All over the study of properties, advantages and drawbacks of the different conventional marine fuels (Diesel oil and heavy fuel oil) , it can be showed that the traditional liquid marine fuels have worked competently through the most recent decades, particularly with regard to adaptability, performance, safety and the compliance with the emissions regulations. But in the last few years, some troubles have appeared due to its use, these include: the barriers of compliance with the new emissions regulations (Fotis et al., 2014), the increase of the fuel cost, which presents the main element in the ships operating cost (Banawan et al., 2013) and finally the sustainability issue (Seddiek et al., 2013). Uncontrolled emissions from burning traditional marine fuel oils onboard ships have a significant impact upon our environment, especially with increase quantity of ship emissions: Nitrogen oxides (NOx), Sulfur oxides (SOx), Di-oxide (CO2), Mono-oxide (CO), Particulates Matter (PM) and Hydrocarbons (HC) (Welaya et al., 2013). A more comprehensive review was recently carried out by various organizations which are concerned with air pollution and discussed health and welfare impacts from burning the fuel oils and quantified the financial benefits that result from reducing these emissions (Beecken et al., 2014). As a method toward ship emissions reduction, nowadays, the IMO regulations pushed the ships to use expensive fuel type in Ship Emissions Control Areas (SECAs) and will be forced to be worldwide by year 2020 (Herdzik, 2011). Moreover, Marine Environment Protection Committee (MEPC) in its 57th session planned to reduce NOx emissions to the lowest level by year 2016. There is no doubt that this will effect negatively in the ship economic due to the increase of operating cost, which encourage all who interest in marine field to search and present different proposals to find a solution for this problem. Thus, many attempts are carried out to search for a solution for that issue. The present paper discusses this issue from the point of view of statistics, regulations, and the proposed strategies for achieving this target.

STATISTICS AND REGULATIONS OF SHIPS, EMISSIONS

Several inventory studies suggested that in 2000, ocean-going ships have emitted around (600-900) thousands tones of CO2, 15% of all global NOx emissions and 4-9% of global SO2 emissions (Eyring et al., 2010). While in 2007, the quantity of gases emitted from ships estimated to be 25 and 15 million tons of NOx and SOx respectively, and have estimated around 2.7% of all global CO2 are attributable to ships (IMO, 2009). Other studies revealed that shipping-related PM emissions are responsible for 3-8% of global P.M 2.5 -related mortalities (Eide et al., 2013).

IMO regulations regarding nitrogen oxides had planned to achieve NOx emissions reduction through three Tiers. Tier I for ships keel lay-down after 1January 2000, Tier II , for ships keel lay-down after 1January 2011, which requires achievement of 15% emissions reduction of Tier I, and lastly Tier III for ships keel lay-down after 1January 2016 with 85% emissions reduction of Tier I (Lin and Lin, 2006). The current allowable NOx emission level according to IMO regulation depends on the speed category of the engine and ranges from (17

METHODS OF SHIP EMISSIONS REDUCTION

To carry out ships emission reduction process, a set of techniques could be done separately or as a complex concept, including using of: emissions reduction technology, alternative fuels, and fuel saving strategies, as follows:

>

Ship emissions reduction based on applying reduction technologies onboard

Technologies for emissions reduction can be divided into three general areas: In -engine, Fuel -related and Exhaust cleaning technologies. The most emissions reductions technologies are concerned with NOx and SOx emissions due to their bad effect on the marine environment (Seddiek et al., 2013).

NOx emissions reduction technology

Many researches (Stationary, 2000; Andersson and Winnes, 2011; Lamas and Rodriguez, 2012; Lamas et al., 2013) showed the possibility of achieving acceptable NOx emissions reduction. One of the old methods that used was adding water to the liquid fuel (Genesis Engineering Inc., 2003). So, using the puriNOx product, who mix Lubrizol, s proprietary additives with liquid fuels to form a stable product may cause reduction of about 20% & 50% for NOx and P.M respectively (Stationary, 2000). Recently, it was shown by (Lamas et al., 2013) that several engine’s internal modifications may achieve NOx reduction by considerable percentage. Practically, Selective Catalytic Reduction (SCR) system is currently used onboard many ships and considered the best efficient method of NOx reduction than the other methods due to its durability and compliance with most commercial ships (Andersson and Winnes, 2011; Woodyard, 2004).

