Protection from hazardous materials is emerging as an important social issue since toxic substances and infectious bacteria threaten human health and the environment(Singh et al., 2001; Kenawy et al., 2007; Sun & Dave, 2005). The most commonly used antimicrobial agents are titanium dioxide(Kwon et al., 2003; Li et al., 2009; Tryba, 2008), halamine compounds(Sun & Sun, 2003), and quaternary ammonium(Tashiro, 2001). They are usually attached to the surfaces of substance and released slowly so that they can directly react with germs. Recently, among various antimicrobial agents, photoactive antimicrobial research has attracted increased attention as a clean technology(Mills & Hunte, 1997). The chromophoric group of organic photosensitizers such as benzophenone are commonly used as photosensitizers. The carbonyl group of benzophenone generates free radicals through UV irradiation. The triplet structure can be easily quenched with oxygen; in addition, it extracts a hydrogen atom from any active hydrogen sources to form a ketyl radical. Harmful materials in contact with the ketyl group are oxidized and destroyed(Hong & Sun, 2009; Hong & Sun, 2007). Our previous study(Lim & Oh, 2011; Lim et al., 2012) found that polymers containing organic photosensitizers provided good antimicrobial properties. Photoactivity and mechanical properties of film containing various photosensitizers were significantly affected by type, the amount of photosensitizer, and contact areas.

Leather has various properties such as durability, elasticity, plasticity, resistance to perspiration, slipperiness and stiffness (Sundar et al., 2006). Generally leather goods were produced by a series of successive preparation processes such as pre-tanning operations to clean the hides or skins, tanning to permanently stabilize the leather, and finishing operation to protect the leather surface and give more favorable tactile touch. The tactile sensation of leather is related to the comfort, style, and appearance of clothing. The fabric hand is closely related to consumer needs demanded by the market. Therefore, several finishing techniques and coating materials have been continuously developed since final finishing process give significant effect on consumer preference. Among many coating materials, polyurethane(PU) dispersions are the most popular coating materials in leather finishing due to their excellent properties against abrasion and chemicals(Hong & Sun, 2010). In additions, in order to improve the functionality of leather in various aspects, some functional additives were applied to the surface of leather during the finishing process, the final leather products would have desired functions on the surface.

In this study, leathers containing organic photosensitizers by coating method were investigated to demonstrate antimicrobial properties through the application of the material protective clothing and home furnishing. Photosensitizers such as benzophenone(BP), 4,4’-bis(dimethylamino) benzophenone(MK), 4,4’-dihydroxybenzophenone(DHBP) and methylene blue(MB) were used by selecting materials. The materials were dissolved with 1-propanol and distilled water in order to measure UV/V is absorbance. The morphology of the leather were confirmed by Scanning Electron Microscope(SEM) and the color change of materials was detected with CIE L*a*b* colorimetric system. Finally, an antimicrobial test(JIS Z 2801) was utilized to evaluate the antimicrobial activity of the leather.

