviolet LED chips [2]. Therefore, the inspection of epi-wafers of LED structures obtained by MOVPE is essential to evaluate the epitaxial process and epi-layers before chip fabrication. Photoluminescence (PL) is currently the most widely used inspection method for LED materials. Particularly, PL mapping methods are employed in LED production lines, as they enable to analyze the uniformity of the epi-wafers and investigate various properties, such as wavelengths, intensity, half-widths, and epi-layer thickness, within a very short time [3]. However, as PL measurements are based on photo-excitation, which is different from the current injection operating LED chips, the estimation of optoelectronic properties at chip level using PL mapping results has been considerably difficult [4]. An electroluminescence (EL) mapping method, which inspects LED epi-wafers under current injection conditions, similar to those of the real LED chip operation, has been developed as an alternative technique [5]. Even though the EL mapping results showed better correlation with LED chip properties, a significantly longer inspection time than that of the PL measurements has hindered the adoption of the EL method for industrial purposes [5].

We employed a PL imaging method to inspect a wide area of a GaN-based LED epi-wafer in a short time and obtain relevant information to estimate the LED chip properties. The PL imaging method for compound semiconductors was introduced by Livescu

In this work, we analyzed the PL images of GaN-based QW LED epi-wafers. As the nitride materials of the active region have direct bandgap structures, images of the PL properties of that region could be directly obtained using a vision system. In the PL images, the defective regions of the active layer of the wafer appeared as dark spots with diameters in the range of ~ 50 - 1,000 μm. The dark spot defective regions (DSDRs) were analyzed by excitation power dependent PL measurements. Chip-wafers were fabricated from the epi-wafers whose PL images were acquired, and optical and electrical analyses of the LED chips were performed. The information on the defective regions obtained from the PL images was correlated with the optical and electrical properties of the LED chips.

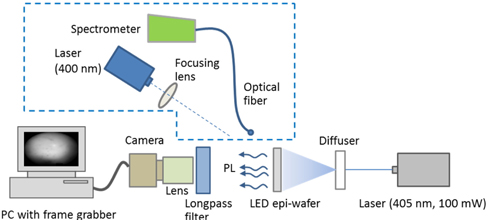

Blue LED epi-wafers with InGaN/GaN multi-QW structures, grown on sapphire substrates by MOVPE, were examined using the PL imaging method based on a vision technology. To obtain the PL images, an experimental vision system as shown in Fig. 1 was assembled. The PL imaging setup was composed of a 405 nm laser as the excitation source, a diffuser for the expansion of the laser beam, a longpass filter for selecting a wavelength range of PL emission, a CMOS vision camera with a zoom lens, and a PC with a frame grabber. The diffused excitation laser beam was directed on the backside of the epi-wafers under inspection, while the camera recorded the images at the front side (epi-side) of the epi-wafers. A laser beam of 100 mW was diffused on the area to be inspected, which ranged from 0.5 to 20 cm2 depending on the optical quality of the epi-wafer. The diffused beam size was reduced to increase the excitation power density and make the defective area more distinguishable when the optical quality of the epi-wafer was relatively low. In this study, we employed a 425 nm longpass filter to prevent the transmitted excitation laser beam and to capture most of the PL intensity from the active region of the blue LED epi-wafers whose PL peak wavelength was near 450 nm. Photo-excitation power dependent PL analyses for the DSDRs observed in the PL images were performed using a 400 nm laser and a spectrometer. The excitation power density was in the range between 1.3 W/cm2 and 1.2 kW/cm2 with a focused beam of 50 μm.

To compare the PL imaging results with the LED chip properties, the epi-wafers were used to fabricate LED chips. We obtained chip-wafers with LED chips of 1 mm × 1 mm in size after the chip fabrication processes, excluding lapping and dicing. The properties of the LED chips on the chip-wafers were mapped using a chip prober. Detailed current-voltage (I-V) characteristics and current-optical power (I-L) properties of the LED chips with DSDRs were measured using a semiconductor parameter analyzer and a light-emitting device measurement setup, respectively. The data obtained from the PL imaging and the chip measurements were compared to evaluate the correlation between the PL images and chip characteristics.

