Epoxy resins are well-known materials in insulation systems for heavy electric equipments, because they have good mechanical and thermal properties as well as excellent electrical properties [1-3]. In the last two decades, many researchers have developed new epoxy-based composites, considering a much higher performance with lower cost in the electric applications, and they found that the loading of micro-silica particles improves the dimensional stability and the mechanical and thermal properties of neat epoxy systems during their manufacturing process or service lives. Messersmith and Giannelis [4] reported that the storage modulus of epoxy resin increased 58% at the glass transition region and increased 450% at the rubbery plateau region by loading of only 4 vol.% of clay. Mulhaupt et al [5] demonstrated that the toughness and stiffness of epoxy resin were modified by adding nano-sized mica, bentonite or hectorite. T. Tanaka et al [6] showed that epoxy/layered silicate nanocomposite had much better insulation breakdown strength than that of the non-filled epoxy resin system in needle-plate electrodes geometry. We previouslyreported that the insulation breakdown strength of epoxy/layered silicate nanocomposites was 33% higher than that of the system without nano-silicate [7].

Epoxy resins are generally prepared by the reaction of epichlorohydrin with active hydrogen-containing compounds forming chlorine [8]. However, the formed chlorine caused some problems such as a decrement of mechanical strength due to the loss of crosslink density, corrosion of metals in equipments, and accelerated degradation of polymer chains, etc. Therefore, the generated chlorine should have been removed; however, a small amount of chlorine remained in the final production.

In this current study, a low-chlorine reactive diluent was used in order to develop an epoxy matrix for micro-silica filled composites and the electrical treeing phenomenon was investigated in order to estimate the insulation characteristics of a neat epoxy. A reactive diluent was used in order to decrease the viscosity during mixing and the viscosity that occurs in the crosslinked network of epoxy during curing reaction. The treeing growth mechanism has previously been divided into three processes [9-12]: (1) incubation process, (2) initiation process, and (3) propagation process. When electrical treeing was initiated, it propagated rapidly until finally breakdown occurred. Hence, the initiation time needs to be delayed and the propagation rate needs to be retarded in order to obtain excellent insulation polymeric materials.

A commercial DGEBA (diglycidyl ether of bisphenol A) type epoxy resin, with the trade name of YD 128 (Kukdo Chem. Co.), was used. The chlorine content was 0.05 wt% (max) and the equivalent weight was 184~190. The viscosity was 11,500~13,500 cps at 25℃. The curing agent was Me-THPA (3- or 4-methyl- 1,2,3,6-tetrahydrophthalic anhydride), of whichthe grade name was HN-2200 (Hitachi Chem. Co.). Me-THPA is widely used in electric insulation. The accelerator was benzyl-dimethyl amine (BDMA), (Kukdo Chem. Co.). Low-chlorine 1,4-butanediol diglycidyl ether (1,4-BDGE) the as a reactive was donated by Hajin Chemtech Co., Ltd. It was an aliphatic epoxy resin of which the chlorine content was 4,000 ppm (max). Its equivalent weight was 120~140 and the viscosity was 15~30 cps at 25℃. High-chlorine 1,4-BDGE was purchased from Kukdo Chem. Co., of which the chlorine content was 25,000 ppm (max), which was 6.25 times higher than that of the low-chlorine 1,4-BDGE. Equivalent weight and viscosity were the same values, regardless of chlorine content. A needle-type steel electrode was purchased from Ogura Jewelry Co., Japan. Its diameter and length were 1 mm and 60 mm, respectively, with a tip angle of 30o and a curvature radius of 5 μm.

2.2 Specimen preparation for AC treeing test

DGEBA (100 g), Me-THPA (92 g), and 1,4-BDGE (10 g) were well-mixed using a high-speed mechanical agitator at 5,000 rpm for 10 min, and BDMA (1 g) was mixed with the mechanical agitator at 5,000 rpm for 3 min. The mixture was then poured into a mold having a cavity of 15×15 mm2 with a 30 mm height, in which a needle electrode was arranged a priori to ensure the distance to the needle-plate electrodeswas 4.2 mm. The mixture was then degassed in a vacuum oven at 50℃ for 30 min, cured at 120℃ for 2 hr, and continuously post-cured at 150℃ for 2 hr; it was then cooled slowly at a rate of -0.5℃/min until room temperature in order to avoid internal stress. Finally, the opposite-side of the needle electrode in the epoxy specimen was coated with the conductive silver paste to form a plate electrode.