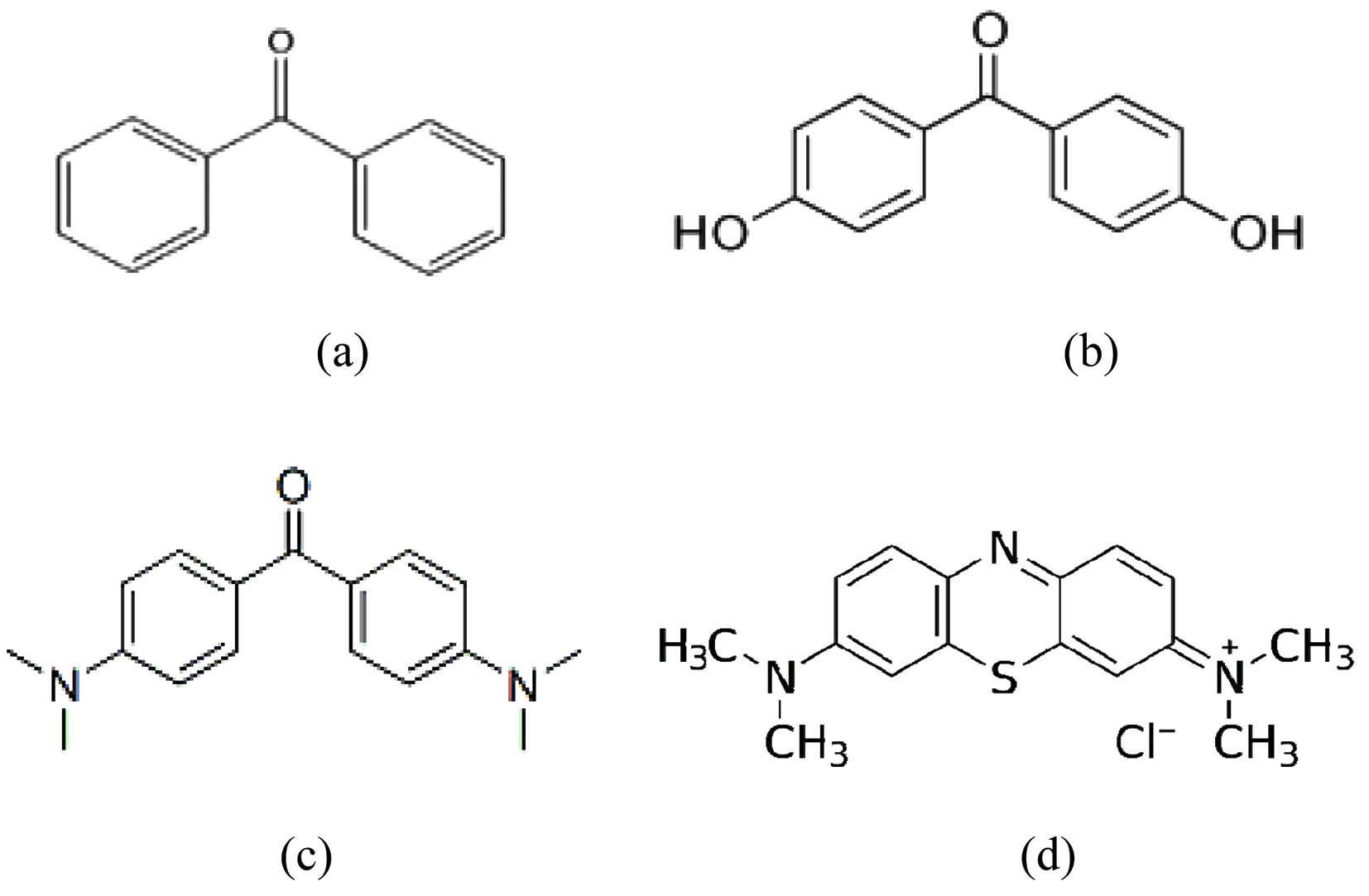

Organic photosensitizers(PS) such as benzophenone(BP, 99% pure), 4,4’-bis(dimethylamino) benzophenone(MK, 98% pure) and 4,4’-dihydroxybenzophenone(DHBP, 99% pure) and methylene blue(MB) were used after purchase from Sigma-Aldrich Co. (Fig. 1). 1-propanol (99.5%, Cas no. 71-23-8) (a solvent of organic photosensiters) was purchased from Junsei Chemical Co. Leather (grade c) and PU-based solution were purchased from Samang- Tongsang Co.. PU-based solution was made up some materials such as silicon wax, polyurethane and union compact binder.

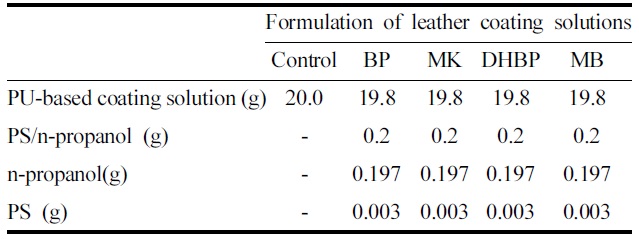

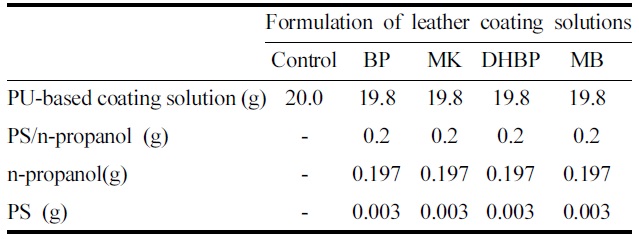

Unfinished leather was cut into 30×30 cm2 and the surfaces were cleaned by air compression. PS and PU-based solutions were prepared by in Table 1. After pre-experiment, optimum concentration of 1.5 wt% PS were added to the PU-based solution. The PU-based solutions with/without PS were coated to the surface of the unfinished leathers by spray method in an approximate amount of 5.0 g

