Lead-based piezoelectric ceramics have been widely used in electronic devices such as actuators, sensors, and transformers because of their high piezoelectric electric properties [1,2]. However, these materials may be restricted because of various environmental problems, owing to its high content of toxic lead oxide. Therefore, lead-free piezoelectric materials are being extensively investigated as a replacement for PZT-based ceramics. Among several candidates regarding lead-free piezoelectric materials with properties comparable to PZT, alkali niobate-based materials, such as potassium sodium niobate, are well-known harmless materials and are promising candidates for PZT-based alternative materials due to their excellent piezoelectric properties. The NaxK1-xNbO3 system has a perovskite structure in its composition (x < 0.093). Among the alkali niobate compounds, (Na0.5K0.5)NbO3 (NKN) has a dielectric constant in the range of 300 to 600, a piezoelectric d33 coefficient from 80 to 100 pC/N, high Curie temperature of more than 400℃ and polarization Pr 33 mC/cm2[3]. In the case of NKN, it is difficult to achieve high density NKN ceramics because of the volatility of the Na2O and K2O components and its high reactivity to moisture, and so the piezoelectric properties are poor. In order to improve the densification and piezoelectric properties of NKN ceramics, many binary systems have been studied, including NKN-(Ba,Sr)TiO3, NKN-KTaO3, NKN-LiNbO3, NKN-LiSbO3, and NKN-K4CuNb8O23 [4-6]. Although many binary systems have been investigated, the NKN-K5.4Cu1.3Ta10O29 (KCT) binary system has rarely been studied [7,8]. This paper describes the effect of the KCT addition and the sintering temperature on the phase structure and piezoelectric properties of the NKN ceramics. The optimum sintering temperature, density and microstructure of NKN ceramics with KCT have also been evaluated.

Conventional mixed oxide processing was used to prepare the (1-X)(Na0.5K0.5)NbO3-XK5.4Cu1.3Ta10O29 (NKN-KCT) composition. The NKN powder was fabricated with high purity oxide powder, Na2CO3 (Kojundo Chemical, 99.9%), K2CO3 (Kojundo Chemical, 99.9%), and Nb2O5 (MCP Inc., 99.9). The powders were weighed to achieve the desired compositions and mixed by ball milling in an anhydrous ethanol solution for 24 hours. To enhance the homogeneity of the composition, the mixtures were calcined at 850℃ for 2 hours. The KCT powder was also prepared by using the solid state reaction method using K2CO3, CuO (Kojundo Chemical, 99.9%) and Ta2O5 (Kojundo Chemical, 99.9%). The initial materials were weighed and mixed for 24 hours in an anhydrous ethanol solution. The mixture was calcined at 1,100℃ for 5 hours. The mixture of NKN and KCT powders was ground using ball milling in an anhydrous ethanol solution for 24 hours, and then granulated with polyvinyl alcohol as a binder. The granulation was then pressed into ceramic disks, 16 mm in diameter, at 1,500 kg/cm2. The green disks were sintered at the optimum sintering temperatures of 1,025-1,100℃ for 2 hours at atmospheric pressure. The sintered disks were polished, supplied with silver electrodes on the sides, and poled in a silicon oil bath at 120℃ under 3 kV/mm for 30 minutes. The bulk densities of the sintered ceramics were measured by the Archimedes method. The crystal structures were determined by X-ray diffraction (XRD, D-max 2200; Rikaku) measurements that were utilized to determine the resultant phase. The sample microstructures were examined using scanning electron microscopy (SEM, JSM-6360; Jeol) and the compositional analysis of the selected areas was determined by using an attached X-ray energy dispersive spectroscopy (EDS, Oxford ISIS). The dielectric properties at the frequency of 1 kHz were measured by an impedance gain phase analyzer (HP-4194A; Agilent Technologies, Santa Clara, CA, USA). The electromechanical coupling factor (kp) and the mechanical quality factor (Qm) were measured using the resonance-antiresonance method with an impedance gain phase analyzer (HP-4194A, Agilent Technologies).

