The advantages of a plasma treatment for polymers in general have been quite intensively studied(Lei et al., 2011; Yasuda et al., 1984). However, the use of plasma treatment applied to fabrics is limited, based on the publications appearing in literature. This may be due to the fact that fabrics are much more complicated than films(Clark et al., 1987). When the surface of the polymer is exposed to plasma, plasma functionalizing and plasma etching always coexist on the surface, which are dependent on plasma parameters(Lei et al., 2011). When increasing the plasma treatment time, the surface roughness on the polymer film continuously increased, which was associated with a depletion of the polar functional groups by ion-flux bombardment(Lei et al., 2011). Although the wettability of fibers modified by different plasmas has been studied extensively(Kan & Yuen, 2011; Liu et al., 2013), independent control of plasma functionalizing and plasma etching to control the surface polarity and the roughness of the fabrics has been difficult to realize. Therefore, the plasma-modification mechanism for the wettability of fabrics is also not clear, because the description of the surface dynamic behavior of the modified fiber relative to surface polarity and roughness is not fully understood.

PP fibers has good tensile strength, abrasion resistance, wrinkle recovery, and chemical resistance, but it has low wettability. The recently developed polypropylene fabrics knitted with hollow polypropylene fibers are suitable for the wicking materials that draw moisture away from the body. The micro surface of the PP fiber may be suitable for the quick wetting materials. The PP membranes were developed successfully bu Kosaraju and Sirkar(2008). The surface and the pore interior of PP flat sheet and hollow fiber membranes were hydrophilized first by pre-wetting with acetone followed by oxidation with chromic acid solution. Weon and Lee(2012) found that Ar-plasma treatment provides a hydrophilic state on the PP blended surface.

Glow discharge plasma treatment at low pressure has been employed to modify the surface characteristics of PP(Sarmadi et al., 1993; Tsai et al., 1997). Improved wettability and dyeability of PP fabrics were obtained using glow discharge plasma by grafting nitrogen-containing active groups on the surface(Sarmadi et al., 1993). Hydrophilic surfaces have been developed through glow discharge plasma at one-atmosphere on PP webs(Tsai et al., 1997). After atmospheric air plasma treatment, the oxygen content of the synthetic textile fibers was increased indicating that hydrophilic groups had been introduced into the fabric leading to the improved wettability(Kan & Yuen, 2013). Although there is an abundant amount of literature on surface modification of using plasma to improve wettability of natural or synthetic fibrous materials, few in depth studies of oxygen(O2) plasma on PP fabrics exist. The present investigation was aimed at surface modification and characterization of PP surface by O2 plasma treatment.

Commercial PP plain fabric(fabric density 108×104/inch and fabric weight 134 g/m2), purchased from Test Fabrics Inc. was used in all experiments. The fabric samples were Soxhlet extracted in benzene and distilled water for 4 hours each and dried under vacuum condition before use. O2(Aldrich Chemical) was used without further purification.

O2 plasma treatments were carried out in a commercial installation. The apparatus include the parallel plate electrodes, a 30 kHz RF generator, water-cooling system, a vacuum pump, pressure gauge, and gas flow meter. In a typical experiment four fabric samples(9 cm in diameter) were placed on the grounded electrode. Then the system was vacuum to ground pressure level. After creating the selected gas pressure, the plasma was ignited and maintained for the desired reaction period. At the end of the irradiation, the samples were removed from the reactor and stored in Pyrex containers under constant relative humidity(50%) and temperature(27℃) conditions for 24hours, then subjected to analytical measurements.

ESCA spectra were obtained by using a Perkin-Elmer 5400 spectrometer with an Ng X-ray source and a data reduction system. For the elemental analysis, the pass energy of 35.73 eV was utilized for multiple spectra analysis. The sample fabrics were cut by clean scissors and carefully mounted on the sample holder, where binding energy assignments for particular functionalities are made.