[Table 1.] Preparation of PU solution containing the organic photosensitizers

Preparation of PU solution containing the organic photosensitizers

per 900 cm2. The coated leathers were placed in roller convection oven at 80℃ for 40sec. Then the leathers were dried in atmospheric condition for 24 hours.

The UV/V is absorbance of each material was measured with a UV/V is spectrometer(Scinco Co., S-4100, Korea) that ranged from 200 nm to 800 nm. The morphology of the leather was measured with field-emission scanning electron microscopy(JEOL, JSM-6701F). The color measurements of the leathers containing organic photosensitizers were examined with a color spectrophotometer( Scinco Co., color mate). Color changes of the leathers according to each photosensitizer were reported with a CIE L*a*b* colorimetric system. Reference illuminant was D65(standard daylight) and observer angle was Diffuse/10° (illumination/measurement). The wavelength ranged from 400 nm to 700 nm. An average value was taken from the 5-measurements. The color fastness to crocking of the leather was confirmed to the tendency of colorants to migrate from a test material as a result of rubbing by AATCC 8.

Lastly, Antimicrobial properties of the PS coated leather were measured against

Next, the PS coated leathers were immersed in a 20 ml quenching solution (distilled water) and 1 ml of the solution was put in a test tube with a 9 ml saline solution in order to dilute the microbes. Then 1 ml of the diluted microbial solution was taken by micropipette and poured in new Petri dish with a growth medium. The bacteria were incubated at 37℃ for 24 hours and the bacteria means were measured by a colony counter.

(Ma: average number of bacteria in reference sample immediately after vaccination of testing bacteria

Mb: average number of bacteria in reference sample after incubation for 24 hours

Mc: average number of bacteria in antimicrobial sample after incubation for 24 hours)

Ma is the value as average number of bacteria in reference sample immediately after the vaccination of testing bacteria and is a standard to confirm activity change in comparison with Mb as average bacteria number in reference sample after incubation for 24 hours. If the value of Ma is lower than that of Mb, the measurement of sample is confirmed to fail by nature reduction due to the external environment. The equations of antimicrobial activity (S) and degree of reduction (%) are a system to measure in comparison with reference and antimicrobial samples after incubation for 24 hours; however, Ma is not used in the equation and is only included as a point of reference for the test.

