Epoxy resins are well-known materials in the field of insulation systems for gas insulated switchgears (GIS) [1-3], because they have good mechanical and thermal properties as well as excellent electrical properties. Switchgears are used to control, protect and isolate electrical equipment by combining electrically disconnected switches, fuses or circuit breakers. By the early 20th century, a switchgear line-up was a metal-enclosed structure with electrically operated switching elements that usde oil circuit breakers. Today, oil-filled equipment has largely been replaced by air-blast, vacuum, or SF6 equipment, allowing large currents and power levels to be safely controlled by automatic equipment. SF6 is an alternative to other conventional insulating and quenching media such as oil and air. The use of SF6 gas considerably increases, in some applications, the efficient utilization of resources in energy transmission and distribution with respect to technology, finances and personnel [4,5]. An overall evaluation considering all ecological, economic, safety and technological aspects has proven that SF6 is still an excellent choice as an insulating medium [6,7]. Existing SF6 technology in the field of energy transmission and distribution is the result of decades of optimization and contributes essentially to the further development of economically efficient power distribution.

In general, pure SF6 is chemically inert and cannot, therefore, cause corrosion. In the presence of moisture, however, the primary and secondary decomposition products of sulphur hexafluoride form corrosive electrolytes, which may cause damage and operational failure, particularly in electrical equipment. As a result, silica particles and silane coupling agent are corroded. Therefore, alumina is used in SF6 type switchgear materials.

Usually, epoxy systems for GIS have been used in composite forms by loading micro-sized alumina particles, typically around 65~80 wt%, in order to achieve the same low level of thermal expansion as that of a conductor to avoid exfoliation between the epoxy casting and the conductor since many electric apparatus are operated under various heat-cycles of outside environmental temperatures [8].

In this study, epoxy/micro-sized alumina composite was prepared, and then dielectric properties were measured. Nano-sized alumina was also incorporated into epoxy/micro-sized alumina composite and its dielectric properties were studied.

A commercial solid, unmodified bisphenol A type-based epoxy resin was used with an epoxy equivalent weight of 2.30~2.45 eq/kg and a viscosity of 650~850 mPa·s at 120℃. Its melting range was 35~50℃. Carboxylic acid anhydride-based curing agent was used with a melting range of 128~132℃ and an acid content of ≤ 3. The accelerator used was BDMA (benzyl-dimethyl amine) purchased from Kukdo Chem. Co. Its viscosity was ≤ 300 mPa·s at 120℃. Micro-sized alumina with an average particle size of 5.0 μm was purchased from Sibelco Korea. Nano-sized alumina with an average particle size of 30 nm was purchased from Sukgyung AT Co., Korea. Its product name was SG-ALO30. In order to modify the surface characteristics of nano-sized alumina, 1,3-diglycidyl glyceryl ether (DGE) was used. DGE was purchased from Sigma - Aldrich Co.

First, solid type epoxy base resin (30 g) was dissolved intoluene(100 g) at 80℃, and DGE (0.3, 0.9 or 1.5 g,) was also dissolved in the toluene. Then, nano-sized alumina (3 g) was poured into the toluene, and the mixture was mixed using the homogenizer at 10,000 rpm for 3 h together with a 500 W probetype ultrasonic processor (VC 505, Sonics & Materials Inc.) at a frequency of 20 kHz in order to disperse the nano-sized alumina into epoxy resin. The toluene was then removed from the epoxy/nano-sized alumina composite using a vacuum oven at 80℃ for 24 h. The dried epoxy/nano-sized alumina was stored in a desiccator.

In the second step, epoxy base resin (90 g) was melted at 140℃ in another beaker, and the epoxy/nano-sized alumina mixture (11 g) and micro-sized alumina (0, 88, 132, 198 or 308 g) were poured into the beaker and mixed for 4 h using a mechanical agitator at 600 rpm, The mixture was degassed in a vacuum (0.1 MPa) for 1 hr under the same temperature with agitation. And then, curing agent (30 g) and BDMA (1 g) were poured into the beaker and mixed for 30 min under the same vacuum, temperature and agitating conditions. In the final mixture, the micro-sized alumina content was 0, 40, 50, 60 or 70 wt%, and the nano-sized alumina content was 1 phr, where phr represents part per one hundred epoxy base resin.

The mixture was poured into specimen molds that were preheated at 140℃ in a vacuum oven. The mold for dielectric properties was designed to be 1 mm in thickness with a 100 × 100 mm square. The mixture in the mold was cured at 140℃ for 16 h and was cooled slowly at a rate of −0.5℃/min to room temperature in order to avoid internal stress. which would be acted as demerit in the electrical insulation material.

Dielectric tests were carried out in ASTM D 150 (1998). The specimen was located in a guard electrode, and capacitance (Cp) and dielectric loss (tanδ) were measured. The dielectric constant (εr) was obtained from Cp. The specimen was pre-treated at 23 ± 2℃ with 50 ± 10% RH for 40 h, and the dielectric test was carried out at 24℃ with 50% RH. Applied voltage and frequency were 500 V and 60 Hz, respectively.

