In the current competitive world, it is imperative for Small & Medium Enterprises (SMEs) to be technologically innovative as well as to exhibit improved economic performance on a sustained basis (Jain and Kiran, 2012). Innovation is considered a central determinant of longer-run success and failure for manufacturing firms (Utterback, 1996). For SMEs, a greater innovation capacity is considered a counterbalance for their greater vulnerability in a globalized business environment (Hoffman, et al., 1998). Particularly, manufacturing SMEs must continuously improve their manufacturing processes in order to ensure their long-term sustainability and growth (Lagace and Bourgault, 2003).

However the pertinent issues are: (i) What prompts an SME to innovate? (ii) How does an SME initiate and carry out innovations? (iii) How does the innovation carried out by an SME facilitate its economic performance and growth? This is because innovation is a multi-faceted effort caused by a diverse set of factors leading to different possible results (Lin and Chen, 2007). These issues assume added importance in an emerging economy like India where SMEs are known for operating within different kinds of constraints (Government of India, 2010). Accordingly, the present study makes an attempt to throw light on the causal factors, the process of undertaking innovations and their dimensions, and finally, their outcomes, in terms of impacting the economic performance and growth of firms, based on two case studies of engineering industry SMEs in Bangalore city of India. The advantage in a case study is that, though qualitative, it explores and analyzes a case in-depth (Krishnaswamy, et al., 2006). Therefore, it can adequately illuminate the process and outcomes of technological innovations in SMEs (Krishnaswamy et al., 2014).

A description on the definitions of two key concepts, namely, “technological innovations” and “SMEs”, adopted for the present study is in order. “Technological innovations” are defined to comprise both product and process innovations, whether new (to the industry) or improved. Technological Innovation for the purpose of this study is defined as follows: Introduction of a process or a product new to the economy of the particular developing country regardless of whether it is used before elsewhere (Cooper, 1980). It includes all modifications or adaptations of processes or products however minor they may be within the developing country context and the deformation covers the processes and products which a firm masters and implement the design and production of the goods that are new to them (Mytelka, 2000). Innovation activities are broadly classified as either incremental or radical. A cumulative series of minor changes or introducing minor improvements to previous products/processes is called incremental innovation, whereas an abrupt major change or doing something markedly different from what the firm has done before to its product/process is called radical innovation (Lin and Chen, 2007). “SMEs” are defined as the manufacturing enterprises with an investment in plant & machinery not exceeding Rs.100 million, as per the MSMED Act, 2006 of the Government of India (Ministry of MSMEs, 2015).

In any SME, the key decision maker and therefore the focal point of interest is the entrepreneur (in the case of individual proprietorship), managing partner (in the case of partnership), or the Chief Executive Officer (CEO) (in the case of private limited companies). Considering this, we have concentrated on the entrepreneur/managing partner/CEO, his perceptions of the need, nature and processes of the technological innovations and how the organization has adapted and implemented his ideas regarding the innovation and of the route to firm performance. The authors had detailed interactions with the entrepreneur CEOs and head of the technology group, but bulk of the information was obtained in the interviews with the entrepreneurs and supplemented by in-house publications, technical documents, and on the spot discussions with technical and supervisory personnel. The case study protocol used consisted of questions on the history of growth, characteristics of the industrial sector, management problems, views on what causes growth, whether innovation helps growth, whether technological innovation was supplemented with organizational and marketing innovations/changes, nature and problems of innovation management, and the need and willingness to interact with other organizations for innovation. The detailed interactions were transcribed by the authors themselves, which formed the basis for case development and case analysis.