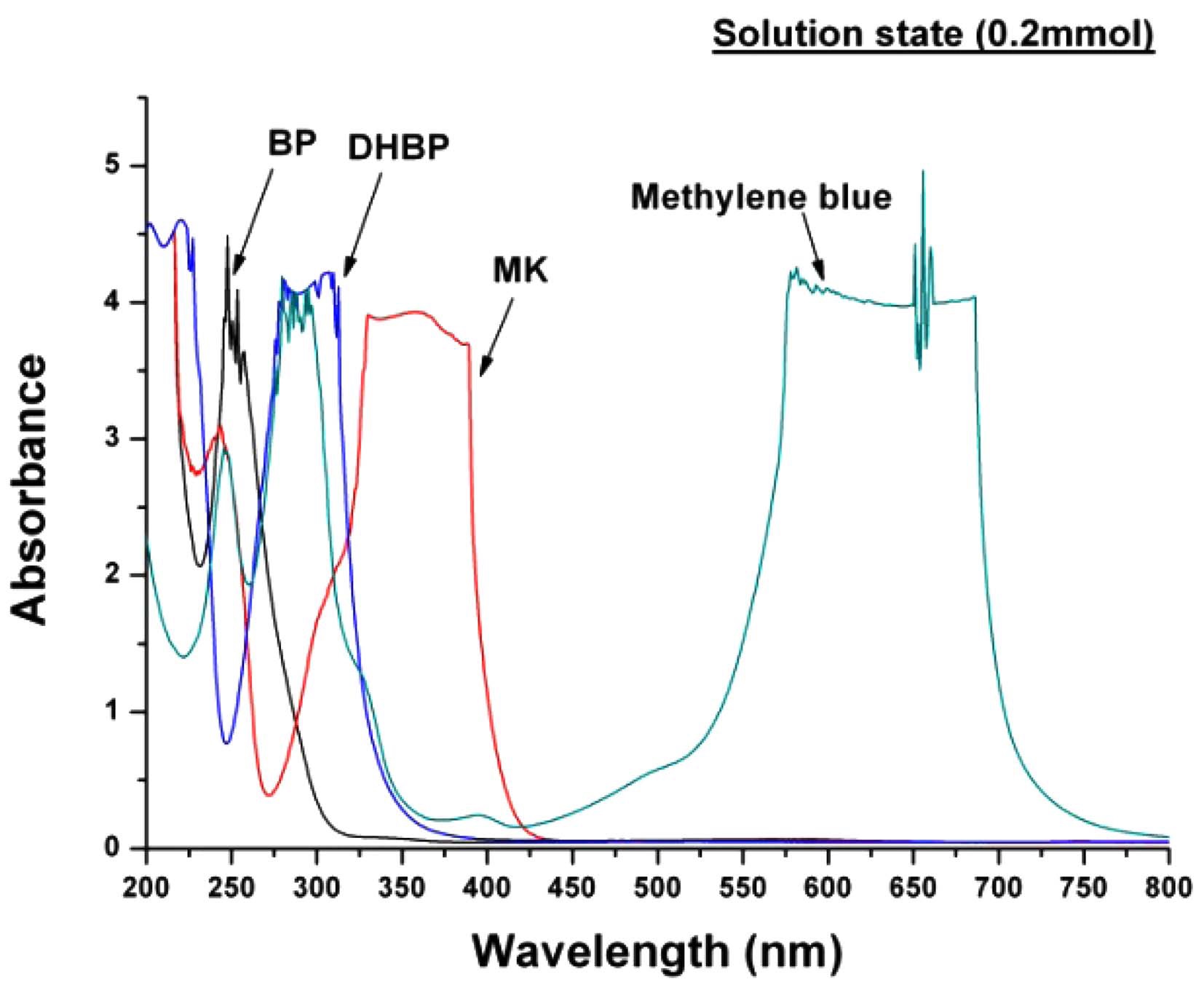

3.1. Optical properties of organic photosensitizers

The UV/V is spectra of BP, MK, DHBP and MB selected as organic photosensitizers is shown in Fig. 1. The materials were dissolved in an1-propanol to measure the light absorbance that ranged from 200 nm to 800 nm. Absorbance peak wavelength and intensities of BP (around 250 nm), MK (360 nm), DHBP (305 nm) and MB (295 nm, 570-685 nm) were observed. The intensity of the UV absorbance at the wavelength of UVA (315-400 nm) light used for the antimicrobial test showed the highest value with MK; this was

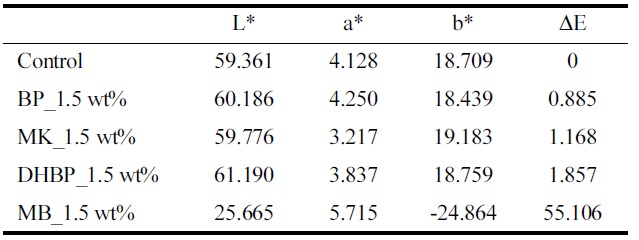

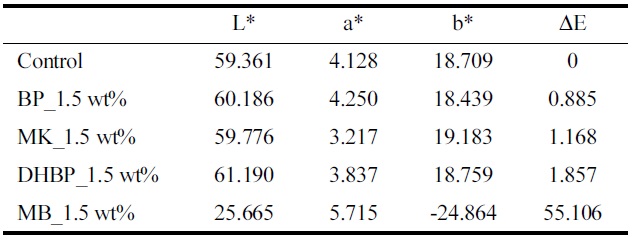

CIE L*, a*, b* colorimetric system of pristine leather and leather containing photosensitizers; BP, MK, DHBP, and MB

followed by DHBP, MB and BP in decreasing order. This greater intensity of UVA absorbance peaks for MK, DHBP, and MB than that of benzophenone (Fig. 2) demonstrates hyperchromic effect of substituents.

