In order to encourage the beneficial reuse of animal feed, fertilizers and other organic substances, disposal of organic waste in landfills is forbidden under Korean law. This recycling policy for food waste, in tandem with concerns about environmental and technical problems, has also restricted the use of food waste disposers. One particular concern is the possibility for increased loadings on existing wastewater treatment facilities, since disposers disintegrate kitchen waste, then transfer it to sewers for transportation. However, demand for efficient transportation of food waste has risen, due to recent problems with alternative technologies. Convenience is not the only concern when it comes to disposer technology; other, more drastic effects must also be considered [1]. In Korea, where people separate food waste into a recycling box by themselves, the application of food waste disposers seems to be a particularly attractive option, since the odors produced by recycling boxes and unpleasant aesthetics near collection areas are both targets of public grievance.

Disposer systems are considered for kitchen waste treatment on the assumption that additional treatment of wastewater from the disposer is introduced, to mitigate the adverse effect on sewerage. This technology, of disposers combined with on-site wastewater treatment systems, has been studied in Japan [2]. However, it is very different from disposer systems widely applied in USA, where disposer wastewater is transported to public wastewater treatment plants. Many on-site wastewater treatment processes have been developed, and have become popular in Japan; most of these systems are household-sized units, with a capacity of 1-2 m3/day [3]. In order to remove both nitrogenous and carbonaceous pollutants, wastewater treatment generally makes use of biological nutrient removal (BNR) processes, designed to include anaerobic, anoxic, and aerobic conditions. Predenitrification processes, such as the modified Ludzack-Ettinger (MLE) process, are particularly important for kitchen wastewater containing a high ratio of chemical oxygen demand (COD) to nitrogen. Successful results have also been achieved through application of advanced processes, including nutrient removal in the disposer system [2, 3]. However, settling problems in secondary clarifiers often occur when using the conventional processto treat high strength wastewater, due to the bulking nature of such wastewater [4, 5]. The membrane bioreactor (MBR) process is a

biological treatment process with enhanced solid-liquid separation, by the use of a membrane in the conventional activated sludge process [6]. In MBR, a longer solids retention time (SRT) independent of hydraulic retention times (HRT) is possible, and results in a high biomass concentration and flexibility in operation [7, 8]. These advantages are also desirable for treatment of high strength wastewater, such as that produced by food waste disposers [4]. Recently, MLE coupled with MBR has been used for treating many kinds of wastewater [5]. However, there are few reports that show simultaneous removal of organic materials and nutrients from disposer wastewater using MLE-type MBR.

This paper suggests an MLE-type MBR process as a treatment system for disposer wastewater. The purpose of this study is to investigate the biological treatability of organic materials and nutrients in disposer wastewater, as well as the operational stability of the suggested process.

2.1. Disposer Wastewater Characterization

The composition of the disposer wastewater is monitored from a pilot facility in Changwon, Korea [9]. In order to reduce fluctuations in the influent, disposer wastewater is comprised of previously suggested standard food waste [2, 10]. Food waste used in the present study has the following composition (wet weight in 35 L of tap water): carrot, 45 g; cabbage, 45 g; banana skin, 25 g; apple, 25 g; grape skin, 25 g; cooked chicken, 20 g; fish,