2.4. Contact angle measurement

The advancing contact angles of water on fiber surface were obtained by the Wilhelmy balance technique(Miller & Young, 1975). This technique was utilized to demonstrate the effects of several treatment variables on the surface character of PP fibers. The average values o contact angles of 10 fibers from the PP fabrics.

2.5. Surface Morphology by SEM

A JEOL scanning electron microscope was used to observe the surface morphology of fibers. To provide conductivity for the fiber samples, a coating of gold was applied in a Gold Sputter-Etch unit. The O2 plasma-treated and untreated samples were observed at magnifications 4700 and 10000 X.

The effect of plasma treatment on the spontaneous water uptake amount of fabrics was determined by the demand wettability test(Miller & Tyomkin, 1984). The demand wettability test is a sensitive gravimetric method which is capable of measuring the rate and the total amount of liquid uptake in the direction perpendicular to the plane of a fabric. The initial water uptake and the equilibrium water uptake amount of PP fabrics before and after O2 plasma treatment were measured. To determine the effect of aging on the surface properties of the plasma, all the above measurements of O2 plasma treated samples were carried out after 1, 7, 30, 60, and 150 days.

3.1. Surface modification of PP fibers

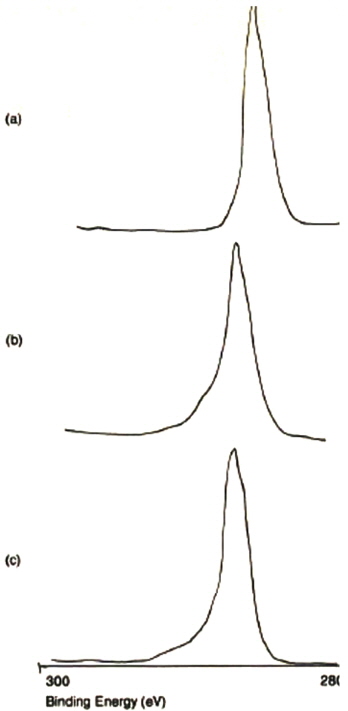

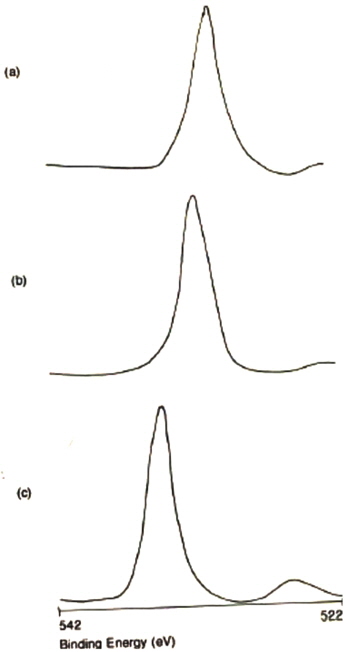

Fig. 1 shows the C1s spectra of PP before and after O2 plasma exposure. The untreated PP exhibited a strong single carbon peak at 285 eV. The oxygen substituted C1s peak of the treated PP was much wider than that of the untreated PP. The C1s shifts between 286 and 292 eV arise from a mixture of oxidized group. Carbon containing a single bond to oxygen, such as with alcohol or ether, could occur around 286 to 288 eV. Carbonyl carbon was around 289 to 291 eV. Fig. 2 shows the O1s spectra of the untreated and the O2 plasma-treated samples at 532 and 535 eV, respectively. The higher binding energy of O1s shift is oxygen bonded to carbon atoms.

