Many kinds of inorganic fillers, such as silica (SiO2) [1], alumina (Al2O3) [2], mica [3], aluminum nitride (AlN) [4],and titanium dioxide (TiO2) [5], have been used for conventional polymer composites, in order to apply them to insulation materials. In particular, silica or mica has been widely used in epoxy composites for high voltage (HV) applications. Epoxy/silica composites are used as mold-type transformers, current transformers (CT), potential transformers (PT), metering out-fit (MOF) and gas switching gears [6,7], and epoxy/mica composite can be applied in HV rotating machines [8,9], which play a significant role in generating electrical energy, as they are the key component in converting mechanical energy (wind propeller, gas, steam or water turbines) into electric power.

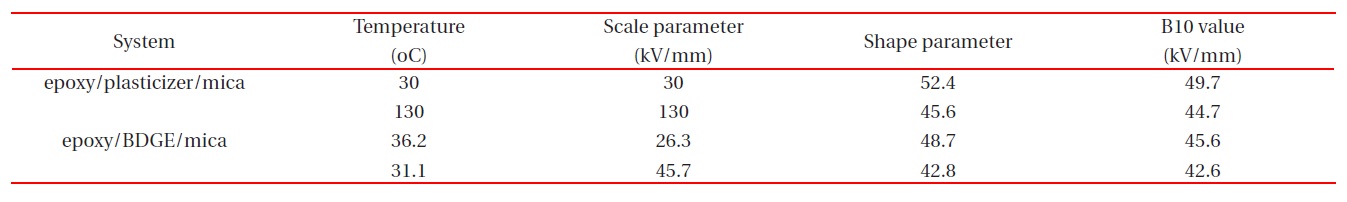

To improve the electrical breakdown strength of the insulative materials in HV rotating machines, continuous advancement has been achieved over time. In the beginning, silk, wool, cellulose or flax, together with natural varnishes and petroleum derivatives, were used for insulation and these materials were displaced by mica, quartz, and asbestos. The greatest historical step forward was made in the middle of the last century, when mica paper, in combination with epoxy resin or polyester resin, was introduced as the main insulation of high voltage machines [10]. The mica paper was combined with a carrier (glass cloth, PET film or PT fleece). The mica tape was wound on a strand or coil turn-by-turn, with, for example, a half overlap of the mica tape, and then impregnated with an epoxy resin in a vacuum pressure impregnation (VPI) process, and the epoxy resin was cured [8,9]. However,an electrical tree may propagate through the impregnated epoxy region without mica wall, as shown in Fig. 1(left). Thus, there is a need to incorporate the epoxy resin with mica, silica, etc. as shown in Fig. 1(right), where the inorganic filler will act as a barrier to interrupt propagation of the tree. However, the viscosity of the varnish with mica was too high to penetrate into the inter-mica tape, so liquid plasticizer was added, in order to decrease the viscosity.

In this paper, the effects of mica content and test temperature on the AC electrical breakdown strength were studied, in order to develop an impregnated epoxy/mica composite. Those for a system with a plasticizer, or a low molecular aliphatic epoxy resin, were also tested.

A commercial DGEBA (diglycidyl ether of bisphenol A) type epoxy resin, YD 128 (Kukdo Chem. Co.) was used. The equivalent weight was 184~190, and the viscosity was 11,500~13,500 cps at 25℃. The curing agent was Me-THPA (3- or 4-methyl-1,2,3,6- tetrahydrophthalic anhydride), whose grade name was HN-2200 (Hitachi Chem. Co.). It is widely used in the field of electric insulation. BDMA (benzyl-dimethyl amine, Kukdo Chem. Co.)was used as an accelerator. A polyethylene glycol, under the trade name of DY-040 (Ciba-Geigy Co.),was employed as a plasticizer. Its molecular weight was about 7,000~10,000, and its viscosity was 60~90 cps at 25℃. An aliphatic epoxy resin with low molecular weight was purchased from Kukdo Chem. Co., under the trade name of BDGE. Its equivalent weight was 120~140, and its viscosity was 15~30 cps at 25℃. A synthetic mica (synthetic sodium fluorohectorite Somasif ME-100), whose average particle size was 5~7 μm, was purchased from CO-OP Ltd., Japan. It was well dried at 110℃ for 24 h in vacuum oven, and stored in a desiccator before use.