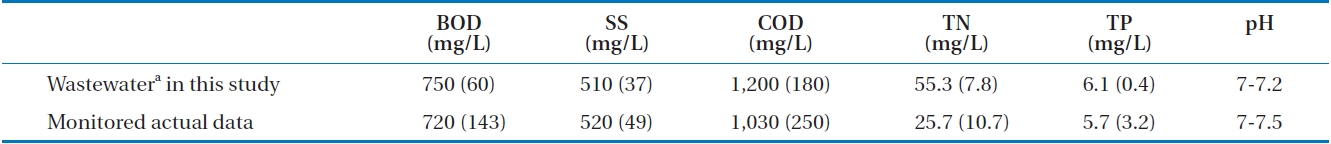

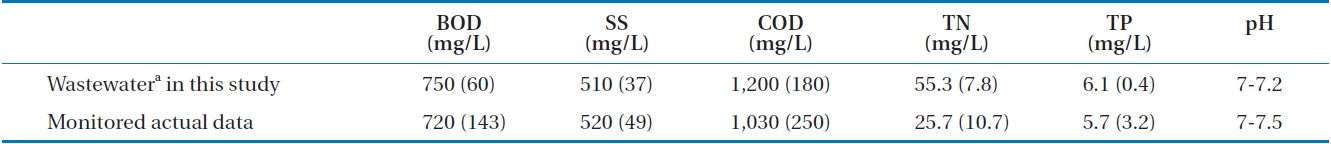

[Table 1.] Composition of disposer wastewater

Composition of disposer wastewater

25 g; egg shells, 5 g; rice, 25 g; tea leaves, 10 g; bean flour, 24 g; corn steep liquor, 30 mL. Food waste is ground down, and stored at 4℃ in a refrigerator before use. This results in a composition of disposer wastewater as shown in Table 1. Biochemical oxygen demand (BOD), suspended solids (SS), COD, total nitrogen (TN), and total phosphorous (TP) contents of the samples are measured according to standard methods [11].

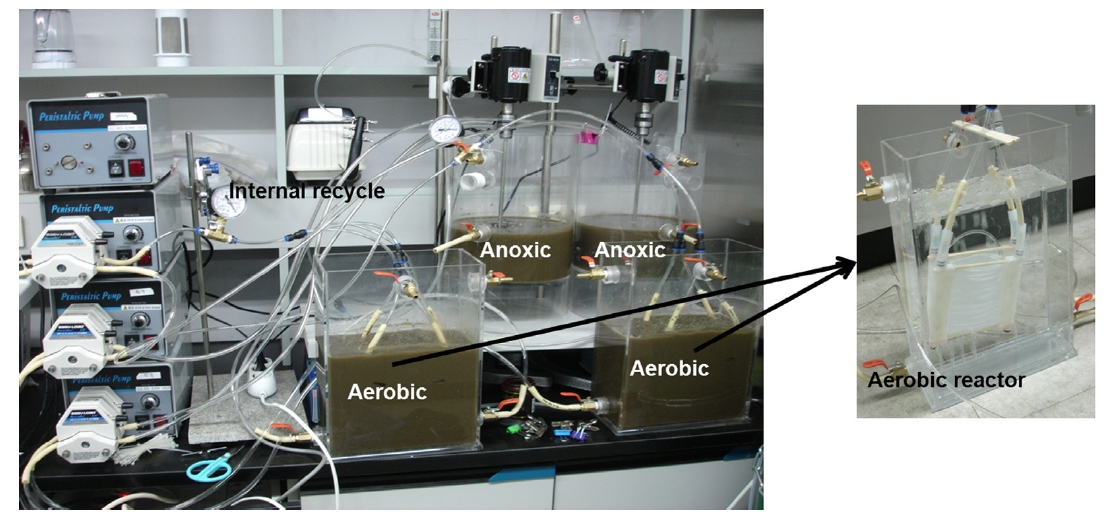

The laboratory scale MLE-type MBR process makes use of a 4 L anoxic tank and 8 L aerobic tank. The membrane module is submerged in the aerobic tank, as shown in Fig. 1. A hollow fiber membrane (KMS Co., Ltd., Yongin, Korea) is used, with a nominal pore size of 0.4 μm, and total membrane area of 0.2 m2. The reactor is fed with disposer wastewater, and the effluent is directly drawn from the membrane module via a suction pump. The MBR process operates at a constant permeate flux mode, except when sampling the activated sludge for analysis and excess sludge wasting.