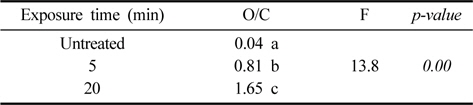

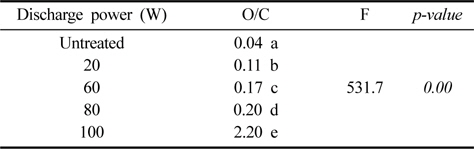

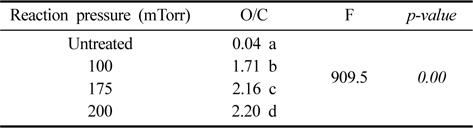

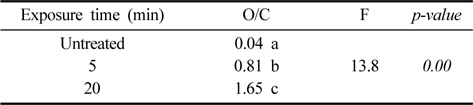

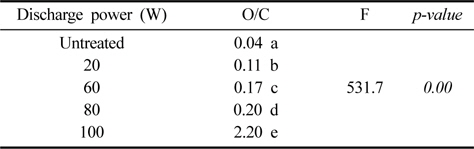

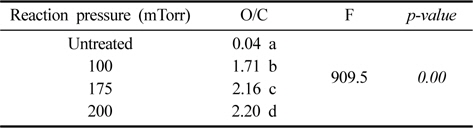

Table 1 shows variation of the surface atomic ratios, O1s/C1s of PP treated with different exposure time. As the exposure time increased from 5 min. to 20 min, the O1s/C1s ratio significantly increased from 0.04 to 1.65. The O1s/C1s ratio for the specimens treated under different discharge powers(20W, 60W, 80W and 100W) are shown in Table 2. The discharge power increased, the O1s/C1s ratio increased. The specimens treated at the discharge power of 100W demonstrated a 5,500% higher oxygen atom content than the untreated specimens. The O1s/C1s ratio increased also as reaction pressure from 100 mTorr to 200 mTorr increased. The Table 3 indicates that the ratio of O1s/C1s is 1.71 for the PP treated at 100 mTorr and 2.20 for the PP treated at 200 mTorr.

[Table 1.] Effect of O2 plasma exposure time on the surface atomic ratios of PP

Effect of O2 plasma exposure time on the surface atomic ratios of PP

[Table 2.] Effect of RF power on the surface atomic ratios of PP

Effect of RF power on the surface atomic ratios of PP

[Table 3.] Effect of reaction pressure on the surface atomic ratios of PP

Effect of reaction pressure on the surface atomic ratios of PP

3.2. Contact angles of PP fibers

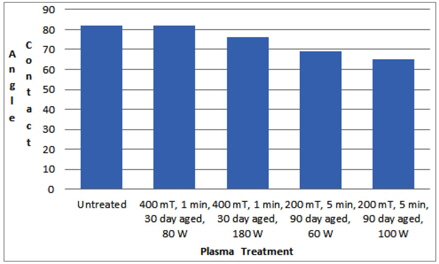

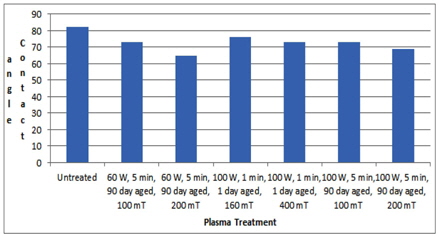

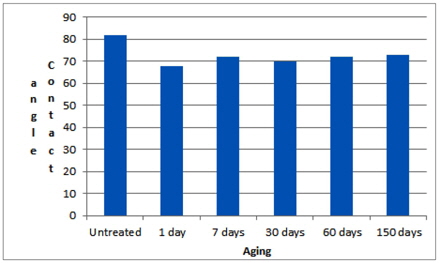

The decreased contact angles of all the treated PP fibers indicates more hydrophilic surfaces generated by O2 plasma. The O2 plasma treatment improved hydrophilic properties of PP fibers. The water contact angles of PP fibers decreased with increasing discharge power, as shown in Fig. 3. The contact angle of PP fibers decreased from 82° up to 65° with increasing discharge pressure, as sown in Fig. 4. Fig. 5 shows the water contact angles for the O2 plasmatreated PP fibers that were aged for 1, 7, 30, 60, and 150 days. ESCA analysis showed that the fiber surfaces treated in the O2 plasma system have a chemical composition that consisted of various oxygen containing polar groups even after 150 days of aging. Therefore. the contact angles of PP fiber were still significantly lower than those of the untreated PP fiber even after 150 days of aging. Long-term stability of polar groups was important for creating durable water wetting. Wettability decreases and levels off with aging because the O2 plasma-treated PP fiber is depolarized with time, and the polar groups stay without reversible reaction.