SOx emissions reduction technology

Some, attempts are carried out for improving of marine fuel oil regarding SOx emissions for a clean environment and for keeping the running cost as low as possible. One of these attempts is mixing heavy fuel oil with thermal oil processed from Waste Plastics, but practically it was too difficult due to some technical problems (Banawan et al., 2010). Worldwide concerns about emissions of SOx emissions from marine vessels have created an impetus to replace high sulfur marine residual oil with cleaner lower sulfur fuels. Two such fuels being discussed as substitutes for residual oil are Marine Gas Oil (MGO) and marine diesel oil (MDO) (Bengtsson et al., 2011). Moreover, seawater scrubbing system appeared as an efficient SOx emissions reduction (Andreasen and Mayer, 2007). Widespread adoption of seawater scrubbing will likely be dependent upon satisfactory resolution of the issue of its impact on water quality and ship operating cost (Johansson et al., 2013). The IMO MARPOL regulations, the European Union (EU) regulations and the US EPA regulations are aligned except on some points of detail. They all allow for equivalents and so permit the use of Exhaust Gas Cleaning Systems (EGCS), which are called scrubbers. They have to achieve the same limits on SOx content of the exhaust whatever fuel is burnt as if the ship was burning fuel with a sulfur content less than 0.1%. Each scrubber also has to be approved as an equivalent by the flag administration of the vessel so some different flag state requirements may apply.