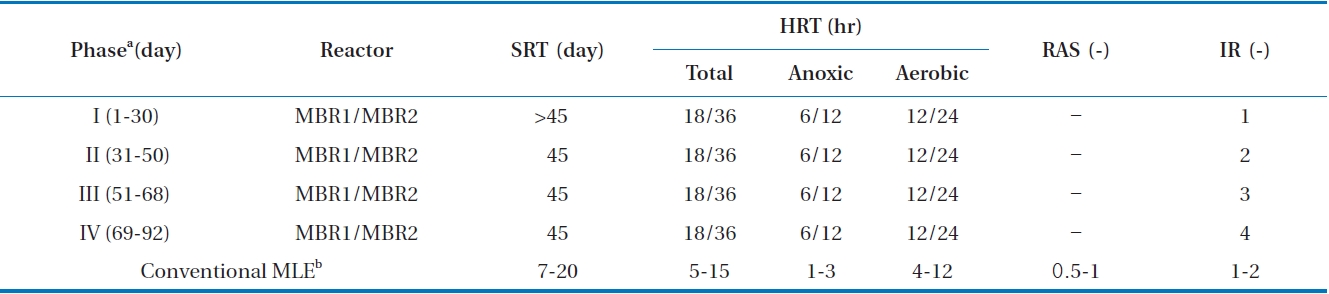

Both systems, MBR1 and MBR2 are operated in parallel. Effluents (membrane permeate) are intermittently withdrawn at sequential intervals of 10 min suction and 2 min idle, in order to diminish membrane fouling. A diffuser is used to provide continuous aeration at the bottom of the tank. The permeate flux is set at 7.5 and 15 L/m2/hr, and the corresponding HRT of the process is 18 and 36 hr, longer than normal for MLE plant sewage treatment [12]. Peristaltic pumps are used to maintain water flows, including influent wastewater, internal recycle (IR) ratio, and excess sludge wasting. However, the MBR process does not include the return activated sludge (RAS) flow, while IR is increased in order to facilitate nitrogen removal. The operational conditions of this study are summarized, and compared with those of a typical MLE process in Table 2.

