In this paper, we discuss near-term prospective nuclear energy cooperation measures, related to the back end of the nuclear fuel cycle that may be implemented by the U.S. and the Republic of Korea (ROK) as part of a comprehensive program of long-term nuclear cooperation. These suggestions represent a perspective on near-term measures the ROK might consider to enhance its nuclear cooperation with the U.S. Korean experts may have a parallel suggestions; an exchange of opinions may eventually lead to mutually acceptable and practical cooperation. Importantly, none of these propositions prejudice the results of the extension of the agreement for nuclear cooperation between the U.S. and the ROK (the 123 Agreement) (1). Some of these proposals may be implemented independently of these discussions, and may enhance the prospects for a successful conclusion of the negotiations. We then suggest a joint long-term nuclear energy development program that will require changes to the current 123 Agreement. These changes are not imminent and may be worked into the extension Agreement as step-wise conditional modifications reflecting future trends in nuclear cooperation.

2. THE SPENT FUEL STORAGE PROBLEM IN ROK NUCLEAR POWER PLANTS

There are currently twenty-three operating nuclear reactors in the ROK, located at four sites. These reactors, at 20.7 GWe total generating capacity, provide 35% of the ROK’s electricity supply. The ROK’s goal is to have 40 reactors in operation by 2030, providing 59% of total generation. Four of the operating reactors are 700 MWe class Canadian type CANDU natural uranium heavy water reactors, the rest are mostly 1,000 MWe pressurized water reactors (PWRs) fueled with low enriched uranium oxide (LEU). A summary of the nuclear energy system of the ROK is shown in Figure 1 below (2).

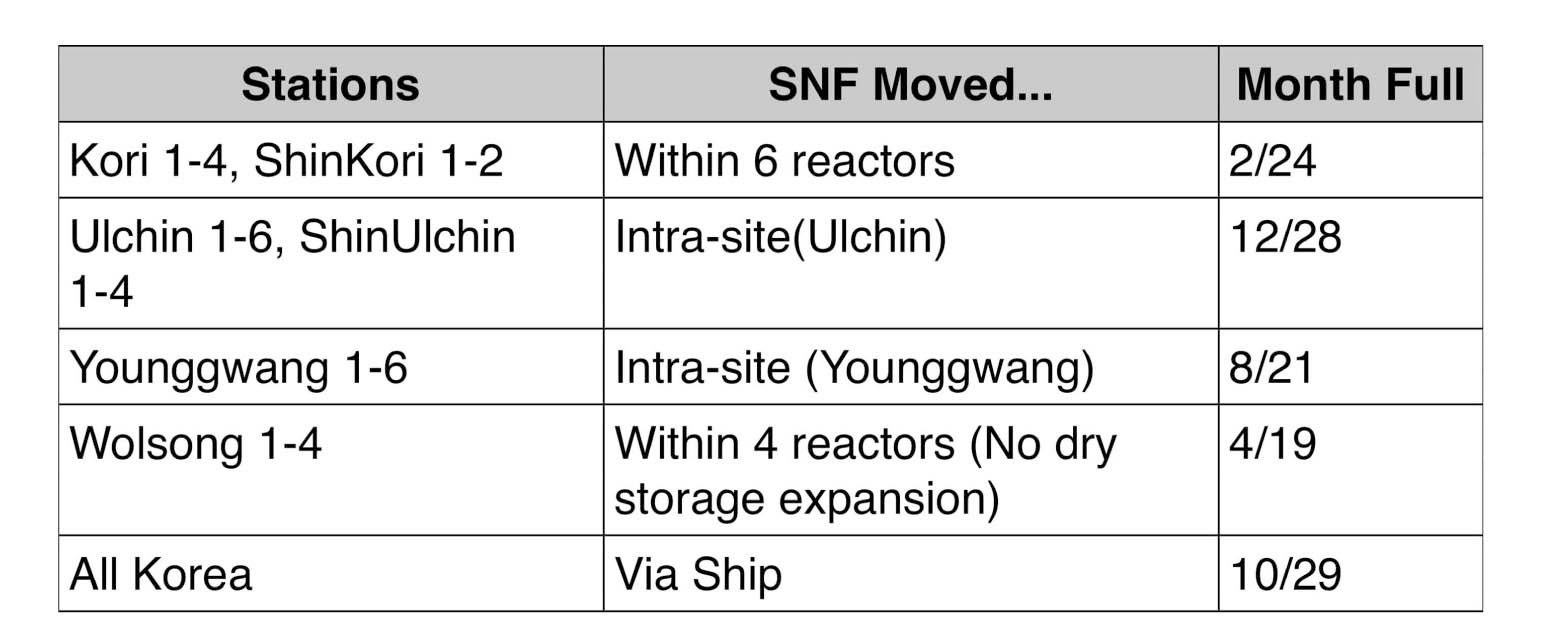

Currently, all spent nuclear fuel (SNF) from operating ROK nuclear power plants (NPPs) are stored on plant sites, mostly in the SNF pools attached to each reactor. This practice is referred to as on-site wet storage. It is expected that the SNF storage pools in these NPPs will be full (saturated) within the decade. The ROK may arrange for several additional years of pool storage via various mechanisms. For example, they may upgrade to high density racking of all SNF pools; ship SNF from saturated pools, to relatively empty SNF pools located on the same site; and they might transport SNF by ship between NPP sites. Fuel transshipment between NPP sites, each located in a different province of the ROK, requires logistical planning, regulatory approval, and consent of both province authorities ? a nontrivial bureaucratic hurdle. These temporary measures will eventually run their course, SNF pools will approach saturation, and the fundamental problem of SNF disposition will remain.