Other emissions reduction technology

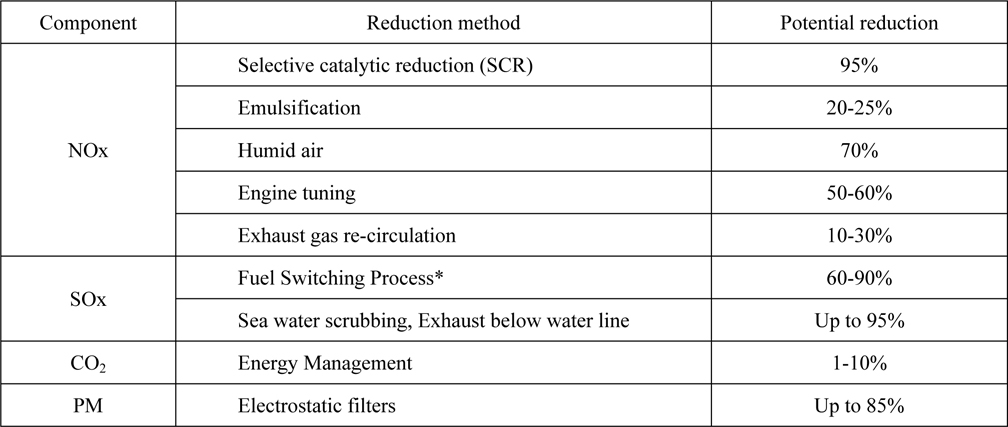

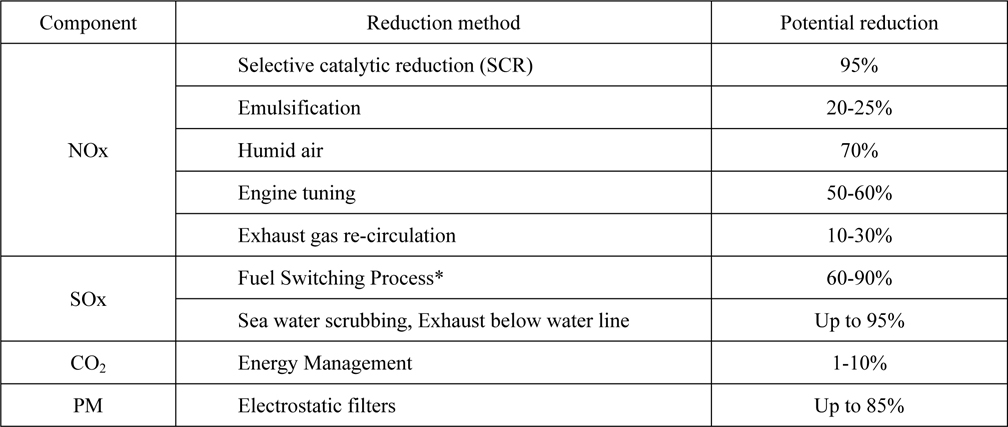

In addition to the technologies used to reduce both NOx and SOx, there are some other technologies which are used for other pollutants such as P.M, CO2 and HC. A less concern is paid for those pollutant comparative with NOx and SOx emissions. This is due to the fact that NOx and SOx emissions have the higher negative effect towards environment and human health issues. The most common technologies used for PM emissions reductions are using of: low sulfur fuel oil, and catalyzed particulate filter (Daniel et al., 2012). CO emissions reduction achieved through improving the process of fuel combustion inside the engines to insure the complete combustion process. Moreover, reduction of CO2 and HC will be achieved as a part of whole ship’s emissions reduction technology (Seddiek et al., 2012; Banawan et al., 2013). Currently, a combined SCR systems can be used for reducing NOx, CO, and HC emissions together. This systems work in two efficient stages, the oxidation stage for CO and HC emissions reduction and the SCR stage provide NOx emissions reduction. Applying the basic or combined SCR system is the matter of economic considerations and the essential of a certain emissions reduction. Table 1 summarizes the average emissions reduction percentages as a result of using the mentioned and other emissions reduction technologies for marine diesel engines.

Available methods for reducing ship emissions (Buhaug et al., 2009; EPA, 2009; Ariana et al., 2006; Woodyard, 2004).

>

Ships emissions reduction based on using of alternative fuels

The main alternative marine fuel types may be found in two forms - liquid and gaseous fuels. Liquid marine alternative fuels include: Methanol, Ethanol, and Bioliquid fuel, among them methanol has the promise to use for marine application in the future (Kolwzan et al., 2012). On the other hand, the main alternative gasses fuels include: Hydrogen, Propane, and natural gas. Among the previous types, Hydrogen and natural gas showed many attempts to applied onboard ships, and more emphasis on those fuels regarding their characteristics can be illustrated as follows:

Hydrogen

A variety of alternative hydrogen energy production technologies are available in practice, including: Steam reforming, Off-gas cleanup, Electrolysis Photo process, thermo chemical process and Partial oxidation of hydrocarbons (Hagh, 2004). Until now the use of hydrogen as a main fuel for marine power plants is very restricted due to some technical problems (Christos et al., 2014).

Natural gas

The use of natural gas also offers a number of environmental benefits over other fossil fuels, particularly liquid fuels (Elma et al., 2014; Seddiek et al, 2013; Banawan et al., 2010). The combustion of natural gas releases very small amounts of sulfur dioxide and nitrogen oxides, virtually no ash or particulate matter and lower the levels of carbon dioxide, carbon monoxide, and other reactive hydrocarbons (Bengtsson, 2011). Many researchers showed the possibility of using natural gas for marine application either for ships powering system (El-Gohary, 2012; El-Gohary and Seddiek, 2013) or for electric generation, using fuel cells (Welaya et al., 2011; 2013). The compression had been presented by (Radwan et al., 2007; Banawan et al., 2010) among the most marine alternative fuels and the other one, which was presented by (Bengtsson et al., 2011) between current onboard fossil fuel and liquefied natural gas indicated that NG considers the best alternative fuel for marine applications.

