Several candidates for future high-

Low-temperature deposition and oxidation may be used in an attempt to prevent the crystallization of high-

The HfSixOy films were deposited by the ALD method on the p-type Si substrate at 450℃. Prior to the deposition of HfSixOy film, the Si wafers were treated in a buffered HF (HF:H2O =1:100) solution to remove native oxide and contaminants. The precursors used in this work were Hf[OC(CH3)2CH2OCH3] and Si[OC(CH3)2CH2OCH3] at a ratio of 75:25% and remote-plasma oxygen with carrier N2 gas. The remote-plasma oxidation has been demonstrated to reduce the amount of impurities, thus improving the electrical properties [11]. The processing parameters were set to obtain a final thickness of 35 A. During the ALD process,the pressure of the reactor was kept at 100 Pa. After completing the deposition cycles, the HfSixOy films were annealed at various temperatures (i.e., 500℃, 700℃ and 900℃) using a rapid thermal processor (RTP) in O2 ambient for 5 minutes. After O2 annealing, Pd (1,000 A) was thermally evaporated through a shadow mask to fabricate the MOS capacitors. The metal gate area was 2.4 × 10-4 cm2. The effects of the annealing process were analyzed by high-resolution transmission electron microscopy(HR-TEM), X-ray photoelectron spectroscopy (XPS), capacitance versus applied voltage (

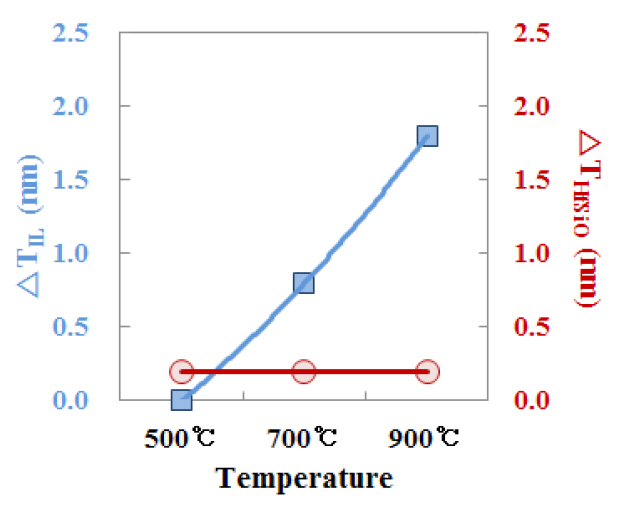

Figure 1 shows regrowth of interfacial layer (IL) and HfSixOy following O2 annealing. Thicknesses were measured by HR-TEM.Initial thicknesses of IL and HfSixOy were 1.6 nm and 2.4 nm,respectively. The data shown in Fig. 1 were obtained from the samples subjected to the post deposition annealing using RTP in O2 ambient for 5 minutes at 500℃, 700℃ and 900℃, respectively.

While the IL thickness increased as the annealing temperature increased, the thickness of the HfSixOy layer (with the exception of IL between Si substrate and HfSixOy layer) shows no visible change after annealing at high temperature. The HfSixOy film is completely amorphous at 500℃ and 700℃. In contrast, in the HfSixOy film with 900℃ annealing, we observed crystallized portions.Recently, it was reported that localized crystallization occurs after a high temperature annealing [12-14].