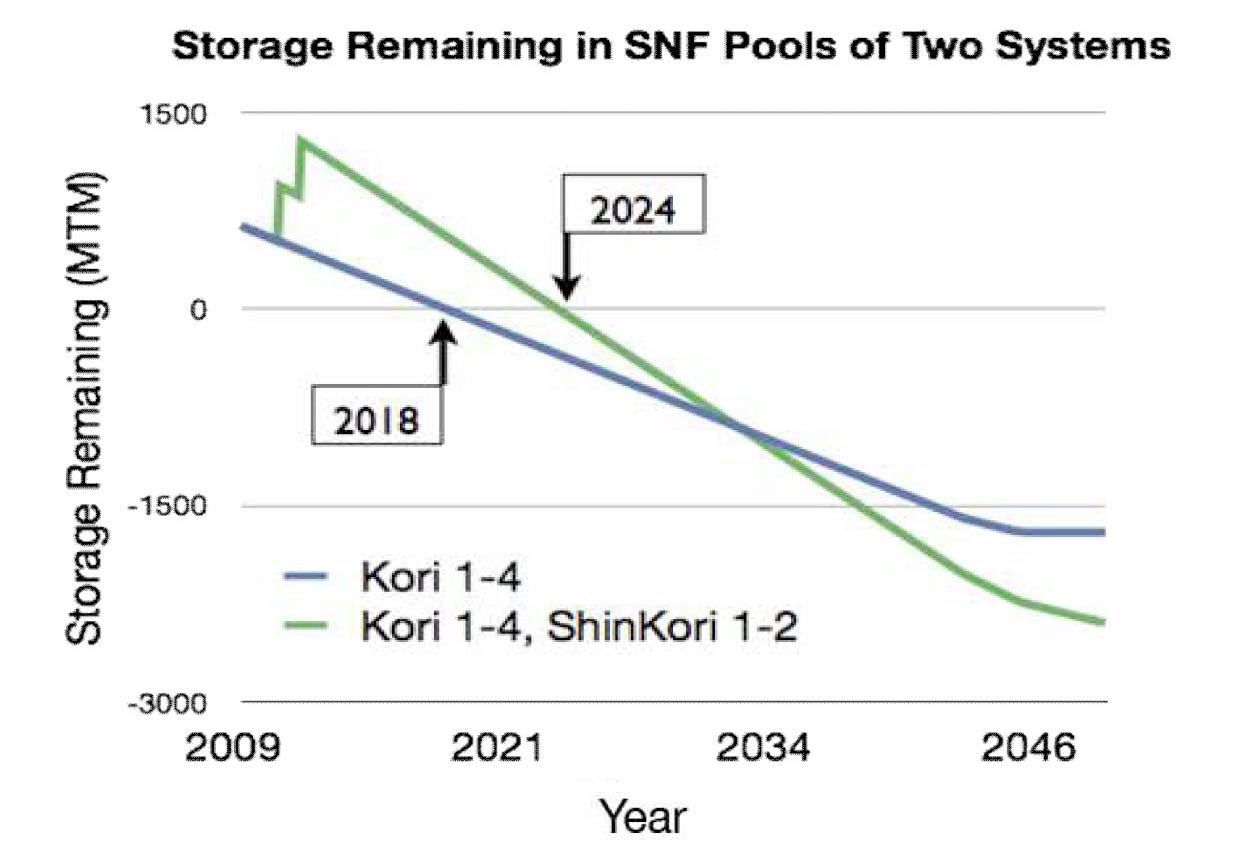

To demonstrate the saturation delay achieved using these enhanced on-site SNF wet storage techniques, we plot the space available in the SNF pools of two different scenarios or 'systems' at the Kori site in Figure 2. In the first scenario we allow transshipment of SNF between only the four oldest reactors, Kori 1-4; in the second scenario, we allow transshipment of fuel between six reactors, Kori 1-4 and the new Shin-Kori 1-2 (as they come online in 2011 and 2012 respectively). We assume historically reasonable fuel burnup, capacity factors and power levels as well as the best available information about pool capacity and inventory status. In the first scenario when transshipment is allowed only between the four reactors, the fuel pools saturate in 2018. In the second scenario, taking advantage of the two new fuel pools upon commissioning of Shin-Kori 1-2, pool saturation is reached in 2024. While immediate saturation is only mitigated by this scheme, it does serve to delay the problem by six years at the Kori site. If additional new units are commissioned at Kori, more pool space

will become available and more time may be gained by this scheme. However, in a short time those pools will also fill up.

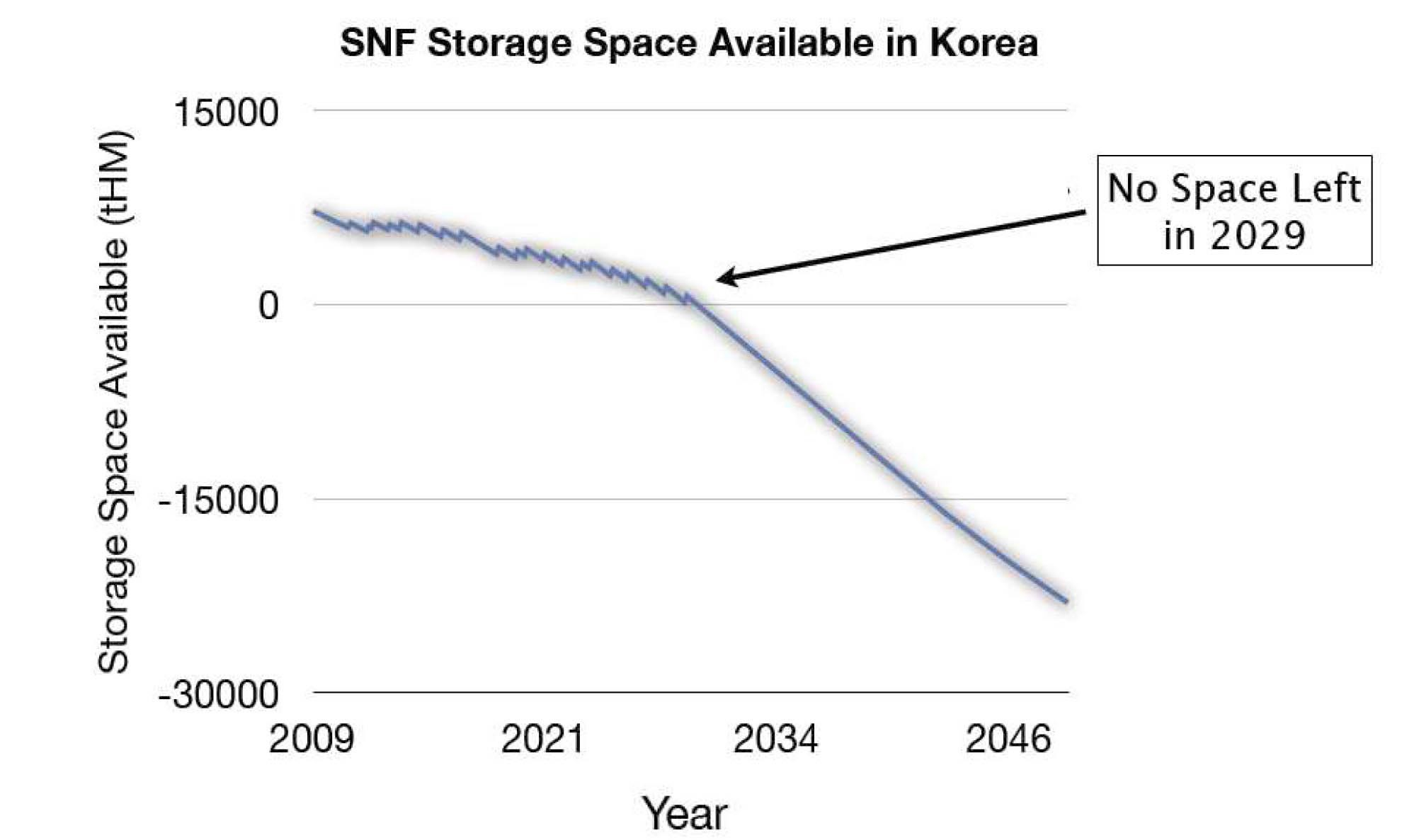

In general, utilities prefer leaving empty space in SNF pools rather than filling them to capacity with high density racking. Seismic stability and radiation minimization considerations from high-density storage dictate avoiding saturation. For operators, there is a balance between economics and operational flexibility. Given these considerations, it is not clear the ROK operators will support saturation of pools, and other solutions may be preferred. Our analysis, applied to all current NPP sites and considering spent fuel movement intra- and inter-site, indicates that even with free fuel movement throughout the country, the ROK will run out of wet storage space in all reactor SNF pools before 2030. This can be seen in Figure 3 for the ROK nuclear energy system as a whole, and considering specific sites in Figure 4.

Similar results to those shown in Figures 3 and 4 were independently developed by others (4). While exact numerical figures might vary based on technical assumptions, initial conditions and information available, the qualitative message is clear: the ROK will run out of wet SNF storage space in the next decade, and complementary options will be required.