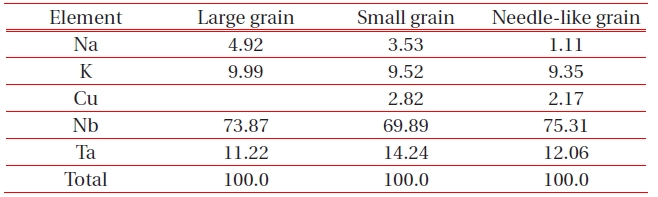

Figure 1 illustrates the XRD patterns of the (1-X)(Na0.5K0.5) NbO3-XK5.4Cu1.3Ta10O29 (NKN-KCT) ceramics, sintered at 1,050℃ for 2 hours. The position of the (111) peak was shifted to lower angles with an increasing X. It was thought that the geometrical distortion of the ceramics was induced by the substitution of part of the KCT for the NKN. In the composition of 0.25 ≤ X ≤ 0.5 mol%, a homogeneous orthorhombic NKN phase was well developed without a secondary phase. This would indicate that only a small amount of the Cu2+ in the KCT entered the NKN ceramic matrix. The radius of the Cu2+ (~0.72 Å) ion is similar to that of

the Nb5+ (~0.68 Å) ion, suggesting that the Cu2+ ion entered the B site of the perovskite unit cell and replaced the Nb5+ ion. However, when X exceeds the 0.5 mol%, a peak for the K5.4Cu1.3Ta10O29 phase, indicated by circle symbol, was observed. In addition, the NKN phase changed from orthorhombic to pseudo-tetragonal with increasing KCT content.

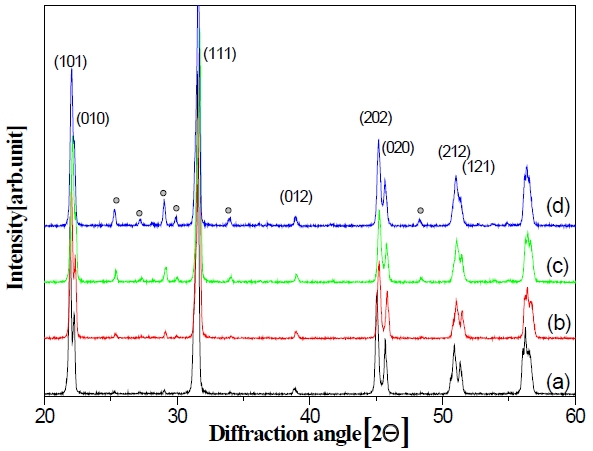

Figure 2 shows the density of the (1-X)(Na0.5K0.5)NbO3- XK5.4Cu1.3Ta10O29 (NKN-KCT) ceramics, sintered at various temperatures. As the amounts of KCT increased, the density improved from 4.43 g/cm3 to 4.76 g/cm3 by the addition of 1.5 mol% at 1,025℃ for 2 hours. However, the density decreased with a further increase in the sintering temperature, which was due to the volatility of the K and Na in the ceramics with a high sintering temperature.

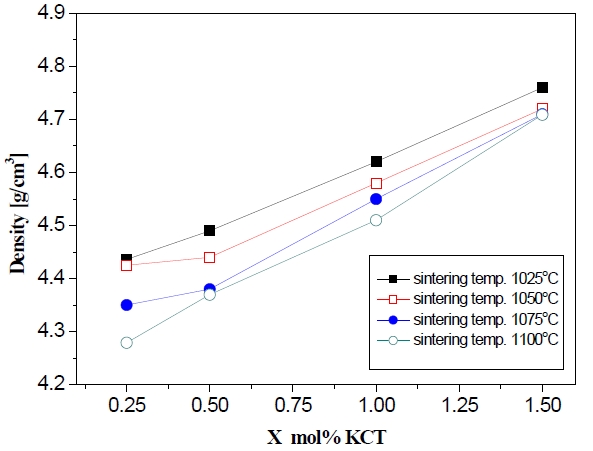

Figure 3 presents the microstructure of the (1-X)(Na0.5K0.5) NbO3-XK5.4Cu1.3Ta10O29 (NKN-KCT) ceramics, sintered at 1,050℃ for 2 hours. A characteristic quasi cubic morphology of the grain with a clear grain boundary was observed. The change in the microstructure may be due to the source of the liquid phase regarding Cu2+ in KCT, which was formed during the sintering process. With the addition of higher amounts of KCT, the optimum sintering temperature decreased and abnormal grain growth began. The average grain size increased upon increasing the KCT

content up to approximately 4.5 μm for the 1.0 mol% KCT.