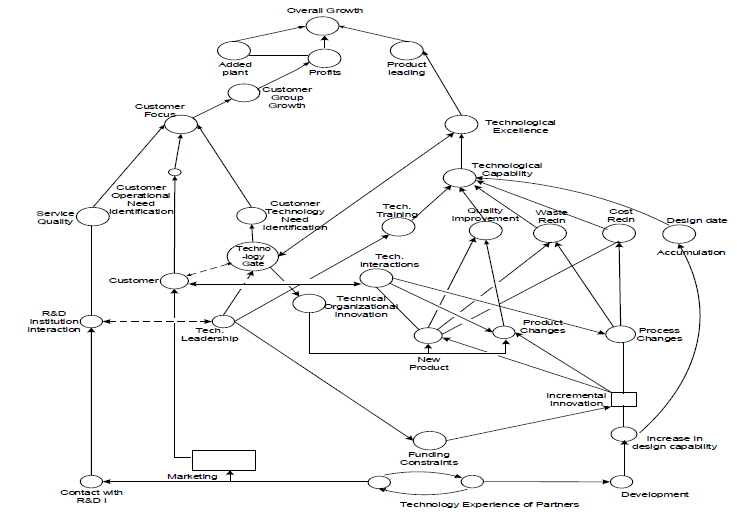

In an SME the perceptions of the entrepreneur about the strengths and weaknesses of the enterprise and his cognition of threats and opportunities in the environments have a considerable influence on the success of the enterprise. These were captured through interview data, case analysis and information from the entrepreneur in the form of a cognitive map. The cognitive map is a picture of the perceptions of a decision maker about a decision problem or situation. The cognitive map offers a holistic picture of the perception of the decision maker (Krishnaswamy et al., 2006). In the cognitive map, the links are represented as lines and the perceptions as nodes. The value of the nodes increases as one moves up the diagram and the top node has the highest value to the decision maker. The nodes with a large number of links are the critical ones. Furthermore, cognitive map helps in understanding how an SME is guided by the entrepreneur towards success and growth. This insider’s view supplements the facts of the case collectively. We have developed cognitive maps for both the case studies to establish the relationship between innovation and firm growth (as represented by the growth of sales turnover).

The two case studies were conducted by the authors themselves. For both the two cases, two visits each were made to corroborate the details gathered in the initial visit. The interviews were of two hours duration each time. A description on the selection of the two SMEs for the case study is appropriate: The authors wanted to study the SMEs which did considerable innovations and grew rapidly in comparison to others. Accordingly, we picked up two SMEs in the engineering product industry of Bangalore, which registered above average innovation sales (as a percent of total sales turnover) and above average sales turnover growth during 2001/02-2005/06 (from the data gathered for an empirical research study). We have undertaken the two case studies with the objective of understanding the processes of innovation, the role of the entrepreneur in this process, and the impact of the innovation on firm growth.

II . A Brief Literature Review

Innovation has long been considered the key factor for the survival, growth and development of SMEs (Raymond and St-Pierre, 2010). In a dynamic and competitive global economic environment, SMEs, which exert a strong influence on the economies of many countries through their ability to innovate new products and processes, are considered the engine of economic growth and technological progress (Bruque and Moyano, 2007). In such an environment, SMEs must continuously seize new opportunities in order to sustain a competitive advantage, and their capacity to develop new products through innovation is in the very core of their value creation (Hurmelinna-Laukkanen et al., 2008).

However achieving effective innovation is a complex and formidable task. The ability of SMEs to meet growing customer expectations is largely based on their ability to innovate and deliver new products at competitive prices (O’Regan et al., 2006). There is a strong need for new product development in SMEs as it leads to market differentiation and serves as a major opportunity for innovative SMEs in competitive markets (Jain and Kiran, 2012). Therefore, innovation is a key driver of sustainable competitive advantage and one of the key challenges for SMEs (O’Regan et al., 2006). Growth, success and survival all depend on the ability of firms to innovate on a sustained basis ((Varis and Littunen, 2010). As innovation is generally considered a pre-requisite for a firm’s survival, success and growth, a growing number of studies have been conducted to determine what drives it, and what a firm achieves out of it. However, despite a growing amount of empirical literature to deal with these issues, research that encompasses all the relevant constructs in an integrated manner remains rather limited (Rhee et al., 2010). In particular, there are two pertinent issues in the context of SME innovations: (i) Why and how SMEs undertake innovations? How does the entrepreneur/CEO plan, direct and implement innovations within a firm? (ii) What are the final outcomes of such innovations? How does it impact on the firm performance?

Regarding the first issue, some empirical studies have focused on firm level resources and brought out that it is the firm level competence, and entrepreneurial background and motivation which together prompt SMEs to undertake innovations (Ciemleja and Lace, 2008; Radas and Bozic, 2009; Griffiths and Webster, 2010). But Pitt et al. (2006), Kaminski et al. (2008), and Zeng et al. (2010) have found that the complexity of innovation processes has led to a tremendous growth in the use of external networks by SMEs. These studies indicate that neither firm level competence nor customer pressure alone will suffice to drive an SME to undertake innovations. Furthermore, in the Indian context Bala Subrahmanya et al. (2010) and Bala Subrahmanya (2013) have revealed that innovation will emerge successfully only when a technically competent firm is able to identify and respond to customer requirements by completing its internal technical strength with external technical support (either from its own customers or other agencies) to improve existing or develop new products/processes.