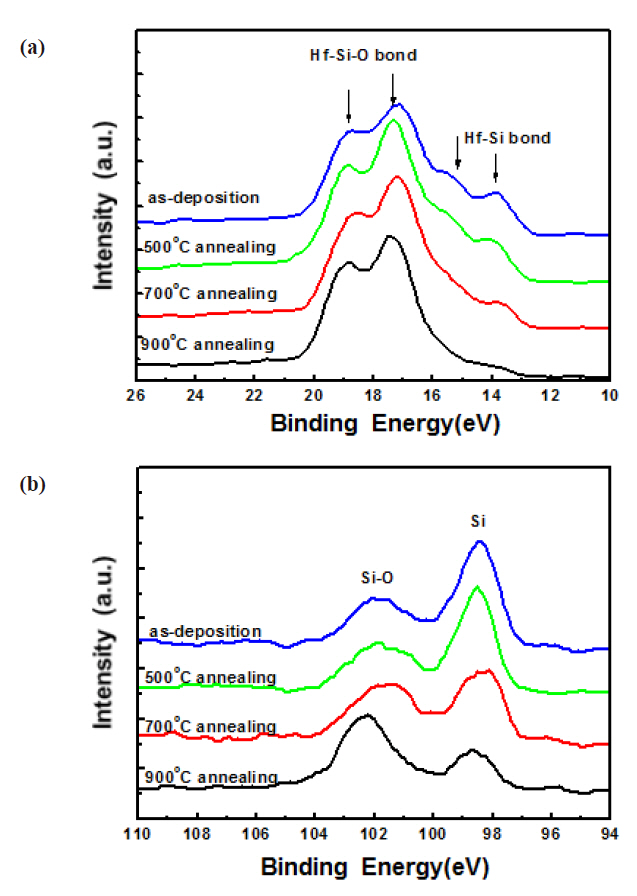

In order to examine the structural change associated with the

annealing temperature, we measured the XPS spectra of the asdeposited HfSixOy film and annealed HfSixOy (Fig. 2). Figure 2 exhibits the (a) Hf 4