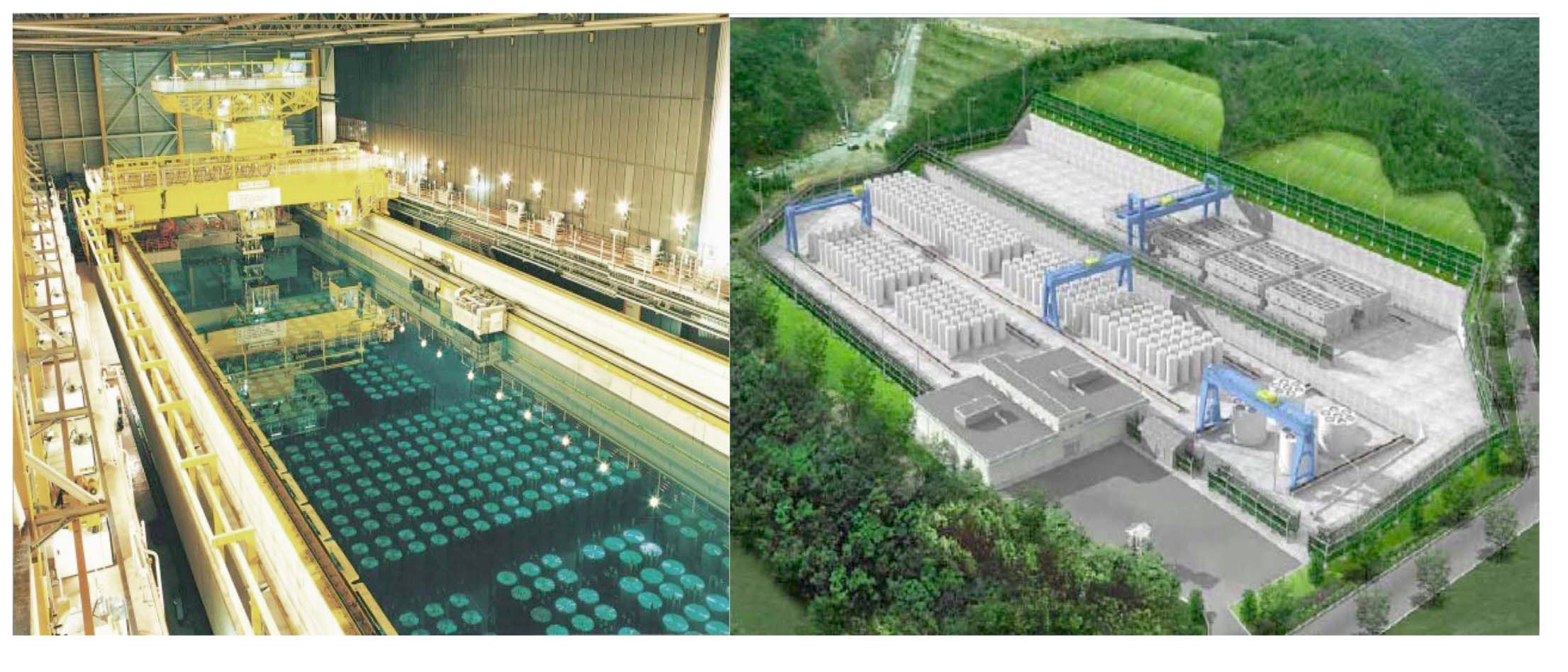

An additional option for handling excess SNF is construction of dry cask storage facilities on-site, and transport of SNF from wet storage pools to these dry storage facilities. However, not all NPP stations have adequate land on which such facilities may be constructed. Also, the local population

may object to such facilities, particularly if located close to communities. Resistance to on-site dry storage will be stronger if such facilities are perceived as permanent should no national nuclear waste repository program be developed. Nevertheless, on-site dry-cask storage facilities were licensed in the ROK for the NPP sites of Wolsong and Hanul (formerly Ulchin), and a limited dry storage program has been implemented in Wolsung. This facility handles low burnup CANDU fuel with lower radioactivity than higher burnup PWR spent fuel. Moreover, the smaller length of the CANDU assembly makes it easier to handle and store within a tall concrete silo. No PWR spent fuel assembles are currently stored in dry cask containers at ROK NPP sites. A schematic view of on-site wet and dry storage options is shown in Figure 5.

A typical 1,000 MWe PWR operating at about 90 percent capacity factor with a burnup level of 50,000 MWth- Day/MT will discharge about 20 MT of SNF per year. The 40 reactors planed by the year 2030 will annually discharge more than 1,000 MT of spent PWR and CANDU fuel. Given the above factors combined with the storage capacity of SNF pools, the current four sites along with an additional site to be opened by 2030 will be unable to contain all SNF accumulated by that point.

An alternative would be construction of a centralized away-from-reactors dry-cask storage facility in the ROK and transportation of SNF from NPP sites to this facility. Such centralized facility is referred to generically as an Independent Spent Fuel Storage Installation (ISFSI). A general discussion of the centralized dry cask storage option is provided in (5). Given that all ROK NPPs are located near the ocean, if overland transportation proved infeasible, SNF could be transported from NPP sites by ship (assuming such a storage facility were also located close to shore). For reasons mentioned above, public opposition might also plague a large national facility. While a low level waste facility was approved by the community and constructed at Kyongju /Gyeonju on the East coast, 370 km from Seoul (6), no similar site for centralized SNF or high level waste has been approved. The ROK recently announced plans for a dry cask centralized facility to be licensed and constructed by about 2020 (7). While there is no doubt as to the ROK's ability to design and construct this facility, no site has been selected, named or licensed. Furthermore, the ROK has no experience in constructing such a facility for high burnup PWR SNF.

3. POTENTIAL ROK ? U.S. COLLABORATION ON DRY-CASK SPENT FUEL STORAGE

The ROK will likely have to implement a centralized dry-cask storage program within the next decade, even with successful development of alternatives such as pyroprocessing (discussed later). It is logical then to take advantage of this unavoidable requirement.

With U.S. technical, licensing and operating experience support, the ROK could implement within the next ten years or so a centralized dry cask SNF storage demonstration program. In the subsequent decade this could lead to the construction of a large centralized ISFSI. The demonstration program we propose is limited to one small concrete pad on which approximately ten dry cask concrete storage silos would be constructed containing well-packaged SNF elements. The facility would be instrumented and monitored to analyze performance over time. The small dimensions of such a facility allow for it to be located in any remote area. Public opposition could be ameliorated by siting such a facility on a larger military reservation. The facility could be developed and constructed with U.S. help since the U.S. has accumulated significant experience in the design, licensing, construction and operation of such facilities for high burnup PWR fuel. The U.S. can contribute technical and operational data to such a program without jeopardizing the ROK’s long-term interest in pyroprocessing.

There are several advantages in developing a joint centralized storage program with U.S. collaboration:

First, the U.S. has significant experience with dry cask storage facilities. Although all U.S. dry cask storage facilities are located at NPP sites, such facilities are of the size of the ROK demonstration facility we recommend, so U.S. experience is highly relevant to a ROK program.

Second, the U.S. Nuclear Regulatory Commission (NRC) is interested in dry cask storage issues for U.S. NPPs in the post-Fukushima regulatory environment. This is based on the recommendations of the Blue Ribbon Commission on America’s Nuclear Future (BRC) The NRC is developing additional research and regulatory frameworks for dry cask storage (8) in which the ROK may be interested. A joint demonstration program will improve the regulatory and technical bases for an ROK program and would support the U.S. program as well.

Third, the ROK has embarked on a program to export reactor technology worldwide. The attractiveness of its commercial offerings would be enhanced if it were to offer a package of fuel cycle services, including dry cask storage, to the client country. To do this, the ROK must demonstrate it has mastered the technology in its own nuclear energy program. Collaboration with the U.S. will support developing such credentials. A successful ROK reactor and services export program with U.S. participation would benefit both parties.

Fourth, developing a joint dry cask storage program with the U.S. will have a positive impact on ROK-U.S. discussions on the extension of the 123 Agreement. The ROK's SNF policy is criticized because it is claimed to be pursuing pyroprocessing to the exclusion of other options such as interim storage. The ROK might strengthen its negotiating position if it were to present a more comprehensive and balanced program including a centralized dry cask storage component.

Just as the ROK and the U.S. have developed a joint pyroprocessing research program, it is to their mutual benefit to develop a parallel joint demonstration program for centralized dry cask SNF storage. Both the ROK and the U.S. could capitalize on the results of the BRC work which were recently embraced by Dr. Ernest J. Moniz the incoming U.S. Secretary of Energy as a basis for parallel and joint programs on spent fuel storage.

