Despite expectations of refrained expansion following the recent accident at Fukushima in Japan, projects to construct new nuclear power plants are continuously increasing worldwide, to cope with the increasing demand for power, as well as global warming and climate change. Accordingly, there is a high possibility that nuclear power plant structures will be constructed in various environments, including hot and cold regions.

Concrete for nuclear power plant structures is fabricated by introducing mineral admixtures, like fly ash, as substitutes for cement, in order to reduce the hydration heat, and improve the permeability and durability [1,2,3]. However, concrete adopting such mineral admixtures is more sensitively affected by temperature and humidity than concrete using type I ordinary Portland cement [4,5,6]. This stresses the importance of securing uniform quality concrete by applying appropriate curing methods enabling control of the temperature and humidity when constructing nuclear power plant structures in diversified environmental conditions.

The prevention of frost damage at an early age is critical for concrete works conducted in winter, or in cold regions like Russia and Kazakhstan. Concrete undergoing early frost damage in cold weather will experience significant loss of strength, permeability and durability, all of which shorten the service life of the structure. Accordingly, concrete standards and codes like ACI-306R[7] prescribe the minimum compressive strength and curing duration to enable a secure quality of concrete and prevent early frost damage. It should be noted that the so-prescribed strength and duration of curing are mostly based on the strength development of concrete. Even if the strength of concrete is generally closely related to its durability, this relationship may become invalid in the case of frost damage at early age, because of structural changes in the hardened cement paste [8]. However, studies investigating early frost damage in terms of durability are still insufficient. Since durability is of utmost importance in nuclear power plant structures, the effects of frost damage should be imperatively clarified.

Accordingly, this study examines the adequate strength and curing duration of concrete to secure the quality of nuclear power plant structures constructed in winter or cold climates, from the viewpoint of strength development and durability. After the execution of curing until a strength of 5 MPa is reached under cold climate conditions, concrete for nuclear power plants undergoing early frost damage is evaluated in terms of compressive strength and resistance to chloride ion penetration and freeze-thaw.

2. MINIMUM COMPRESSIVE STRENGTH AND CURING DURATION TO PREVENT EARLY FROST DAMAGE

If concrete experiences frost damage at an early age, before having developed sufficient strength, the internal free-water freezes, leading to expansion in volume, which in turn relaxes the structure of the paste or induces failure. In such cases, concrete will undergo significant loss of its performance, even after hardening [9,10,11]. Preventing early frost damage of concrete is thus of utmost importance in cold climates, and numerous researchers have conducted investigations on the minimum compressive strength or duration of curing enabling to prevent early frost damage.

Powers [12] found out that, in the absence of an external water supply, the degree of saturation of the placed concrete reduces with time, due to the progress of the hydration of cement. The author reported that, under such circumstances, the critical value of the degree of saturation below which damage occurs, even for a single cycle of freezing, corresponds approximately to a developed compressive strength of 3.5 MPa. ACI-306R defines this compressive strength as the minimum strength to prevent early frost damage. Moreover, the British Standards and RILEM prescribe to perform curing at temperatures higher than 5℃ until the development of a compressive strength of 5 MPa is reached, in order to prevent the occurrence of early frost damage. In addition, the Korean and Japanese Concrete Codes specify minimum values of the compressive strength ranging between 5 and 15 MPa, according to the cross-sectional thickness of the structure and its exposure conditions.

The work of Bernhardt [13] indicated that the time of occurrence of frost damage has the largest effect on the early frost damage of concrete, rather than the duration of freezing, or temperature conditions. The author also reported that early frost damage does not occur 2 days after placing. Based on the results of a series of early frost damage tests considering various water-cement ratio and types of cement, Yi et al. [14] analyzed the minimum duration of curing with regard to the degree of hydration, and proposed minimum durations of curing of 6 to 16 hours for type I cement and 4 to 10 hours for type III cement. ACI-306R recommends a minimum duration of curing of 1 to 6 days according to the type of cement, loading and exposure conditions. The Korean Concrete Code specifies this minimum duration to be 2 to 12 days, according to the type of cement, exposure conditions and temperature.

Most of the above mentioned minimum compressive strengths and durations of curing rely on the development of the compressive strength after the occurrence of early frost damage. However, concrete experiencing early frost damage at an early age may exhibit an inconsistent relationship between its strength and durability. Accordingly, this study investigates the strength development and durability to prevent early frost damage of concrete for nuclear power plants, so as to verify the pertinence of the minimum compressive strength prescribed by ACI-306R.