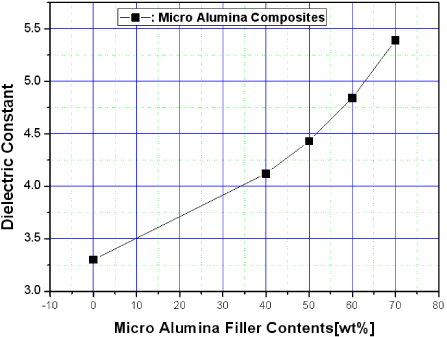

Figure 1 shows the dielectric constant of epoxy/micro-sized alumina composite with different alumina content, and Figure 2 shows the dielectric loss of the epoxy/micro-sized alumina composite with different alumina content. In Figure 1, the dielectric constant increased with increasing alumina content. The value of neat epoxy was 3.32, and those of epoxy/micro-sized alumina composites with alumina content of 40, 50, 60, and 70 wt% were 4.13, 4.43, 4.48, and 5.36, respectively. In general, dielectric constant increased in polymer/micro-sized inorganic filler composite as the content of micro-sized inorganic filler increased.

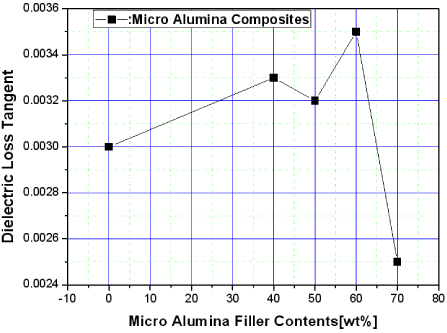

In Fig. 2, dielectric loss increased with increasing alumina content until 60 wt%, and decreased at 70 wt% of alumina content. The value of neat epoxy was 0.003, and those of epoxy/micro-sized alumina composites with alumina content of 40, 50, 60, and 70 wt% were 0.0033, 0.0032, 0.0035 and 0.0025, respectively. The physical meaning of dielectric loss is the generated heat in the inside of the insulator due to the application of alternating voltage, that is to say, alternating loss.

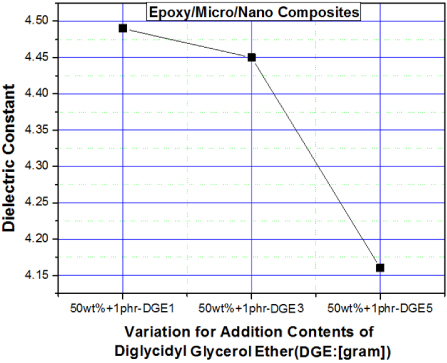

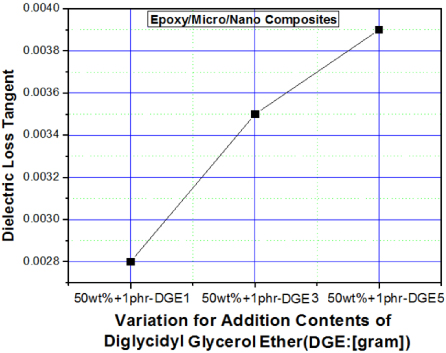

Figures 3 and 4 show the effect of DGE content on dielectric constant and dielectric loss in epoxy/micro-sized alumina (50 wt%)/nano-sized alumina (1 phr) composite, in which applied voltage and frequency were 500 V and 60 Hz, respectively, at 24℃. DGE content was 1~5 g where DGE was used in order to modify the surface of micro- and nano-sized alumina particles. As DGE content increased, dielectric constant decreased and dielectric loss increased. The dielectric constant of 5 g DGE was 4.16, which was 0.33 smaller than that of 1 g DGE at 4.49. This was due to weak electric field enhancement as a result of homogeneous dispersion of micro- and nano-sized alumina particles in an epoxy composite.

The dielectric constant of the micro-alumina (50 wt%) system was 4.43 as shown in Figure 1, and that of the micro-alumina (50 wt%)/nano-alumina (1 phr)/DGE (5 g) system was 4.16, shown in Fig. 3, which was a 7.3% lower value. This demonstrates that nano-sized alumina particles were evenly positioned among the micro-alumina particles.

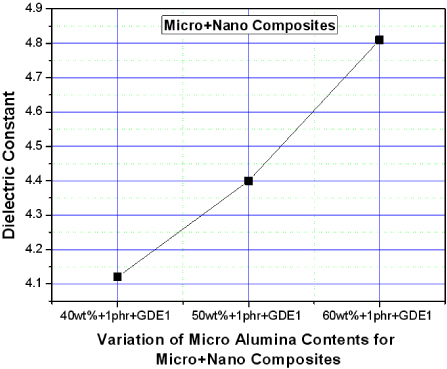

Figure 5 shows the effect of micro-sized alumina content on the dielectric constant of epoxy/micro-sized alumina/nano-sized alumina (1 phr) composite. Applied voltage and frequency were 500 V and 60 Hz, respectively, at 24℃. As was expressed in Fig. 1, dielectric constant increased with increasing micro-sized alumina content in epoxy/micro-sized/nano-sized alumina content.

Epoxy/micro-sized alumina composite was prepared, and the effects of micro-sized and nano-sized alumina content on dielectric properties were investigated in order to develop an insulation material for gas insulated switchgears (GIS). As micro-sized alumina content increased, dielectric constant increased in the epoxy/micro-alumina system. The value of neat epoxy was 3.32 and that of the epoxy/micro-sized alumina (70 wt%) composite was 5.36. As DGE content increased, dielectric constant decreased. The dielectric constant of 5 g DGE was 4.16, which was 0.33 smaller than that of 1 g DGE at 4.49. This is due to weak electric field enhancement that occurred as a result of homogeneous dispersion of micro- and nano-sized alumina particles in an epoxy composite.