In order to prepare epoxy/mica composite, DGEBA (100g) and aliphatic epoxy (10 g) or plasticizer (10 g) and mica (0, 20, 30 or 40 wt%) were well-mixed with a high-speed agitator at 5,000 rpm for 30 min in one beaker, and THPA (80 g), BDMA (0.9 g) and mica (0, 20, 30 or 40 wt%) were well-mixed with a high-speed agitator at 5,000 rpm for 30 min in another beaker. Then they were mixed for 10 min. The mixture was poured into a mold, and degassed in a vacuum oven, to prepare specimens with the thickness of 1, 2, and 3 mm, for the AC electrical breakdown test. They were cured at 120℃ for 2 h, and continually postcured at 150℃ for 24 h.

The AC insulation breakdown test was carried out in the arrangement of sphere-to-sphere electrodes, with a distance of 1, 2 or 3 mm. The electrode diameter was 7.40 mm. The specimen arranged between the electrodes was dipped into the insulating oil for 2 hr, and HV was applied by an AC Endurance Voltage Tester (Haefely, Germany) at a rising speed of 1 kV/s, until the electrical breakdown took place. The insulation breakdown data were estimated by Weibull statistical analysis [11].

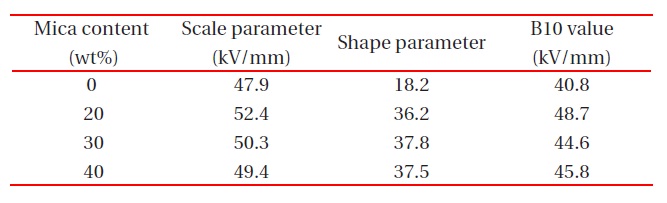

The morphology of the mica dispersion, and the interface between epoxy and mica were observed by field emission scanning electron microscopy (FE-SEM, JMS-6701F, JEOL), at an acceleration voltage of 10 kV.

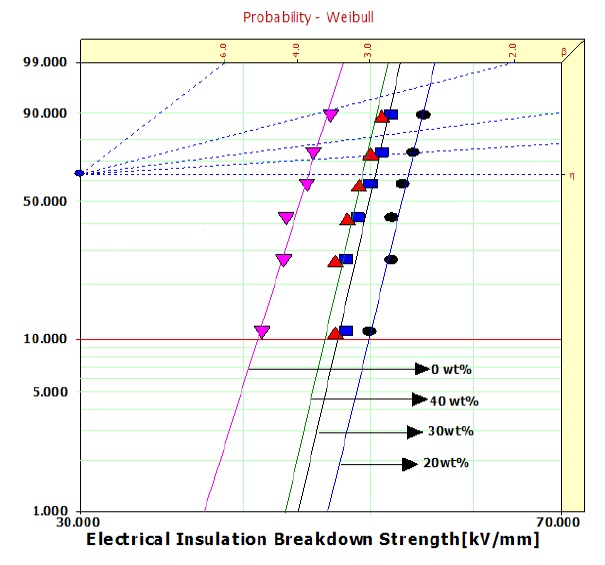

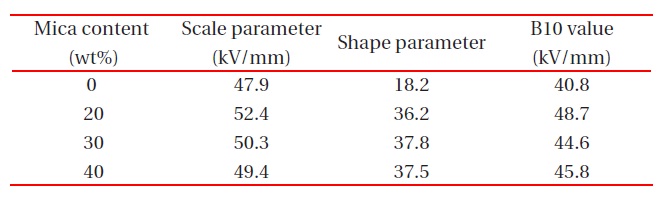

Figure 2 shows Weibull plots of the AC electrical breakdown strength for epoxy/BDGE/mica composites with 1 mm thickness, and the parameters, such as the shape and scale parameters and B10 value, were obtained from the Weibull plots.Here, the shape parameter could be obtained from the slope, meaning the data distribution, and the scale parameter represented the

Weibull parameters for the ac electrical breakdown strength in epoxy/BDGE/mica systems obtained from Fig. 2.