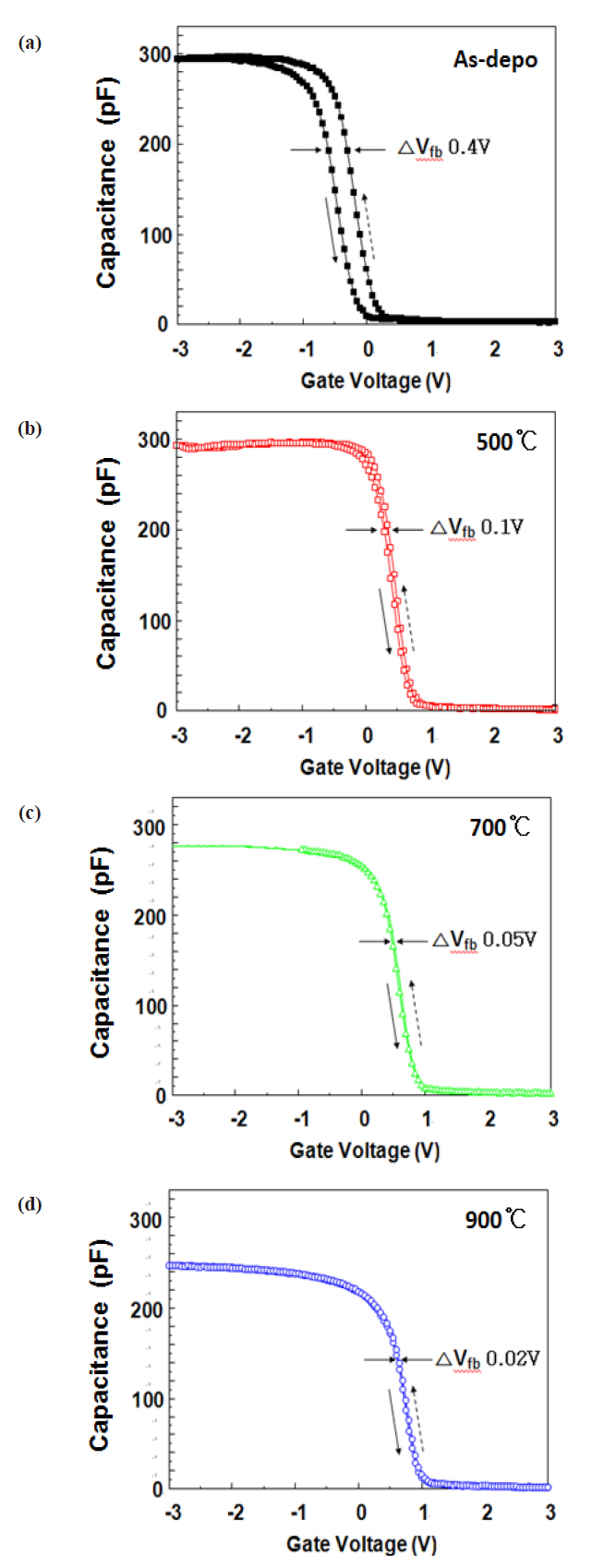

Figure 3 shows the capacitance versus applied voltage (

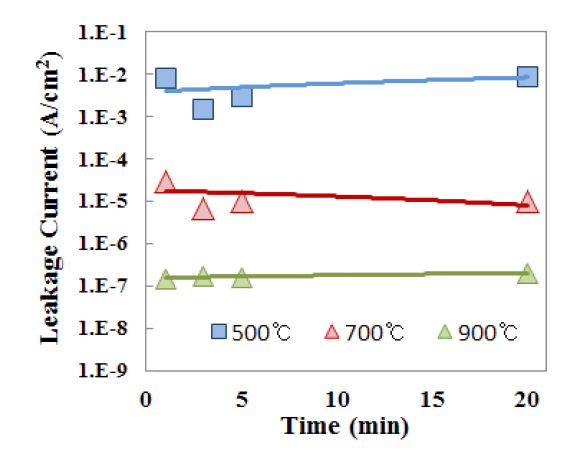

Figure 4 shows the leakage current density characteristics of

the p-Si/HfSixOy/Pd capacitor according to annealing temperature.The leakage current is dependent on annealing temperature.

For example, we obtained the lowest value of leakage current

density from an annealed sample at 900℃ due to the increase in the IL thickness. The leakage current density of HfSixOy film annealed at 500℃ is similar to that of the as-deposited sample.Moreover, both samples have nearly the same capacitance value.

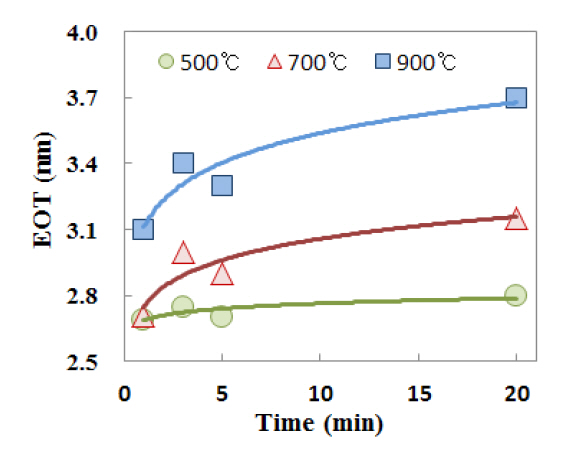

Figure 5 shows equivalent oxide thickness (EOT) characteristics of p-Si/HfSixOy/Pd capacitor according to annealing temperature and time. EOT was dependent on annealing temperature.

EOT and the leakage current density of the HfSixOy film is less dependent of the post deposition annealing time, as shown in Figs. 4 and 5. As the annealing time increases, both the EOT and leakage current density show only a little change. This result indicates that the relationship between the electrical characteristics and annealing condition is more strongly dependent on the annealing temperature than the annealing time.

We have studied the effect of annealing on HfSixOy film deposited by ALD. We found that post deposition annealing causes oxidation of residual Hf metal components, resulting in an improvement in the hysteresis window and leakage current density.These experimental results indicate that the post deposition annealing improves the electrical and physical characteristics (e.g.,hysteresis window and leakage current were decreased). In addition, we found that the role of annealing temperature is more important than that of annealing time in post deposition annealing.However, EOT increased as increasing the temperature due to IL regrowth. Based on the current observation, the annealing temperature has to be carefully controlled to minimize the growth of interfacial oxide, which degrades the value of the EOT.