4. PYROPROCESSING AS A SNF MANAGEMENT OPTION

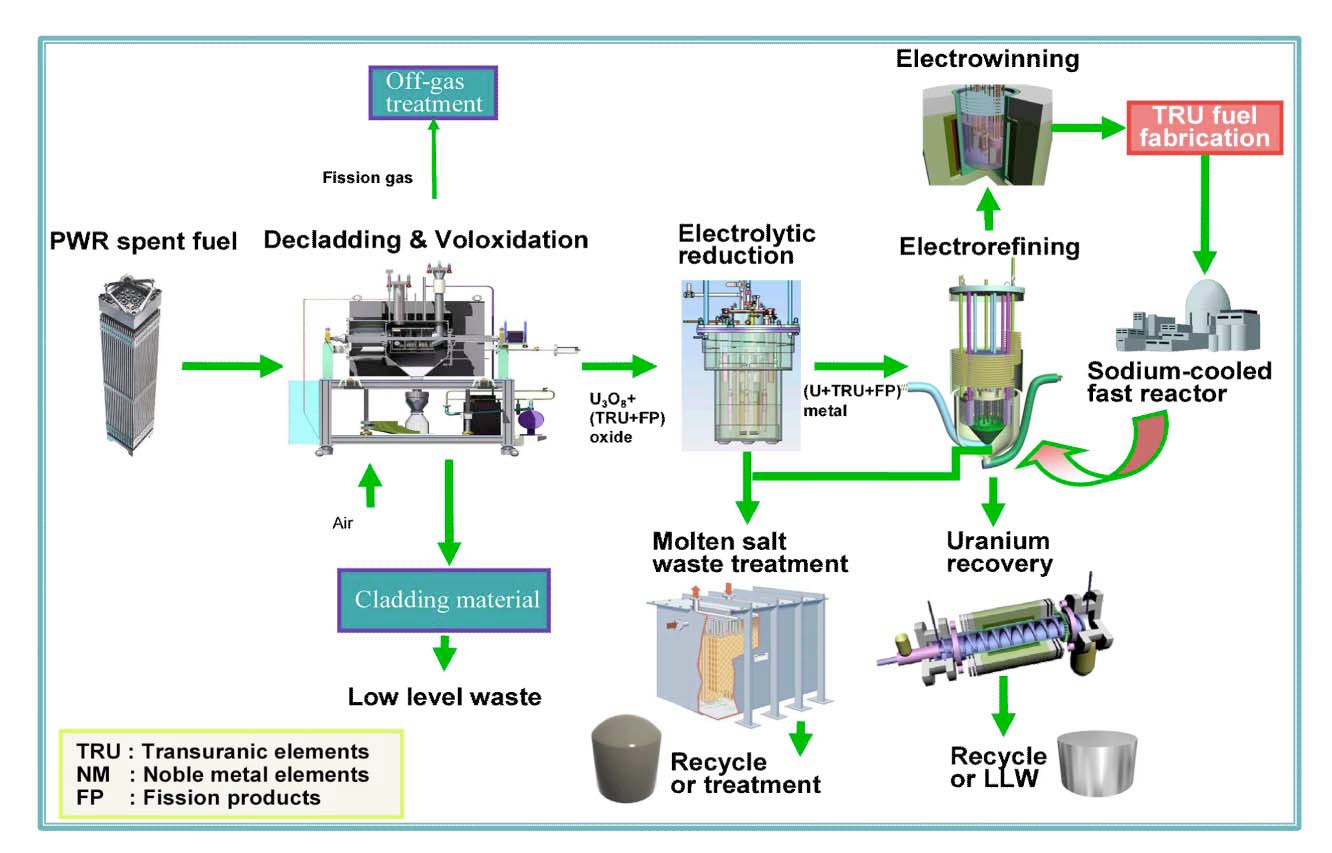

Reprocessing and refabricating fuel is another option to aid in SNF disposition. It entails recycling useful content of SNF back into operating NPPs and sending remaining high-level waste to a repository. A schematic depiction of a specific type of reprocessing, pyroprocessing and its role within a nuclear energy system is shown in Figure 6.

Reprocessing, specifically pyroprocessing in the ROK, is not a waste management solution in itself. Rather, it is an enabling technology. It is a step in producing a type of fuel ? a metallic mix of uranium and plutonium in a zirconium matrix that can be burned in sodium fast reactors (SFRs), more generally fast breeder reactors (FBRs). Pyroprocessing requires an additional fabrication step for the fuel, increasing the cost of the technology compared to the current once-through fuel cycle. Without a concurrent remote fuel re-fabrication and breeder reactor, pyroprocessing in itself will only partially ameliorate the SNF problem. In fact, pyroprocessed fuel alone will increase proliferation concerns: it will make the plutonium in SNF more accessible to proliferators, particularly in its metallic form, without the self-protection of the gamma radiation in the original SNF. Furthermore, fuel from pyroprocessing (U+Pu+Zr metallic fuel mix) is not suitable for recycling in PWRs as is the product of traditional (wet chemistry PUREX) reprocessing. Without concurrent availability of a fuel re-fabrication plant and a breeder reactor, pyroprocessing in itself is not an adequate solution to the SNF disposition problem.

A pyroprocessing plant is currently unavailable to the

ROK since enrichment and reprocessing (ENR) of nuclear fuel are prohibited under the current U.S. ? ROK 123 Agreement. The ROK is trying to free itself from this restriction in the upcoming revision of the Agreement based on two main technical arguments. First, reprocessing is necessary to reduce the volume of waste to be sent to the final repository and it mitigates the need to construct a large final repository. Second, reprocessing is required to recover fissile content of SNF and recycle it in fast breeder reactors. As mentioned above, fuel recycling in SFRs could guarantee long-term viability of nuclear energy, without dependence on imported uranium and enrichment services (10). The ROK is engaged in research and development of pyroprocessing. Indeed, the ROK and U.S. Governments have started a ten year review program of pyroprocessing to determine its technical and commercial feasibility (11). The final report is due by 2020. Basic research in pyroprocessing is now carried out in the PRIDE facility in the KAERI research center in Daejeon (shown in Figure 7 below). Both authors visited the PRIDE facility in January 2013 and were impressed with the significant amount of progress in the facility since its inception less than two years ago.

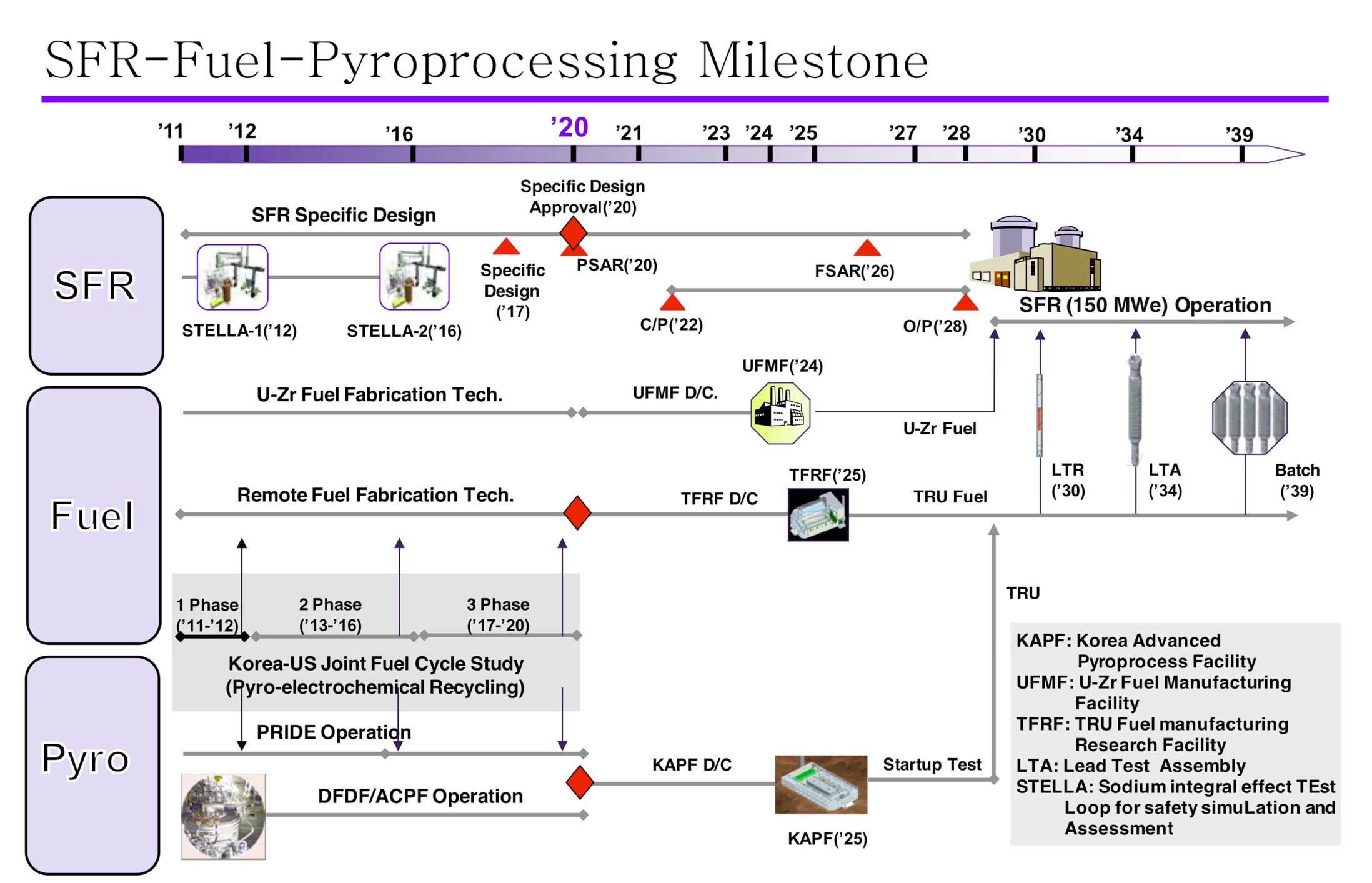

After the completion of the joint pyroprocessing study in 2020, the ROK plans proceed to the design, licensing and construction of a commercial demonstration plant with a capacity of 100 MT/Year, referred to as the Korea Advanced Pyroprocessing Facility (KAPF) (12), assuming that all the requisite approvals are obtained within the general framework of the 123 Agreement for Cooperation with the U.S. Formal plans call for commercial operation of the KAPF by 2028, just eight years after completing the joint studies with the U.S. conditional on U.S. acceptance mentioned above. In parallel, the ROK is planning a fuel refabrication effort and a 150 MWe Sodium Fast Reactor (SFR) by 2028. This plan is shown schematically in Figure 8.