3.1. Performance of the MLE-type MBR System

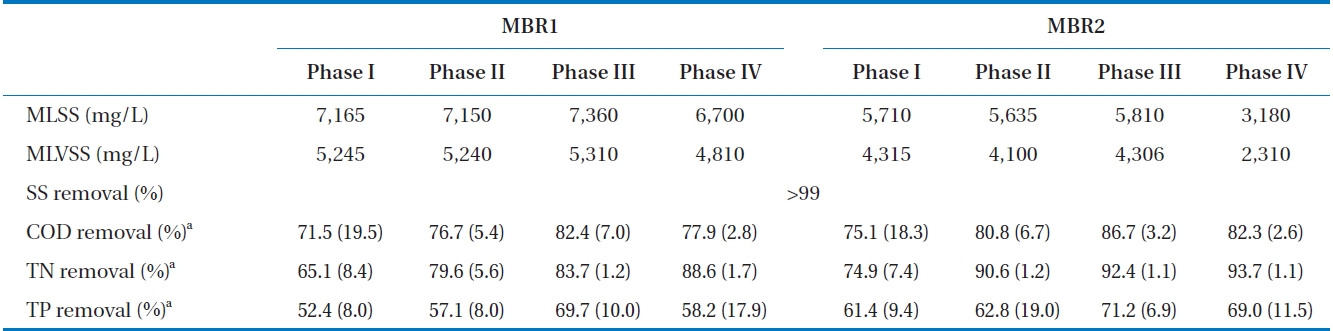

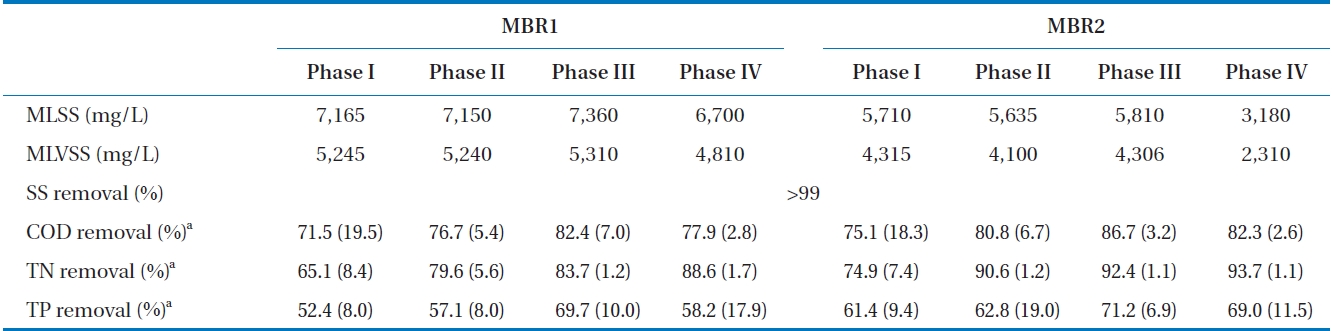

Table 3 summarizes the long-term performance results of the control system during the operation period. The MLE-type MBR is operated at 18 hr of HRT, consisting of 6 hr and 12 hr for anoxic and aerobic reactors, respectively. During the overall operating period, the average mixed liquor suspended solids (MLSS) concentrations of the anoxic and aerobic reactors are most likely the same, and change according to loading variations. The IR ratio varies from 1Q (Q is influent flow) to 4Q for high rates of nitrogen removal. The system operates at a relatively long SRT of 45 days, which is important for reliably evaluating the performance of the MLE-type MBR system. In spite of the extremely low SS of the effluent, the effluent COD is fairly high at 220-280 mg/L, corresponding to 72-82% removal efficiency. The high COD concentration in the effluent is deemed to be associated with two sources: the residual non-biodegradable organic substances present in the high-strength influent, and soluble microbial products

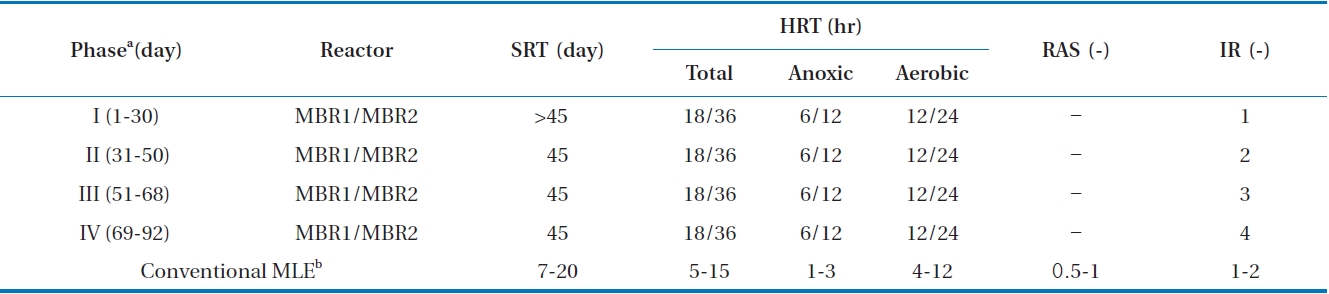

[Table 2.] Operation parameters

Operation parameters

[Table 3.] Performance MLE-type MBR

Performance MLE-type MBR

(SMPs) originating from the biomass at high concentration levels. However, the removal of TN is satisfactorily achieved with an efficiency of 86%. This is because the high C/N ratio of the wastewater is beneficial for denitrification, and the readily biodegradable organics can be effectively used for external carbon sources in the anoxic reactor. In contrast, phosphorus removal is limited at higher SRT, and the efficiency of phosphorus removal ranges from 50% to 71%, despite the low concentration of phosphorus in the influent.