3.1. PL Images of LED Epi-Wafers

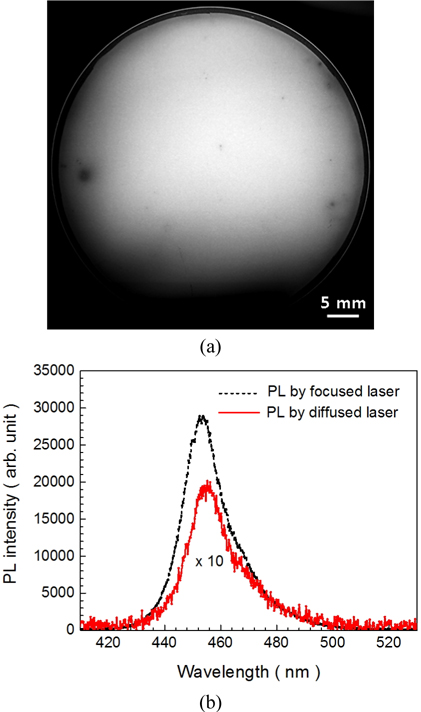

The images obtained from the PL imaging measurement showed integrated PL intensities for a spectrum range defined by a longpass filter. Figure 2(a) shows a spatial map of the integrated PL intensity of a 2-inch LED epi-wafer obtained using the PL imaging setup. The shape of the PL spectrum obtained under the excitation by a diffused laser beam was not different from that of the spectrum obtained using a focused excitation. There was a difference in the intensity and slight change of the peak wavelength due to the excitation power density difference. Figure 2(b) shows a comparison between PL obtained using a focused excitation and PL under a diffused laser over 2 inch wafer. The integrated PL intensity was displayed in gray scale. In addition, defective regions were observed in the PL images as dark spots of various sizes, as shown in Fig. 2, indicating that PL intensity of the DSDRs was lower than that of other regions.

3.2. PL Analyses on Defective Regions

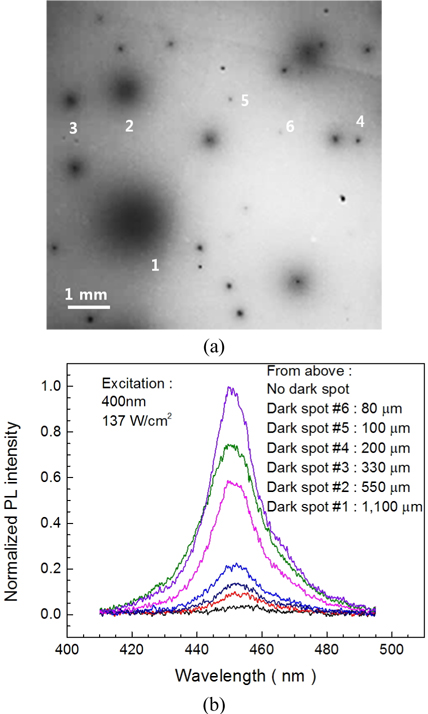

We measured the PL of DSDRs to analyze their optical properties. Figure 3(a) shows a PL image of a part of a 2-inch LED epi-wafer with DSDRs of various sizes. From the imaged region, dark spots with diameters in the range of ~ 80 μm - 1100 μm were selected, and PL spectra from the centers of the DSDRs were obtained using a 400 nm laser as the excitation source. The laser spot diameter was 50 μm, which was smaller than the diameter of the smallest dark spot considered. Six DSDRs with different sizes and a region with no DSDRs were compared. In Fig. 3(b), the PL spectra of those seven regions under excitation of 137 W/cm2 are shown. The PL intensity decreased as the size of the DSDRs increased, which is fairly consistent with previous reports on microscopic PL intensity imaging [8, 9].

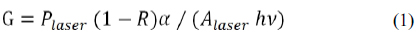

For the seven regions, the dependence of the integrated PL intensity on the photo-excitation power density was analyzed. The photo-excitation power density (

The generation rate can be expressed using Shockley-Read-Hall (SRH) nonradiative recombination (

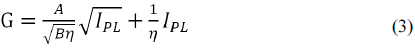

Figure 4 shows the relationship between the integrated PL intensity and the generation rate for the seven regions mentioned above. In Fig. 4(a), experimental results (symbols) and fitting results (lines) are shown. The experimental data were fitted using Eq. (3), and we could derive