Basing SNF disposal policy solely on concurrently

commercializing pyroprocessing technology (and related fuel re-fabrication and fast reactor systems) before 2030 is fraught with uncertainty. First, it is not clear that pyroprocessing will live up to its technical and economic expectations. Furthermore, the combined costs of pyroprocessing and remote metallic fuel re-fabrication might exceed the costs of nuclear fuel supply at the front-end of the current PWR fuel cycle. Second, even if suitable, it would take at least ten additional years to develop, demonstrate, design and construct commercial-scale pyroprocessing plants beyond the projected completion of the KAPF demonstration facility by 2028. We expect this process to extend towards 2040 or so, if all the technical and economic issues are solved and all the requisite bi-national approvals are obtained. Thus large scale pyroprocessing of SNF that could seriously mitigate the PWR’s SNF accumulation will likely happen sometime post-2040. Third, Even if pyroprocessing and fuel re-fabrication technologies could be commercialized within the timeframe claimed, it is likely the commercialization of fast breeder reactors would require longer than

currently assumed. This is borne out by the experience of other countries ? France, Japan, India, and China, where SFRs commercialization is a long, drawn-out process, extending beyond original estimations. While an SFR demonstration reactor might be constructed by 2030, we are hesitant to estimate when a larger 150 MWe SFR may become operational. Currently there is no SFR facility in the ROK. Leaping to a 150 MWe operating reactor in fifteen years might prove difficult. While it is possible that a small pyroprocessing and re-fabrication plant might operate in the ROK around 2030, the fuel from such facilities would have to be stored under stringent safeguards for some time until a commercial SFR is operational. We address SFR development issues in the next section of this paper, where we consider that full maturation of commercial-sized SFR in the ROK is even more daunting than commercializing the pyroprocessing technology.

As discussed above, there is a mismatch between SNF discharged from operating PWRs during the 2030’s and the capacity of the pyroprocessing plant. By 2030, we estimate more than 1000 MT of SNF will be discharged annually from ROK NPPs and SNF pool storage will be saturated by 2029. We also assume that the KAPF will start commercial operation in the 2030’s. However, its capacity will be only 100 MT/year ? a tenth of the annual SNF discharged. Most of the SNF will have to be stored until a larger commercial-sized pyroprocessing plant is constructed ? probably sometime around 2040. To store excess SNF, on-site dry cask storage might become available on some nuclear sites, though likely not enough to totally solve the problem. Therefore, a centralized dry cask storage facility ? an ISFSI ? will have to be implemented regardless of the success of the pyroprocessing program. As mentioned, we assume a commercial-sized pyroprocessing plant could be ready in about thirty years time. Pyroprocessing is a thirty year solution to a ten year problem.

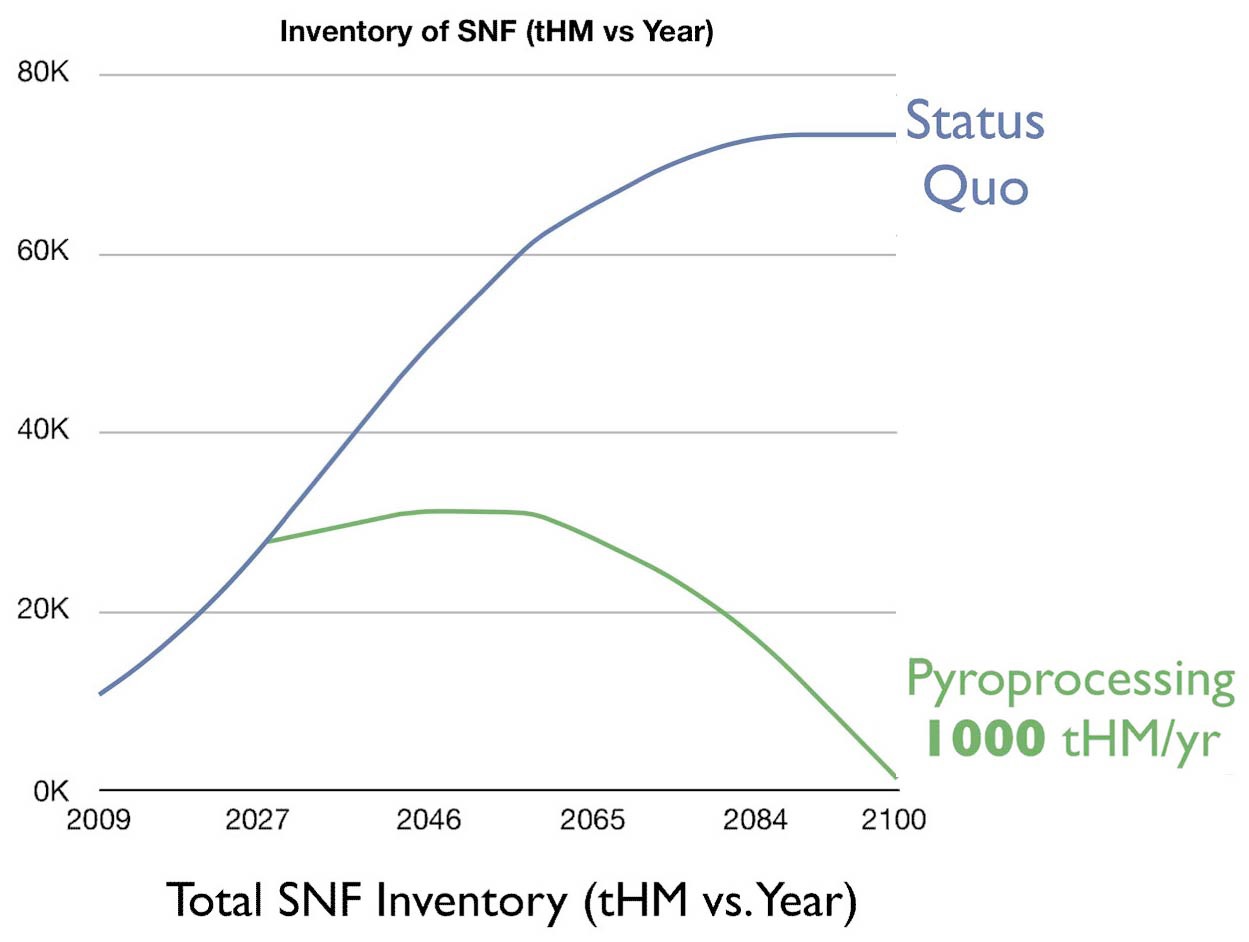

To reiterate, even if a commercial-sized pyroprocessing plant of 1,000 MT/year is built as follow-on to the KAPF by 2040, this facility would have to deal with a large backlog of SNF. We demonstrate this in figure 9.

In Figure 9 we plot total SNF in ROK under status quo and pyroprocessing scenarios. We optimistically assume a successful on-time completion of the Korea Advanced Pyroprocessing Facility (KAPF) by 2028, which mitigates 100 MT/year of SNF, assuming, again, that all the requisite approvals from the U.S. side were obtained, and in a timely manner. This will be followed by a commercial-sized facility processing 1,000 MT/year beginning in 2038, should all technical, licensing and economic issues be successfully resolved. Between 2028 and 2038 the accumulation of SNF surpasses pyroprocessing capacity. After 2038 pyroprocessing of SNF, should it be successfully implemented, approximately matches the annual rate of production of new SNF until a significant number of PWRs reach their end of life and are decommissioned and SNF can be processed faster than it is produced. However by that time a significant backlog of untreated SNF will have accumulated, which will require additional years to process.