3.2. COD in the Reactor and Membrane Fouling

The disposer wastewater has a high strength, compared to typical domestic wastewater. The COD and BOD concentrations of the influent are 1,200 and 750 mg/L, respectively, which are considered to be four to six times higher than in typical domestic wastewater. Hence, the HRT is determined to be at least two or three times longer than that of a typical wastewater treatment process. Both the long HRT and high MLSS concentration lead to generation of a substantial amount of SMP in the reactor [7]. This may result in fouling of the membrane, and increased COD concentration in the effluent.

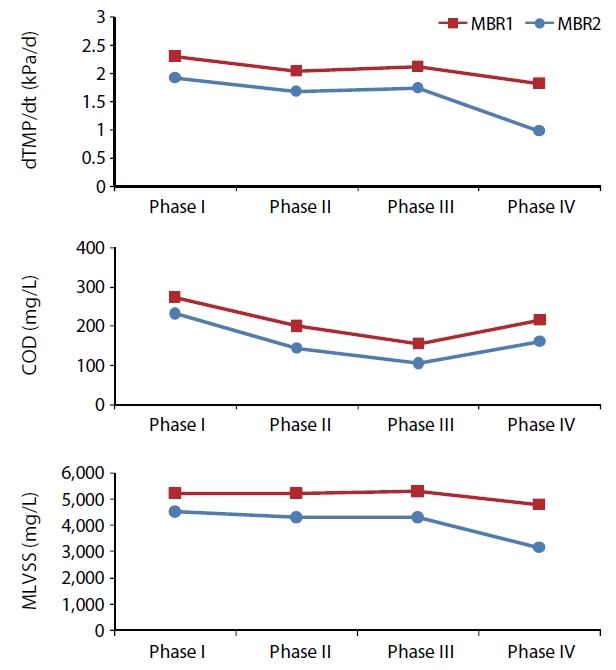

Permeation of the membrane occurs at four different phases, with two constant flux values of 7.5 and 15 LMH. Transmembrane pressure is monitored to examine the trend of membrane fouling at each phase. For the high flux value of 15 LMH, the increase of pressure drop occurs rapidly, so that both physical and chemical cleanings are conducted at a pressure of 4-5 Mpa. Permeability of the membrane is improved after cleaning, with a decrease of pressure from 0.04 to 0.003 MPa. Transmembrane pressure is decreased at MBR2 with a half flux of MBR1, and this allows for a longer operation period without cleaning. The operation period is extended at MBR2. Membrane fouling is presumably attributed to the large content of biomass and soluble organics, including SMPs, present in the reactor. The membrane fouling rate (d

3.3. Internal Recycle and Nitrogen Removal

The MLE-type biological nitrogen removal process is strongly affected by the COD/N ratio of wastewater. As such, a COD/N ratio of eight to nine is generally suggested for complete denitrification [13]. The COD/N ratio of the disposer wastewater used in this study is very high compared to typical sewage. The potential suitability is thus increased for processes like anoxic/aerobic configuring in the pre-denitrification step. Effluent nitrogen concentration can be controlled by the IR ratio, since this ratio determines the concentration of nitrate loading the anoxic tank. The concentration of nitrate leaving the aerobic reactor is calculated by mass balance of nitrogen in the aerobic reactor [14]. As the MLE-type MBR does not involve RAS, the equation can be simplified as follows:

where: NO3 is the effluent concentration of nitrate, TN0 is influent total nitrogen, IR is internal recycle ratio (-), and Ns is nitrogen synthesized into biomass, which is also expressed as follows [14]:

where: HRT is hydraulic retention time of the system, and SRT is solids retention time of the system.