AC electrical breakdown strength by which 63.2% of the cumulative probability was expected to fail. The B10 value referred to the AC electrical breakdown strength at which 10% would fail (90% would survive) under a given stress. The statistical analysis of the neat epoxy showed that the scale parameter was 47.9 kV/ mm, with a shape parameter of 18.2. As the mica was added to the neat epoxy system, the scale parameter became higher; and the highest value, 52.4 kV/min was shown in the 20 wt% system,

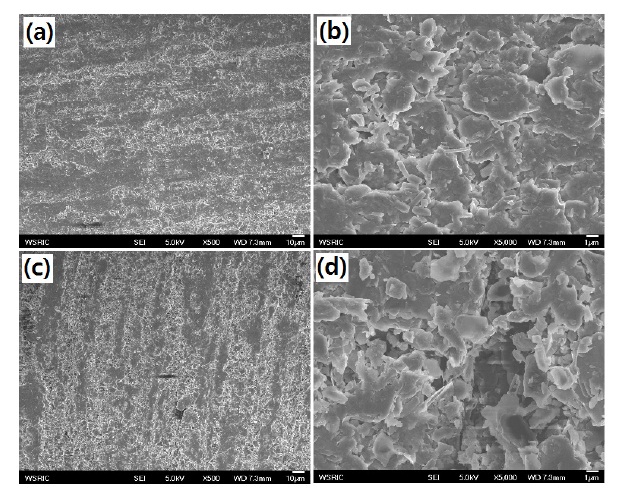

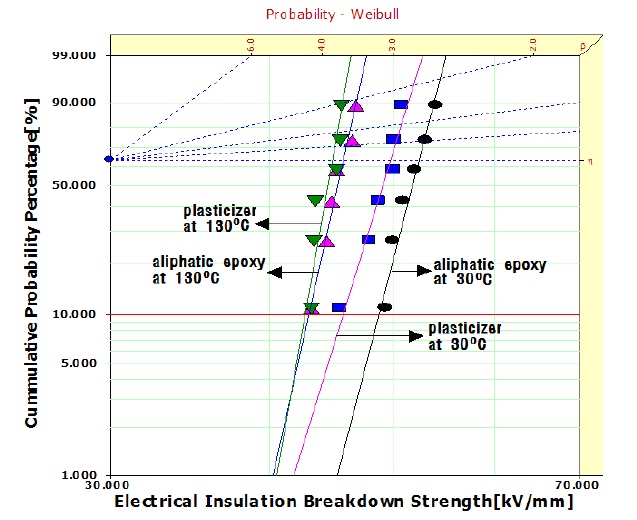

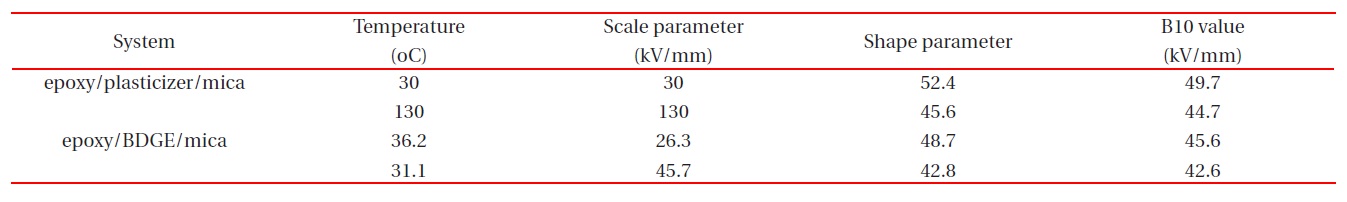

Weibull parameters for the AC electrical breakdown strength in epoxy/BDGE/mica and epoxy/plasticizer/mica systems at 30℃ and 130℃, obtained from Fig. 4.

with the shape parameter of 36.2, as shown in Table 1. It may be because the mica would have acted as a barrier, to interrupt the propagation of the electrical trace.

SEM was used to observe the mica dispersion, and the interface between epoxy and mica. Mica particles were well dispersed in the 20 wt%, while there were some voids in the 40 wt%. It meant that the well dispersed mica particles effectively interrupted the propagation of the electrical trace; however the barrier effect decreased in the higher mica content, because there were some bubbles.

The effect of ambient temperature on the ac insulation breakdown strength in epoxy/BDGE/mica and epoxy/plasticzer/mica systems was studied at 30℃ and 130℃.The Weibull statistical analyses are shown in Figure 4, and the Weibull parameters are listed in Table 2. As the ambient temperature increased, the scale parameter decreased. In the epoxy/BDGE/ mica system, the AC breakdown strength at 30℃ was 13.0% higher than that at 130℃; and in the epoxy/plasticizer/ mica system, that at 30℃ was 10.1% higher than that at 130℃. These results were because the mobilization of the epoxy chains increased at higher temperature.