3.3. I-L Characteristics of LED Chips with DSDRs

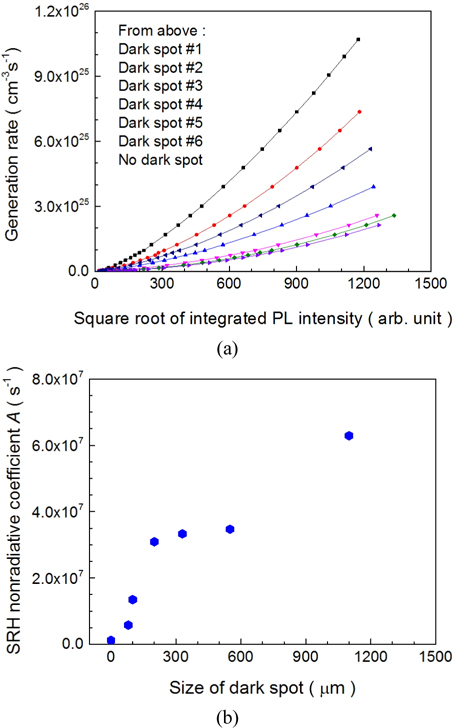

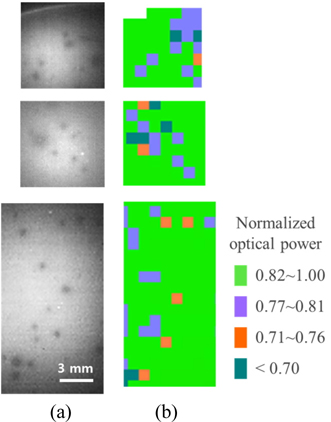

To investigate the correlation between the PL images and LED chip properties, we fabricated a chip-wafer from an LED epi-wafer whose PL images had been acquired. Photoluminescence images of small areas of the epi-wafer were obtained before starting the LED chip fabrication processes. After the PL imaging, a chip-wafer with LEDs of 1 mm × 1 mm in size with an electrically active area of 0.85 mm2 was fabricated from the epi-wafer. The chip-wafer was evaluated using a chip prober, and the PL imaging results were compared with the chip probing results. In Fig. 5, PL images of small areas of the epi-wafer and optical power mapping obtained from the same areas by a chip prober are shown together for comparison. The optical powers of the chips were normalized, and are shown in different colors according to the normalized power range. The DSDRs in the PL images match well with the chip locations having low optical power. Most of the chips fabricated at the DSDRs showed lower optical powers than the chips at the regions with no dark spots.

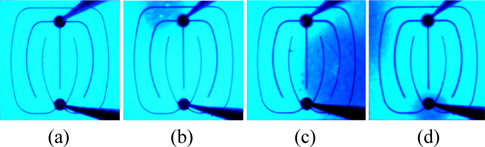

Individual LED chips with or without DSDRs were further optically and electrically characterized. The properties of the LED chips fabricated at the DSDRs were compared with those of the chips obtained from the regions with no dark spots. When the LED chips were electrically operated, the EL images showed the DSDRs as observed in the PL images. Some of the EL images are shown in Fig. 6.

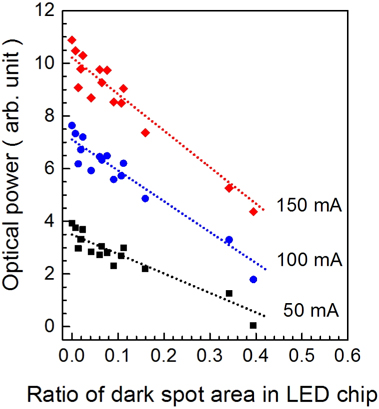

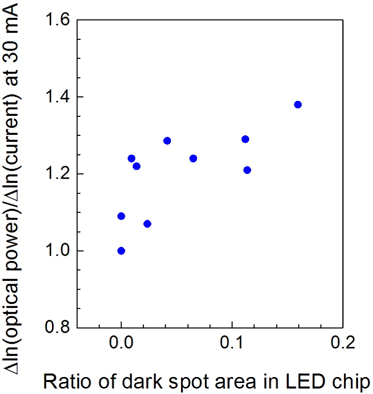

The I-L characteristics of the chips with DSDRs of various sizes were measured. The optical powers at injection currents of 50 mA, 100 mA, and 150 mA were plotted as functions of the ratio of the DSDR area to the active area of the LED chips as shown in Fig. 7. The optical power decreased with the area ratio of the DSDRs at a given injection current. Choi