>

Ships emissions reduction based on fuel saving strategies

Several studies, aiming to saving and reducing fuel consumption and consequently exhaust gases emissions onboard ships, have shown that there are different methods to achieve that. The present section describes some of the main strategies which may be applicable onboard ships in order to achieve maximum fuel saving.

Ship resistance reduction

Ship's fuel consumption is a part of ship's powering calculation, which depends mainly on the ship's resistance. There are many options to reduce ship resistance, such as anti-fouling, ship's weight reduction as traditional methods (Apostolos, 2010; TAYLAN, 2010; Philippe, 2009) and air bubbles as a new concept (Winkler, 2009). Each method of them can contribute by different fuel saving percentages according to ship type.

Renewable energy

Although there is a high degree of preference for renewable energy over fossil fuels as energy source for ship power, the study of development of a renewable infrastructure for marine transportation is still in the first steps. Wind energy, Solar energy, Wave energy, and Hydrogen combustion present the most common sources of renewable energy that may be used onboard ships (Alexandros et al., 2010; Mekhilef et al., 2011).

Energy performance improvement

The contribution of marine power plant efficiency in issue of fuel saving may be achieved through fuel quality improvement and engine tuning process (Rosli, 2008; Fredrik, 2008). Engine tuning process can be achieved through tuning of fuel system, air system, and exhaust system.

Energy conservation management

In the maritime field, energy conservation and management processes onboard ships are made more efficient, concerning the fuel to help stretch the fuel budget as far as possible and make ships more environmentally friendly (Oihane et al., 2012; Gerasimos and George, 2013; Kjeld, 2009; Elgohary, 2009). One of the new proposed waste heat recovery application was presented by (Seddiek et al., 2012), which showed the possibility of using exhaust gases to operate absorption air condition unit.

Reduce ship speed

Fuel consumption and the amount of ships exhaust gas emissions are in direct relation. Consequently, saving any amount of ship fuel consumption will affect positively on marine environment (Harilaos et al., 2009). Furthermore, with the continuous fuel price increment, some companies forced to reduce their ships speed (Shuaian and Qiang, 2012). An estimate of fuel saving percentage as a result of speed reduction was introduced and expressed by (Banawan et al., 2013):

Shore side power connection

A huge amount of fuel is consumed by auxiliary engines at the ports. (P.M) emissions are responsible for approximately 60000 cardiopulmonary and lung cancer deaths annually, with most of those deaths occurring along the coasts (Yang et al., 2011). Shore power connection system used to saving the quantity of fuel consumption through ships berthing periods. The economical and environmental benefits due to applying of shore power connection were demonstrated by (Hall, 2010; Seddiek et al., 2013).

CHOICE OF THE SUITABLE EMISSIONS REDUCTION METHOD

There are many factors affecting choice of the suitable ship emissions reduction method which include ship type, power rating, economic issue, adaptability, and compliance with the current and future emission regulations. As a case study, the present paper handling this factors in case of applying the previous methods onboard high speed passenger ships Choice of these types is the matter of power rating which conjuncts directly with the amount of exhaust gas emitted from ships. Moreover, these ships call ports on more regular basis in short time compare to any other ships which make them more effect in the health of population at the areas near from ports. According to the nature of ships, operating and based on the previous researches, carried out by (Elma et al., 2014; Christos, 2014; Johansson et al., 2014) using of alternative fuels and emission reduction technologies seem the most suitable methods to be applied for passenger ships, especially from the point of view of applicability.