3.1 Summary of Early Frost Damage Test

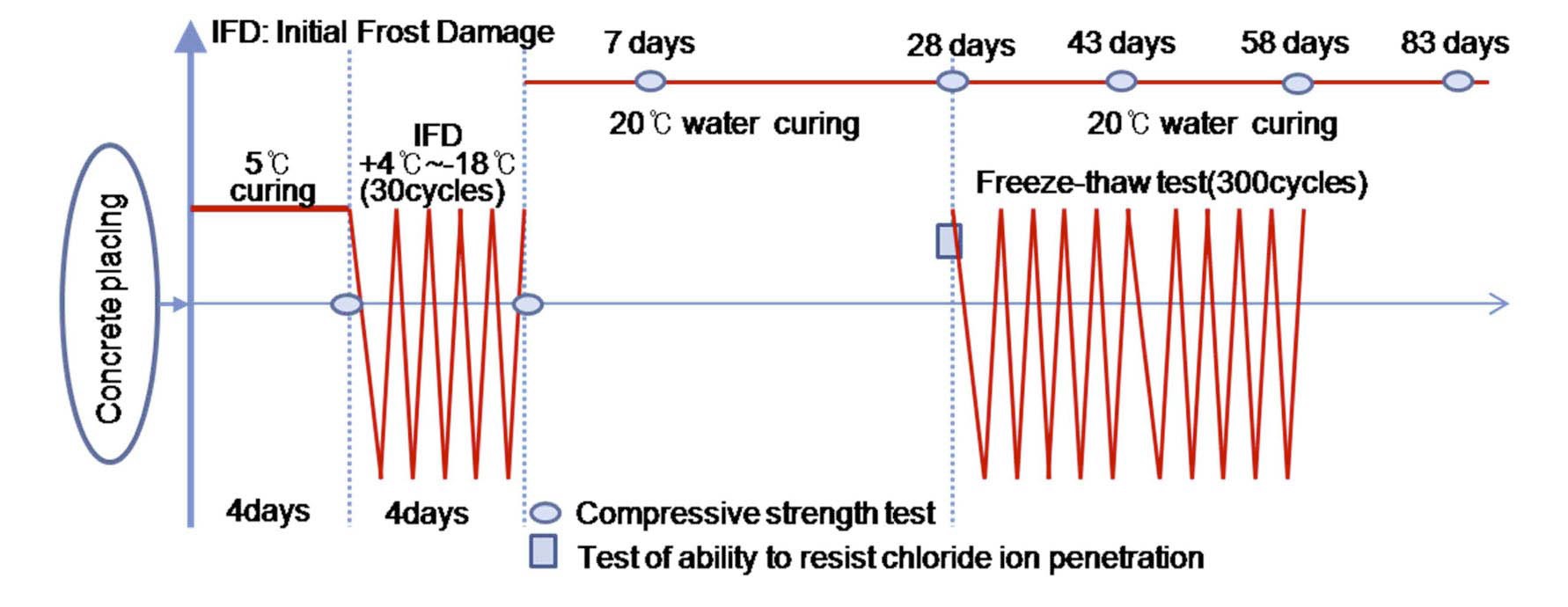

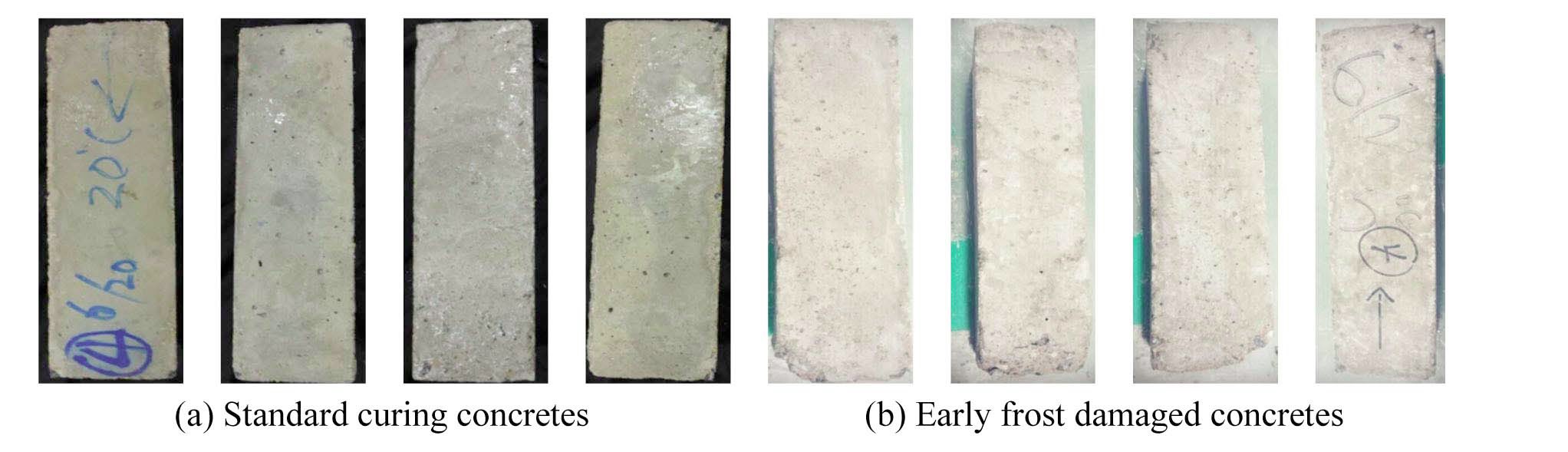

In this study, the test shown in Fig.1 was conducted to verify the pertinence of the minimum compressive strength of 5 MPa, established to prevent early frost damage. Sealed curing was performed at 5℃ until the development of a compressive strength of 5 MPa, considering the protection measures adopted for curing in winter or in cold regions. After concrete had secured a compressive strength of 5 MPa, early frost damage was inflicted by applying 30 freeze-thaw cycles at temperature conditions of +4℃ to -18℃. Despite some regional discrepancies, the lowest temperature in winter in Korea may drop down to -20℃ and the annual average freezing temperature runs around -3.1℃ to -6.5℃. The number of freeze-thaw cycles is known to range between 40 and 172[15]. It is known that one freeze-thaw cycle applied to the concrete mix used in this study in the laboratory test corresponds to 12 to 54 cycles in a real, natural environment [15]. In addition, surveys report that harsher conditions can be found in very cold regions, like Russia and Kazakhstan. After the early frost damage, water curing was carried out at 20℃ to accelerate the curing process. This accelerated curing

was executed to reflect the warming conditions encountered after winter, or the standard curing conditions. Through this process, the compressive strength, resistance to freezethaw and resistance to chloride ion penetrationwere evaluated on the concrete for nuclear power plants subjected to early frost damage. Furthermore, an identical test was conducted on concrete that did not experience early frost damage in order to enable comparison with concrete that experienced early frost damage.