The specimen was inserted into the insulating oil at 130℃ and maintained for 2 hr until the temperature of the needle tip area reached 130℃. To measure the treeing initiation and propagation rate, a constant alternating current (AC) of 10 kV with three different electric field frequencies (60, 500, and 1,000 Hz) was applied to the specimen. High voltage (HV) was applied by using an AC Endurance Voltage Tester (Haefely, Germany) at a rising speed of 1 kV/s until the testing electric strength was reached and the test voltage was maintained until electrical breakdown occurred. The treeing morphology was monitored using a video microscope system (ICS-305B, SOMETECH Inc.) and the treeing images were collected every 1 min.

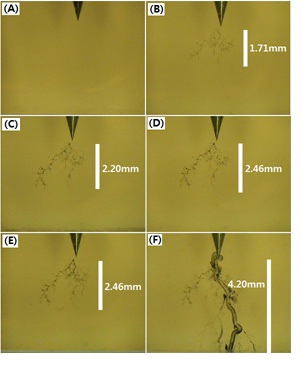

The morphology of electrical treeing propagation at the constant AC electric field strength of 10 kV/4.2 mm (60 Hz) for the DGEBA/BDGE system with high-level chlorine is shown in Fig. 1. The typical behavior of branch type electrical treeing was obtained from the morphology observation. In other words, when the AC electric field was applied, the electrons were injected and extracted at the needle tip so that small electrical treeing was faintly initiated from the needle tip (Fig. 1(b)). Also, the electrons injected and extracted at the newly generated conductive treeing tip which had been carbonized so that several branches were newly appeared and grew, became fatter and darker with many new branches (Figs. 1(c)~(e)), finally, the penetration breakdown rapidly occurred from the needle tip to the silver electrode plate (Fig. 1(f )).

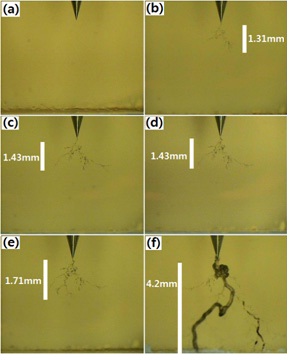

To compare the effect of the chlorine content on the treeing phenomena, the treeing morphology at 10 kV/4.2 mm (60 Hz) for the DGEBA/BDGE system with low-level chlorine is shown in Fig. 2. The figure also shows the typical behavior of branch type electrical treeing was obtained from the morphology observation. The tree propagation length was shorter than that of the system with high-chlorine obtained at the same time. Thismeant that chlorine had A negative effect on the electrical insulation property of the epoxy system.

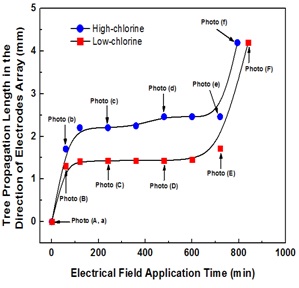

Treeing growth rate curves for the DGEBA/BDGE systems with high-level and low-level chlorine under the constant electric field of 10 kV/4.2 mm (60 Hz) at 130℃ were obtained from Figs. 1 and 2, as shown in Fig. 3. In the DGEBA/high-chlorine BDGE system, electrical treeing waspropagated at the speed of 5.29×10-3 mm/min, and breakdown finally occurred after 794 minGEBA/ low-chlorine BDGE system, electrical treeing propagated at the speed of 5.00×10-3 mm/min, which was 6% slower than that of the high-chlorine system, and the breakdown time was 840 min. The negative effect of the chlorine element was numerically confirmed from the data. This was possibly due to the simple reaction between the epoxide group and chlorine atom, forming the loose crosslink network [13]. Therefore, electrical treeing was easily grown through the weak network structure. Furthermore, the treeing propagation rate increased rapidly during the last stage and abrupt breakdown occurred. This could be explained by the Masons formula [14], Etip = 2 V/(r·ln(1+4x/r)), where Etip is the applied electrical field at the needle tip, V is the applied voltage, r is the needle tip radius, and x is the distance between needle-plate electrodes. This meant that the electrical field value at the conductive carbonized tree tip was considerably higher than the applied voltage. Therefore, the tree breakdown occurred abruptly, even when the distance between the tree tip and plate electrode was significant.