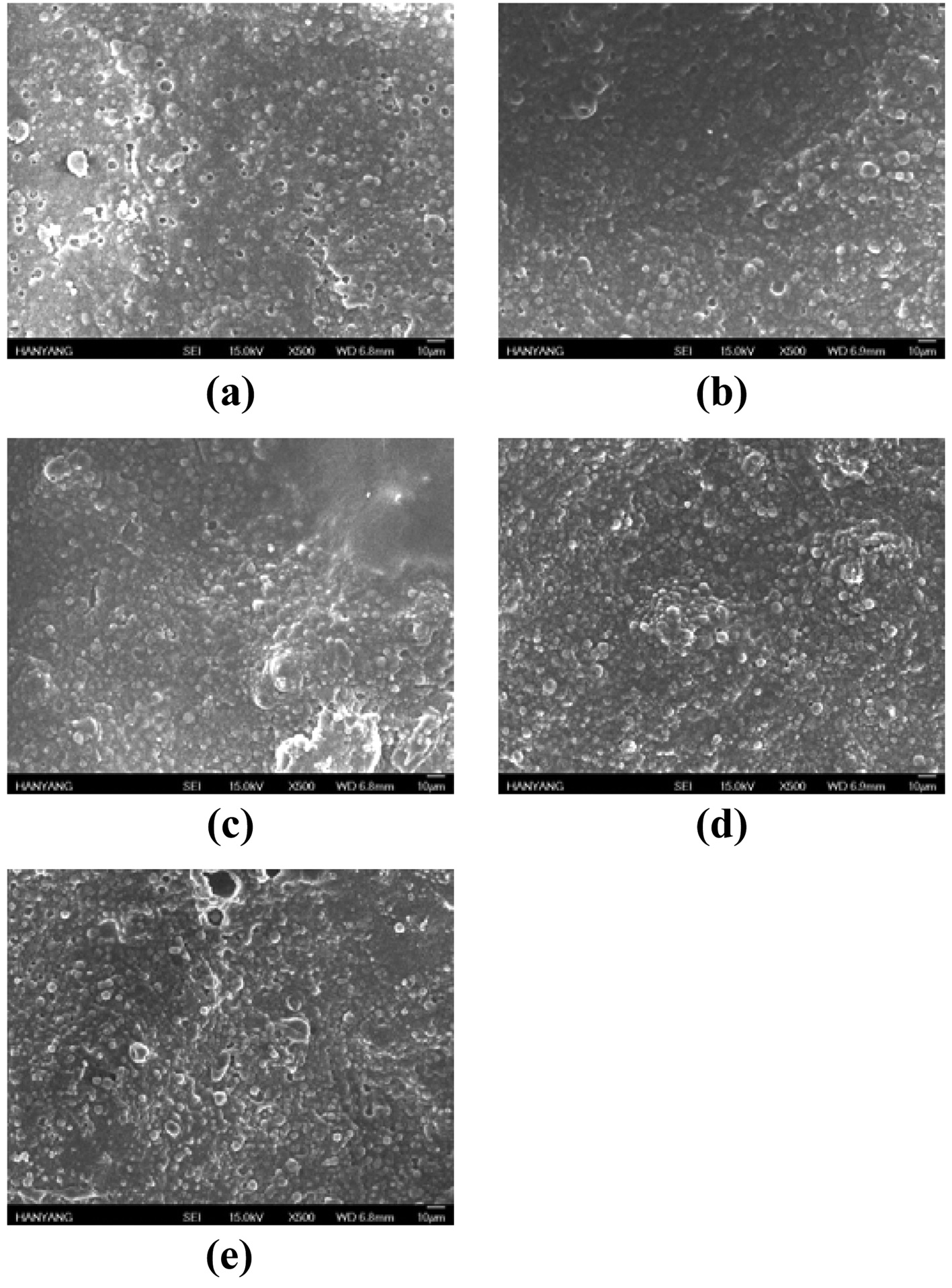

3.2. Surface morphology and color appearance

The color change of the leather that contains organic photosensitizer is presented in Table 2. The lightness (L*) of the leather containing BP, DHBP and MK shows similar higher values than the pristine leather; however, the lightness of MB is darker than other materials because of blue coloring. The a* value of all materials except DHBP is higher than that of pristine leather (target) and then shows indicate a dark redish color. Also the b* value of MB shows lowest negative value along the materials. The leather containing MB has the dark bluish color. Therefore the color of the leather is associated with wavelength of the UV/V is spectra.

Fig. 3 shows the morphologies of the control leather (only PU-coated) and sample leathers that contain various organic photosensitizers.