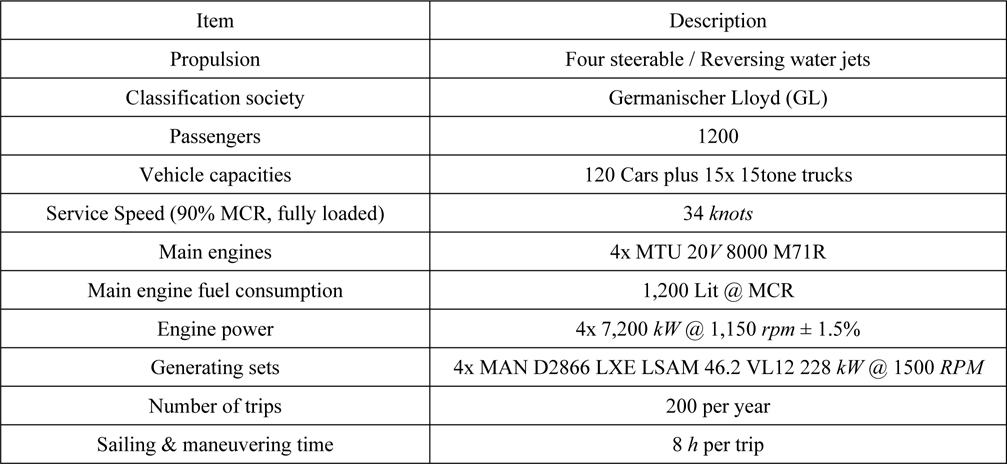

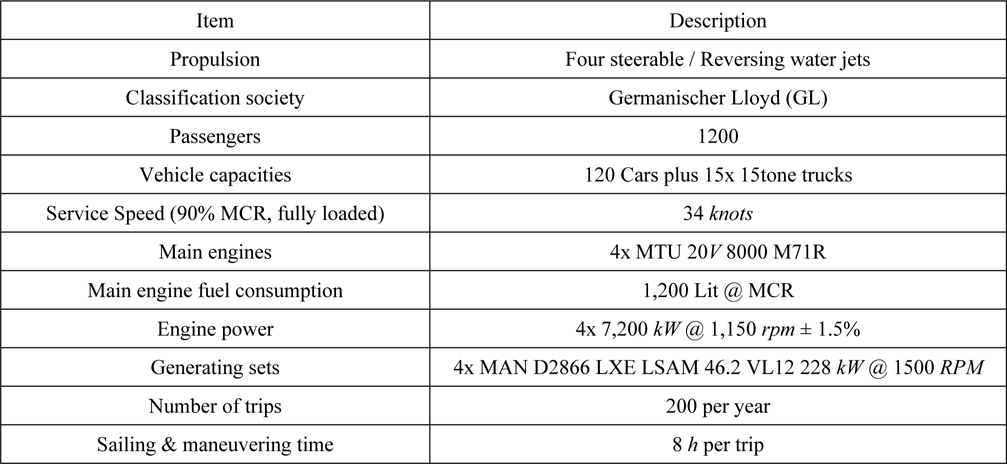

In recent years, the number of short-voyage passenger ships sailing in the Red Sea area has increased. There is no doubt that these ships have contributed to develop maritime transport in this area. On the other hand, it was shown by (Seddiek et al., 2012; Seddiek et al., 2013) that the high power of these ships contributed to the increasing gaseous emission rate and affect adversely on the environment in this area. The present paper discusses the viability of applying the mentioned two methods onboard one of the high-speed crafts operating in the Red Sea area, called Alkahera, as shown in Fig. 1. The ship operates between Hurghada port in Egypt and Duba port in the Kingdom of Saudi Arabia. The ship's technical data is summarized as shown in Table 2.

[Table 2] M/V Alkahera main technical data.

M/V Alkahera main technical data.