3.2 Materials and Concrete Mix Proportions

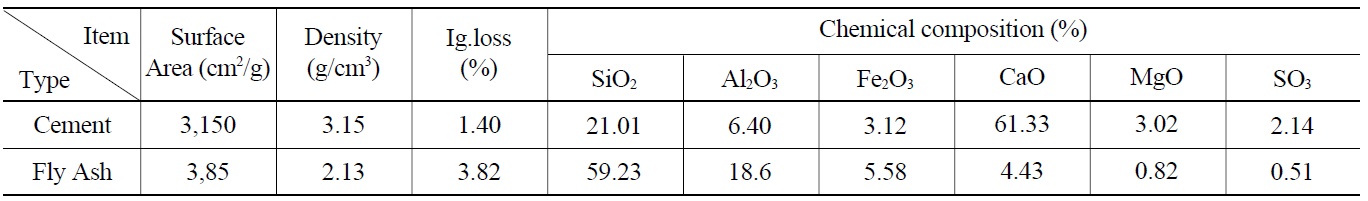

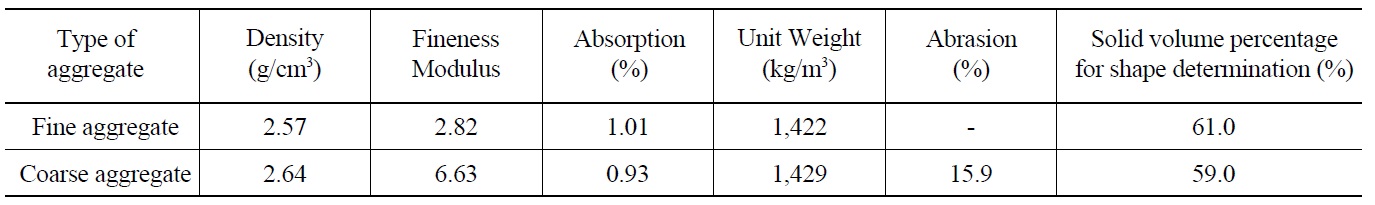

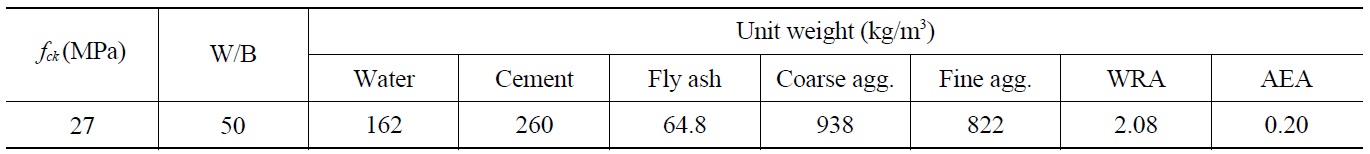

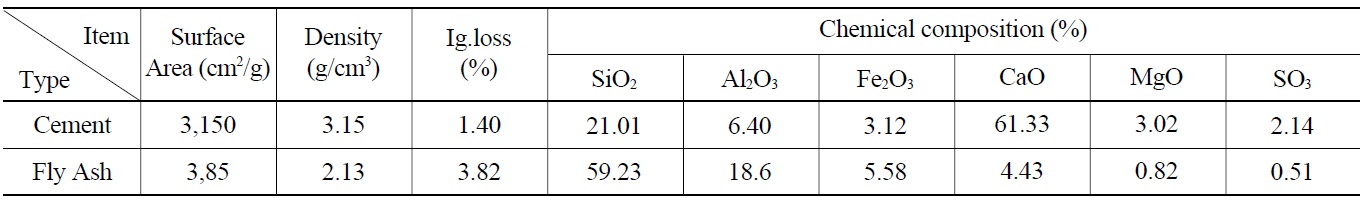

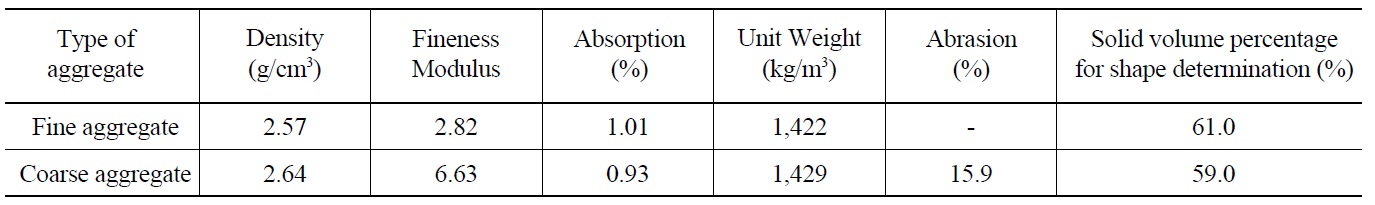

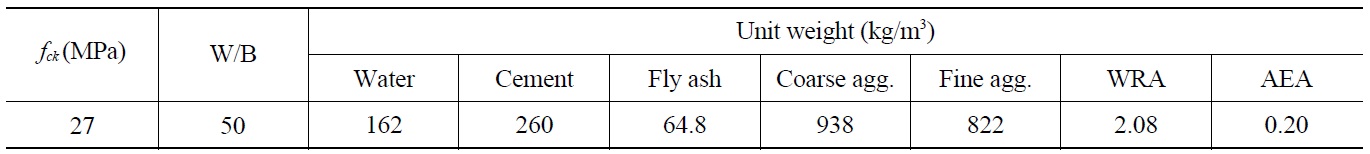

The properties of the materials adopted in the test are arranged in Table 1 and Table 2. These materials are produced in Korea. Ordinary Portland cement (OPC) and class F fly ash (FA) complying with the standards of ASTM C 150 and ASTM C 618, respectively, are used. Coarse aggregate (crushed stone) of a maximum size of 20 mm and fine aggregate (sea sand) according to ASTM C 33 are used. A naphthalene-based water reducing agent (WRA) and a negative ion type air-entraining agent (AEA) are used to control the workability and the air content of the Table 3 lists the mix proportions of the concrete. The mix proportions correspond to those actually applied for the concrete of nuclear power plant structures with a specified compressive strength of 27 MPa. This mix used a water-binder ratio of 0.50, and adopted 20% replacement of cement by fly ash. The target slump and air content for the concrete investigated were maintained at 110±25 mm and 4.5±1.5%, using the water reducing agent and airentraining agent, respectively.

[Table 1.] Chemical and Physical Properties of Cement and Fly Ash

Chemical and Physical Properties of Cement and Fly Ash

[Table 2.] Physical Properties of Aggregates

Physical Properties of Aggregates

[Table 3.] Mix Proportions of Concrete

Mix Proportions of Concrete

3.3.1 Compressive Strength

The compressive strength was measured on

3.3.2 Resistance to Chloride Ion Penetration

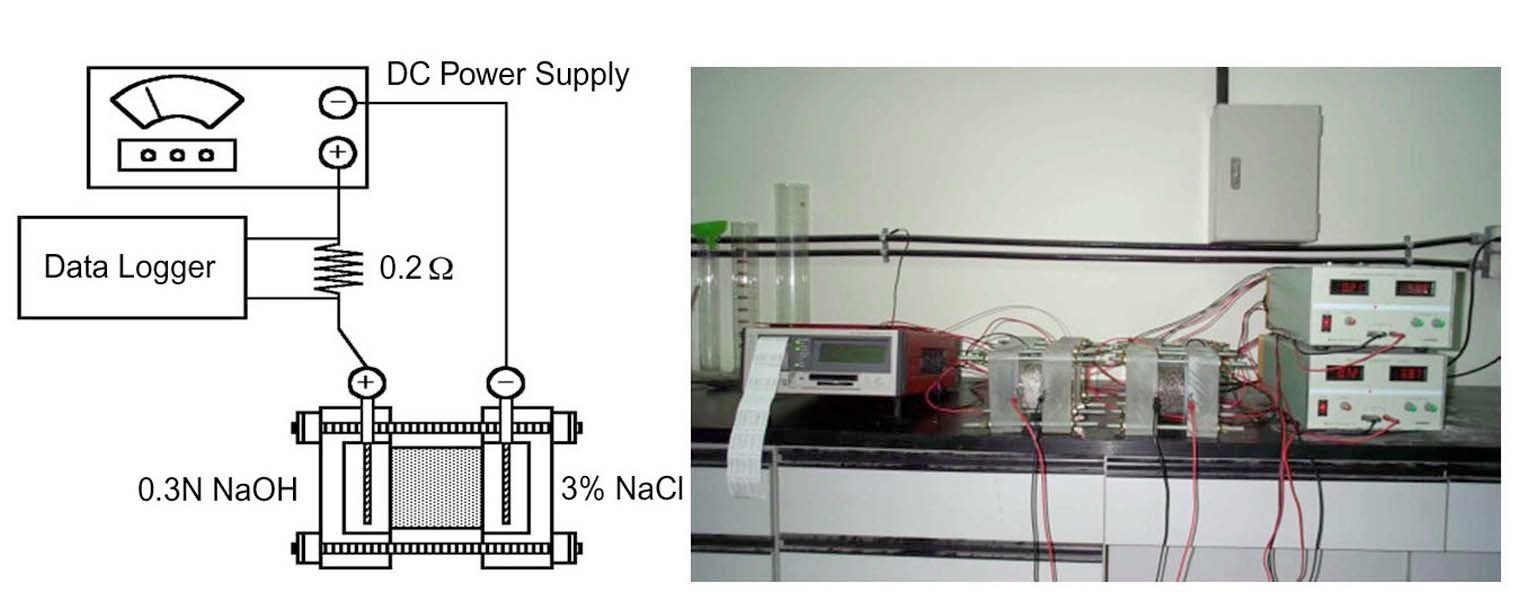

The rapid chloride permeability test, in accordance with ASTM C 1202, was applied as shown in Fig. 2 to evaluate the resistance to chloride ion penetration. Specimens in