Also, the values for the epoxy/BDGE/mica at each temperature were higher, than those for the epoxy/plasticizer/mica. This was because the BDGE, having two epoxy groups in a molecule, was crosslinked to the DGEBA network, so the mobilization of the chains was disturbed; while plasticizer could not react with the epoxy network, so the epoxy chains could be easily mobilized.

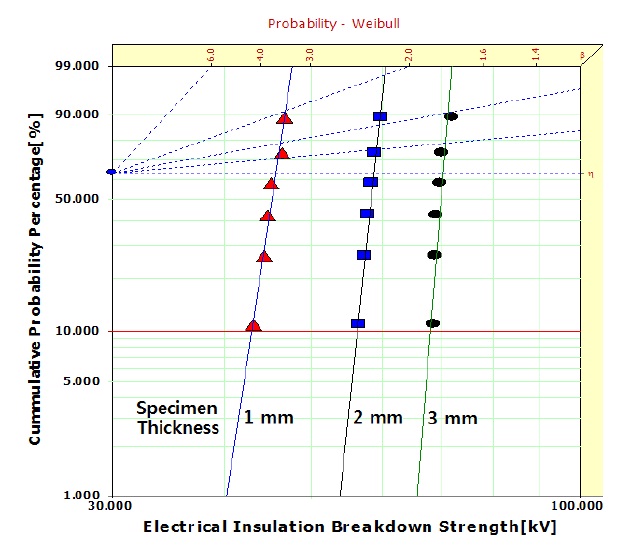

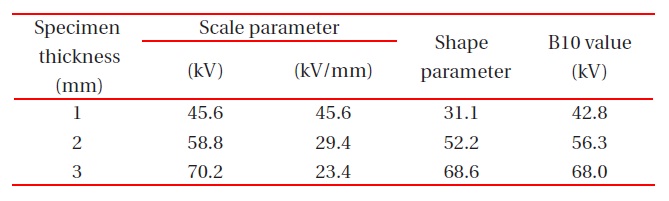

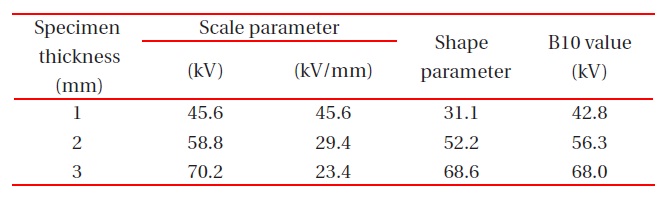

Figure 5 shows Weibull statistical analyses of the AC electrical breakdown strength, for the specimens with various thicknesses in the epoxy/BDGE/mica system at 130℃. Also, the Weibull parameters are listed in Table 3. The breakdown strength increased with the increasing specimen thickness; however it was not in

Weibull parameters for the AC electrical breakdown strength in epoxy/BDGE/mica systems, obtained from Fig. 5.

direct proportion to the thickness, contrary to expectation.

The thickness dependence of electrical breakdown strength is purely empirical, and is obtained from many electrical breakdown experiments of different dielectrics under AC,DC, and impulse conditions, and various attempts have been made to understand why such a relationship exists. However the detailed mechanisms are poorly understood [12].

Epoxy/mica composite was synthesized and its electrical breakdown strength was estimated, in order to use it in a high voltage rotary machine. As the mica was added to the neat epoxy system, the breakdown strength became higher; and the highest value, 52.4 kV/min, was shown in the 20 wt% system. As the ambient temperature increased, the scale parameter decreased in the epoxy/BDGE/mica or epoxy/plasticizer/mica systems, and the values for the former at each temperature were higher, than those for the latter.This was because BDGE could be crosslinked to the DGEBA network structure, while plasticizer could not. From these results, epoxy/BDGE mica system would be used as the impregnation resin in a vacuum pressure impregnation (VPI) process for manufacturing.

![Delay of tree propagation through impregnated epoxy/mica resin [8].](http://oak.go.kr/repository/journal/11391/E1TEAO_2012_v13n4_200_f001.jpg)