Flexible transparent conducting films (TCF) are technologically important for future wearable displays. Although present indium-tin-oxide thin films have excellent electrical properties and high optical transmittance, their flexibility upon bending is extremely poor. Therefore, development of an alternative material with high mechanical flexibility is highly desired. Carbon nanotubes (CNTs) have been recently proposed as a promising candidate to satisfy the desired flexibility, owing to their high aspect ratio and excellent elastic property, in addition to high electrical conductivity [1-3]. Consequently, the fabrication of flexible TCFs with CNTs has recently been carried out. These recent studies have shown that the electrical conductivity and optical transmittance of CNT films varies, depending on the coating methods and the intrinsic properties of the CNTs [4-14]. In general, the performance of CNT-based TCFs are typically governed by the inherent properties of the CNTs, such as purity, defect concentration, and electrical conductivity. Efforts have been made to associate material-induced factors with better TCF performance [1,15]. However, the characteristics of CNT-based TCFs are still not clear due to a lack of systematic studies on the relationship between preparation conditions and film properties. The performance of CNT-based TCFs depends strongly on the higher order structure of the CNTs, such as entangled and bundle structures. This feature could be evaluated while investigating the performance-determining factors for designing better TCFs.

We assume that the performance of CNT-based TCFs directly depends on the number of intersecting, interconnected CNT bundles, and the coverage of SWCNTs on the substrate. In this study, we microscopically and macroscopically evaluated the performance of TCFs to elucidate performance-determining factors, by using experimental results of single-wall CNTs (SWCNTs)-coated TCFs on flexible polyethylene terephthalate (PET) film prepared by dip-coating process [14].

Highly pure SWCNTs synthesized by arc discharge process were purchased from Iljin Nanotech. The SWCNT diameters were in the range of 1.4 to 1.5 nm with a length of 5 to 20 μm. Thermogravimetric analysis profile gave 1.3 wt% of metal catalyst.

The purified SWCNTs were well dispersed in 1,2-dichloroethane (DCE) solvent without additives [14,16,17]. The low vaporization temperature of DCE (83.5℃) allows more SWCNT to be deposited on the substrate. Ten milligram of SWCNTs were immersed in 100 mL of DCE solvent. These were then sonicated in a bath type sonicator for 500 min at room temperature, followed by centrifugation at a speed of 6800 rpm for 10 min. The supernatant was decanted and sonicated prior to film formation. The PET substrate was sonicated in acetone for 10 min and then washed with deionized water to clean the substrate surface. The PET substrate was vertically positioned above a container of the SWCNT-dispersed DCE solution and then immersed into the SWCNT solution for 2 s, and withdrawn upward, with a continuous speed of 50 mm/min. Then, the PET substrate was dried for 5 s. This procedure was repeated between 100 to 400 times. The dip-coating was conducted in a glove box in Ar atmosphere in order to avoid moisture adsorption into the DCE solvent.

Field emission scanning electron microscopic (FE-SEM) images of the SWCNT-based TCFs were obtained with a JSM-63301 (JEOL). Their electrical conductance was measured using a four-point probe method. Optical transmittance was measured using UV-visible spectrometry (Carry 5000) in the range of 400 to 800 nm.