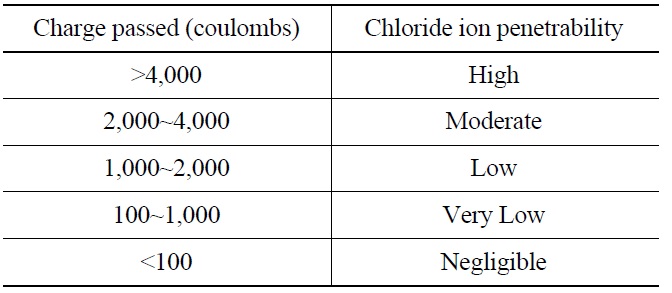

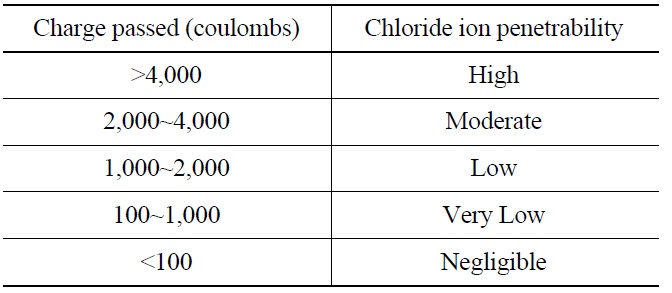

[Table 4.] Rating of Chloride Permeability of Concrete

Rating of Chloride Permeability of Concrete

solutions. The system was then connected, and a 60 V potential was applied for 6 hours and measured every 30 minutes by means of a data logger. The measured potential was used to obtain the passing electric charge as expressed in Equation (1) so as to evaluate the resistance to chloride ion penetration.

where

Table 4 shows the rating of the chloride permeability of the concrete, according to ASTM C 1202.

The chloride ion diffusion coefficient

3.3.3 Resistance to Freeze-thaw

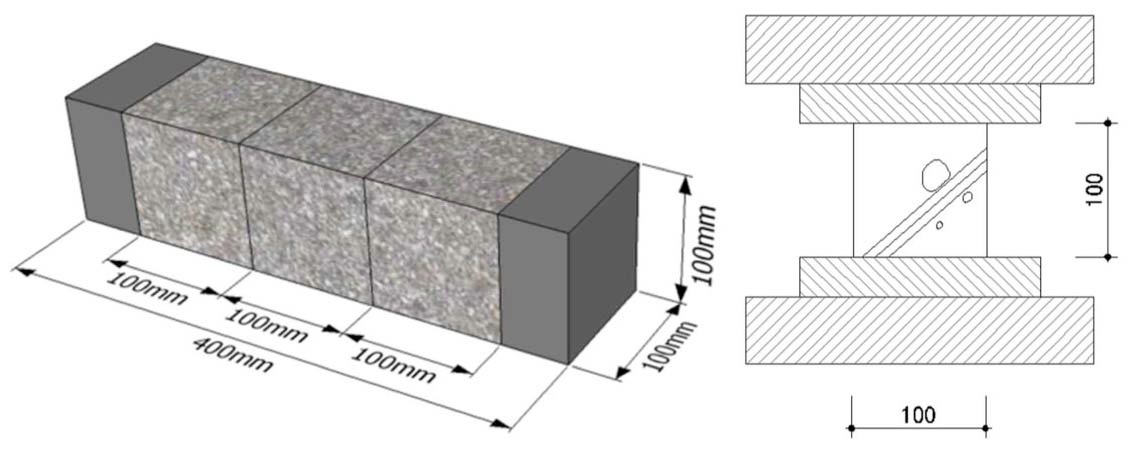

The test for the resistance of concrete to freeze-thaw used specimens with dimensions of 100×100×400 mm. Rapid freezing in air and thawing in water, as specified in Procedure B of ASTM C 666, was adopted. For the freeze-thaw test, the temperature in the central part of each specimen was controlled to fall in the range of 4.0℃ to -18℃ and the duration of one freezing-thawing cycle was fixed to about 4 hours. The fundamental transverse frequency and mass of the specimens were measured every 30 cycles until 300 cycles. The resistance to freeze-thaw was evaluated by means of the relative dynamic elastic modulus and durability factor, obtained using Equations (3) and (4), and the mass change rate.

where

where

In addition, samples of 100×100×100 mm were cut in the specimens that passed the freeze-thaw test, as shown in Fig. 3, so as to measure the strength, which will be used as an indicator for the evaluation of the resistance to freeze-thaw.

4. TEST RESULTS AND DISCUSSION

4.1 Effect of Low Temperature Curing on the Compressive Strength

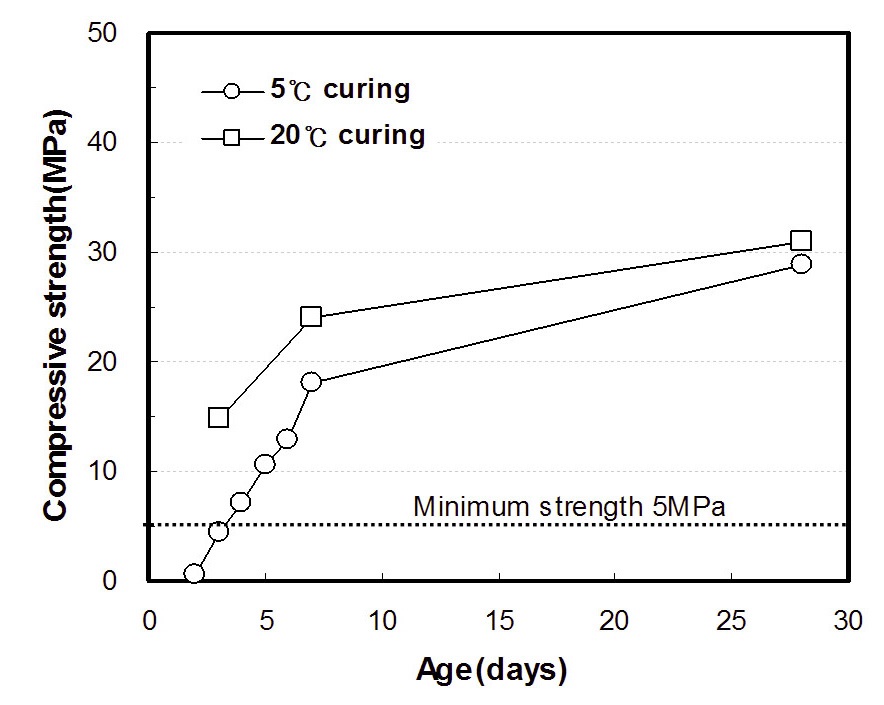

Fig. 4 plots the compressive strength measured in concrete cured at 20℃ and at 5℃, respectively. The concrete for nuclear power plant structures cured at 5℃ exhibits a significant loss of the compressive strength compared to the concrete cured at 20℃. At age 3 days, the compressive strength of concrete cured at 5℃ reaches merely 30% of that cured at 20℃. However, the difference in the compressive strength reduces with age, and at 28 days, the concrete cured at 5℃ develops a compressive strength reaching more than 90% of that of the concrete cured at 20℃. This can be explained by the fact that the strength development of concrete incorporating 20% fly ash is sensitively affected by low temperatures at an early age, but shows improvement owing to the pozzolanic reaction at a later age [17]. This situation stresses the necessity to establish solutions to prevent early frost damage that can be caused by the delay in the development of strength at an early age, exhibited by concrete for nuclear power plant structures using fly ash when placed in winter conditions.

