The increases of economic and environmental demands on reinforced polymer materials are encouraging researchers to develop high strength composite materials. Basalt fiber is environmentally harmless and free from carcinogens and other hazardous compounds. It has excellent properties, such as good thermal performance and chemical stability; thus, a number of studies have investigated its mechanical properties and chemical resistance [1-4]. One of the most important issues for polymeric composites is their degradation behavior when exposed to environmental conditions such as humidity and temperature. The moisture absorption of the polymer causes plasticization and swelling, weakening the interfacial strength between the epoxy and the reinforcing materials [5,6]. Currently, many studies have been performed to investigate the mechanical properties of multiscale composites because such multiscale composites are known to have mechanical performances better than those of conventional composites [7-10]. However, little research has been performed to investigate the effect of moisture absorption on the mechanical behavior of multiscale composites [11].

In this study, we have investigated the effect of moisture absorption on the flexural behavior of basalt/carbon nanotube (CNT)/epoxy composites. Flexural tests were performed using basalt/CNT/epoxy composites with and without moisture absorption. Following the flexural tests, scanning electron microscopy (SEM) was used to examine the fracture surfaces to determine the failure mechanisms based on the moisture absorption.

The carbon nanotubes used in this study were multi-walled CNTs, (MWCNTs, CM-95) purchased from Hanhwa Nanotech Co., Ltd., Korea. The diameter and the length of the nanotubes were in the range 10-15 nm and 10-20 μm, respectively and the purity was more than 95%. The reagents used were 3-aminopropyltriethoxysilane (99% purity; Aldrich, USA), distilled water (99.5%, Dae Jung Chemical, Korea), acetone (99.5%, Dae Jung Chemical, Korea), and ethanol (99.5%, Sigma-Aldrich). The epoxy used was 118.2 g/eq of diglycidyl ether of bisphenol A (YD- 115, Kukdo Chemical, Korea) and the hardener was 60 g/eq of polyamidoamine (G-A0533, Kukdo Chemical, Korea).

The fabrication process of the basalt/CNT/epoxy composites was as follows: silane-treated CNTs were mixed with the ethanol at 1 wt%. Ultrasonication was performed for 5 min for better dispersion. After sonication, the silane-treated CNTs were mixed with the epoxy resin and then stirred for approximately 2 h at 80℃ to completely evaporate the ethanol. Epoxy resin mixed with hardener (2:1 v/v) was prepared using 1 wt% silanized CNTs. Eight plies of basalt fabric were then impregnated into the matrix, and the basalt/CNT/epoxy composites were cured in an autoclave (ISA-CA30, Ilshin Co., Korea) at 3 kgf/cm2 and 130℃ for 2 h.

The fabricated basalt/CNT/epoxy composite plates were machined as flexural test specimens according to ASTM D790 [12]. Then, the specimens were kept immersed in sterile-filtered seawater (Sigma-Aldrich, S-9148, USA) for up to 4 months. After wiping the surfaces dry, the weights of the moisture absorbed specimens were measured quickly, in order to minimize evaporation losses. Flexural tests were performed using a universal testing machine (Model: 8801, Instron, USA) at a cross-head speed of 1 mm/min.

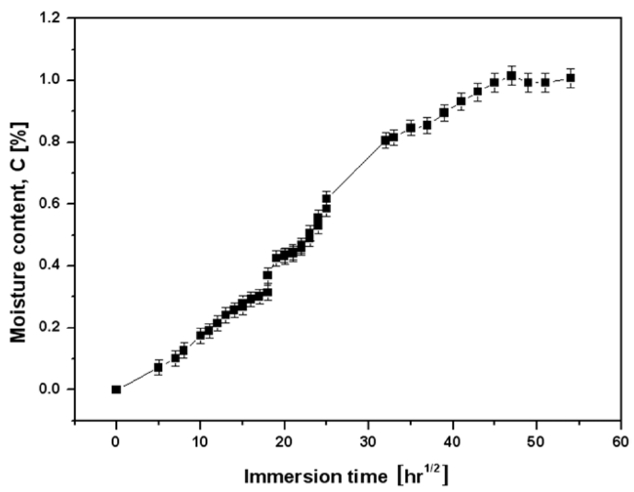

The moisture absorption curves of the basalt/CNT/epoxy composites is shown in Fig. 1; in this figure, moisture uptake is plotted against the square root of immersion time. In general, polymer matrix composites are superior to metals in terms of corrosion resistance; however, they are inferior in terms of mechanical properties after moisture absorption. Additionally, it has been reported that the material characteristics are significantly affected by the rate of moisture absorption [13]. In this work, the absorption content, “