What are the achievements of SME innovations? How do these innovations impact SME performance? Innovation helped the Estonian SMEs to improve their performance in terms of market share and diversified range of goods and services (Lumiste et al., 2004). Innovation output had a positive impact on the growth of sales turnover of SMEs in Germany (Engel et al., 2004). Oke et. al., (2010) brought out in the context of manufacturing SMEs of UK that there is a positive link between innovation and sales turnover growth in SMEs. Coad and Rao (2008) revealed that innovation is of crucial importance for a handful of ‘superstar’ fast-growing SMEs relative to the rest. Innovation sales significantly influenced the sales growth of firms in Bangalore (Bala Subrahmanya, 2013; Bala Subrahmanya, 2015). Bianchini et al. (2015) indicated that the relationship between growth and innovation is likely to be higher for firms which are active in all layers (R&D, product and process innovation, acquisition of embodied and disembodied knowledge) relative to firms that only perform one or two of these activities. Thus, empirical studies, though differ with respect to the role, process, outcomes and impact of innovations on firm performance, they have broadly brought out the significance of both firm (organizational) level competence and external (market related) networks to carry out product as well as process innovations, which in general have a positive influence on firm performance and growth.

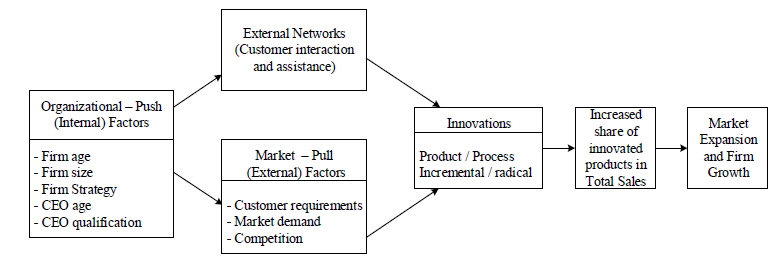

A broad theoretical framework: A firm which has organizational/internal resource capability as reflected in the age and size of the firm, age and technical qualification of its CEO, will be able to perceive its customer requirements and market competition, and respond to it adequately, by seeking and exploiting external support (particularly, interaction and assistance from its customers) to carry out process/product based incremental/radical innovations. The successful implementation of such innovations will lead to a steady increase in the share of innovated products in total sales, thereby leading to an increasing penetration of the market and firm growth (Figure 1). The case study development, discussion and case analysis to derive its inferences are done within this broad theoretical framework.

III. Technology Environment for SMEs in Bangalore: A Backdrop

Bangalore, the capital city of Karnataka State in India, is nicknamed as the “Silicon Valley of India” due to a relatively heavy concentration of engineering, electronics and Information & Communication Technology (ICT) industries in the country. Bangalore is considered one of the 46 “global hubs of technological innovation” (UNDP, 2001) and it is one of the reputed technology cities in the world (Rogers, et al., 2001). Bangalore has a relatively high concentration of engineering industries and SMEs, historically in India (Bala Subrahmanya et al., 2002). Bangalore has many internationally renowned educational and research institutions and R&D centres of MNCs (DST, 2010). It has a significantly high presence of technically qualified entrepreneurs in SMEs, particularly in engineering industries (Bala Subrahmanya, 2005).

In addition, Bangalore has several SME supporting institutions for technology transfer/assistance such as Karnataka Council for Technology Up-gradation (KCTU), Technology Resource Centre (TRC), regional branch of National Research Development Corporation (NRDC), and Central Manufacturing Technology Institute (CMTI). Further, Bangalore has several active SME associations under the umbrella of Karnataka Small Scale Industries Association (KASSIA), which is considered an apex association of SMEs in the state. KASSIA in turn has 47 sector specific Bangalore based SME associations as its members (KASSIA, 2015). These associations facilitate periodic interaction and exchange of information among its members, among others. All these represent different components of the “ecosystem” of Bangalore for SMEs which would have contributed to the “technologically vibrant environment” for SMEs in the city (Bala Subrahmanya et al., 2014).

Added to all these, within the engineering industry, Bangalore has a strong presence of engineering industry comprising both public sector and private sector enterprises, including MNCs and SMEs (Bala Subrahmanya and Kumar, 2011). Therefore, we strongly feel, Bangalore can offer a fertile ground for carrying out in-depth case studies on engineering product SME innovations. Accordingly, we have chosen two SMEs for exploring and discussing the innovation process and outcomes.