Maturity quantifies the effects of curing temperature and time. It is a combination of the curing temperature and time function at a temperature higher than the datum temperature. Maturity is computed from temperature history using the following [18].

where

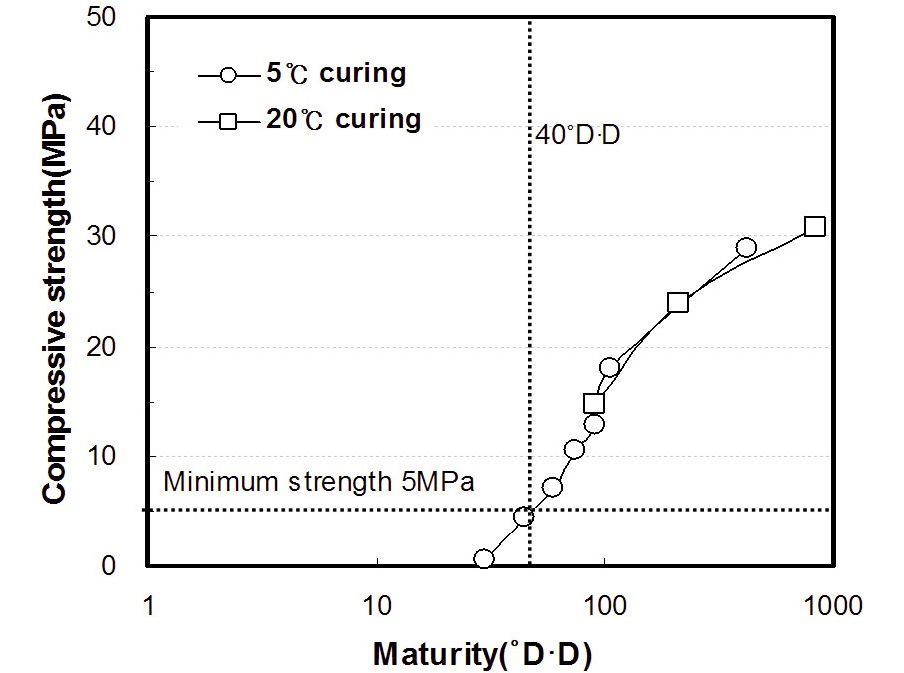

Fig. 5 plots the compressive strength of concrete for a nuclear power plant with respect to the maturity. The compressive strength tends to increase with higher maturity, and identical compressive strength is obtained for identical maturity regardless of the curing temperature. Approximately 40°D·D is estimated to be the maturity at which a strength of 5MPa is developed for a curing temperature of 5℃.

4.2 Examination of the Minimum Compressive Strength to Prevent Early Frost Damage

4.2.1 Compressive Strength

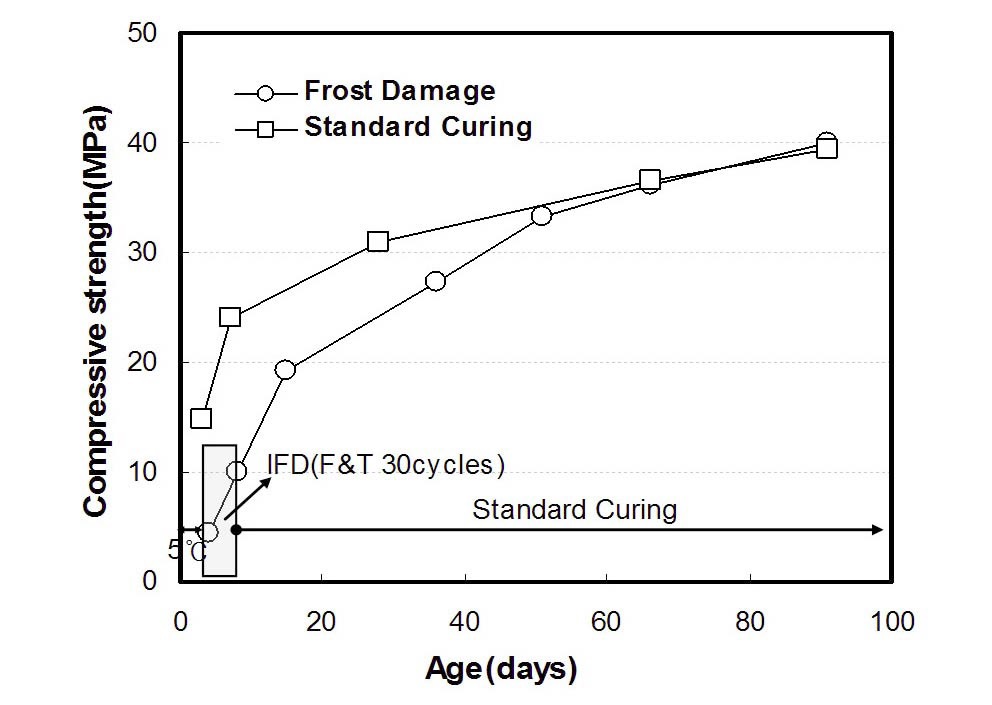

Fig. 6 compares the strength development of concrete according to the eventual occurrence of early frost damage. Until age 35 days, concrete that experienced early frost damage shows a large loss of the compressive strength compared to concrete that did not experience frost damage. This can be explained by the delay of the hydration of cement when exposed to low temperature ranging between 4℃ to -18℃ during the period of early frost damage. However, after age 35 days, the strength development increases, owing to the recovery of the hydration of cement and pozzolanic reaction, to result in similar compressive strengths after age 68 days.

These results indicate that, if the compressive strength of 5 MPa, specified by ACI-306R and the concrete codes, is reached when concrete is cured at a temperature higher than 5℃ in a cold climate, this concrete will secure a strength equivalent to that of concrete in ordinary environmental conditions, even if it experiences several freezethaw cycles after having reached that minimum compressive strength.