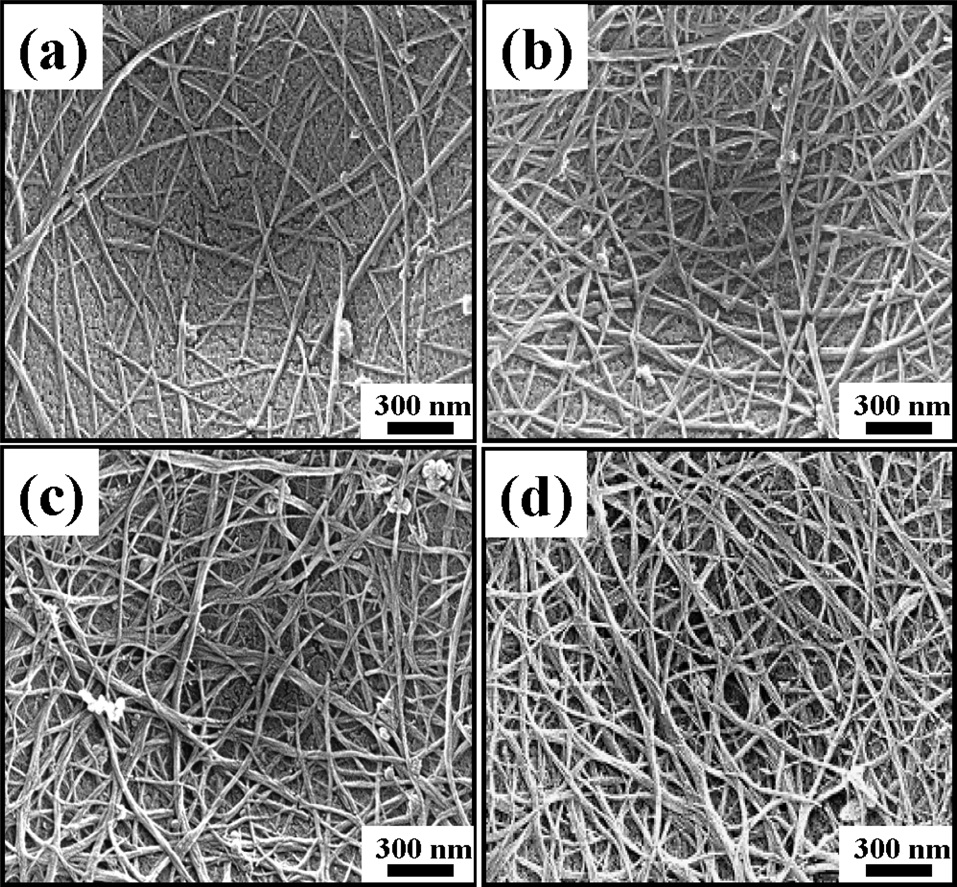

Fig. 1 presents the FE-SEM images of SWCNT network films on the PET substrate as a function of the different number of dippings. With increasing number of dippings, the amount of coated SWCNTs increases considerably. However, the coating of the PET substrate is not enough after a dipping treatment of 100 times, although the DCE completely wets the PET substrate.

The DCE solvent is easily evaporated from the substrate, depositing the SWCNTs film on it. The SWCNT film consists of a network having many intersection points. The intersection points in the TCF film are a crucial factor for good electrical conductivity of the film. The FE-SEM images of SWCNTcoated TCFs according to dipping treatment number show that the number of intersection points increases significantly with the number of dippings. The percolation threshold should reach a minimum amount of SWCNT deposits to maximize optical transmittance [18-20].