IV. Basic Features of the Three Engineering Industry SMEs

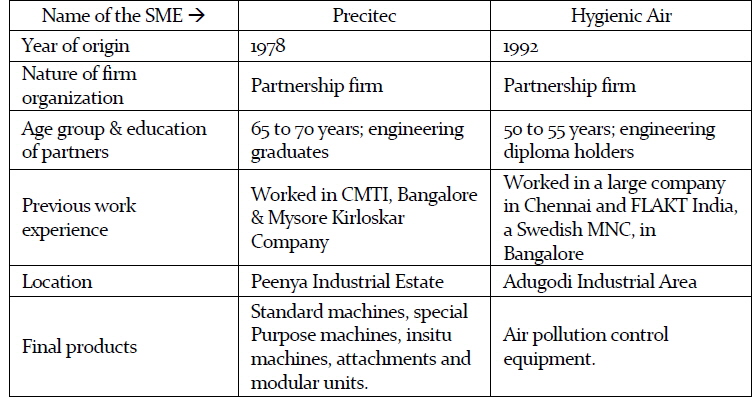

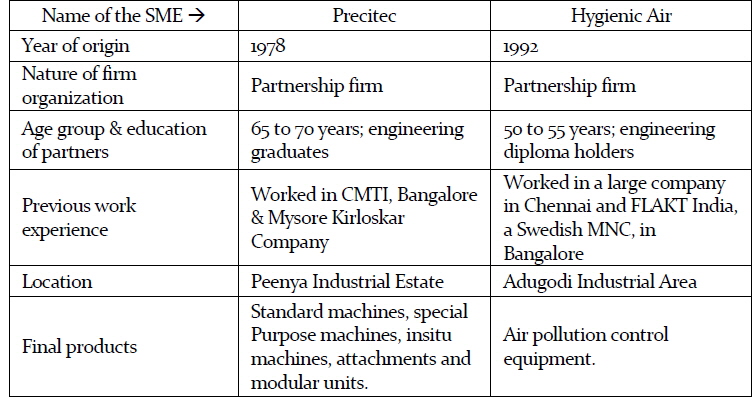

We have covered two engineering industry SMEs, namely, Precitec, and Hygienic Air for case study and analysis, and their profiles are presented in Table 1. Both the SMEs were started by first generation entrepreneurs. Precitec was established in 1978 and Hygienic Air was established in 1992, thus the former was more than three decades old whereas the latter was about two decades old at the time of conducting the study. Both of them were partnership firms. The CEOs of the two SMEs had previous work experience: while the first worked in a technical research institute, the second one worked in a large company. The CEOs of both the SMEs have technical education backgrounds and were in the age group of 50 to 70 years. Thus the CEOs of the SMEs were technically knowledgeable and fairly experienced, and therefore were considered appropriate and capable to describe the process and outcomes of technological innovations.

[Table 1] Basic features of the two engineering industry SMEs in Bangalore

Basic features of the two engineering industry SMEs in Bangalore

The two SMEs are into the manufacturing of different engineering products: the first one was into the production of various kinds of machine tools, whereas the second one produced air-pollution-control equipment. Thus the end products of the two SMEs are used in the day-to-day activities of firms / organizations / institutions. Therefore there is a considerable scope for interaction with their customers for product feedback, etc.

V. Case History, Case Analysis and Cognitive Maps

With the basic understanding of the two SMEs, we present the individual SME case history, followed by a case analysis leading to the development of cognitive maps of the CEOs. As mentioned earlier, the cognitive maps are developed to provide a holistic picture of the perception of the CEO with respect to the initiation and carrying out of innovations and growth activities. The case histories are presented in a terse and stepwise manner in order to achieve brevity.

Mr. H.K. Sridhara and Mr. S.Y. Rao (both engineering graduates) established

Being technocrats, they set up an exclusive design centre right from the beginning. In 1984 they started manufacturing and developing custom built cutting machines for larger enterprise. They made design proposals against the initial orders/enquiries. After several interactions and discussions with

Since 1987

The strategic need for complete testing and certifying the performance and quality of their machines was met by CMTI laboratories. Sometimes these tests were carried out either in laboratories or in situ.

Currently,

In the 1990s, Nikhila (son of Sridhara) joined the enterprise as the Chief Designer. Nikhila had closely participated in the design and development activities of

Nikhila’s main contributions to the innovations with regard to SPMs were the conceptualization of the design for special requirements, operations, inputs etc. for the different product models which led to the design and development of modular parts & components for machine building and assembling. Modular concept was by no means new in India but it was so to the

Nikhila contended that they innovated at every stage. At any time, they dealt with about 10 to 12 projects for designing and developing machines parts/components/complete machines as the end products. The design centre of the enterprise had five engineers exclusively focusing on design and product development projects. Each project took anywhere between eight weeks to one year.