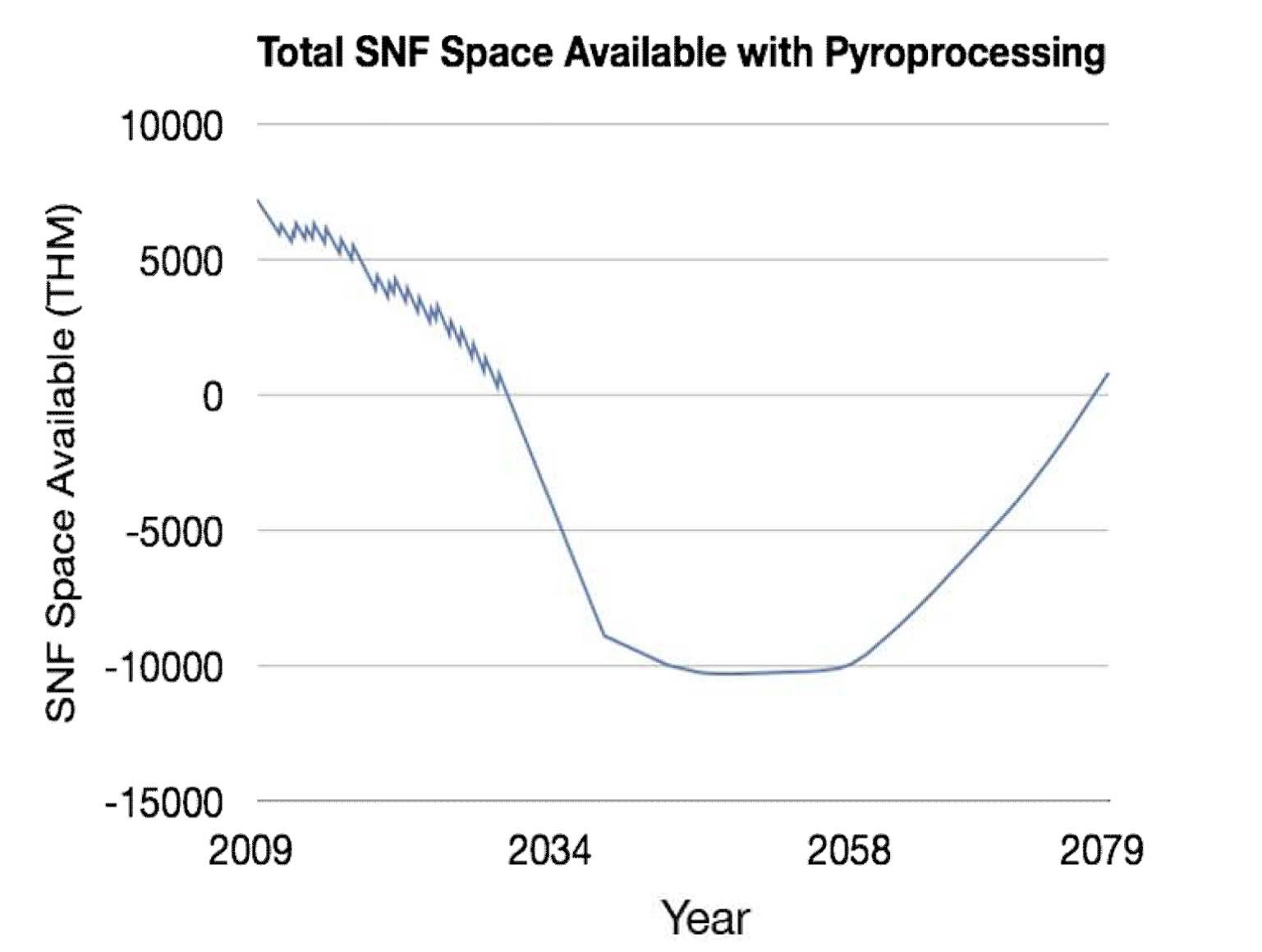

We see in Figure 10 the total space for SNF storage in ROK projected to 2080. We see that even under optimistic assumptions, there will be a dearth of SNF storage in Korea around 2029 and additional SNF storage will be required to continue operating then existing NPPs. The size of accumulated SNF stockpile for which there might not be on-site

storage available either in wet and possibly in dry cast form is shown in Figure 10.

As seen in figure 10, the maximum accumulation of SNF requiring additional storage capacity in dry casks will reaches about 10,000 MT. This is equivalent to about tenyears- worth of SNF discharge from all operating PWRs by about 2030. This would therefore be the ultimate size of the required ROK ISFSI. Given less optimistic assumptions regarding the start-up of KAPF and the follow-on commercial- sized pyroprocessing plants, additional dry cask storage capacity will be required, as implied by the ROK's assumption of an ultimate centralized storage capacity reaching possibly 20,000 MT (14). The ISFSI could, however, be built in modular fashion reaching its maximum size by about 2050, corresponding to Figure 10. In order to ultimately reach such capacity in forty years, it is still be required to build a demonstration facility in the next ten years, as previously discussed.

Such a SNF centralized dry cask storage demonstration program would only expand the SNF disposal alternatives available to the ROK, without committing it to one particular course of action. In fact, we view such demonstration program as enhancing the ROK’s options and flexibility, so a more informed disposal choice could be made in the future. Should such a program succeed, it would open the door for a commercial-sized ISFSI facility, until the commercialsized pyroprocessing plant is constructed. If pyroprocessing is successful, then centralized SNF storage demonstration program would not hinder its commercialization and would still be utilized. Should pyroprocessing ultimately be slow in commercializing, or rejected, the storage demonstration facility could serve as a stepping stone to a larger, fullsized, ISFSI which will then be essential.

In the above discussion we reviewed issues related to successful implementation of a pyroprocessing program in the ROK and the concurrency requirement for commercializing the dry cask storage, the pyroprocessing and the breeder reactor technologies. We turn now to a discussion of prospective Sodium Fast Reactor programs in the ROK

5. POTENTIAL ROK DEVELOPMENT OF SODIUM FAST REACTOR SYSTEMS

Another potential area of cooperation in between the ROK and the U.S. could involve advanced Generation IV reactors, particularly Sodium Fast Reactors (SFR). In the past, scientists at the KAERI research institute have worked on a 600 MWe fast breeder reactor (FBR) design called KALIMER (15), assuming this reactor would be fueled by fissile material provided by pyroprocessing. Recently the ROK scientists have scaled down their SFR development plans and a more advanced version of a SFR is now planned as a 150 MWe reactor, slated for initial operation by 2028, as shown in Figure 8, assuming all technical and licensing issues are resolved in timely manner. The development of fast reactor designs and related fuel cycle facilities in the ROK is a relatively new phenomenon carried out over the past twenty years. Currently there is only one hightemperature sodium loop in KAERI meant for thermohydraulic studies. It is not clear that the ROK could transition from the current sodium test loop to a 150 MWe operating SFR by 2028. A smaller pilot plant might have to be constructed to acquaint engineers with operational issues of sodium-cooled reactors. We are thus concerned that a commitment to an operating 150 MWe by 2028 might prove difficult, given the limited current ROK technology and operational base.

In contrast, the U.S. has extensive experience in FBR plant design, construction, and fuel supply experience extending over the past sixty years. In fact, the first nuclear electricity generated in the U.S. came from an early prototype breeder ? the Experimental Breeder Reactor I (EBR I) in Idaho Falls in 1951. SFR development in the U.S. witnessed many changes over the years. Currently, there are two branches of SFR development pursued in the U.S. in which ROK scientists have expressed interest. First, the Super Prism FBR developed over the past thirty years by General Electric Corporation (GE) (16), second the newer Traveling Wave Reactor (TWR) developed by Terra Power Corporation (17). As mentioned, it is important to have an operating SFR ready when the first pyroprocessing plants start generating significant quantities of metallic U-Pu-Zr fuel. Since this fuel represents a higher proliferation danger than spent PWR fuel, it is preferable to load it into an operating SFR as soon as practical, rather than keep it safeguarded until a reactor becomes available.

Of the two SFR designs developed in the U.S. the Super Prism is an advanced 300 MWe reactor, currently being considered by the U.K. Government for plutonium elimination (18) mission. The Super Prism will operate without its radial blankets in a burner mode. It will employ an external fuel cycle, including fuel reprocessing and re-fabrication plants, and will require a new fuel load every year, as well as reprocessing of the discharged SNF to extract unburned plutonium for further recycling. The PRISM design has been extensively developed by GE over the past three decades, and preliminarily reviewed by the U.S. NRC. Also, there has been significant development of operations and safety systems. A schematic design of the Super Prism is shown in Figure 11.