where

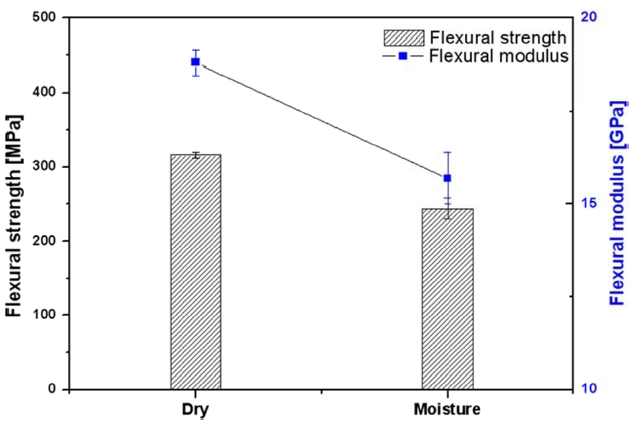

Fig. 2 shows the flexural strength and moduli of the dry and moisture absorbed basalt/CNT/epoxy composites. As shown in the figure, the flexural strength of the dry specimen was greater

than that of moisture absorbed specimen. Specifically, the flexural strengths of the dry and moisture-absorbed specimens were 316 MPa and 244 MPa, respectively. Clearly, the reduction in flexural strength after moisture absorption can be related to the weak fiber and matrix interface due to seawater absorption. The flexural modulus also decreased for the soaked specimens. The reduction in the flexural modulus for moisture absorbed basalt/CNT/epoxy composites was 16% compared to that value of the dry specimen. A plausible explanation for this would be that the basalt/CNT/epoxy composites have matrix-sensitive properties in composites, and, as a result of stress transfer, the capability across the fiber and matrix interface is sharply reduced by moisture absorption.

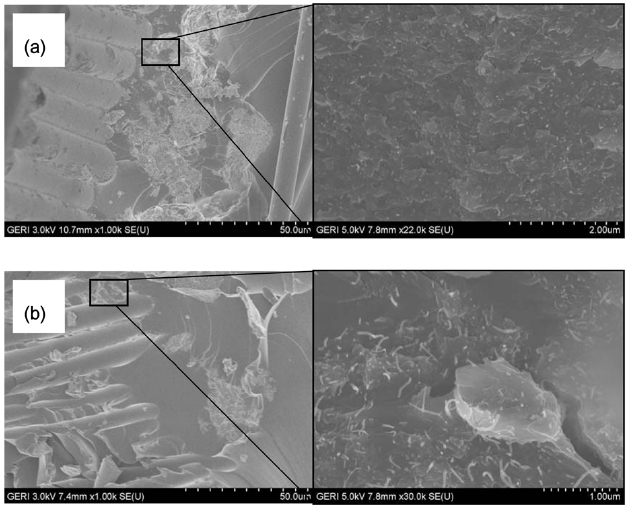

Field emission-SEM analysis was performed on the fracture surfaces of the composites to investigate the failure mechanism due to moisture absorption; the results are shown in Fig 3. For the dry specimen (Fig. 3a), it can be seen that the CNTs were well dispersed and impregnated in the epoxy resin. For the moisture absorbed specimen (Fig. 3b), it can also be seen that the CNTs were well dispersed in the matrix. However, we can see that many interfacial failures occurred at the interfaces between the matrix and the CNTs, which resulted in the reduced flexural strength and modulus.

The effect of moisture absorption on the flexural properties of basalt/CNT/epoxy composites has been studied. The moisture absorption of specimens matched the predictions of the Fickian model, and the moisture content at full saturation was approximately 1% of the specimen weight. The flexural strength and modulus of the moisture absorbed specimen were 22% and 16% lower, respectively, than those values of the dry specimen. The decreases in these values for moisture absorbed specimens were due to the weakening of the interfacial bonding due to swelling of the epoxy matrix.