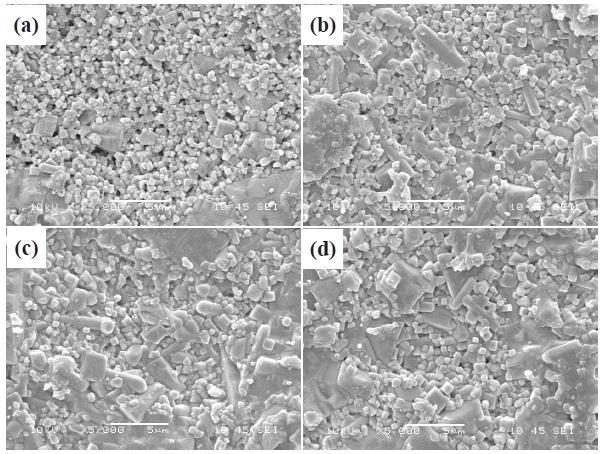

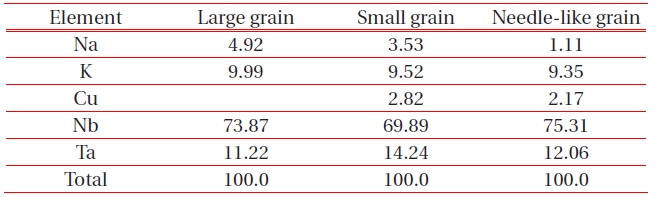

It is observed that there are three types of grains in Figs. 3(b), (c), and (d), the first one is the large grain (~5 μm), the second is the needle-like grain and the third is the small grain (<1 μm). The NKN-1.0 mol% KCT ceramics shown in Fig. 3(d) was subjected to EDS analysis in order to identify these three phases. The EDS analysis results in Table 1. The large grains contained Na, K, Nb, and Ta ions at a ratio similar to that of NKN-0.5mol% KCT. Na, K, Nb, Ta and Cu ions were found in the small and needle-like grains, but the amount of Cu ions was very large, suggesting that the liquid phase was a K5.4Cu1.3Ta10O29 phase.

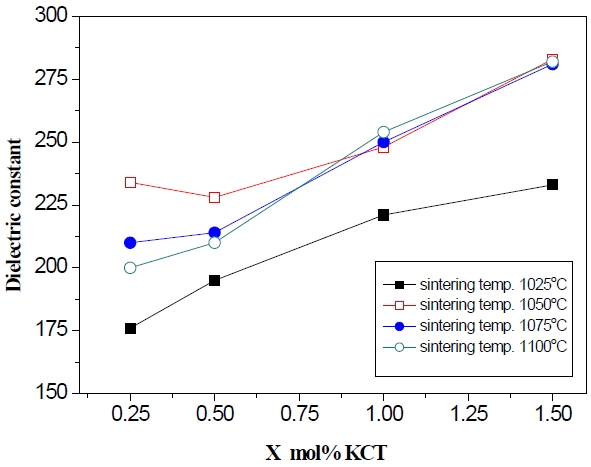

Figure 4 shows the dielectric constant of the (1-X)(Na0.5K0.5) NbO3-XK5.4Cu1.3Ta10O29 (NKN-KCT) ceramics, sintered at various temperatures. The dielectric constant of the ceramics increased with an increase of the KCT and sintering temperature; it reaches a maximum at X = 1.5 mol% at 1,050℃. In general, the dielectric constant is affected by not only the density but also the crystalline phase, chemical composition and microstructure [6]. The discrepancy in the dielectric constant contributes to the slightly different maxima and sintering temperature. These behaviors are probably correlated to the crystal symmetries done by the formation of the solid solution with a small amount of KCT.

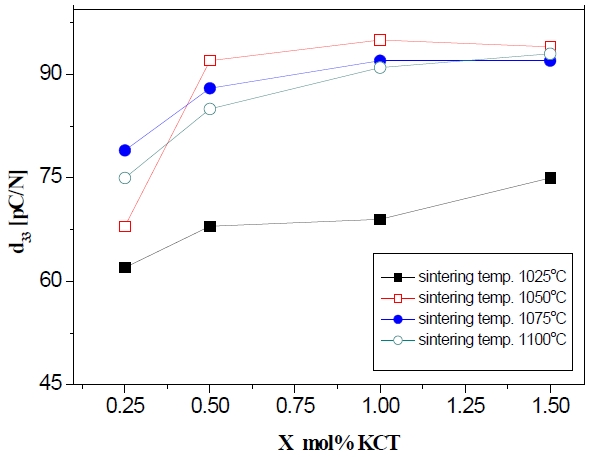

Figure 5 shows the piezoelectric constant d33 of the (1-X)

(Na0.5K0.5)NbO3-XK5.4Cu1.3Ta10O29 (NKN-KCT) ceramics, sintered at various temperatures. The piezoelectric constant d33 value was low at the sintering temperature 1,025℃, but increased with increasing sintering temperature and KCT content.; it reaches a maximum at X = 1.0 mol% at 1,050℃. The piezoelectric constant d33 value of the ceramics sintered at 1,075~1,100℃ increased at KCT ≥0.25mol% and reached a saturated value of 91~93 pC/N at KCT ≥1.0mol%. This improvement in the piezoelectric constant d33 value may have been due to the increased density.

