As environmental issues have attracted much interest at an international, national and local level in recent years, energy efficiency issues have become important. In the industrial motor area, an increasing number of motors now have inverters or adjustable-speed drives to deliver the higher efficiency required for today’s industrial motors. In addition, inverter power supplies that apply a pulse modulated (PWM) technique, in which insulated gate bipolar transistors (IGBTs) are used as a high-speed switching device, can improve the controllability of the motor torque and reduce the switching loss [1-3]. Furthemore, studies have shown that partial discharge (PD) is a key factor in the mechanism of the insulation breakdown due to the inverter surge [3-5]. Generally, PD characteristics have been studied in a twisted-pair with a polymeric insulator enameled wire. When the voltage was applied to a twisted pair, enamel film erosion takes place in an air gap area because of partial discharge according to Paschen’s law [4,5].

Where V is the breakdown voltage in volts, p is the pressure in atm or bar, and d is the gap distance in meters. The constants a and b depend upon the composition of the gas. For air at a standard atmospheric pressure of 101 kPa, a = 4.36 × 107 V/(atm·m) and b = 12.8 and the graph of this equation is the Paschen curve. Therefore, many researchers have also studied the effect of high-speed pulse waves with short-term rise on the insulation breakdown voltage [6-8]

Polyesterimide-polyamideimide enameled wire (EI/AIW) has good thermal and electrical insulation properties. Polyamide is a sort of polymer that has high insulation breakdown strength with good heat resistance, mechanical strength and chemical resistance. Therefore, polyamide insulated wires are used in harsh environmental conditions [9-11]. Polyimides are used in inverter-fed motor windings and high pressure coils for electric translators. In recent years, elements allowing high-speed switching, such as insulated-gate bipolar transistors (IGBTs), have been developed as inverter power devices

In this study, insulation lifetime and insulation breakdown voltage were investigated in a twisted pair with polyesterimide-polyamideimide enameled round wires (EI/AIW) or EI/AI/nano-sized silica hybrid enameled round wires (HW). The enamel thickness was 50 μm and the diameters of enameled copper wires were 0.75, 1.024 and 1.09 mm, respectively.

EI/AIW or HW was prepared by coating a round copper wire with polyesterimide-polyamideimide enamel or EI/AI/nano-sized silica hybrid enamel, respectively (Sam Dong Co., Ltd., Korea). The enamel thickness was 50 μm and the diameters of enameled copper wires were 0.75, 1.024 and 1.09 mm, respectively. Therefore, the copper diameter became 0.745, 1.014 and 1.08 mm, respectively

All twisted pairs were prepared by twisting a couple of two straight lines of 125 mm under constant 1.4 N·m torque using a twisting machine. The number of the twisted turns used to determine the copper wire diameters of 0.75, 1.024 and 1.09 mm was 16, 16 and 15, respectively.

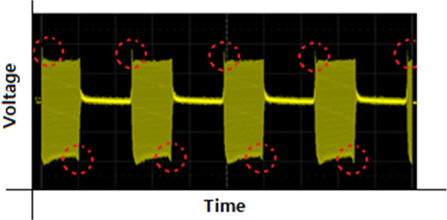

In order to study insulation lifetime and insulation breakdown voltage, an inverter surge waveform voltage was applied to a sample as shown in Figure 1, where inverter surge peaks were marked with dotted circles. In order to apply 0~12 kV with 50~1,000 Hz to twisted pairs, a withstanding voltage tester (Model : APCP-12 kV-100, Sky Innotek Co., Ltd.) for frequency acceleration was used. In order to apply high voltage to a twisted pair, an enamel insulation layer was removed from one side of the twisted pair and the other side remained without eliminating the enamel insulation layer. Subsequently, the specimen was arranged to the withstanding voltage tester. The insulation life-time was then carried out at a speed of 40 V/s until 6.25 kV and it was maintained at 6.25 kV until electrical insulation breakdown took place. The electrical breakdown voltage was also carried out at a rising speed of 40 V/s until electrical breakdown took place.