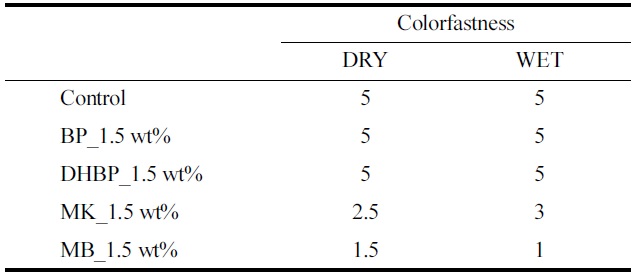

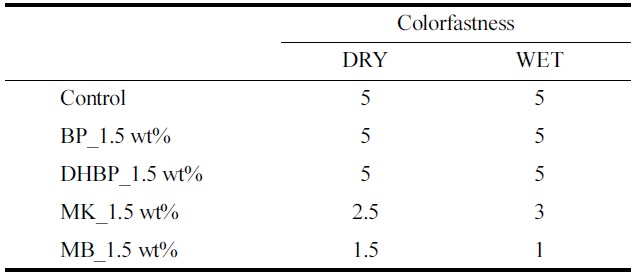

Color fastness to crocking of the leathers that contain photosensitizers; BP, MK, DHBP and MB

It was found that the surface of leathers containing organic photosensitizers became uniform and non-porous nearly. Also it confirmed that organic photosensitizers were distributed evenly on the leather.

The color fastness to crocking of the leather that contains organic photosensitizer is presented in Table 3. The system was measured as dry and wet methods and used by 9 step chromatic transference scale from AATCC in order to evaluate. The photosensitizers such as BP and DHBP didn’t transfer color to the white test cloth by both dry and wet crocking. However photosensitizers such as MK