3.3. Wettability of PP fabrics

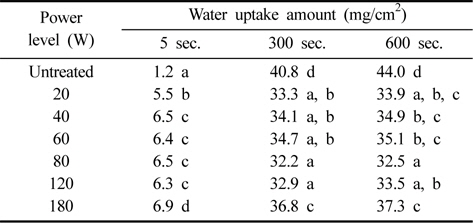

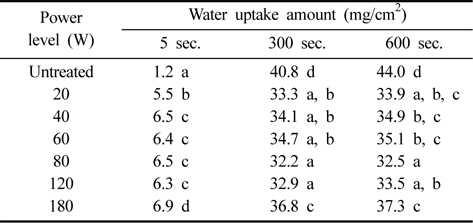

Table 4 shows the effect of the O2 plasma treatments on the spontaneous water uptake of PP fabrics. For this experiment, samples were discharged at a pressure of 200 mTorr and exposure duration of 1 min. Increasing the discharge power up to 180W and keeping all other conditions constant gradually increased the initial water uptake amount. The fiber surface chemical composition might affect the rate of water uptake of PP fabrics. It is believed that functional groups like carbonyl group, hydroxyl group and carboxyl group were formed after the O2 plasma treatment, leading to hydrophilic surface of polypropylene fabrics. Apart from formation of polar groups, the plasma etching effect enhancing the capillary flow was another reason causing improved wettability.

[Table 4.] Effect of discharge power on the water uptake amount of the O2 plasma-treated PP fabrics

Effect of discharge power on the water uptake amount of the O2 plasma-treated PP fabrics

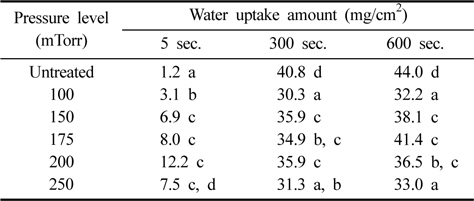

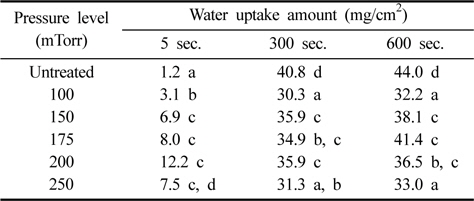

The results of demand wettability test indicate that efficiency of the hydrophilic modification was also dependent on the discharge pressure. Table 5 shows that with increasing discharge pressure from 100 to 5 mTorr. The initial water uptake amount increased from 3.1 to 12.2 mg/cm2, while the total water uptake amount increased from 32.2 to 36.5 mg/cm2. Several aspects affect the total water uptake amount of fabrics, such as pore size, fiber surface roughness, and fiber surface chemical composition.

Effect of discharge pressure on the water uptake amount of the O2 plasma-treated PP fabrics