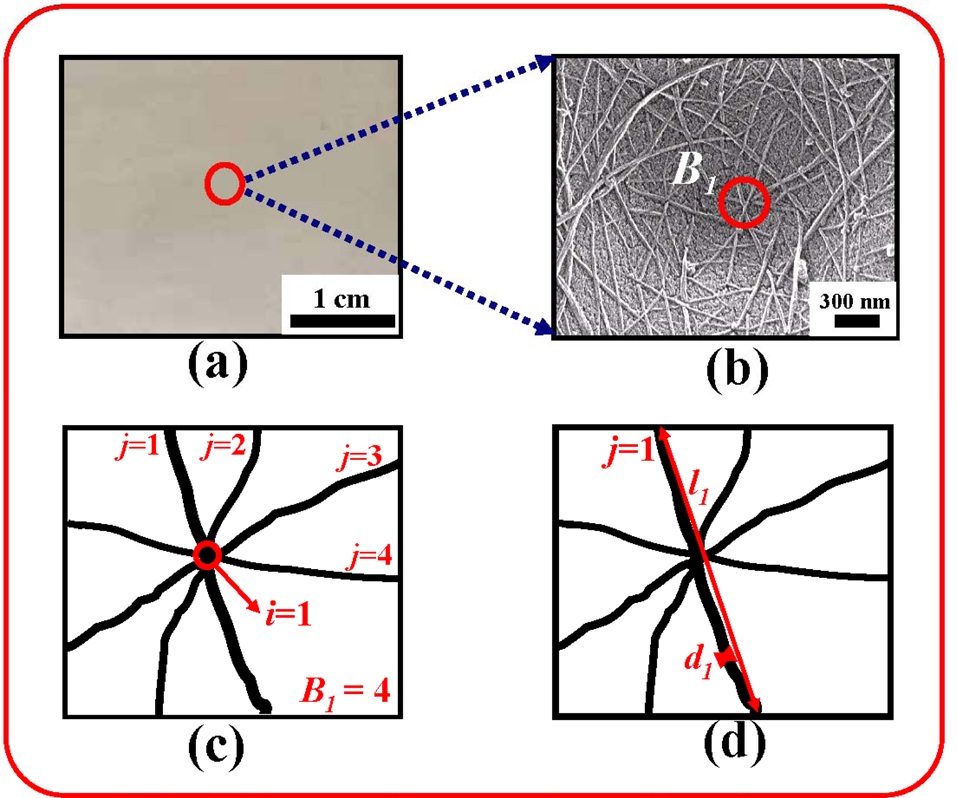

Fig. 2 shows a schematic representation for estimating the performance-determining factors of the TCFs using the observed FE-SEM images. Figs. 2a and b show an optical image and an

FE-SEM image after 100 dippings. We defined two factors that govern the SWCNT-TCF performance. First, the electrical conductance of the film is closely related to the intersection points in the SWCNT network; the electrical conductance of the SWCNT network film should be simply proportional to the number of intersection points of SWCNT bundles, and the number of SWCNT bundles that are interconnected at each intersection point. Therefore, we first define the conductance factor