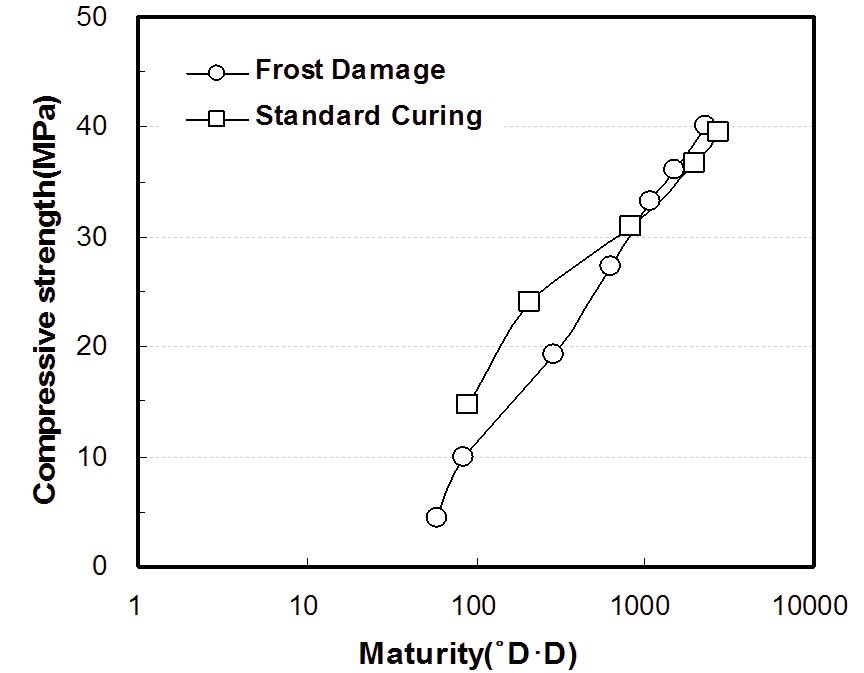

Fig. 7 shows the relation between the maturity and strength development of concrete that experienced early frost damage. In order to compute the maturity during the period of early frost damage in Fig. 7, Equation (5) is used for the maturity at temperatures higher than 0℃, and Equation (6) proposed in previous studies [19] is adopted for the maturity at temperatures below 0℃.

Under identical maturity, the concrete for nuclear power plants that has been cured at the low temperature of 5℃ develops strength at an early age, similar to that of concrete cured at 20℃ in Fig. 5. However, at maturity below 1,000°D·D, concrete that experienced early frost damage exhibits loss of the strength compared to concrete that did not experience early frost damage in Fig. 7. For higher maturity, no difference can be observed.