>

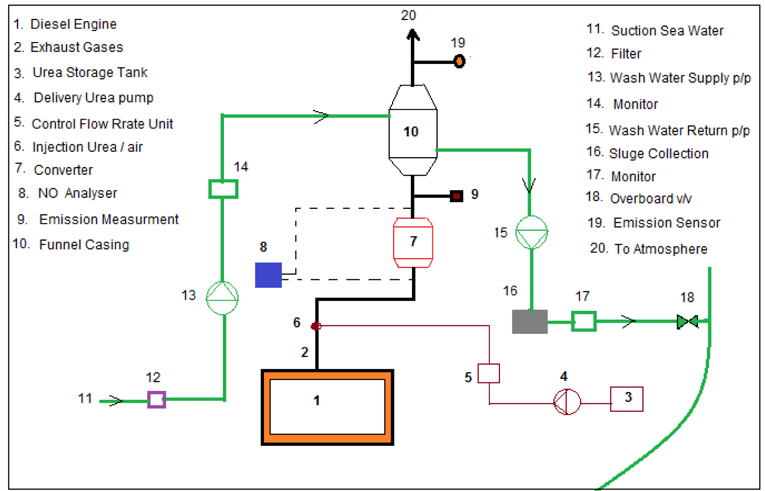

Applying emissions reduction technologies

Fig. 2 shows a simple scheme for emissions reduction model, which can be installed onboard the case. It consists of SCR system for NOx emissions reduction , followed by sea water scrubber system. The present study had been relied on the characteristic and performance of ship’s main engines, SCR system, and Scrubber system. All data were computed using Engineering Equations Solver (EES) program for environmental and economic results.

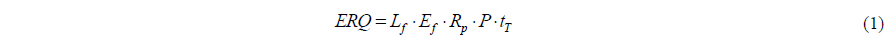

To evaluate the importance of installation of SCR and sea water scrubber system from the view point of environment; quantity of ship's emissions that could be reduced in case of applying these systems may be estimated from the following equation for both NOx and SOx emissions.

where (

where (

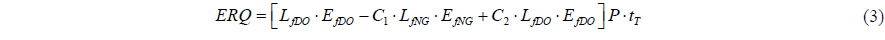

Discussion of using alternative fuels as a strategy for ship emissions reduction revealed that natural gas appears as the most common alternative fuel onboard ships. One of the most outcomes of applying this strategy is the environmental benefit, which may be quantified as follows:

where

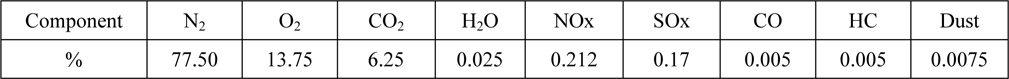

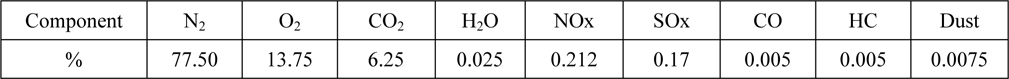

[Table 3] Typical composition of exhaust gases.

Typical composition of exhaust gases.

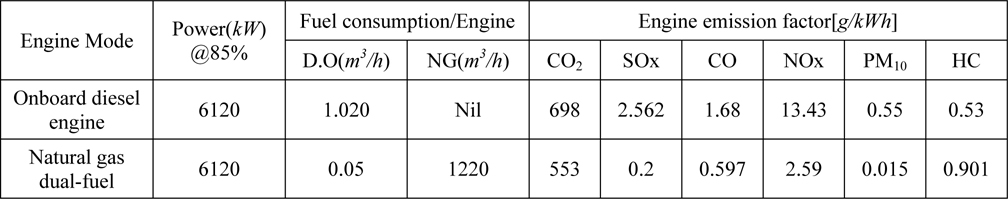

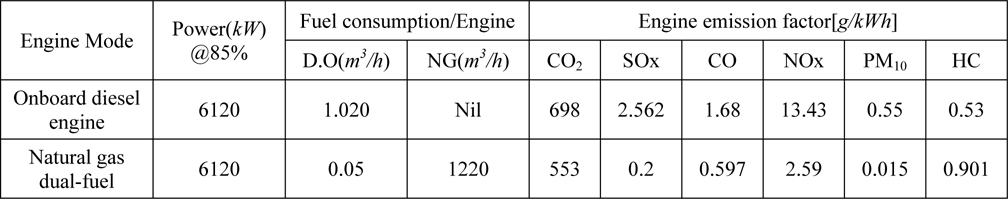

[Table 4] Engines data and emissions factors.

Engines data and emissions factors.