where

where

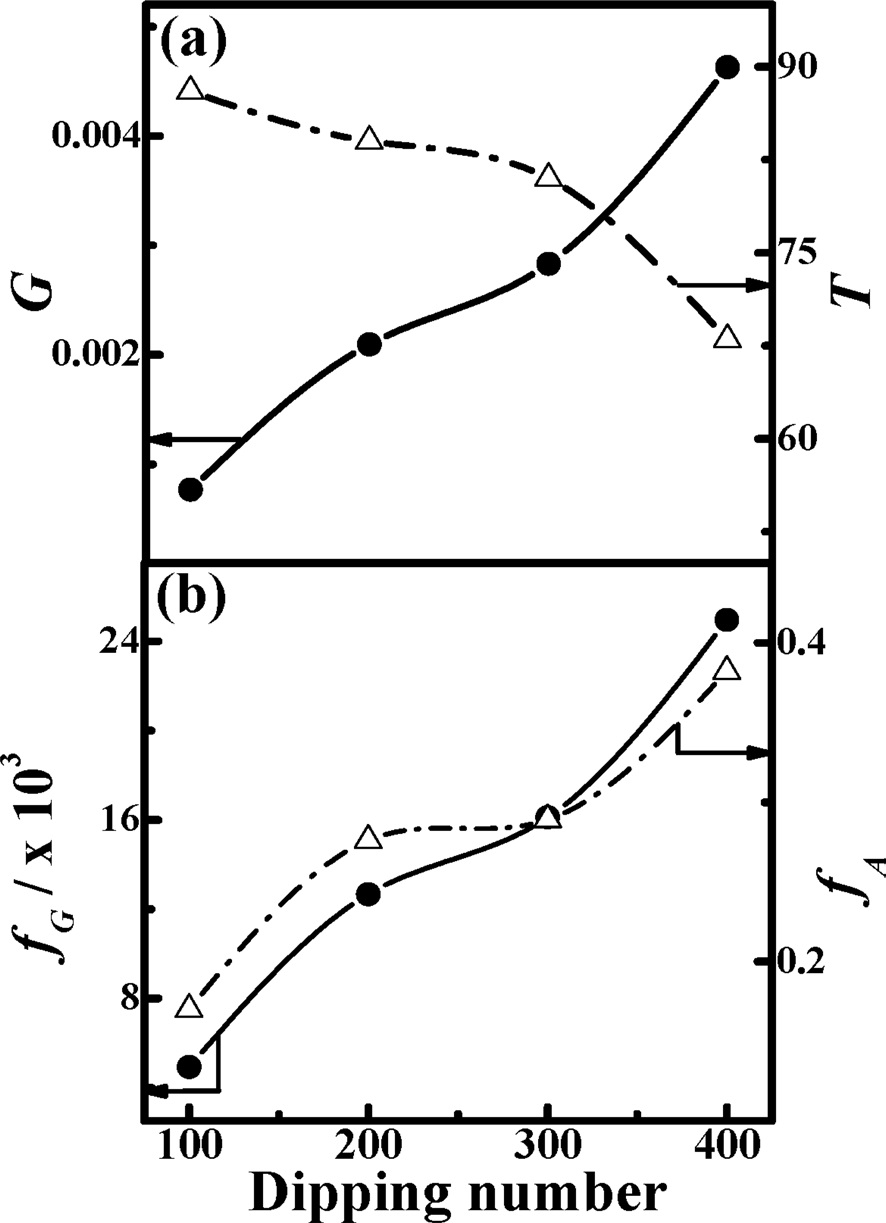

Fig. 3a shows the changes of electrical conductance (

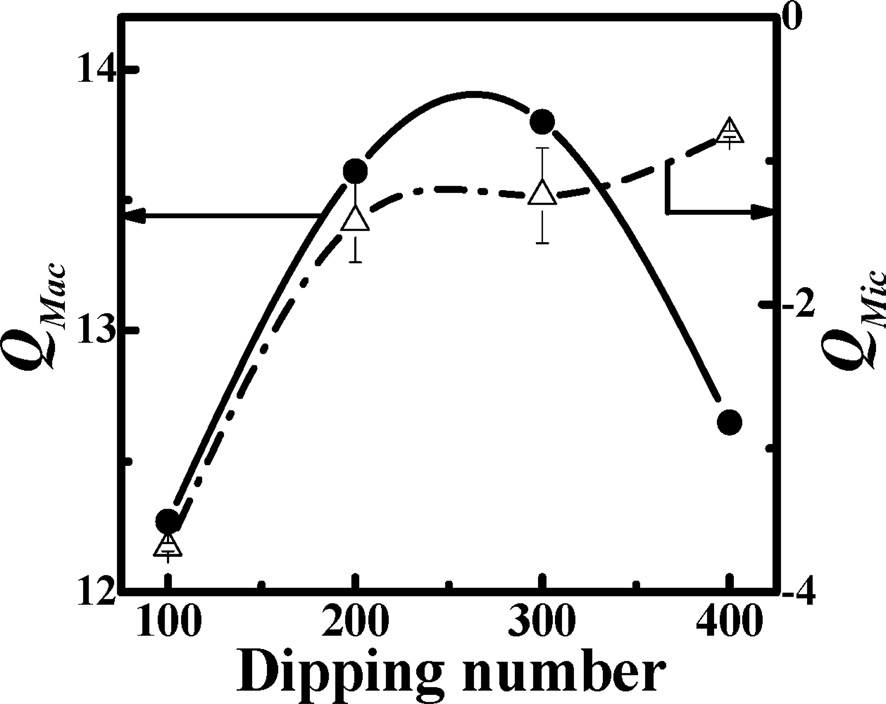

Fig. 4 presents the comparison of

In summary, SWCNT-TCFs were fabricated by dip-coating method. Our dip-coating approach provided reasonable quality SWCNT-TCF films. The film’s microscopic property factor was defined by the number of interconnected SWCNT bundles at intersection points, and the coverage of SWCNTs on the substrate, in FE-SEM images. The microscopically extracted film property factors are in good agreement with macroscopically obtained values, especially for a small number of dippings. Our results clearly revealed that a sparsely entangled random network structure with a sufficient number of intersection points and a minimum SWCNT coverage is a key factor for improving SWCNT-TCF performance. However, the dispersion of SWCNTs is also an important factor influencing SWCNT-TCF performance. Therefore, dispersing SWCNT bundles into individual SWCNTs, or into a smaller bundle size, is desired to improve TCF electrical conductance and optical transmittance.