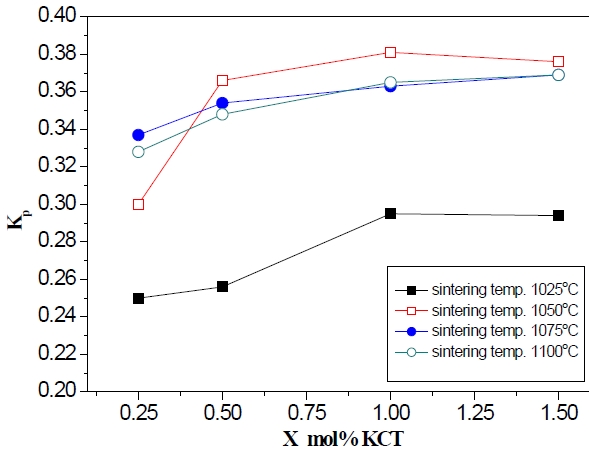

Figure 6 illustrates the electromechanical coupling factor kp of the (1-X)(Na0.5K0.5)NbO3-XK5.4Cu1.3Ta10O29 ceramics, sintered at various temperatures. The trends of electromechanical coupling factor kp with an increase of the KCT were similar to that of d33. The electromechanical coupling factor kp increased with an increase of the KCT and sintering temperatures; it reaches a maximum at X = 1.0 mol% at 1,050℃. This improvement in coupling factor kp value may have been due to the increased density [8,9].

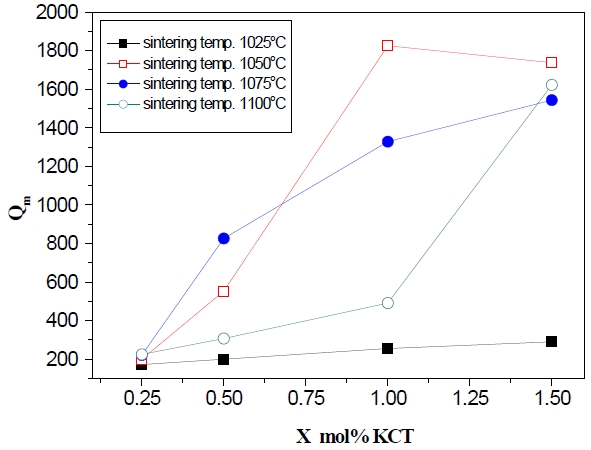

Figure 7 presents the mechanical quality factor Qm of the (1-X) (Na0.5K0.5)NbO3-XK5.4Cu1.3Ta10O29 (NKN-KCT) ceramics, sintered at various temperatures. The mechanical quality factor Qm also increased with an increase of the KCT. The mechanical quality factor Qm with 1.0 mol% KCT at 1,050℃ showed the highest Qm value of 1826. In regards to practical application, it is important to reduce the dielectric dissipation factor tanδ and enhance the mechanical quality factor Qm as much as possible in order to suppress the generation of heat during operation [3]. It was found that the addition of KCT was effective in increasing the Qm. We believe that the Cu ions entered the B site of the perovskite unit cell of the (Na0.5K0.5)NbO3-K5.4Cu1.3Ta10O29 ceramics and behaved as a hardener and improved the Qm value. When the KCT addition exceeds 1.0 mol% at the sintering temperature 1,050℃, however, the Qm tends to decrease, which may be the reason for

the secondary phase, as affirmed by XRD and SEM observations.

A small amount of KCT was added to NKN ceramics to increase their sinterability and to improve their piezoelectric properties. The Qm value increased when a small amount of KCT was added. The hardener effect of the Cu2+ ions was also considered to influence the improvement of Qm. The ceramic having X = 1.0 mol% sintered at 1,050℃ for 2 hours exhibited the superior piezoelectric properties of εr = 246, d33 = 95, kp = 0.38, and Qm = 1,826. These results show that the NKN-KCT ceramics are a promising lead-free piezoelectric material for piezoelectric applications.