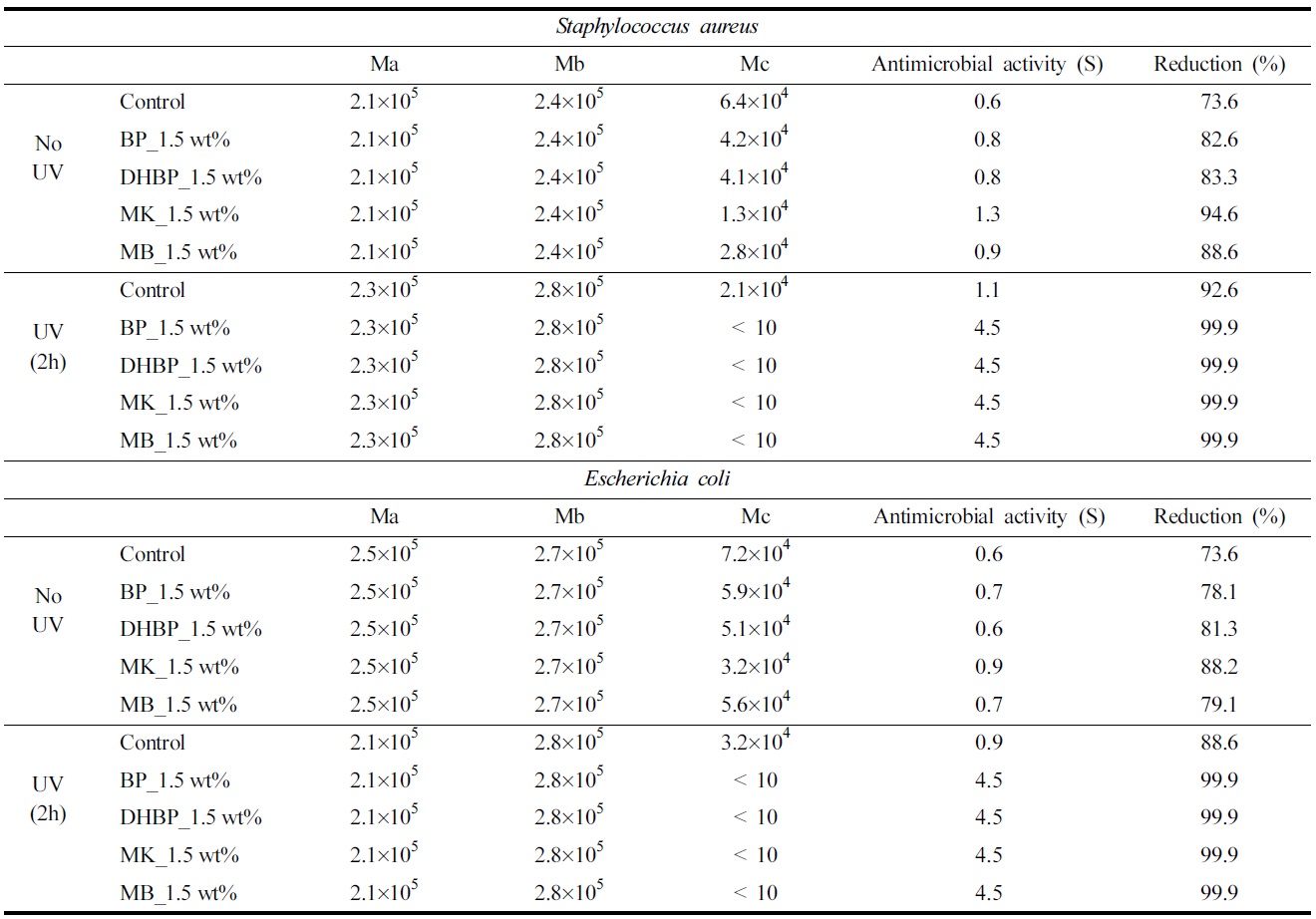

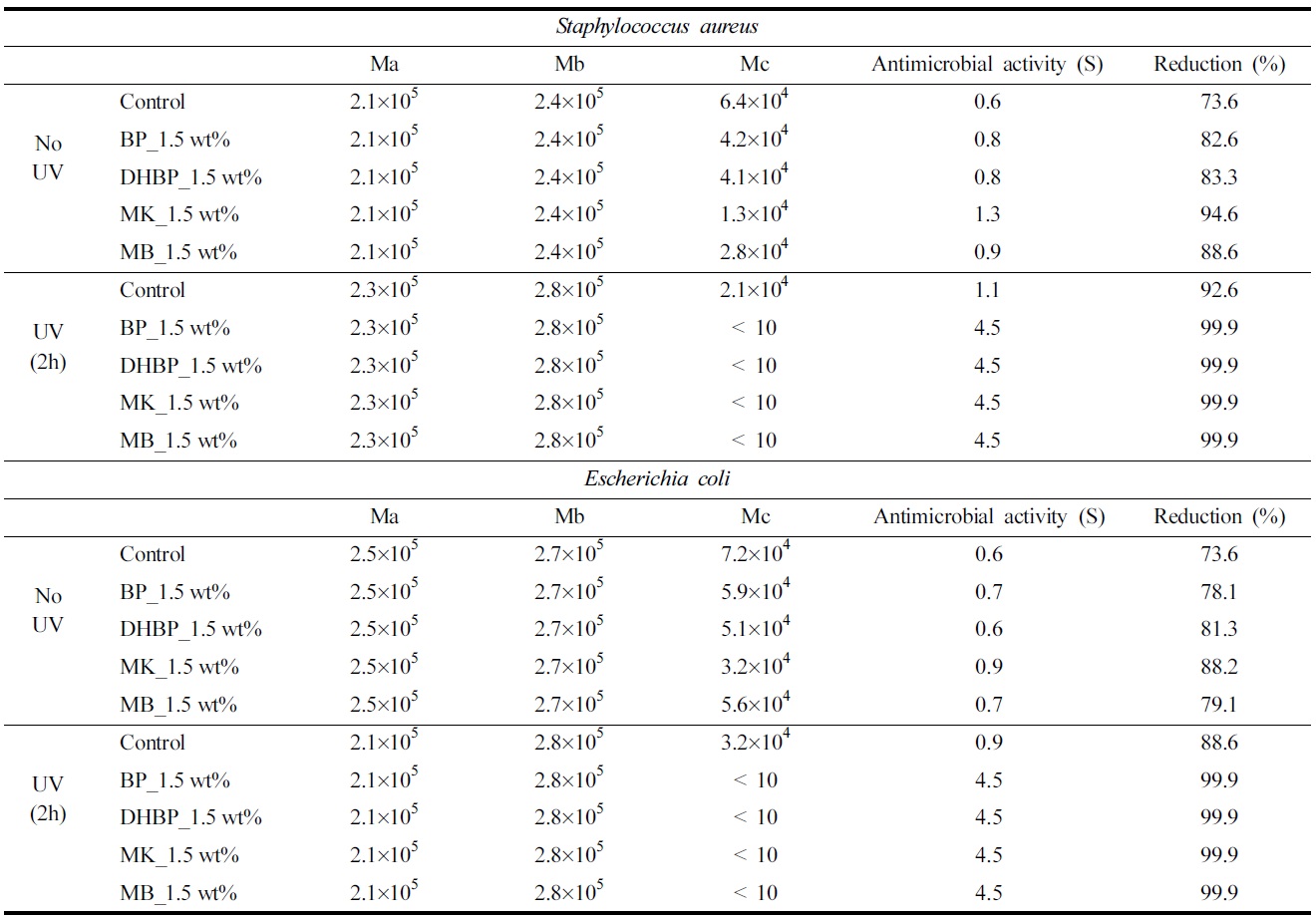

Antimicrobial test results of the leather that contain various photosensitizers (1.5 wt%) with UVA irradiation for 2 hours

and MB showed that they couldn’t be adhered to the leather completely, resulting in color change by abrasion.

Antimicrobial properties of leathers that contain various photosensitizers were evaluated and the results presented in Table 4. It was found that antimicrobial properties of the leathers that contain organic photosensitizers are superior to pristine leather by irradiating UVA light. Most likely, biological agents and toxic materials serve as sources of active hydrogen that result in an antimicrobial effect; subsequently, the materials containing a photosensitizer would be easily excited to the radicals that can decompose bacteria when activated by UV light. The carbonyl group in photosensitizer generates a free radical in the triplet state by UV irradiation and the ketyl group attracts H atoms to form suitable hydrogen donors. The antimicrobial effects for the

Self-decontamination materials were developed with organic photosensitizers in this study. Four photosensitizers with the excellent photoactive efficiency were coated on leather with PU-based solution. The optical properties of organic photosensitizers indicated that active UV absorbance ranges were different; BP (around 250 nm), MK (around 360 nm), DHBP (around 305 nm) and MB (around 295 nm & 570 nm-685 nm). The intensity of the UV absorbance curve at the wavelength of UVA light used for the antimicrobial test showed the highest value with MK; this was followed by MB, DHBP and BP in decreasing order. The lightness (L*) of the leather containing BP, DHBP and MK shows similar higher values than the control leather; however, the lightness of MB is darker than other materials because of the dye. The surface of leathers containing organic photosensitizers became uniform and non-porous nearly. The BP and DHBP didn’t transfer color to the white test cloth by both dry and wet crocking, whereas, MK and MB didn’t. Antimicrobial properties of the leathers that contain organic photosensitizers are superior to control leather. The overall results indicated that DHBP is the most suitable PU coating additive to provide antimicrobial properties to leather as well as color and surface appearance than MK, MB, and BP. The coated leathers that contain effective photosensitizers have a strong potential to protect human health from pollutants and bacteria through the application to various fields such as clothing, bag, shoes and industrial materials.