The enterprise has come a long way since its inception from customer specific machines to SPMs. This transformation had occurred primarily due to the technological innovations of the enterprise. These innovations had emerged due to the in-house efforts of the enterprise.

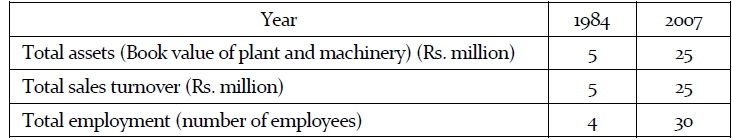

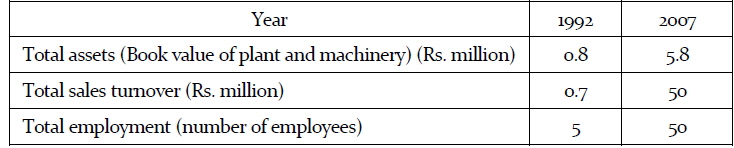

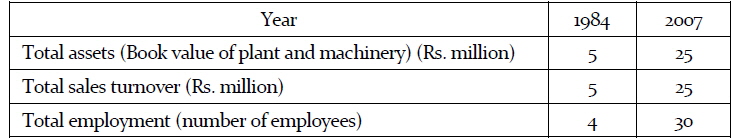

As a result of these product innovations, the enterprise could grow in size in terms of not only employees and assets but also sales turnover (Table 2). By 2007,

[Table 2] Growth of Precitec: 1984-2007

Growth of Precitec: 1984-2007

1.1 Case Analysis of Precitec

The technically knowledgeable and richly experienced partners developed a strong technical capability of the firm by establishing a design team which could carry out the development of strategic machinery components and innovate new ones under their guidance. It also could coordinate the testing of machines from the CMTI. To avoid utilizing their time and skill on run of the mill components, they developed a network of sub-contractors for supplying them. These products included SPMs, CNC machines, Finning machines and assembly machines.

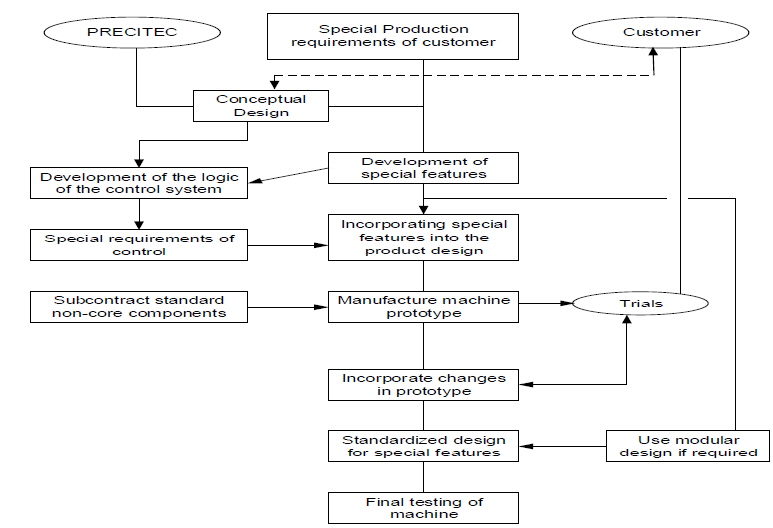

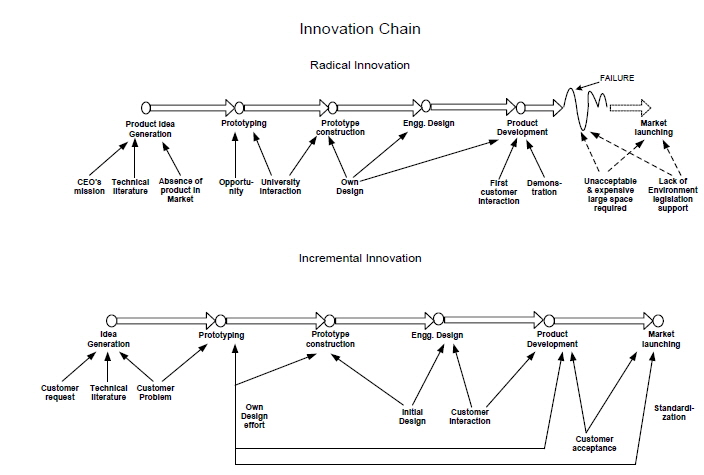

The procedure they adopted for innovating their products is shown in Figure 2. This is the general

1.2 Cognitive Map of the CEO of Precitec

The cognitive map of the CEO of

Customer interactions provided them the ideas for product improvements which could be handled by the strengthened design department effectively. The customer views and operational needs were obtained through the active interactions made by Nikhila in his regular visits, who acted as a gate for the company and coordinated the interactions and design efforts.