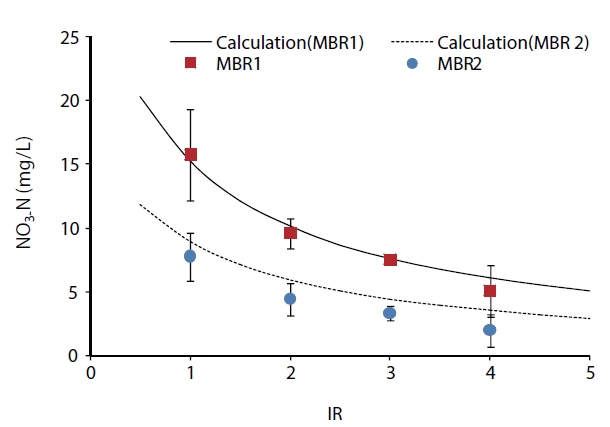

Fig. 3 illustrates the effect of the IR on the effluent nitrate concentration, for the given levels of initial nitrogen concentration. A greater IR value is recommended to reduce the effluent nitrate concentration for a certain influent concentration of TN. The experimental data corresponds to the data calculated by the above equations, demonstrating that increased IR can enhance the removal efficiency of nitrogen under the fixed HRT condition. However, it can be seen that the optimal IR is three or four, because effluent nitrate decline is insignificant past the inflection point.

Maintaining the SRT at a high value means that the effluent phosphorus levels are too high to meet the national discharge standard (2 mg/L). Phosphorus removal in the treatment system is theoretically governed by excess biomass waste. As such, the phosphorus concentration of the effluent can be expressed as a function of SRT, as follows [14]:

where: P is effluent phosphorus concentration, P0 is influent phosphorus concentration, fp is phosphorus content in biomass, Y is true yield, kd is decay rate, fd is the biodegradable fraction of the new biomass, and ΔS is COD removal.

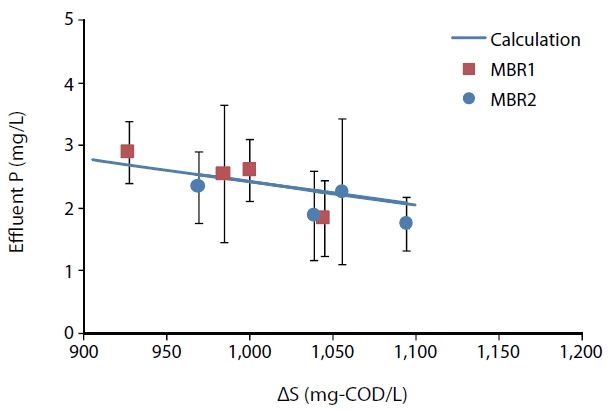

Fig. 4 shows the observed and calculated effluent phosphorus concentrations for a wide range of COD consumption, at each phase of MBRs. The parameters used for the calculation areas follows: fp= 2.3%, which is based on a widely used molecular formula, C60H8.7O23N12P to describe the composition of biomass

given by McCarty [15], and P0 = 6.1 mg/L. In this study, effluent phosphorus concentration is affected by removed COD. However, the MLE-type MBR system for disposer wastewater treatment operates at a relatively long SRT. As such, effluent phosphorus concentration is relatively high, and additional phosphorus removal may be needed to meet the effluent standard.

This paper investigates the treatment potential of wastewater from food waste disposers, through the continuous operation of MLE-type MBR processes. The organic strength of the disposer wastewater is approximately four times greater than that of typical domestic wastewater. SS are completely removed by the process, ensuring a 99% removal efficiency. However, high levels of effluent COD are observed, probably due to the residual nonbiodegradable organics and SMPs. Biomass concentration is found to be a major factor affecting membrane permeability. Increases in the flux are seen to result in rapid membrane fouling. Disposer wastewater with a very high COD/N ratio is suitable for biological denitrification, so that the removal efficiency of nitrogen can be satisfactorily achieved with a high IR ratio. However, effluent phosphorus concentration exceeds national discharge standards due to high SRT, despite a relatively low influent TP concentration.