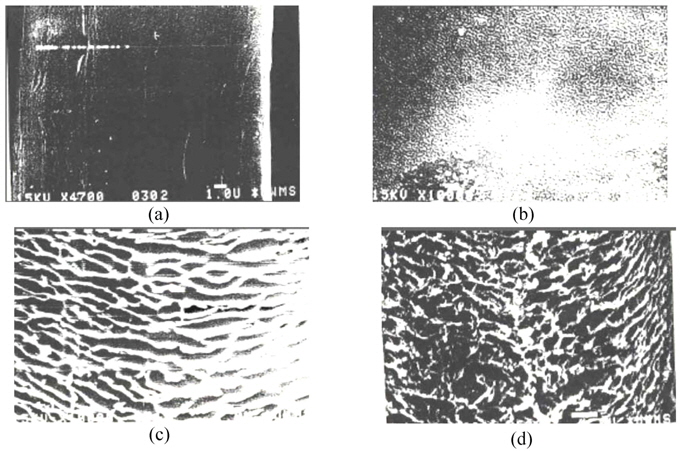

Surface roughness of the plasma-treated PP fiber appears in the SEM photographs. Fig. 6 represents the surfaces of the untreated and plasma-treated PP fibers. The O2 plasma-treatment resulted micro etchings on the PP surface. The width of etch units was 50 to 100 Å and the space of the units were 400 to 800 Å The fold width in polymer single crystals was known to be on the order of 100 Å and was considerably consistent to the width of the etch units exposed PP fiber treated by O2 plasma. The depth of ridges increased with increasing discharge pressure. The ridged structure was the accretion of continuous cavities by the removal of the amorphous chain segments. This greater depth of ridge corresponded to a faster initial water uptake rates and a lower total water uptake amount. The initial water uptake rate is faster with increased dischared pressure or discharge power. The main reason for the improvement in the spontaneous water uptake rate of the fabric was the introduction of hydrophilic functional groups on the surface of PP fibers and it may might also attributed to the oxygen plasma etching effect on the fiber surface which increasesd surface area of the fiber and enhancesd the capillary effect to transport the liquid( Kan & Yueen, 2013). The O2 plasma etching was a physical removing process on the surface of the PP fibers leading to surface roughening. It is suggested that the formation of functional groups containing oxygen was the main reaction on the surface of plasmamodified PP samples treated with 100 mTorr of discharge pressrueeure, whereas the depletion of the polar functional groups carried out due to plasma etching above 175 mTorr of discharge pressrueeure is associated with the increase of surface roughness.

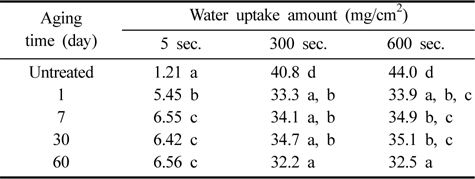

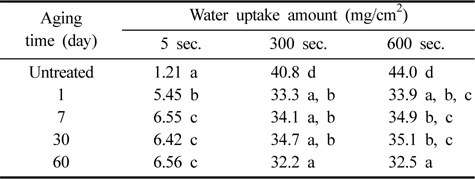

The effect of aging on the spontaneous water uptake of PP fabrics was also investigated, and the results are shown in Table 6. The wettability decay began to level off after treatment for 7 days. We found that the wettable PP fabrics even after more than a year. After 7 days of aging, there was a significant amount of oxygen atoms on fiber surface, which contributed to low contact angle, resulting in a wettable surface.

[Table 6.] Effect of aging on the water uptake amount of the O2 plasmatreated PP fabrics

Effect of aging on the water uptake amount of the O2 plasmatreated PP fabrics

This paper presents a way of improving wettability of PP fabrics by O2 plasma treatment. The surface properties of PP fibers and the dem and wettability of PP fabrics were compared before and after plasma treatment. The results show the oxidized PP fiber surface affects fiber surface wettability because it determines the surface bonding forces with water. The formation of the polar functional groups containing oxygen, not only depends on the oxygen plasma density, but also on the oxygen ion-flux energy. When increasing the treatment time, the surface roughness on the PP continuously increases, which is associated with a depletion of the polar functional groups by ion-flux bombardment. Surface roughness of the plasma-treated PP fiber appears in the SEM photo graphs. These surfaces roughness may affect the fabric wettabiity as well. Wettability decreases and levels off with aging because the fiber is depolarized with time, and the polar groups stay without reversible reaction.

The polar functional groups on the surface of the plasma-treated PP fiber increase the spontaneous water uptake rate. O2 plasmatreatment controlling plasma reaction pressure is probably a simple and effective method to further improve the spontaneous wettability of the plain PP fabrics.