The design groups were pre-occupied with

2. Case History of Hygienic Air (HA)

Due to limited equipment in their enterprise, they outsourced the work whenever demand came for some specialized equipment. Their first product was Centrifugal Fan (blower) for Mico Bosch (now known as Bosch India). By the late 2000s they started manufacturing large blowers to meet the domestic as well as the foreign demand of

The structural requirements of the products were fully met by

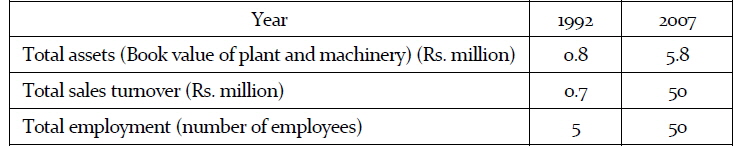

The company did not manufacture against contracts but only against orders and had a somewhat fixed market. The motivation for product innovations was customer requirements. Though standardization of products was possible it was so only to a limited extent while their assembly required customization. Continuous changes, which they implemented for all of their products, gave them an edge over their competitors. This was the crux of the enterprise performance. By 2008, about 50% of their turnover was accounted by innovated products and their major customers were Mico-Bosch (25%), TVS (25%), Goetze, Titan, Saint Gobain (10% each), whereas Hindustan Aeronautics Limited (2%) and other companies accounted for the rest. About 10 companies were their regular customers including the leading ones referred above. As a result,

[Table 3] Growth of Hygienic Air: 1992-2014

Growth of Hygienic Air: 1992-2014

Soon after starting the enterprise they had felt the need for an exclusive design centre and therefore had set up one exclusive design centre in 1994 with two designers. By 2008 the design centre had four designers including PS. Of the remaining three, two were mechanical engineers and one was a chemical engineer. For design and product development, they gathered considerable information through the Internet search. In addition, customers gave their requirements after visiting advanced countries such as Japan, South Korea and European countries. By 2008 they started using CAD for new product development, design changes and routine designs. However,

Of the different product innovations, PS singled out the innovation of bio-filters as a special one and a true radical innovation. This product was introduced in 2004. PS read about bio-filter in a journal and came to know from some sources that Regional Research Laboratory (RRL), Trivandrum was developing it. When he approached RRL and realized that it would be difficult to achieve progress by collaborating with a government owned laboratory like RRL, he engaged a Master of Technology gradaute of National Institute of Technology Karnataka (NITK) Surathkal. At that time, there was an enquiry for a bio-filter from

PS felt that there was a huge market for bio-filters in India but an enterprise like

Regarding the incremental innovation, PS felt that the design modifications, improvements in performance, and quality were only marginal but vital. He believed that the training of young engineers and technicians for these innovations was very satisfying to him, though the attrition of these employees was an issue. Since the number of items sold was small in number, he could not invest more into innovating efforts and the limitation of manpower investment was a constraint.

Investment in innovative efforts was diffused in the organization. No budget was earmarked. PS conceded that their marketing efforts were limited and he looked forward to strengthen it. Even within the limited range of products, the enterprise enjoyed a degree of technology leadership. PS opined that considerable organizational changes were in the offing and were needed to support good innovative possibilities of the firm. The components of the equipment have been standardized but the assemblies were custom built. The incremental innovations through design changes to suit the customer requirements or solve the customer problems were the dominant concern of the company. Since the design teams’ time was shared between regular fabrication work and innovation, there was considerable pressure on the design team to deliver the innovations undertaken.

PS felt the products of his enterprise could not be considered either high-tech or low-tech, though technology was an important component of his products. He contended that these product improvements towards customization enabled his enterprise to register a steady growth in terms of sales turnover and investment but not in terms of labour. He explained the development of product sequence with Blower as the first product in 1992 followed by Dust Collector, Scrubbers, Bag Filters followed by Bio-Filter. Similarly, his enterprise had developed different kinds of Fans starting from small ones to large ones, over the period of time. During this period, he had developed improved versions of (i) Insertable Pulse Filter Unit, and (ii) Hi-Vacuum Portable Dust Collector Unit. PS primarily followed the standard set by American Industrial Hygiene Association. According to him, the goal of the enterprise was to solve any problem relating to air pollution and related equipment. In the previous 5 years HA had introduced 15 to 20 different products. By late 2000s, the focus of product development was on an improved version of blower, with multiple capabilities.