3.4. I-V Characteristics of LED Chips with DSDRs

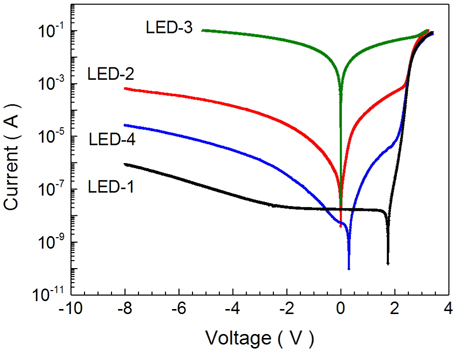

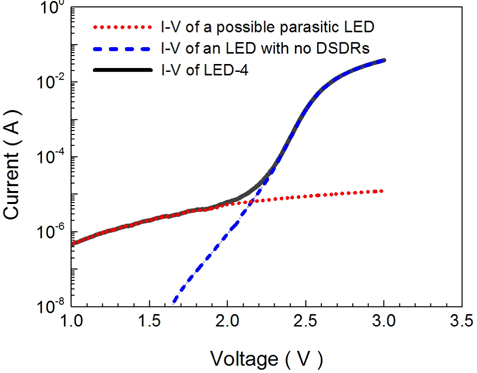

The I-V characteristics of the LED chips with various DSDR areas were analyzed. Figure 8 shows the semi-logarithmic plots of the I-V curves of the four LED chips shown in Fig. 6. A diode I-V curve above the built-in voltage can be expressed as Eq. (4), where

When Eq. (4) was applied to the I-V curve of a chip with no DSDRs (LED-1), the ideality factor,

Tunneling is another important cause of the forward leakage [17-21]. A parasitic diode-like tunnel current at the low-to-intermediate bias deforms the I-V curves from their typical shapes. The I-V curve of LED-4 could be divided into the curves of two parallel diodes as shown in Fig. 9, i.e., the curve of a diode with no DSDRs and little leakage, and that of a possible parasitic diode due to tunneling. The

3.5. Analysis of L-I Characteristics

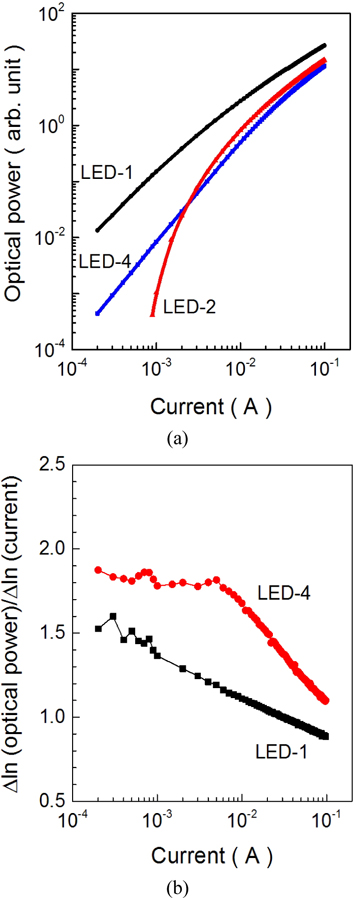

The L-I characteristics of LED were fitted with the power law,

where

To inspect GaN-based LED epi-wafers on sapphire substrates, PL imaging based on a vision technology was employed. The PL images showed a spatial map of the integrated PL intensity and DSDRs with degraded luminescence properties over the wide area of an epi-wafer. The DSDRs observed in the PL images were SRH nonradiative recombination centers, and were closely correlated with degraded light intensities of LED chips fabricated from the epi-wafer. The abnormality of the I-V characteristics of the LED chips with the DSDRs resulted from low parallel resistances and/or tunneling due to the defects present in the active regions. The tunneling caused a very high ideality factor (above 18) for the LED with the DSDRs. In the range of the forward bias at which tunneling occurred, SRH nonradiative recombination was the dominant process in the LED operation. The result was consistent with the reports on trap-assisted tunneling, which employed SRH recombination in the models [17-19]. As the DSDRs have a high density of nonradiative recombination defects, which affect the chip operation, the adoption of the PL imaging technique to detect DSDRs can provide an effective inspection and a quick evaluation of LED epi-wafers, allowing the estimation of the properties of the LED chips fabricated from the epi-wafers.