To adapt the diesel engine to dual-fuel (diesel -methane) engine, a conversion process should be carried out. This includes modification of the main engines parts such as (fuel injector, piston, and valves). In addition, adding NG supply system including NG storage spaces, supply piping and valves, gas detection units and alarms, exhaust ventilation system, and other minor components. Cost analysis of using natural gas, in form of Liquefied Natural Gas (LNG): instead of diesel oil onboard ships it depends on some essential items, including the present and future of diesel fuel prices trend, cost of conversion onboard diesel engine to dual-fuel engine and the difference in maintenance, operation and bunkering costs.

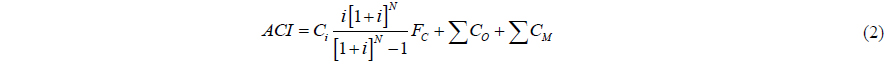

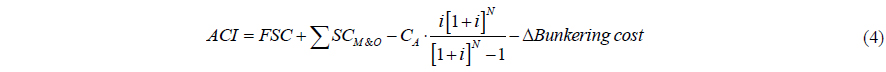

The annual saving or increment cost [

where, (

where, (

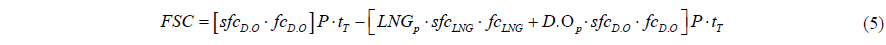

As the present paper emphasis on SOx and NOX emissions; using of the basic type of SCR (which designed mainly for NOx emissions) will be considered rather than using of the combined system which is more expensive than the basic system. From Fig. 3 it can be noticed that the higher NOx emissions reduction percentage could be done through using of (SCR + MGO) system, while applying of (SCR + Sea water scrubber) system which may achieve maximum SOx and HC emissions reduction. On the other hand using of natural gas as alternative fuel will contribute in reducing CO2 emissions more than any other proposed system. A part of this conclusion is due to the fact that NG has lower Carbone content than diesel oil and consequently the combustion of these products of it will contain less CO2 emissions. On the other hand, HC emissions will increase when using NG instead of diesel oil as the main fuel in internal combustion engines, since diesel engines are operated at a much leaner mixture than NG engines are, especially for converted engines (Banawan et al., 2010).

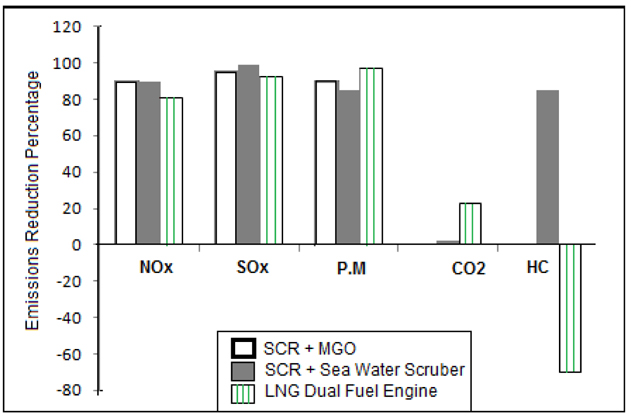

Economically, Fig. 4 presents the average cost saving or increment due to applying the proposed emissions reduction strategies. From the Figure it can be excluded that using of natural gas as an alternative fuel, in LNG form, will be economically either without or with adding the conversion cost. As shown; applying LNG fuel for main engines can achieve annual cost saving of 50 and 18 (

Emissions from ships represent one of the important issues that concern those interested in maritime domain, as it has a negative impact on the marine environment. The present paper discussed the various methods which could carry out to reduce those emissions. Using of SCR and water scrubber systems as treatment technology onboard ships or natural gas as alternative fuel appeared as the best methods from the point view of environmental. Applying one of them depends on some criteria such as the required emission reduction percentage. Those methods were studied to be used for one of passenger ships working at the Red Sea. The results showed the possibility to achieve valuable emission reduction percentage by using of SCR and scrubber systems, but it will be costly and add more ship operating cost. On the other hand, using of LNG as alternative fuel will convince from the view point of environmental and economic issues.