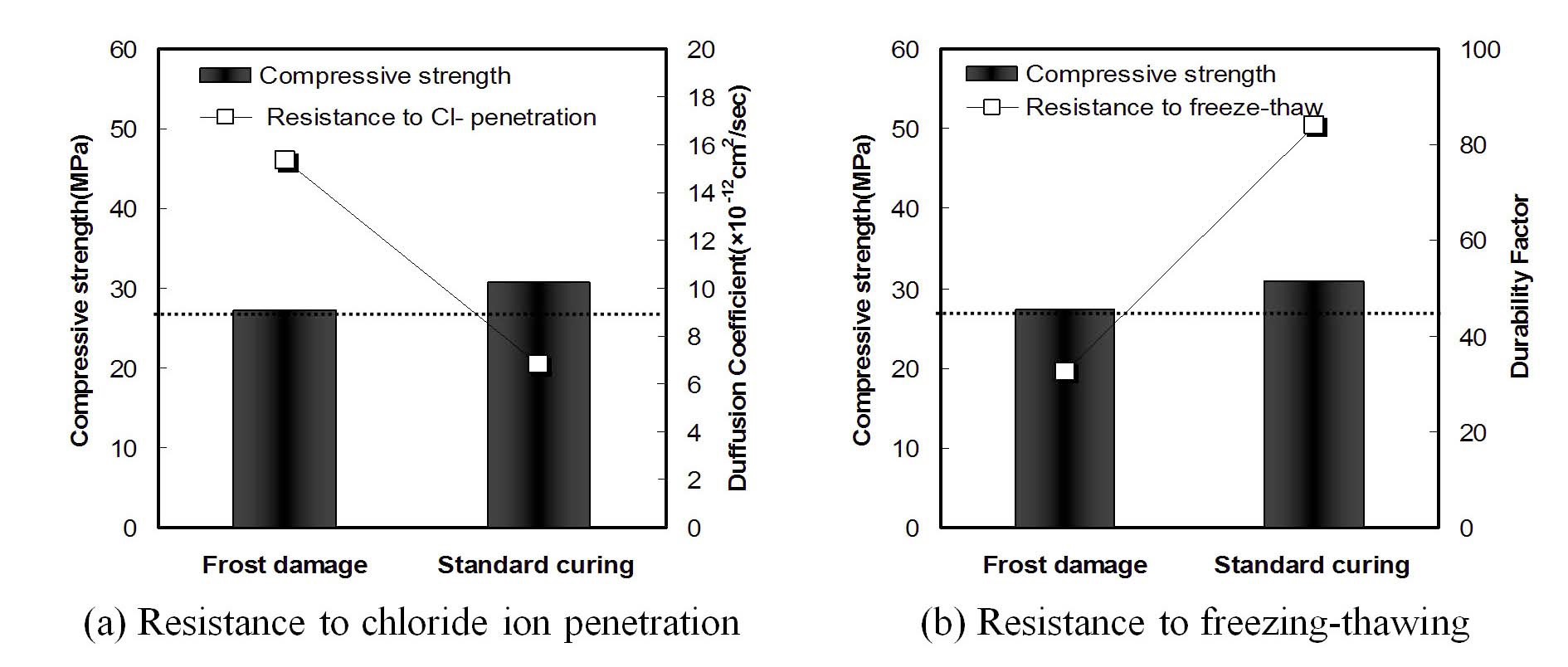

4.2.2 Resistance to Chloride Ion Penetration

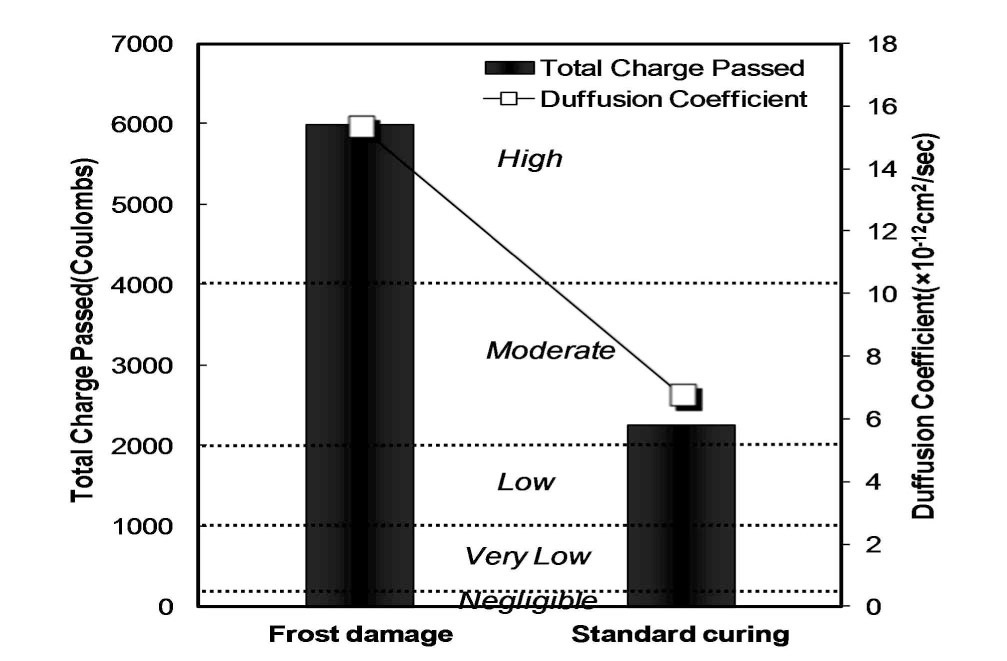

Fig. 8 compares the resistance to chloride ion penetration according to the occurrence or not of early frost damage. The charge passed through concrete that experienced early frost damage reaches 5,991 Coulombs, which is significantly larger than the 2,262 Coulombs measured in concrete that did not experience early frost damage, and indicates the large degradation of its resistance to chloride ion penetration. The evaluation complying with the criteria of ASTM C 1202 related to the permeability to chloride ion shows that concrete that experienced early frost damage exhibits high permeability, whereas concrete that did not experience early frost damage exhibits moderate permeability.

The chloride ion diffusion coefficient of concrete that experienced early frost damage is 15.34×10-12 cm2/sec and is approximately 2.27 times larger than the value of 6.77×10-12 cm2/sec obtained for concrete that did not experience early frost damage. The concrete for nuclear power plants used in this study is evaluated to have a durable lifetime against chloride permeability of longer than 60 years under ordinary maritime conditions and without early frost damage [1]. However, concrete for nuclear power plants that experienced early frost damage appears to have a high probability to undergo significant shortening of the durable lifetime against chloride permeability.

4.2.3 Resistance to Freezing-thawing

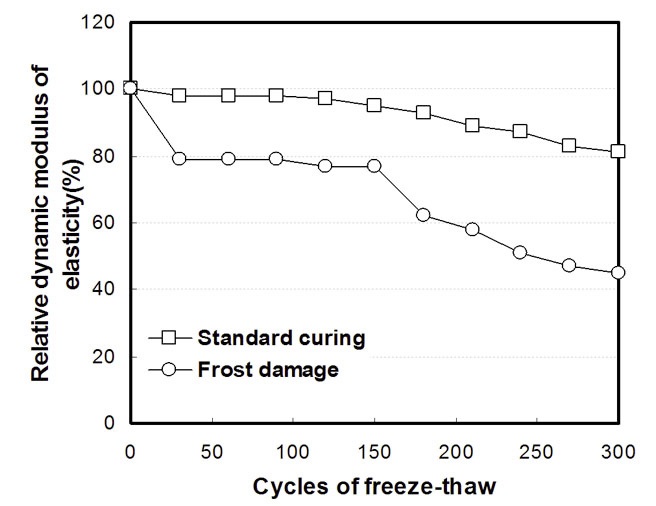

Fig. 9 compares the relative dynamic modulus of the elasticity of concrete for nuclear power plants, according to the occurrence or not of early frost damage. Concrete that did not experience early frost damage shows a relative dynamic modulus of elasticity reaching more than 80% at 300 cycles corresponding to the end of the freeze-thaw test. Such good resistance to freezing-thawing can be attributed to the sufficient amount of entrained air larger than 4.5%, achieved by the adoption of air-entraining agent and the dense structure provided by the hydration of the cement and the pozzolanic reaction of fly ash. However, concrete that experienced early frost damage exhibits degraded relative dynamic modulus of elasticity below 80% at 30 freezing-thawing cycles, below 60% at 210 cycles and below 45% at 300 cycles. This significant loss of the resistance to freezing-thawing observed, despite of the sufficient amount of entrained air larger than 4.5%, can be explained by the formation of micro-cracks caused by the action of early frost damage in a state where strength is not sufficiently developed, and the change of the distribution of porosity caused by the failure of the hydrated structure.

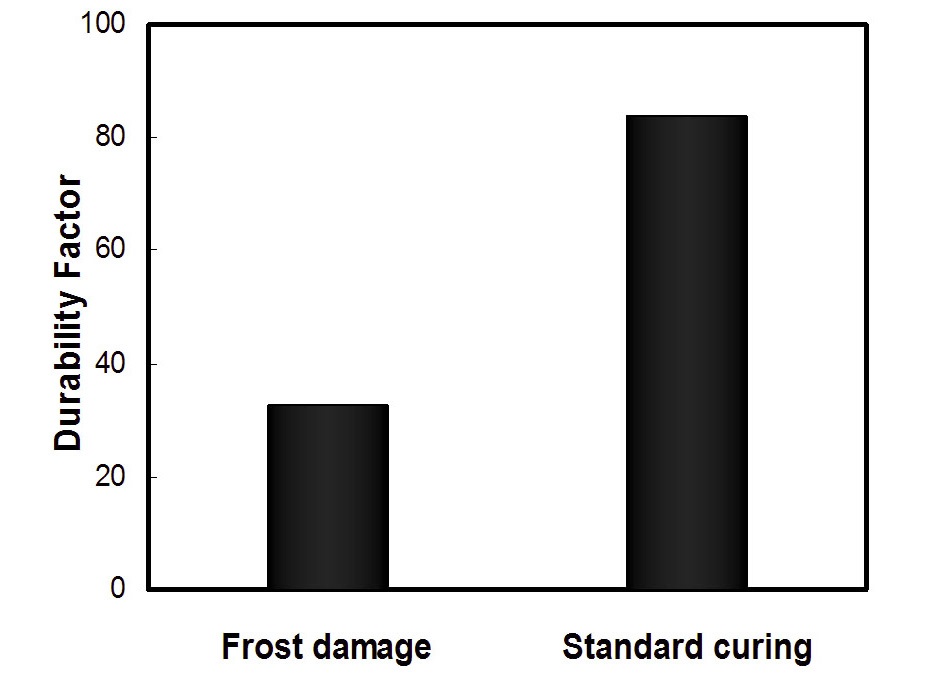

Fig. 10 compares the durability factor of concrete. The durability factor of concrete that did not experience early frost damage shows a value larger than 80, corresponding to the level of highly-durable concrete. On the other hand, concrete that experienced early frost damage exhibits a durability factor of 33, which is much smaller than 60, assumed as limit criterion assessing the resistance to freezing-thawing.