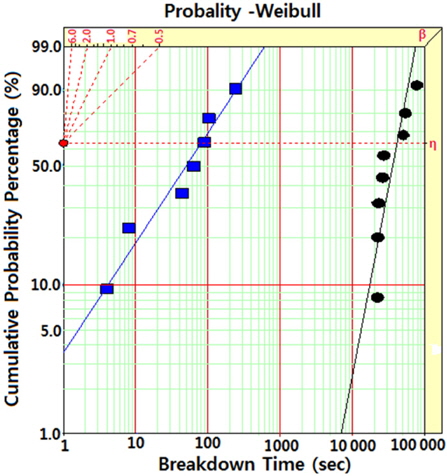

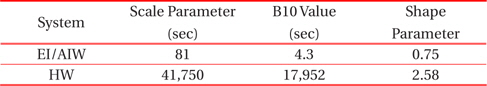

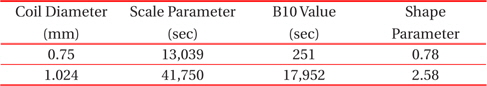

Figure 2 shows Weibull statistical analysis (Weibull++ 7.0) for the insulation lifetime of (■) EI/AIW and (●) HW twisted pairs at 6.25 kV with 60 Hz. The coil diameter of EI/AIW was 1.09 mm and that of HW was 1.024 mm. The scale and shape parameters, and B10 value were obtained from the Weibull plots and listed in Table 1.

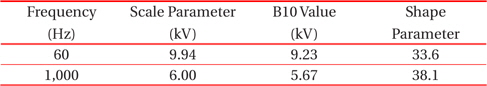

Weibull parameters for the insulation lifetime of EI/AIW and HW twisted pairs obtained from Figure 2.

That is to say, the scale parameter represented the AC electrical breakdown strength by which 63.2% of the cumulative probability was expected to fail and the shape parameter could be obtained from the slope in other words, the data distribution. In addition, the B10 value referred to the electrical lifetime at which 10% would fail (90% would survive) under a given test condition [12]. The scale parameter of HW was 41,750 sec, which was 515.4 times higher than the 81 sec of EI/AIW. The shape parameter of HW was 2.58, which was 3.4 times higher than the 0.75 of EI/AIW,. These results meant nano-sized silica was evenly dispersed in EI/AI and provided an excellent AC insulation lifetime characteristic to EI/AI. Since the slope of the Weibull plot for EI/AIW was gentle and that of HW was very steep, the B10 value of HW was 4,175 times higher than that of EI/AIW, where the B10 value meant the safety factor of an insulation material.

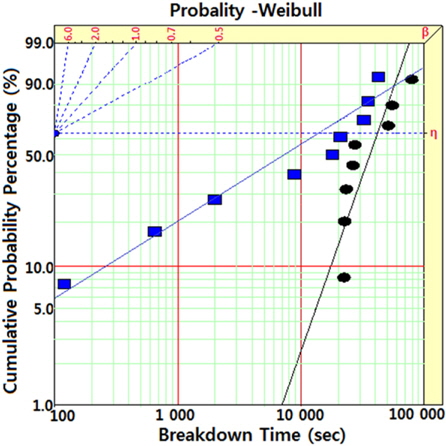

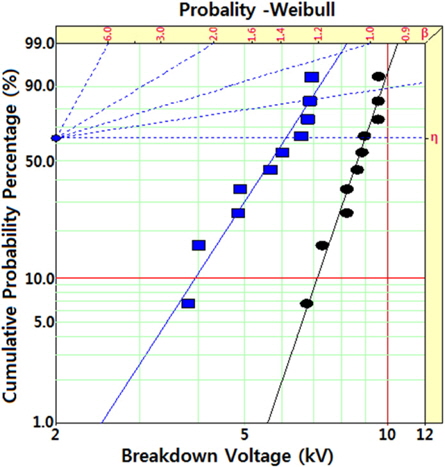

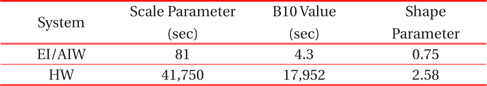

Figure 3 shows the effect of coil diameter on Weibull statistical analysis of the insulation lifetime of HW twisted pairs with different coil diameters: (■) was 0.75 mm and (●) was 1.024 mm, and the AC frequency was at 6.25 kV with 60 Hz. In addition, the Weibull parameters were listed in Table 2. The scale parameter for 1.024 mm was 41,750 sec, which was 3.2 times higher than the 13,039 sec of 0.75 mm. In general, it is well known that air gap distance and temperature affect enamel erosion. As the diameter of the enameled copper wire increased, the air gap distance increased. Therefore, according to Paschen’s law [4,5] electrical breakdown voltage steeply decreased until a low air gap distance and then increased gradually after the air gap distance. Moreover, as the diameter of the enameled copper wire increased, the temperature between the wires decreased. Therefore, the enamel erosion rate was low in the large diameter. The shape parameter of 1.024 mm was 2.58, which was 3.3 times higher than the 0.78 of 0.75 mm.