The growth of the company was continuous over the period 1992 to 2006. The growth of the enterprise was clearly visible in the fact that it had acquired a new factory premises in Bommasandra Industrial Estate, about 15 km away from Adugodi (its present location), sometime in 2001. Further, the new factory comprised new machinery towards expansion of capacity. PS exhibited confidence about the future expansion plans. All these clearly indicated that due to product and process innovations, the firm could grow over time.

2.1 Case Analysis of HA

The skill/ability mix of the partners gave the push to produce environmental hygienic equipments and the heavy customer focus pulled the company towards incremental innovations. Incremental innovations at

The general pattern of these developments took the following route: On receipt of enquiry for the manufacture of a product (Figure 4),

The credit for undertaking and implementing technological innovations, in any form, largely went to PS as he was the ‘brain’ behind every product development made by his enterprise. In addition, he had made novel attempts to improve the process as well. To cite an example, during 2006, he converted a traditional ‘concrete mixture’ into a ‘welding positioner’. This made the task of welding of products easy, better and fast, resulting in a less expensive process and improved the quality of products. Similarly, he imported a second-hand ‘lock-maker’ from China for facilitating the process of product development.

Irrespective of whether the innovation chain led to a product to be sold in the market segment or was supplied to a specific customer, it was imperative for the success of the innovation that the innovating firm had close contacts and rapport with the market segment/or the specific customer right from the first stage of innovation - conversion of a product idea to a prototype. This link was present in the incremental innovations as depicted in Figure 4 which brought market support for the innovations resulting in rich returns to the firm and helped its growth.

The idea for radical innovation did not however originate from the customer side (Figure 4). The origin of the product idea was purely from research literature and the student project. The technical appreciation of its usefulness to Indian industry prompted PS to pursue the product development and the impetus did not originate from his customers, unlike in the case of incremental innovations in respect of blowers and scrubbers. PS felt that attempts at interactions with the organizations like SMEs, and R&D organizations were not very successful because he felt their attitude and response were lukewarm. He opined that people tended towards confidentiality whereas in interactions more open approach is desirable and therefore flows of ideas/technology skill across firms and R&D was very difficult and tedious. A certain degree of mutuality is needed for such successful interactions. Such interactions tend to work better in a supplier-recipient environment as in the case of vendor development and subcontracting relations in the case of larger firms.

The mission of PS enabled identification of a product which was not available in Indian market. There did not appear to be an interaction at that point about customer requirement/problems regarding bio filters (Figure 4). While the innovation was technologically successful because of meeting of appropriate opportunity, motivation, research and design skills, it failed to fructify due to non-consideration of market restrictions in use. Thus, in the innovation chain, failure tended to precipitate at the linkages with the market, and shows up the general weakness of innovation in SMEs, whose forte is not marketing due to their general incapability in market research.

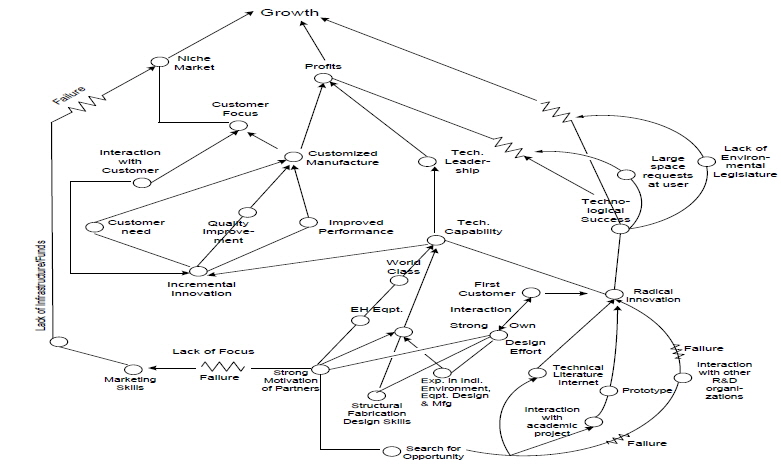

2.2 Cognitive Map of the CEO of HA

The cognitive map developed for the CEO of HA reaffirmed the case analysis presented in the case of Precitec (Figure 5). With a strong motivation and desire for technological excellence, a mission of contributing to environmental hygienic industry, the company developed a strong design team, skills and a product champion in PS, but failed considerably to develop marketing skills and “market gate” to close the innovation chain satisfactorily.