In parallel, the U.S. Argonne National Laboratory (ANL) has developed its own SFR burner reactor design, in part, in response to the Global Nuclear Energy Partnership (GNEP) program. Compared with the GE Super Prism design the ANL burner reactor concept is still in a preliminary design stage and will require additional development effort before it approaches the level of readiness of the Super

Prism design. Thus, further discussion will concentrate on the GE SFR design.

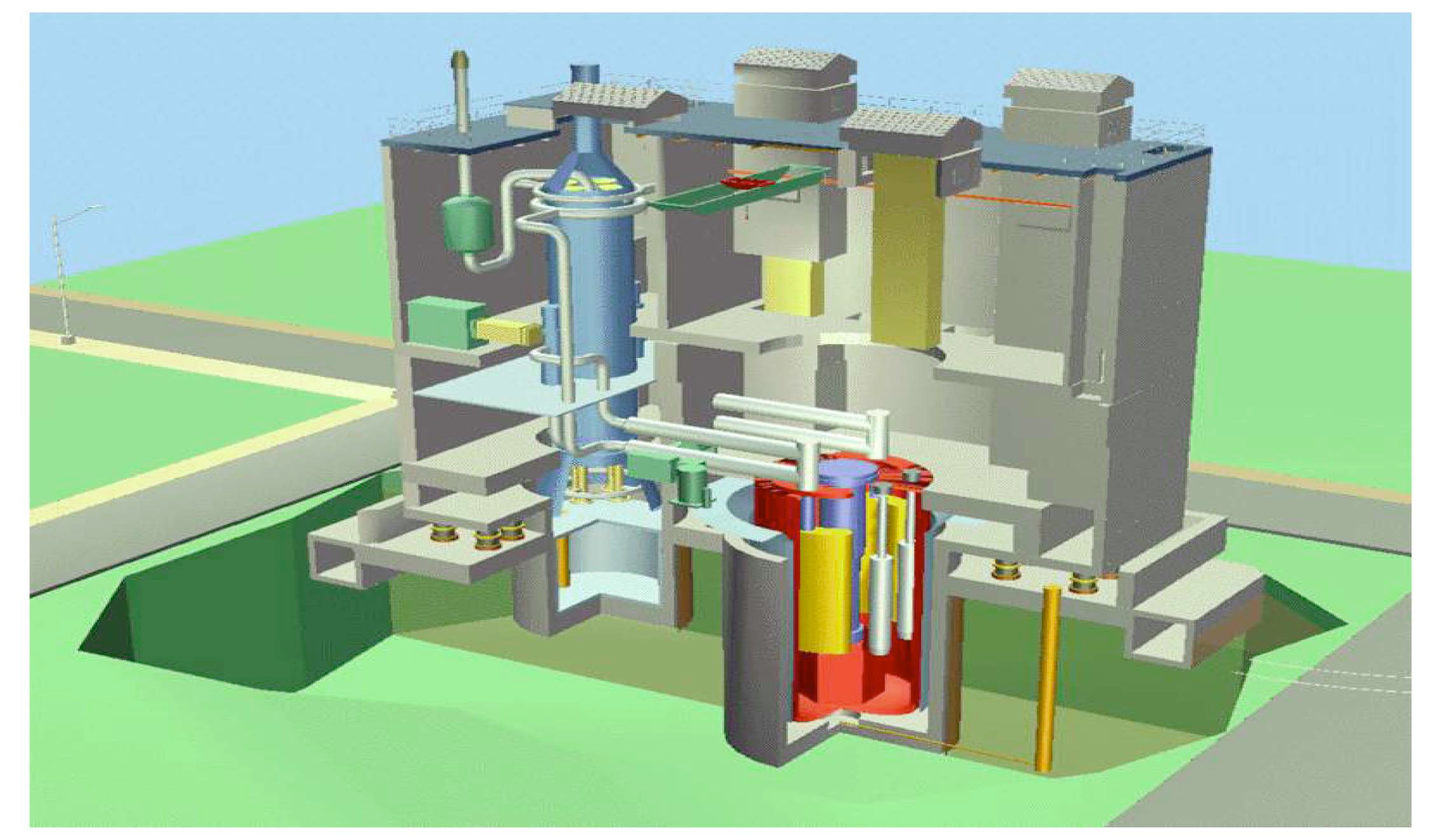

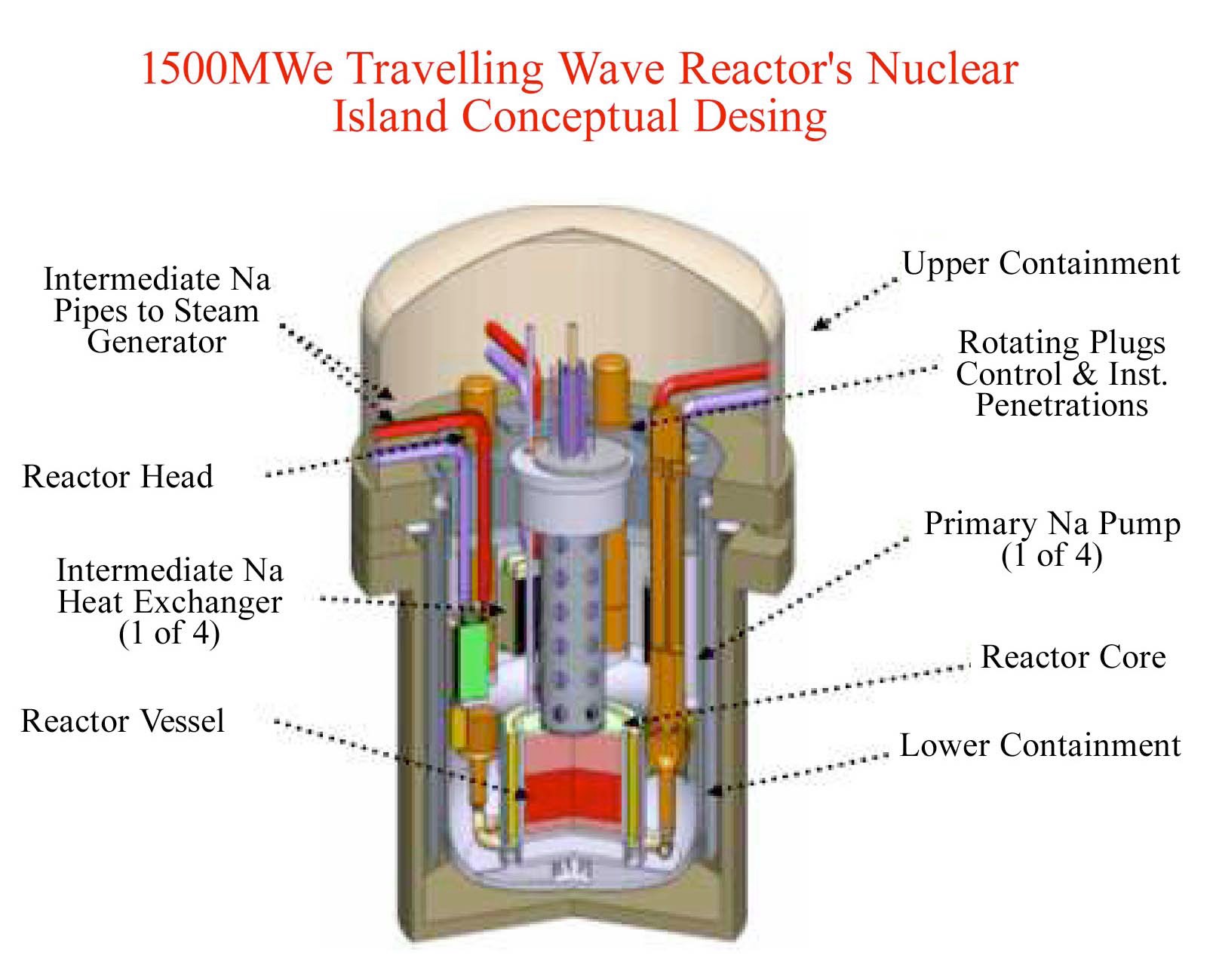

A newer traveling wave reactor (TWR) design is being developed by Terra Power Corporation and supported by venture capitalists affiliated with alumni of the Microsoft Corporation, headed by Bill Gates. TWR development represents a new and unique situation where a nuclear reactor design program is supported by financial corporations independently of the U.S. Government. Terra Power has utilized the most modern nuclear design tools available, employed some of the best reactor designers in the U.S. and has made great strides in reactor modeling over the last seven years. The TWR design does not require an external fuel cycle and can operate for many years on the original fissile fuel load. It will still require some form of simplified pyroprocessing to convert spent PWRs fuel to a form suitable for the TWR. In particular, the TWR will require greater fabrication effort than a conventional SFR since TWR fuel will remain in the reactor for extended periods. The fuel will reach very high burnup levels and burn the original fissile content, converting fertile uranium within the fuel element into fissile plutonium, which it will then also burn in-situ. The TWR will thus requires special high strength steels for fuel cladding and the testing of a lead fuel rod and fuel assembly (LTA) before there can be confidence in the design. Bill Gates recently presented the TWR to the new Park Administration in the ROK (19). This reactor requires a major fuel fabrication development program. We assume such a program is well within the technical capabilities of the ROK. Some versions of the TWR could, in fact, use cleaned-up PWRs SNF as a fuel material, based on earlier reprocessing schemes developed in the ROK, so as to support the elimination of both SNF and fissile and fertile contents (20). A schematic description of a 1,000 MWe (Plus) TWR is shown in Figure 12.

When considering the two SFR options developed in the U.S., especially in the context of possible collaboration

with the ROK, we find an interesting symmetry. There exists the GE Super Prism reactor with advanced reactor design but with extensive external fuel cycle requirements. On the other hand the TWR reactor program lags the more mature Super Prism reactor design, but its external fuel cycle requirements are much simpler. In fact, once fuel is loaded into the TWR, there is no external fuel cycle. The fuel remains inside the reactor until a significant fraction of all fissile and fertile content is consumed. The spent fuel discharged from the TWR will include a smaller fissile or fertile content and a significantly greater fraction of fission products. Discharged TWR spent fuel will have to be disposed of as waste in the then existing spent fuel management system.

We believe it makes sense for a potential reactor-fuel cycle collaboration to be jointly developed by the ROK and the U.S. The U.S. could take care of the reactor development, and the ROK could do more research on the fuel cycle. To assure success, the ROK might wish to choose the reactor that will minimize the fuel cycle development requirements on its part. We stress here that the potential joint program, discussed below, represent our own personal suggestion and does not represent the official position of the U.S. Government.

6. POTENTIAL JOINT ROK ? U.S. SFR REACTOR AND FUEL CYCLE DEVELOPMENT PROGRAM

As mentioned above, the U.S. has developed an extensive SFR program, relying on past experience. The ROK however, with its pyroprocessing program, the earlier DUPIC program (21), the PRIDE facility (Figure 7) and the related fuel re-fabrication program (see Figure 8) has carried the SFR fuel development effort forward much further than the U.S. Since all SFRs require a joint development of both reactor and fuel cycle, the above situation presents an opportunity for a joint reactor-fuel cycle development effort between the ROK and the U.S. We suggest a joint ROK - U.S. development program funded by both parties. U.S. industry will be responsible for further development of the SFR (With ROK financial and engineering support). Limited financial support is available from the U.K. and from venture capital corporations now, and further U.S. private as well as Governmental support might become available within about four years, depending on political developments in the U.S. This is well within the remaining time period for the ROK ? U.S. initial pyroprocessing studies.

In parallel, the ROK will be principally responsible for developing the fuel for the reactor design chosen as well as the design of facilities required. Such a joint program calls for reliance on the strengths of the two programs ? the U.S. in reactor design by industry teams, and the ROK in fuel development by Government organizations. The end product of such potential joint effort could be a package of reactor and fuel cycle facilities, which will take in spent PWR fuel, re-constitute it, and be ready to burn it in an SFR. This will eliminate the PWR SNF’s fissile content, generating more electricity, and reducing the ultimate amount of nuclear waste going to a final repository. Advanced versions of such reactor-fuel cycle system could operate in the breeder rather than burner mode as required in the future.