Weibull parameters for the insulation lifetime of HW twisted pairs at 60 Hz. Coil diameters obtained from Figure 3.

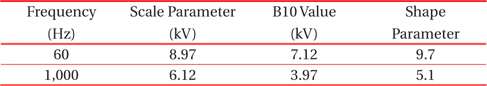

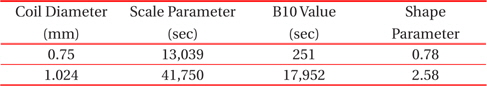

Figure 4 shows Weibull statistical analysis of the insulation breakdown voltage for HW with a coil diameter of 0.75 mm in a twisted pair form at 60 Hz. The shape and scale parameters were obtained from the Weibull plots and listed in Table 3. The insulation breakdown voltage value at 60 Hz was 8.97 kV, which was 1.5 times higher than the 6.12 Kv at 1,000 Hz. Furthermore, the B10 value at 60 Hz was 7.12 kV, which was 1.8 times higher than the 3.97 at 1,000 Hz. In addition, the shape parameter at 60 Hz was 9.7, which was 1.9 times higher than the 5.1 at 1,000 Hz.

Weibull parameters for the insulation breakdown voltage of HW twisted pairs at (●) 60 Hz and (■) 1,000 Hz obtained from Figure 4. Coil diameter was 0.75 mm.

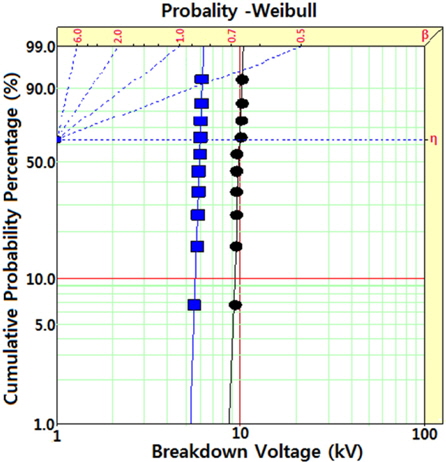

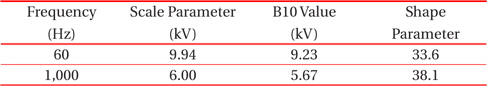

Figure 5 shows Weibull statistical analysis of the insulation breakdown voltage for HW with a coil diameter of 1.024 mm in a twisted pair form at 1,000 Hz. The shape and scale parameters were obtained from the Weibull plots and listed in Table 4. The insulation breakdown voltage value at 60 Hz was 9.94 kV, which was 1.7 times higher than the 6.00 kV at 1,000 Hz. In addition, the B10 value at 60 Hz was 9.23 kV, which was 1.6 times higher than the 5.67 at 1,000 Hz. In addition, the shape parameter at 60 Hz was 33.6, which was 0.9 times higher than that at 1,000 Hz, 38.1.

Weibull parameters for the insulation breakdown voltage of HW twisted pairs at (●) 60 Hz and (■) 1,000 Hz obtained from Figure 5. Coil diameter was 1.024 mm.

Insulation breakdown characteristics of an inverter surge resistant enameled wire were investigated in a twisted pair prepared with organic/inorganic hybrid nanocomposite. The organic polymer was polyesterimide-polyamideimide (EI/AI) and the inorganic material was a nano-sized silica.

The insulation lifetime of the hybrid wire was 41,750 sec, which was 515.4 times higher value than the 81 sec of EI/AIW. In addition, the shape parameter of HW was 2.58, which was 3.4 times higher than the 0.75 of EI/AIW. These results meant nano-sized silica was evenly dispersed in EI/AI and provided an excellent AC insulation lifetime characteristic to EI/AI. The insulation lifetime for 1.024 mm of the coil diameter was 3.2 times higher than that for the 0.75 mm of the coil diameter. This meant that the enamel erosion rate was lowered in the sample of larger coil diameter. This was because air gap size and temperature affected the enamel erosion according to Paschen’s law. The insulation breakdown voltage for HW with a coil diameter of 0.75 mm at 60 Hz was 1.5 times higher than that value at 1,000 Hz.