However, incremental innovations with strong links to the market and customers, enabled HA to successfully implement product innovations and penetrate the market to achieve firm growth over a period of time. Therefore, given the limited firm size and resource constraints, with a strong customer focus and links, SMEs tend to succeed in achieving incremental innovations to further their market penetration and growth.

VI. Summary, Inferences and Conclusions

In the current competitive global economy, there is increased pressure on SMEs to innovate, as a means of competitiveness, to survive and grow. SMEs in general have several advantageous features for undertaking innovations, but at the same time, they do suffer from various kinds of constraints, particularly in emerging economies like India. Given this, it is appropriate to examine and understand what factors prompt SMEs in these economies to undertake innovations, how, what are its achievements and how does it finally impact firm performance.

We have attempted to answer these questions based on two engineering industry SME case studies in Bangalore, which occupies a unique position in India, in view of its vibrant technology environment. The two cases are largely similar in terms of entrepreneurial backgrounds, and firm characteristics. With previous industry experience and technical education background, the CEOs of both the SMEs were encouraged to undertake innovations, due to customer pressure, understanding of customer requirements, and constant customer interaction. The development of technological capability through product design expertise and necessary skills, both SMEs were able to achieve incremental innovations successfully, periodically.

Based on the two case analyses, we have derived some inferences, which are as follows:

The CEOs with technical education and prior industry experience can play a decisive role in developing appropriate technological capability and carrying out customer oriented product and process innovations for firm growth. Market-pull (market demand induced) innovation tends to be incremental in nature both for product and process developments. Incremental innovations rather than radical innovations are likely to promote firm growth in the SME sector. Interaction with customers both in the initial stages of development and right through to the delivery of the product can play a decisive role in the success of innovations. Adequate and timely financial support to the incremental innovations of SMEs will act as a boon for SME innovation promotion. Organizational-push (firm level strength induced) innovations, which are more radical (new design, new products) where the leader’s technological motivation is high, tend to fail in the market as they depend on technological inputs rather than on market feedbacks. Linkages with R&D institutions and long standing experience with respect to a particular technology tend to facilitate SME innovations.

The two case studies analyzed and the inferences derived lead us to a few general conclusions. They are specific to the Indian context of SMEs and they are the following: (i) The two cases adequately demonstrate that SMEs in the engineering product industry of Bangalore are able to aim, plan, strategize and implement technological innovations successfully in terms of new product developments. (ii) Entrepreneurial motivation was the prime factor which was responsible for the emergence and implementation of innovations in all the cases. (iii) Entrepreneurs played an instrumental role in recognizing the market opportunities, building up the crucial in-house technological capability, supplement it with appropriate external assistance, put in place the process of carrying out technological innovations including its modifications to suit customer requirements and finally deliver it to the market. (iv) An important feature of these innovations is that constant interaction with its customers is in-built into the system. This finding enables us to postulate the first hypothesis: A SME with technological capability will be able to perceive customer requirements adequately and respond to it appropriately through product/process innovations.

(v) Periodic new product developments have been the performance indicators of their continuous innovations. A natural development of this process of innovations is the entry of these SMEs into the international market which facilitated their learning process further. (vi) The overall outcome of innovations is their growth, experienced not only in terms of factor inputs but more importantly in terms of sales turnover. This enables us to state the second hypothesis: Technological innovations enable SMEs to enter the international market and achieve firm growth.

Finally, based on the aggregate analysis of the two cases, we have developed a theoretical construct, with an inspiration derived from the arguments of Eisenhardt (1989), Siggelkow (2007) and Burgleman (1994) on case studies. We postulate that innovation is an evolving process in a SME, with three identifiable stages as follows:

In the

But in the

The “individual reputation and social capital” of the entrepreneur plays a central role in the success of the innovation. Adequate knowledge of demand variations as well as the competitors’ alignment for emerging customer requirements in the industry is of great value. The choice of strategies of cost reduction or quality improvement under varying competitive conditions at a particular point is critical to both innovation and firm success.

In the

In the light of these observations, inferences and conclusions, we recommend an exclusive innovation promotion scheme as part of India’s SME policy. The objective is to (i) facilitate the in-house technological capability building efforts of SMEs, (ii) provide information on the kinds of external assistance that they can access, (iii) organize workshops to motivate dynamic entrepreneurs to undertake innovations, (iv) encourage financial institutions to extend support to innovative SMEs, (v) promote linkages between large enterprises, including MNCs and SMEs having threshold technological capability, etc. Promoting SME innovations and SME growth would enable the “gradual growth of SMEs into large enterprises” at the aggregate and in turn industrial development of India.