A major concern of all such concepts is the need for fuel reprocessing and for the recycling of plutonium in the new fuel. Given the U.S. refusal to condone ENR facilities in countries that do not already have such capabilities, how could the U.S. support such programs in the ROK? Previously, it was claimed that pyroprocessing is different than 'conventional' PUREX reprocessing. The U.S. however views pyroprocessing as reprocessing and therefore objects to it on nonproliferation grounds (22).

A different perspective on the role of pyroprocessing could, however, be based on recognizing the fact that the U.S. Government has permitted the transfer of pyroprocessing technology to the ROK. It should come as no surprise that ROK scientists have considerably advanced the state of the art of pyroprocessing technology. The financial support by U.S. venture capital corporations independent of U.S. Government funding represents a new phenomenon. Nevertheless, the development and commercialization program could still be controlled under a joint program. Early studies with the PRIDE facility will extend till 2020. Then, development of the KAPF facility will require an additional five to ten years. With additional time for construction, this may take until at least 2030. A follow-on commercial pyroprocessing plant will require another five to ten years, reaching maturity by about 2040, assuming no technical or political “show-stoppers” along the way. Real decisions about the path to take are about fifteen to twenty five years away. It may be possible to design a 123 Agreement with off-ramps mirroring this development process. This could represent a step-wise conditional decision process, wherein each step depends on successful completion of the previous steps and fulfillment of a set of pre-determined criteria. Such conditional requirements could be incorporated into the language of a revised 123 Agreement. This could be negotiated in the next two years if the right framework could be agreed-upon. The U.S. knows the pitfalls of a reactor development process and the large effort and time required for licensing reviews and approvals. A long commercialization process still awaits even well-developed SFR and fuel cycle programs such as the Super Prism the TWR, and their associated fuel cycle facilities. Further reactor design work could proceed in the next four years in the U.S. and the ROK based on a mix of venture capital and ROK funding while the joint pyroprocessing studies are continuing. Yet, with a potential ROKU. S. joint program, the chances of success are greatly enhanced. In the meantime, useful collaboration on a reactorfuel supply package could be accomplished under a carefully crafted 123 Agreement under the right political umbrella, without irretrievably forcing the commercialization barrier.

We have reviewed many SNF management and disposition options available to the ROK. We showed that under most circumstances the ROK will require a dry cask ISFSI facility to be commercialized in the late 2020’s. We have also modeled and defined the ultimate size of such facility. An ISFSI facility is modular in nature, and can be easily expanded as the need arises. However, an early demonstration program is required soon if a larger scale facility is to meet scheduler and operational requirements. We thus proposed a potential joint ROK ? U.S. away-from-reactors dry cask demonstration program. Such demonstration program is relatively easy to implement and has many benefits. The ground-rules for consensus based siting of spent fuel storage facilities and for enhancing public acceptance of nuclear waste management programs were laid out in the U.S. BRC report and are equally applicable in the ROK and in the U.S.

Realizing the ROK is mostly interested in pyroprocessing SNF we have argued that pyroprocessing and centralized dry storage are not mutually exclusive but complementary under ROK nuclear energy system conditions. With any realistic schedule of pyroprocessing development, centralized dry storage will still be required and will reduce pressure to accelerate the commercializing of pyroprocessing on a large scale before the technology matures. Since the ROK will likely require centralized storage, it could develop this approach with U.S. support. A successfully demonstrated centralized dry cask storage program would also have positive impacts on the U.S. spent fuel management program, and on the ROK international nuclear sales. This will further cement ROK - U.S. global nuclear energy cooperation.

Finally, we address the issue of fast reactors and their fuel in the ROK. We discussed that Pyroprocessing is an enabling technology for SNF management and not an endpoint; there is little point in developing pyroprocessing without a complementary SFR program. Since historically the U.S. is advanced in SFR reactor technology while the ROK has accumulated experience in developing SFR fuel supply systems, there is an opportunity in a complementary and synergistic program combining both efforts. We envision a joint U.S. ? ROK potential program to develop a package SFR reactor and its associated fuel cycle. Both efforts will require between ten and twenty five years to develop, and could start on a relatively limited scale until political support improves and additional funding is obtained. We should stress here that this represent our personal suggestion and not the official position of the U.S. Government. It would be possible to begin such a program now while making final implementation decisions in conditional format later. This process could be defined in a carefully crafted step-wise permitting process incorporated in a revised 123 Agreement for Nuclear Cooperation between the ROK and the U.S.