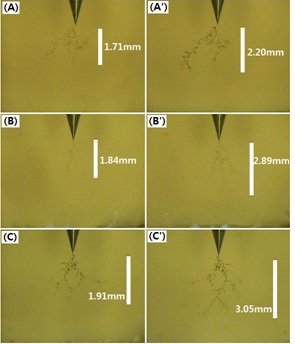

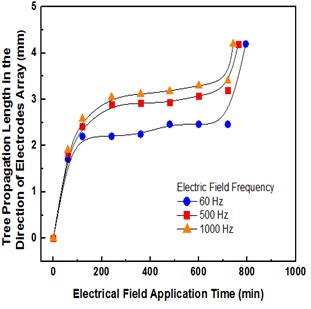

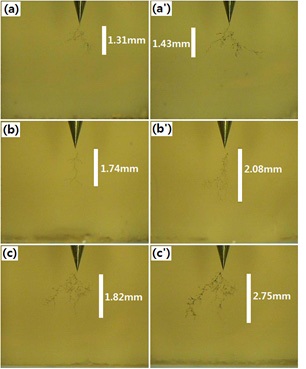

Figure 4 shows the morphology of electrical treeing for the epoxy/high-chlorine BDGE system tested in the constant electric field of 10 kV/4.2 mm with different electric field frequencies: at 60 Hz for (a) 60 min and (a') 240 min; at 500 Hz for (b) 60 min and (b') 240 min; at 1,000 Hz for (c) 60 min and (c') 240 min. As the electric field frequency increased, the treeing propagation rate increased and the breakdown time decreased. Treeing growth rate curves for the high-chlorine system are shown in Fig. 5. Electrical treeing at 60 Hz was propagated at the speed of 5.29×10-3 mm/min, and finally breakdown occurred after 794 min, while the former at 1,000 Hz was 5.66×10-3 mm/min, which was 7% faster than that at 60 Hz. The breakdown at 1,000 Hz occurred after 742 min.

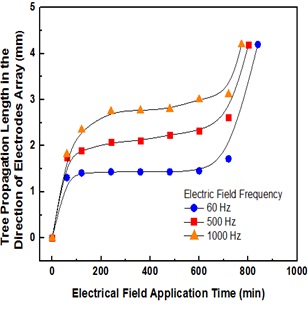

A similar tendency for the epoxy/low-chlorine BDGE system is

also shown in Figs. 6 and treeing growth rate curves for the highchlorine system are shown in Fig. 5. The electrical treeing propagation curves at three frequencies are shown in Fig. 7. Electrical treeing at 60 Hz was propagated at the speed of 5.00×10-3 mm/min, and finally breakdown occurred after 840 min. The treeing propagation rate increased and the breakdown time decreased, as the electric field frequency increased. When 1,000 Hz was applied, the former was 5.43×10-3 mm/min, which was 9% faster

than that at 60 Hz. The breakdown time at 1,000 Hz occurred after 773 min. As was expected, the propagation rate at each frequency for the system with low-chlorine was lower than that for the system with high-chlorine.

The effects of chlorine content and electric field frequency on the AC electrical treeing phenomena in a DGEBA/BDGE epoxy system were studied in needle-plate electrode geometry. The chlorine content for low-chlorine BDGE was 6.25 times lower than that for high-chlorine BDGE. The treeing propagation rate of the DGEBA/high-chlorine BDGE system was higher than that of the DGEBA/low-chlorine BDGE system. At electrical field frequency of 60Hz, electrical treeing in the DGEBA/low-chlorine BDGE system was propagated at the speed of 5.00×10-3 mm/min, which was 6% slower than that of the high-chlorine system. This meant that chlorine had a negative effect on the electrical insulation property of the epoxy system. As the electric field frequency increased, the treeing propagation rate increased and the breakdown time decreased. In the DGEBA/low-chlorine BDGE system, when 1,000 Hz of electrical field frequency was applied, the propagation rate reached 5.43×10-3 mm/min, which was 9% faster than that at 60 Hz.