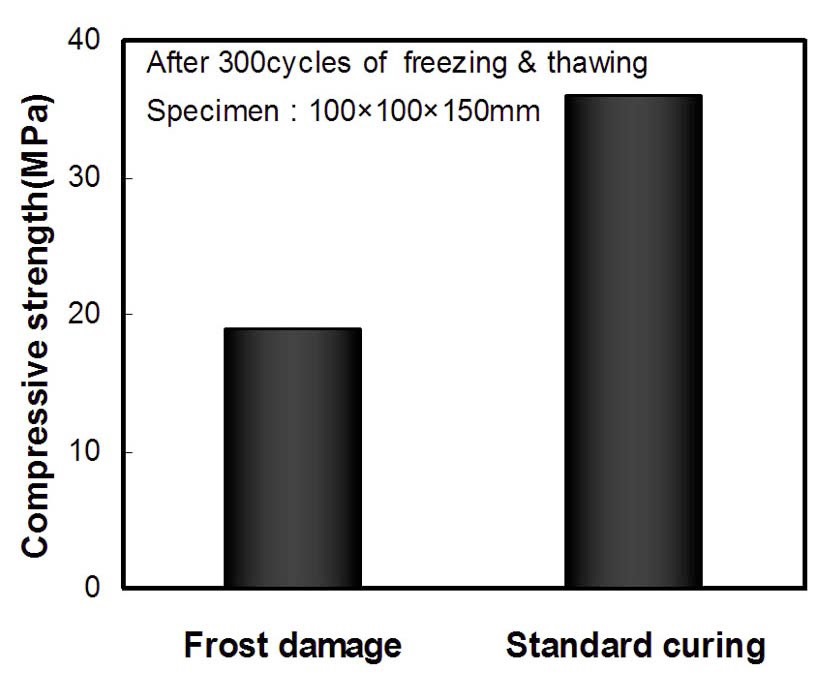

Fig. 11 compares the change of strength after completion of 300 freeze-thaw cycles. The results are similar to those of the relative dynamic modulus of elasticity. Concrete that experienced early frost damage shows a loss of strength of about 47% compared to concrete that did not experience early frost damage.

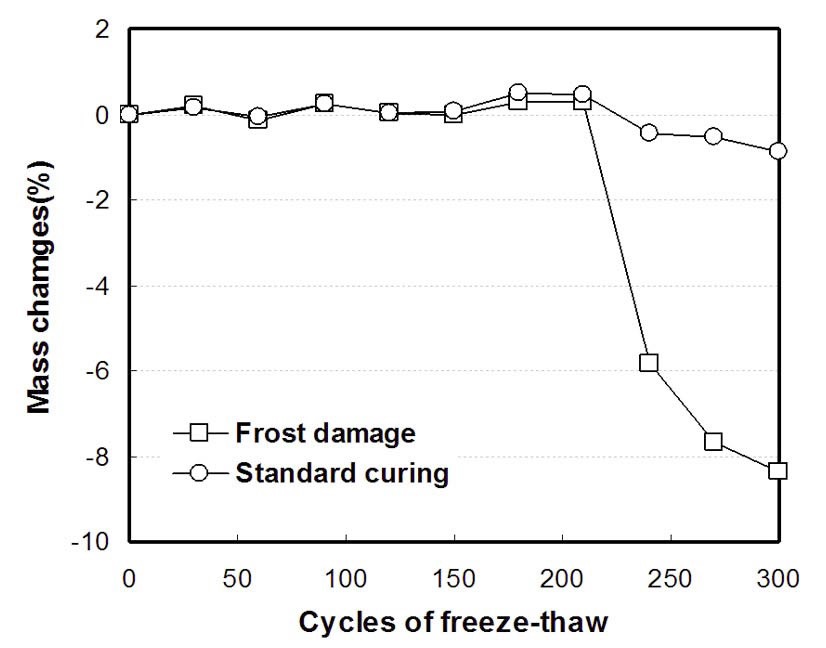

Fig. 12 plots the mass changes of concrete according to the eventual occurrence of early frost damage. Similar to the relative dynamic modulus of elasticity, practically no mass change occurred in concrete that did not experience early frost damage, but concrete that experienced early frost damage shows a loss of mass of approximately 9% due to the occurrence of significant surface spalling, as shown in Fig. 13.

Such results indicate that, even if the concrete satisfies 4.5% of entrained air content, a nuclear power plant concrete structure may undergo shortening of its lifespan, due to the significant loss of resistance to freezing-thawing when exposed to a cold environment after having developed a strength of 5 MPa at the beginning of curing. Accordingly, there is a need to propose the required curing strength to secure the durability of concrete for nuclear power plants in cold climates.

4.2.4 Relationship between the Strength and Durability of Concrete Subjected to Early Frost Damage

Fig. 14 describes the relation between the strength and durability according to the eventual occurrence of early frost damage. It can be observed that the compressive strength

satisfies the specified strength of 27 MPa, regardless of the occurrence or not of early frost damage. The loss of strength due to early frost damage appears to remain small, at about 12%. On the other hand, the resistance to chloride ion penetration and the resistance to freeze-thaw show large differences reaching more than 200% according to the eventual occurrence of early frost damage. It is known that when concrete experiences early frost damage, the moisture in concrete freezes and remains as pores after thawing[4]. The strength of the concrete degrades with higher degrees of porosity or with a larger distribution of large pores. Its durability and resistance to freeze-thaw have been reported to depend on the presence of specific pores larger than 0.01μm [8]. In this study, it also appears that the strength and durability do not exhibit a concordant relationship due to the change in the pore structure of concrete that experienced early frost damage.

In view of these results, the relation between the strength and durability of concrete experiencing early frost damage presents a large possibility to fail in exhibiting consistency. Therefore, it is recommended to conduct an investigation into both strength and durability when evaluating early frost damage of concrete for nuclear power plant in cold climates.

This study investigated the minimum compressive strength preventing early frost damage of concrete for nuclear power plants from the viewpoint of the strength development and durability. The results of the investigation on the minimum compressive strength specified by concrete codes like ACI-306R enable the drawing of the following conclusions.

(1) There is a need to establish measures against the highly probable risk of early frost damage in concrete incorporating 20% fly ash for nuclear power plants in which strength development is delayed due to low temperatures.

(2) The value of 5 MPa prescribed as the minimum compressive strength to prevent early frost damage by concrete codes like ACI-306R appears to be reasonable in view of the development of compressive strength. However, this value appears to be inappropriate to satisfy the resistance to chloride ion penetration and freeze-thaw. Accordingly, a minimum compressive strength should be proposed to prevent early frost damage not only in terms of strength development, but also in terms of durability, in order to secure the quality of concrete for nuclear power plants in cold climates.

(3) Since the strength and durability of concrete experiencing early frost damage are likely to show inconsistencies, it is recommended to conduct an investigation into both strength and durability when evaluating early frost damage of concrete for nuclear power plants in cold climates.

Within the scope of this study dedicated to nuclear power plants, the minimum compressive strength to prevent early frost damage was limited to 5 MPa for a mix proportion of 27 MPa. Further studies should propose minimum compressive strengths to prevent early frost damage considering the various mix proportions of concrete to secure stable construction of nuclear power plant structures in cold climates.